A highway cold-formed U-shaped composite girder bridge and its construction method

A U-shaped, cold-formed technology, applied in the direction of bridges, bridge materials, bridge construction, etc., can solve the problems of large number of concrete cracks, prone to insects, cracking of plate beams, etc., to reduce the impact of creep shrinkage, The effect of reducing concrete cracking diseases and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

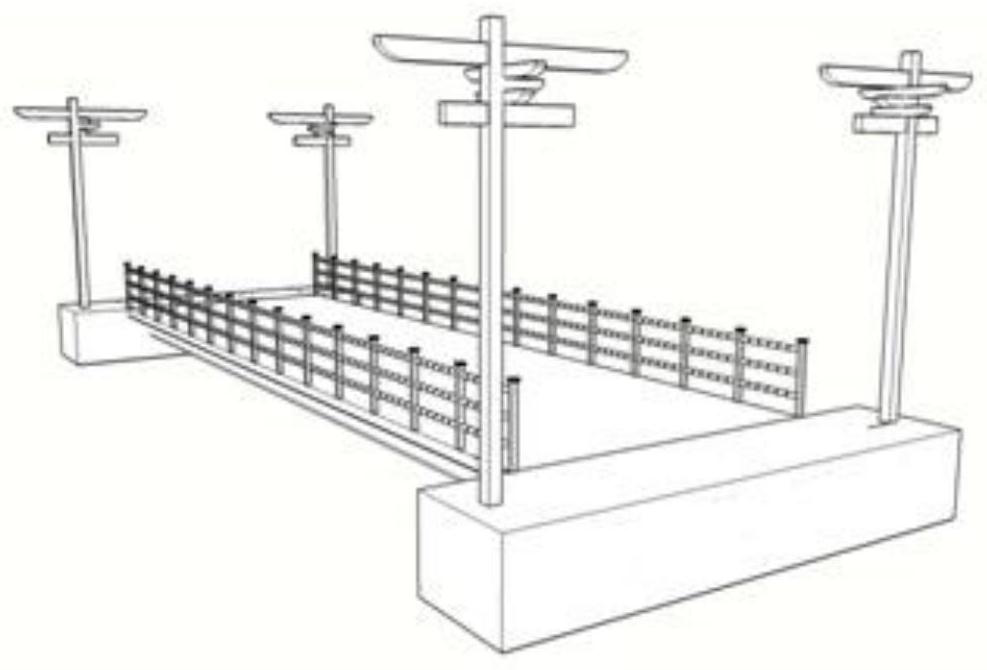

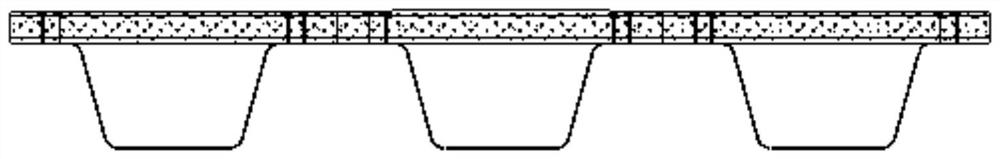

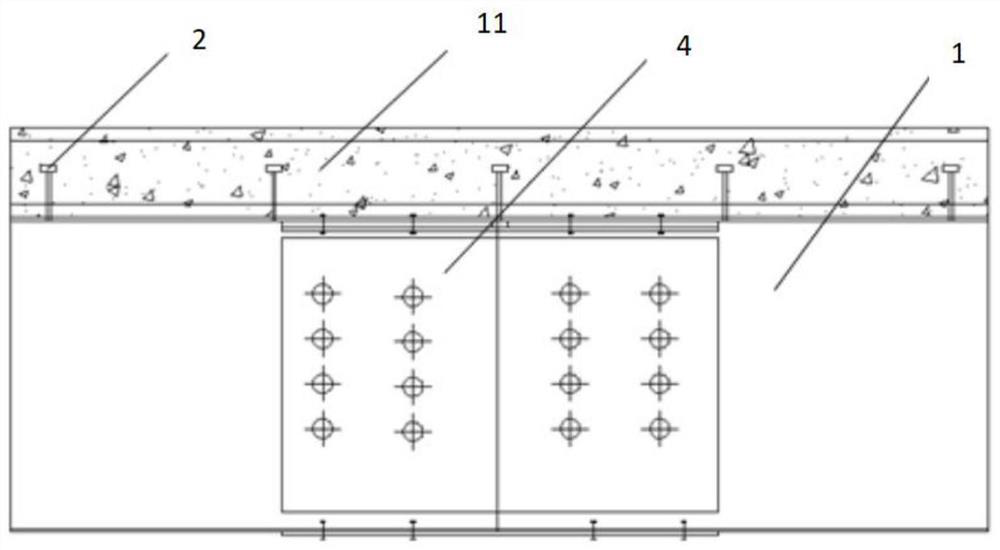

[0037] As shown in the figure, a cold-formed U-shaped composite girder bridge of the present invention, according to analysis, the span of the cold-formed U-shaped composite girder bridge is within the range of 10m to 20m, compared with the same span hollow plate girder The amount of steel used is reduced by about 30%-50%, and the hoisting quality is reduced by about 50%-70%; the longitudinal wet joint 3 and the transverse wet joint 10 are connected with the U-shaped steel plate 1 by welding nail connectors, and the reinforced steel The connection performance of the mixed interface. The flexural bearing capacity of the U-shaped steel plate composite girder bridge is three times that of the hollow plate girder with the same span;

[0038] The bucket arch lamp post 8 is made of oxidized steel plate, and the top structure is a bucket arch structure; steel bars are placed inside the guardrail, and bamboo is used outside, and the bamboo is cut into equal lengths, cut along the diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com