Patents

Literature

88results about How to "Reduce the excitation force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

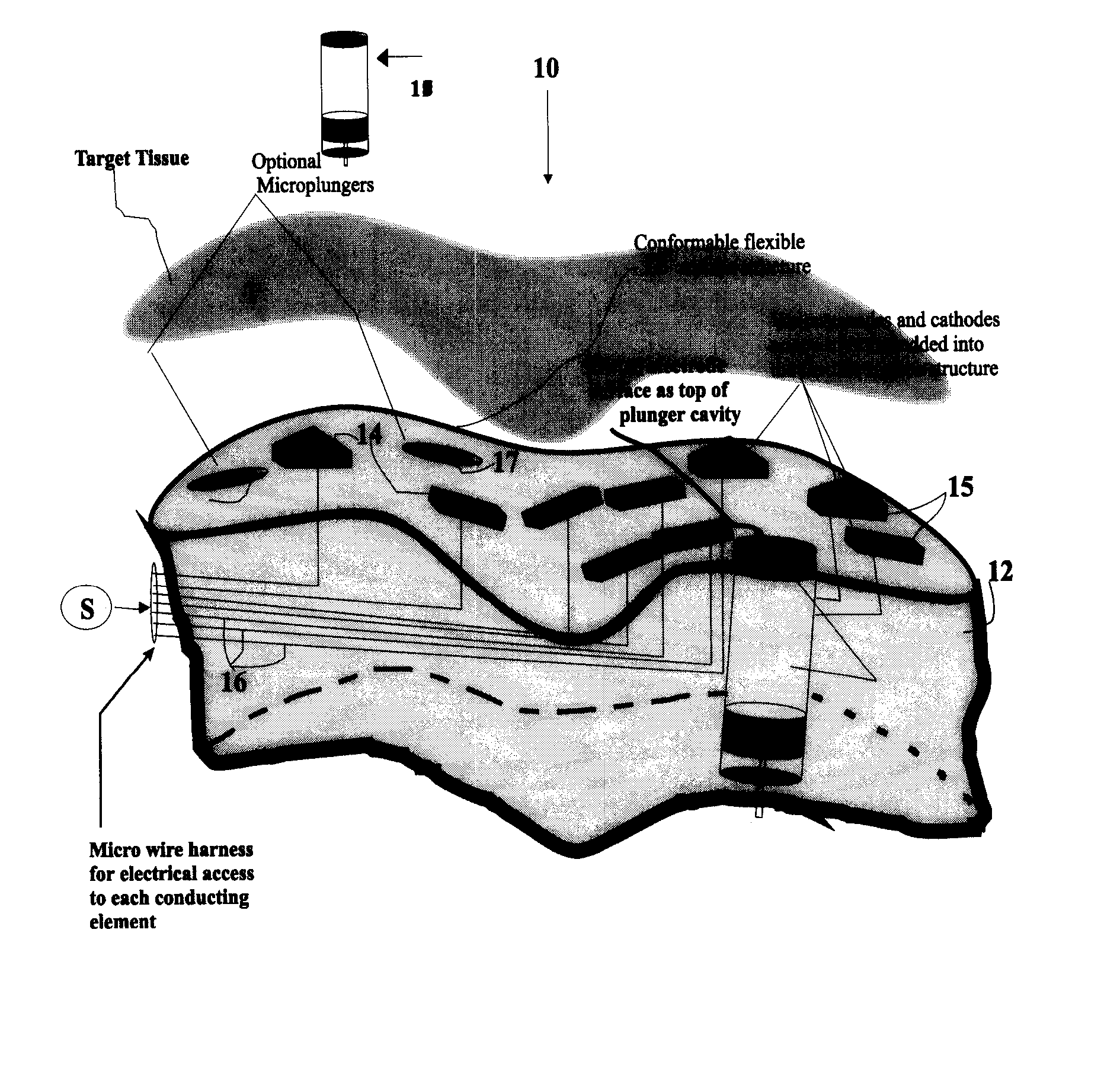

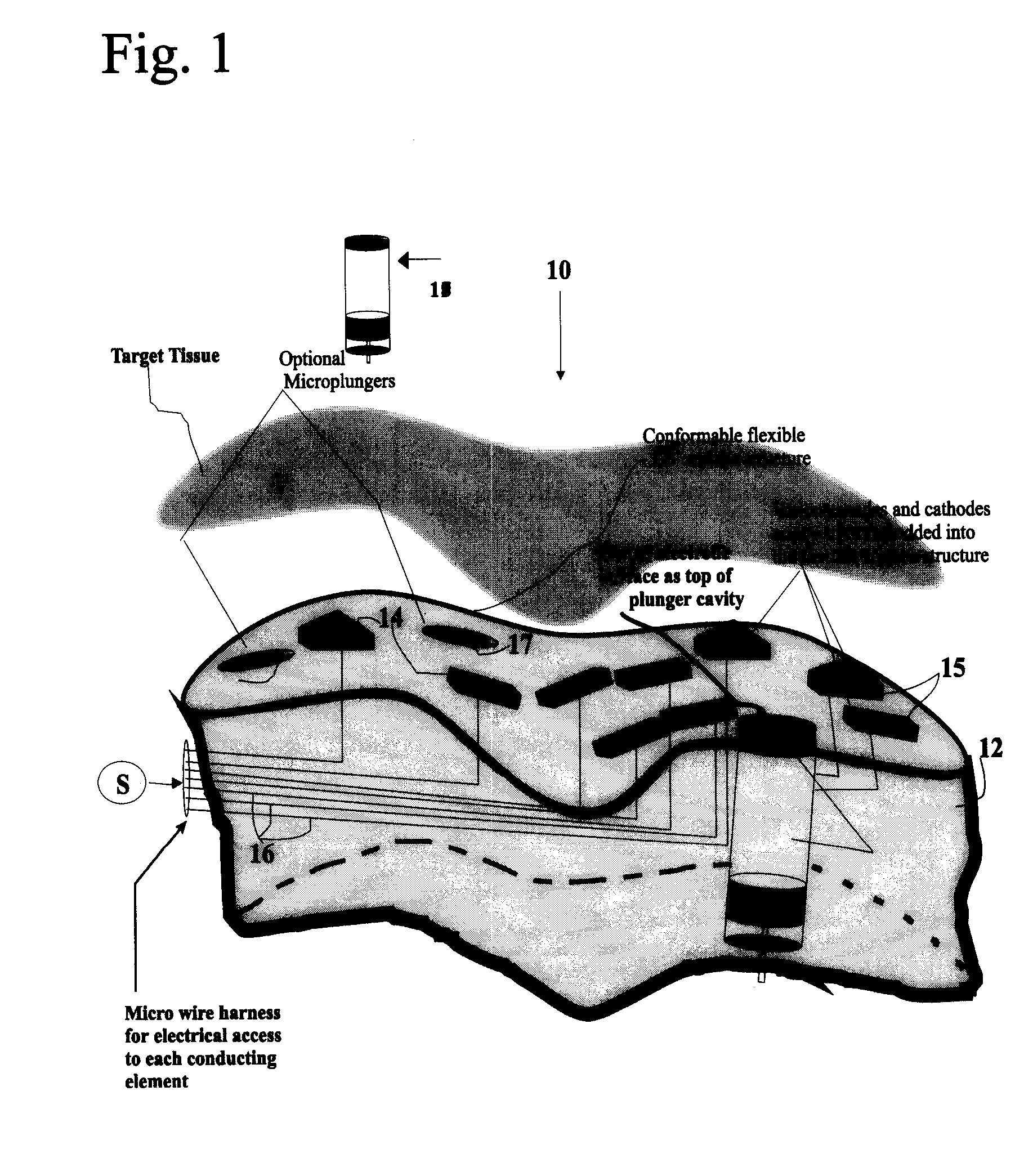

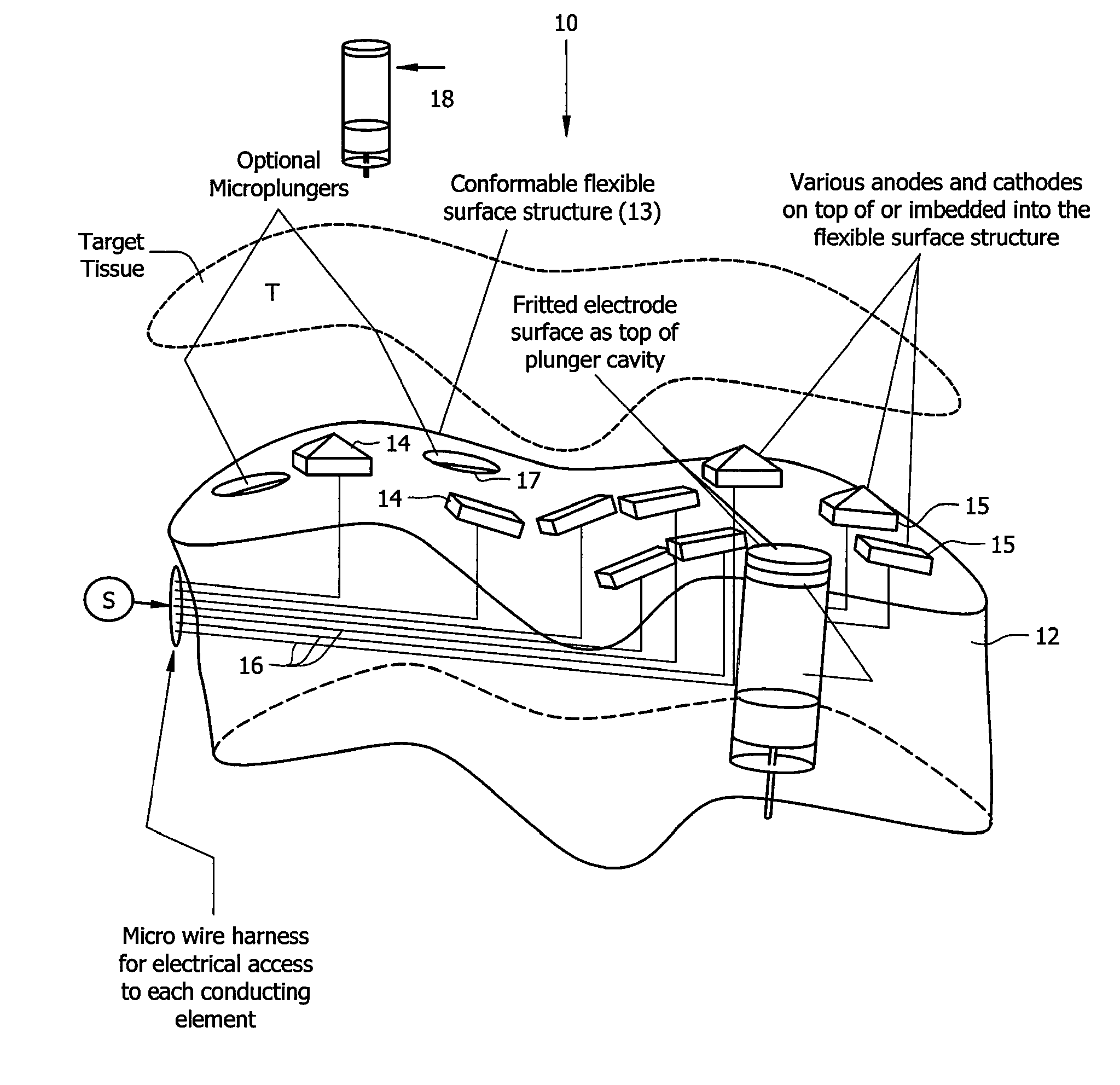

