Cooling system of battery-powered electric hydraulic excavator

A hydraulic excavator and cooling system technology, applied in the direction of earth mover/shovel, construction, etc., can solve the problems of power consumption, reduce the working time of a single charge of the machine, and high noise, so as to reduce cooling and reduce noise Radiation, the effect of reducing power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

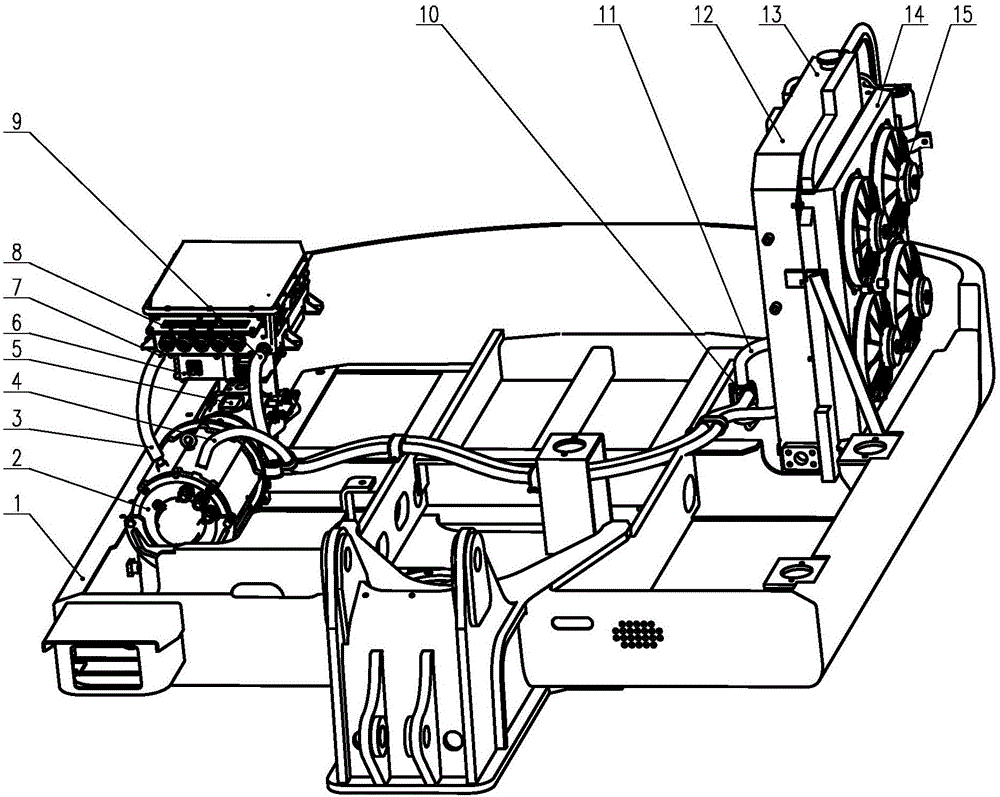

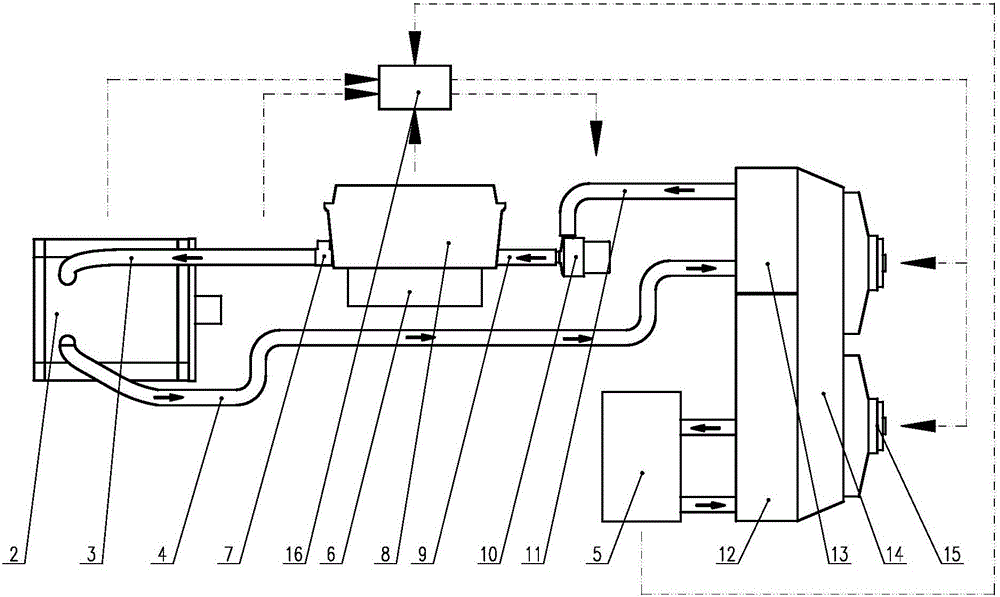

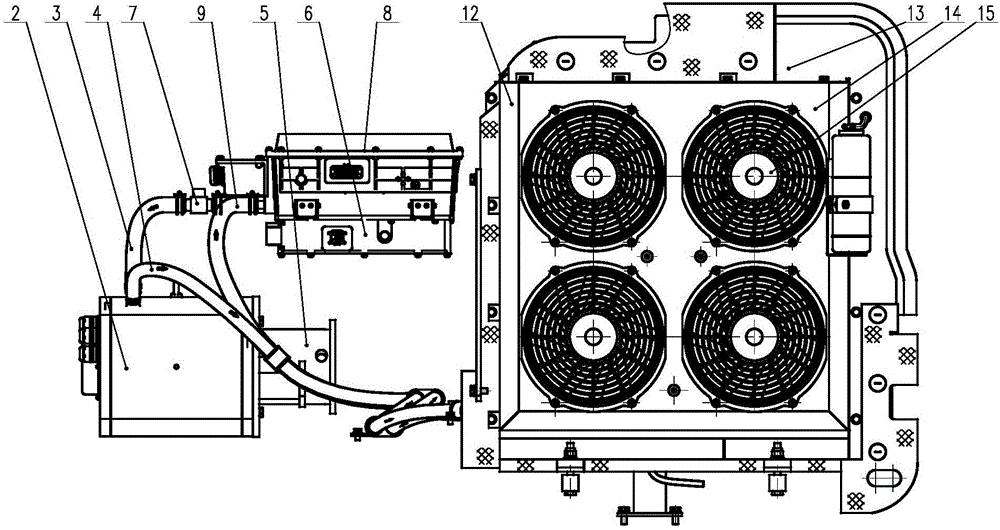

[0028] The technical solution of the present invention will be further described with reference to the accompanying drawings.

[0029] Such as Figure 1 to Figure 4 As shown, the cooling system of the battery-powered electric hydraulic excavator according to the present invention includes 1 excavator platform, 2 motors, 3 water pipes I, 4 water pipes II, 5 hydraulic systems, 6 DC / DC, 7 water temperature sensors, and 8 motor controls 9 Water pipe III, 10 Water pump, 11 Water pipe IV, 12 Hydraulic oil radiator, 13 Coolant radiator, 14 Wind guide cover, 15 Cooling fan, 16 Controller, the specific structure and connection method are:

[0030] The motor is installed on the left front of the excavator platform to provide power for the hydraulic system; the DC / DC and the motor controller share the same cooling plate and is installed above the motor; the water pump is installed on the left rear of the excavator platform, at the center of the excavator platform near the radiator Side;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com