Exhaust silencer for automobiles with output volume of 2.0L

An exhaust muffler and automobile technology, applied in the direction of exhaust devices, noise reduction devices, machines/engines, etc., can solve the problems of noise pollution, noise transmission to the outside world, etc., to increase structural strength, stabilize internal structure, and reduce exit noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

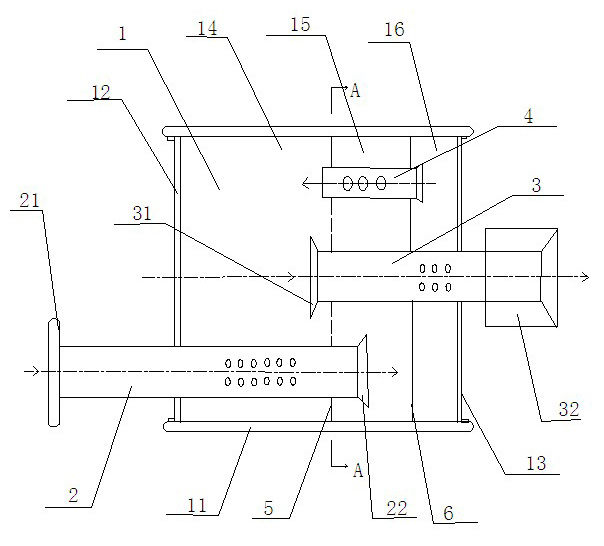

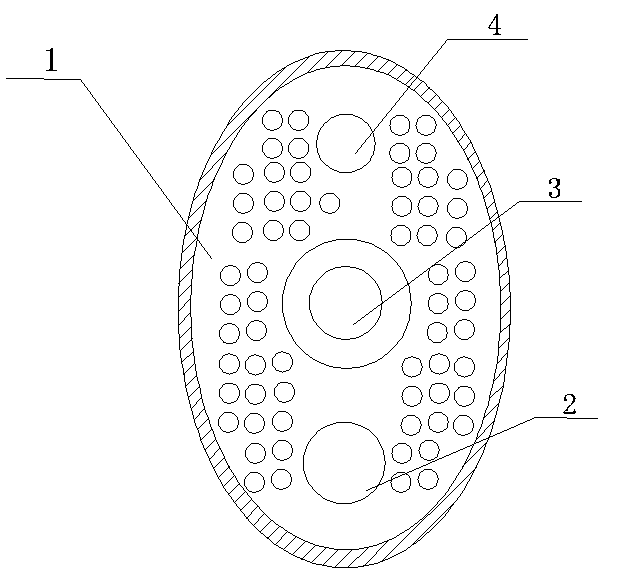

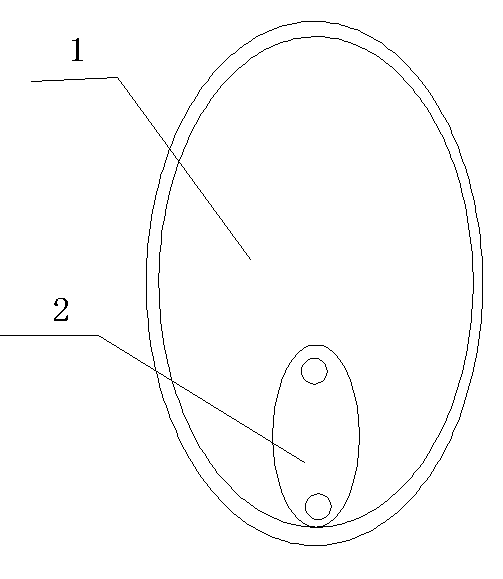

[0016] Such as Figure 1-4 As shown, an exhaust muffler for a 2.0L automobile comprises a main cavity 1, an intake pipe 2, an exhaust pipe 3 and an intermediate pipe 4, and the main cavity 1 is composed of a cavity wall 11, a front cover 12 and a rear The end cover 13 surrounds; the front partition 5 and the rear partition 6 set in the main cavity 1 divide the main cavity 1 into a front cavity 14, a middle cavity 15 and a rear cavity 16, and the front partition 5 is provided with There is at least one air hole; the front end cover 12 and the rear end cover 13 are double-layered, and there is a gap between the inner and outer layers; the air intake pipe 2 for connecting the exhaust pipe of the automobile passes through the front cavity 14 and is directly inserted into the middle cavity 15. The air inlet end is connected with a flange 21, and the air outlet end is provided with a gradually flared mouth 22, and there is at least one air hole with a diameter of 6-8mm on the pipe w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com