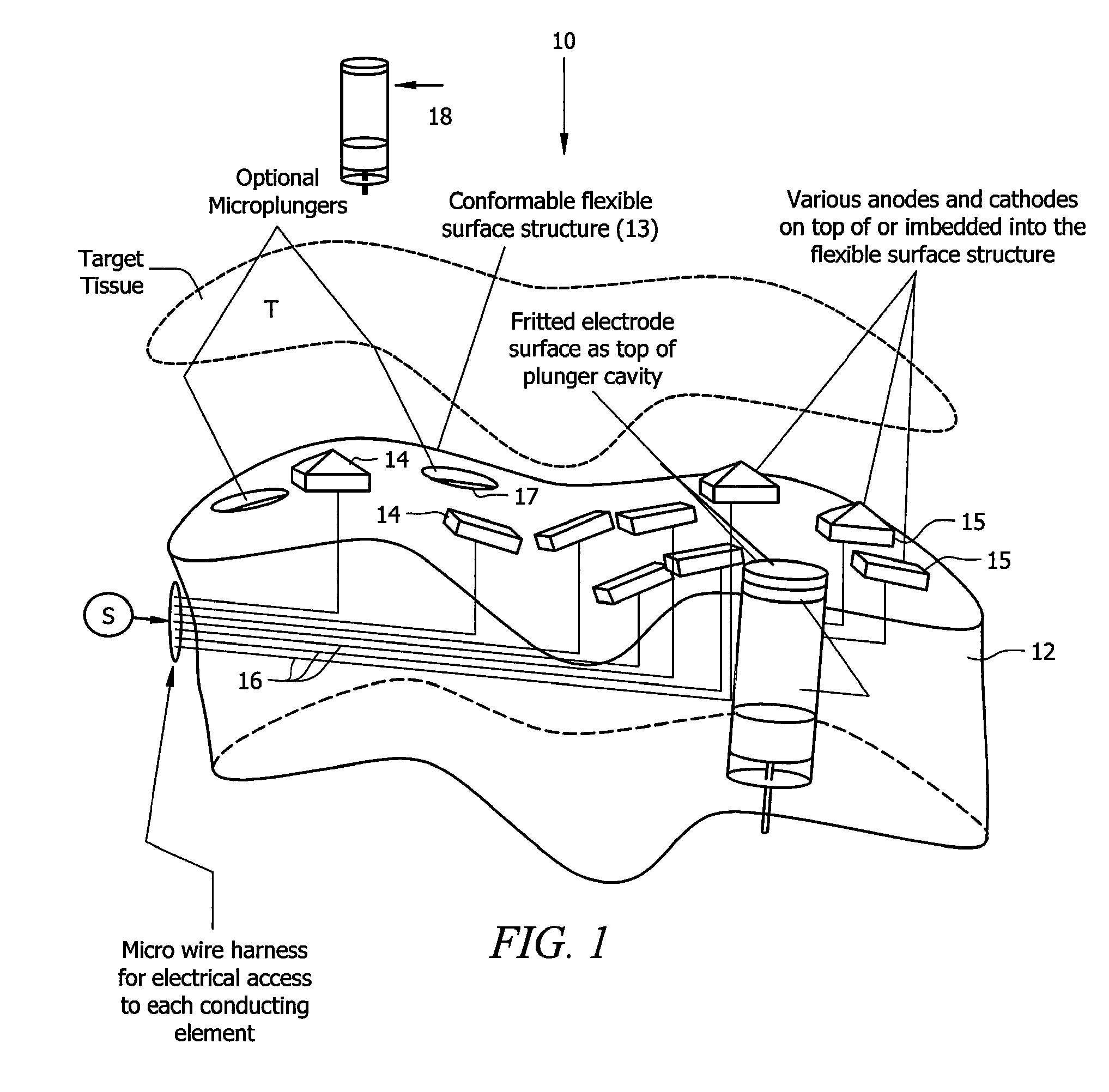

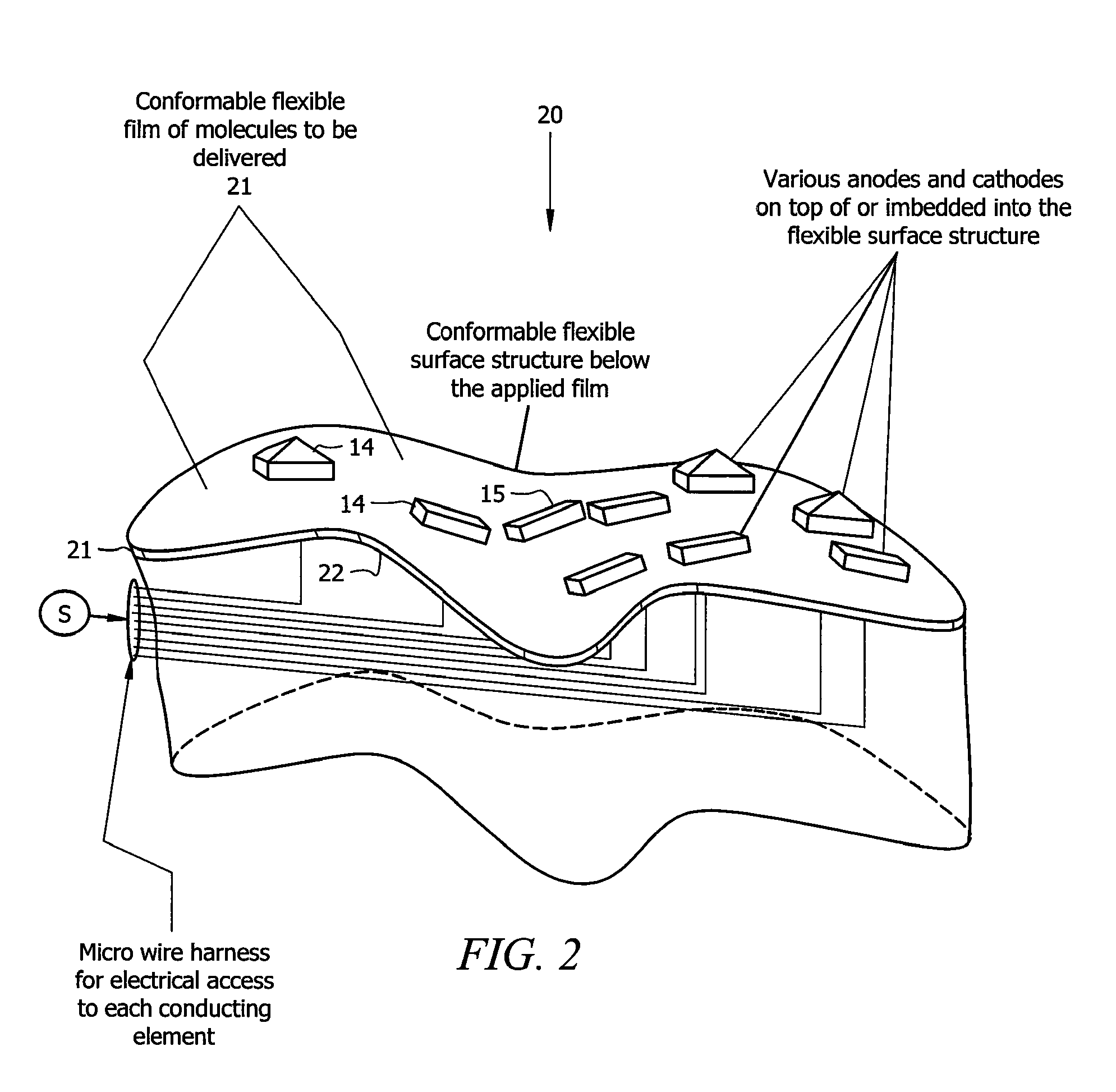

Electromanipulation Device and Method

ActiveUS20050054969A1Facilitates electroporationLow powerElectrotherapyOther foreign material introduction processesChemical substanceElectricity

The present invention is a device for electromanipulation of chemical species in vivo relative to a target tissue including a nonconductive, conformable array base adapted to be placed coincident to the target tissue, a plurality of electrode elements projecting from the array base towards the target tissue, the electrode elements addressable individually, an electrical source coupled to the plurality of electrodes, a control means interposed between the electrical source and the plurality of electrode elements and in circuit communication therein, the control means adapted to establish an electrical potential between at least two electrodes, and a delivery means adapted to introduce chemical species to the target tissue.

