Excitation device

A technology of vibration excitation device and coil frame, which is applied in the direction of fluid using vibration, can solve the problems of workpiece fatigue damage, low vibration frequency, large amplitude, etc., so as to prevent fatigue cracks of the workpiece, prevent fatigue damage, and prevent the occurrence and development of the workpiece. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings.

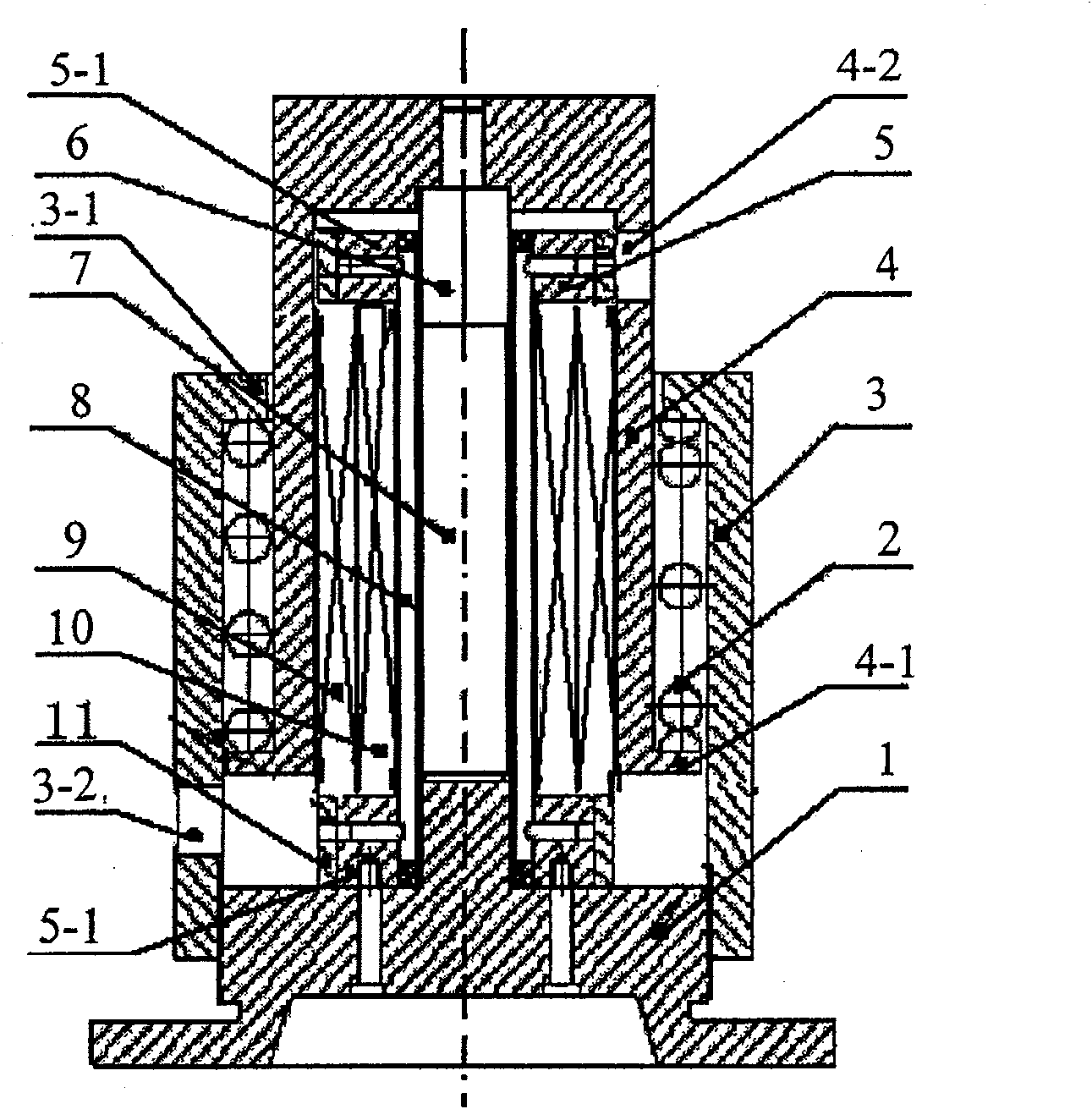

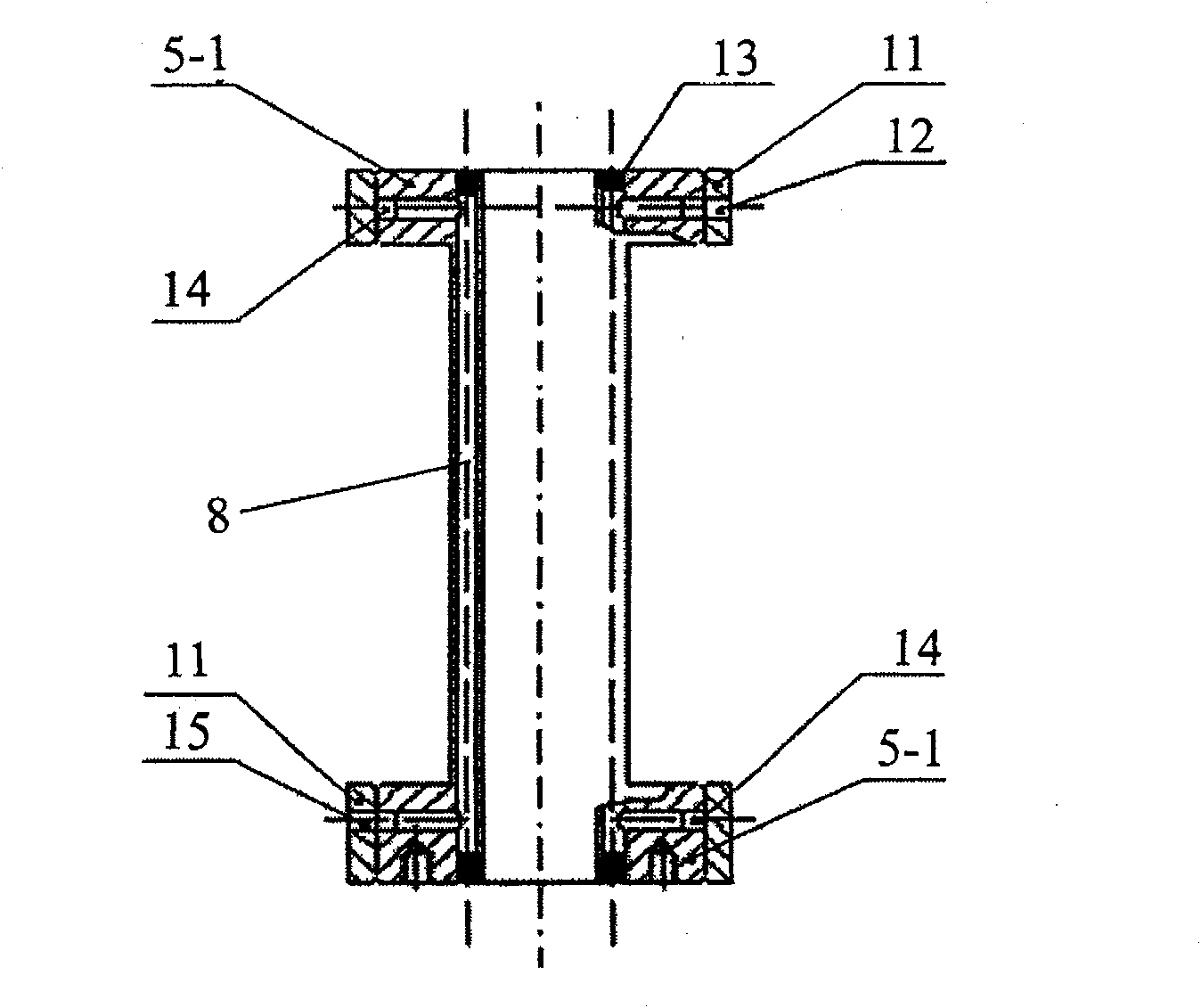

[0013] refer to figure 1 , figure 2 , the inventive vibrating device comprises a base 1, a bobbin 5 of a coaxial line device from inside to outside, an AC coil 10, a DC coil 9, an inner sleeve 4, a spring 2 and an outer sleeve 3, and the bobbin 5 has a central hole and several axial through holes 8 for cooling. In the specific example shown in the figure, there are 8 axial through holes of Φ3 in total, and the two ends of the 8 axial through holes are sealed with rubber nuts 13 respectively. The two end surfaces of the two convex rings 5-1 respectively have an annular channel 14 inside the outer convex ring, and the annular channel 14 communicates with the axial through hole 8, and each of the circumferential directions of the two outer convex rings 5-1 A copper hoop 11 is fastened. In the illustration, the upper copper hoop 11 is provided with a water inlet 12 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com