Owner:UNIV OF SOUTH FLORIDA

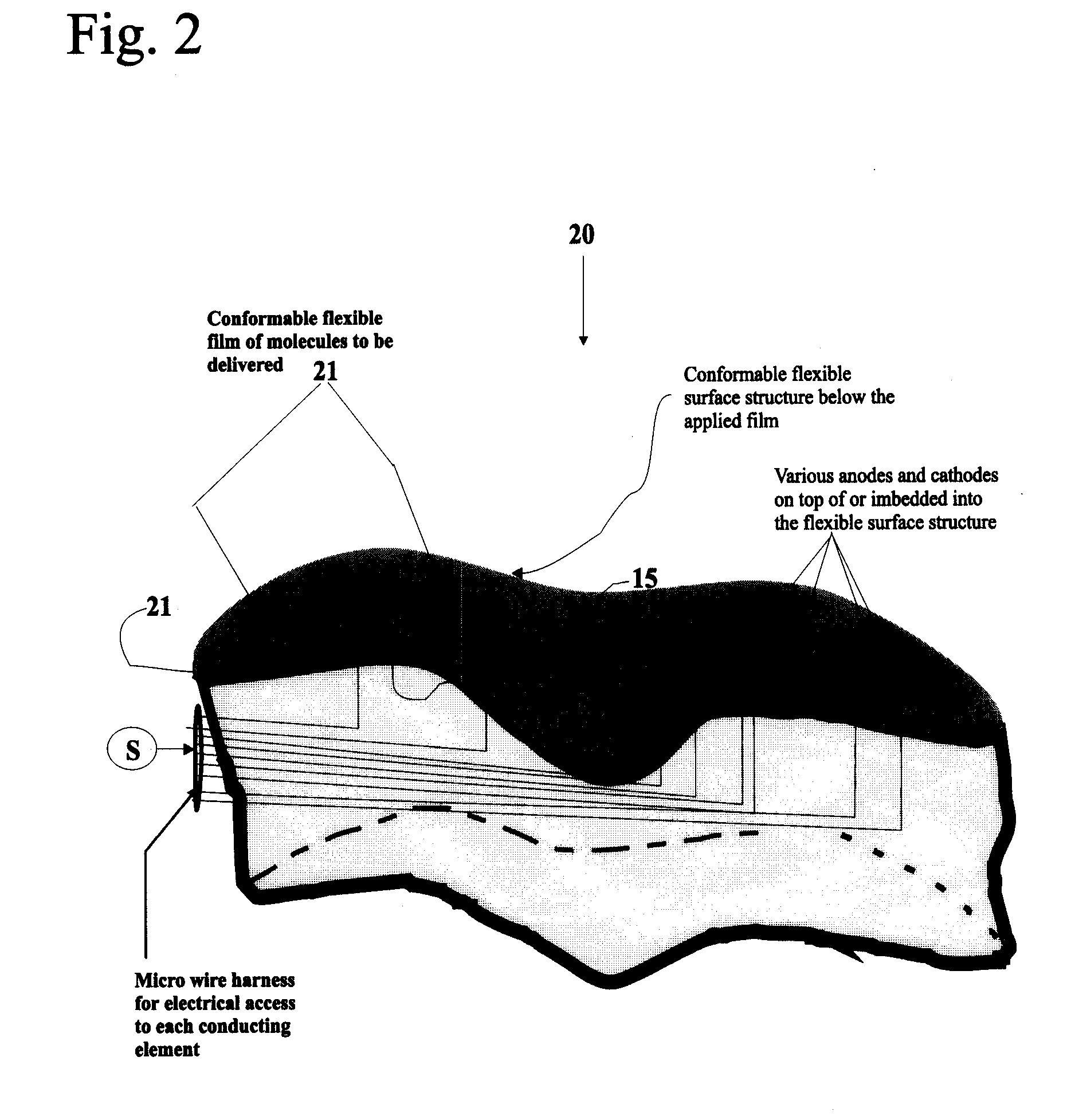

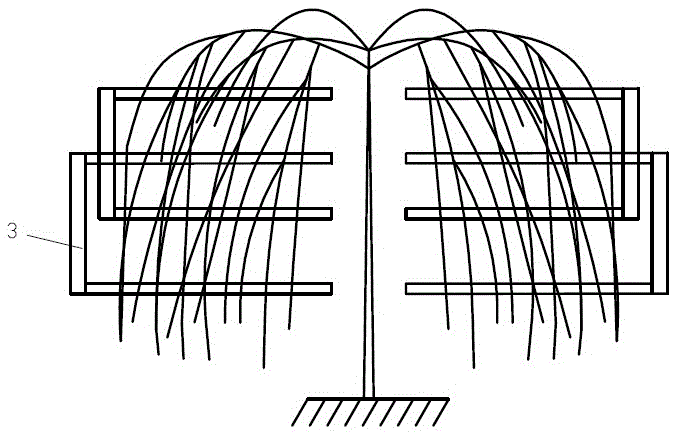

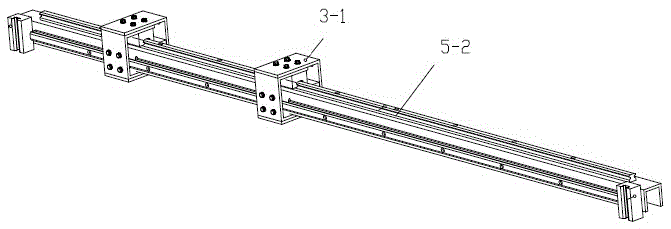

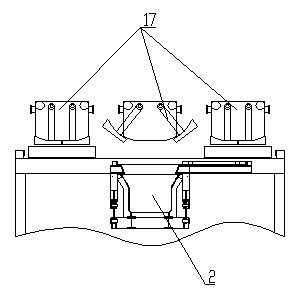

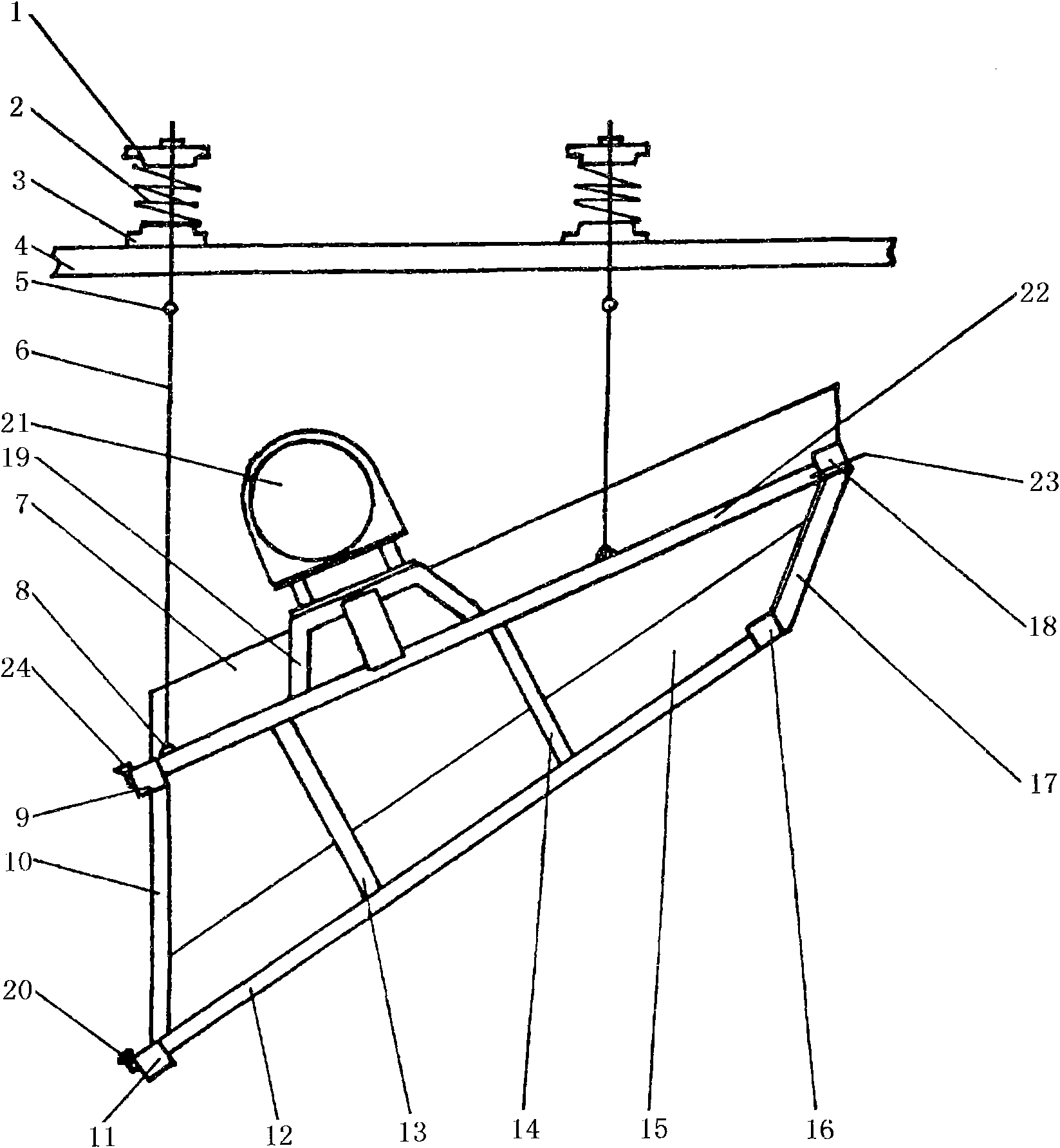

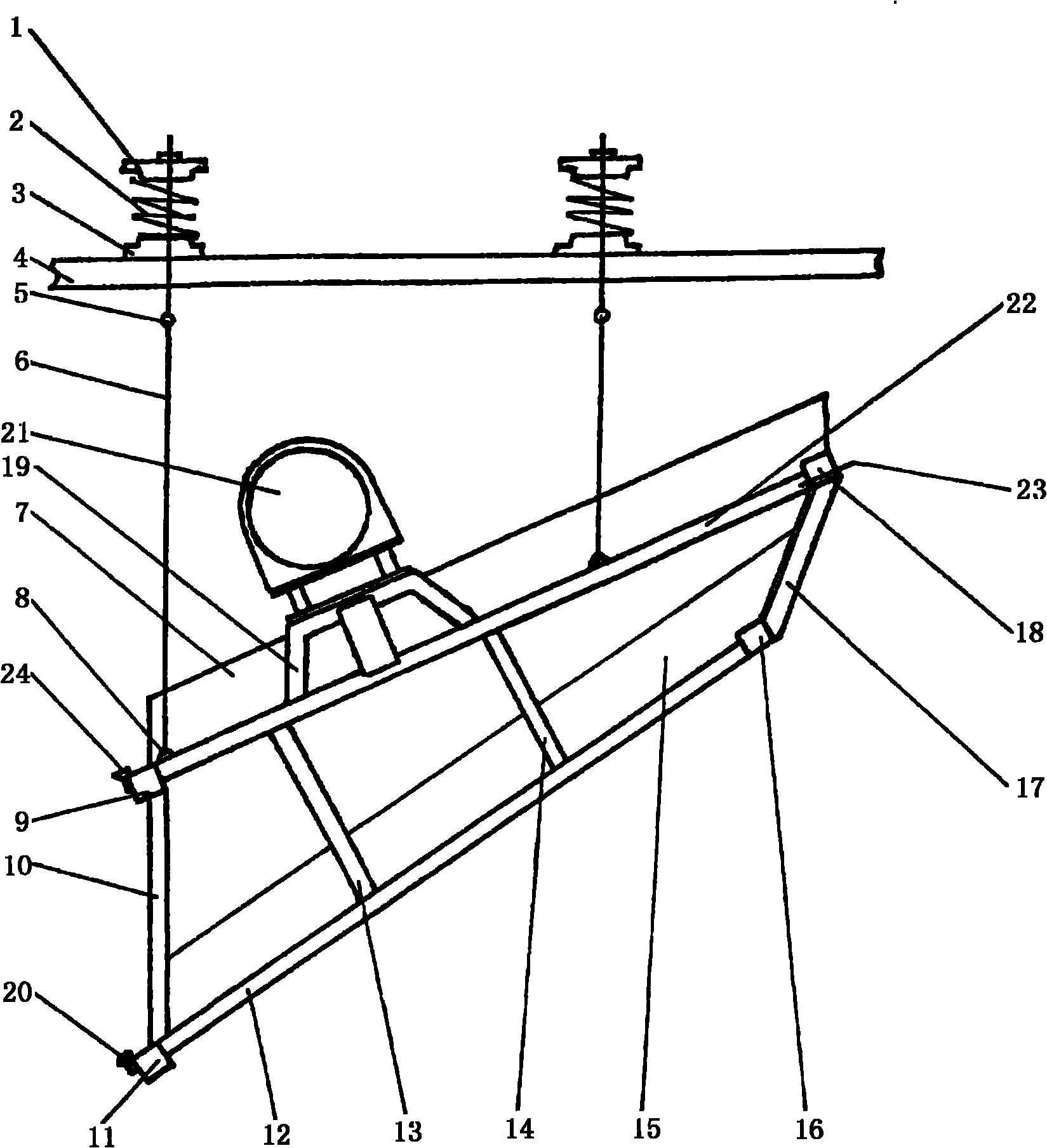

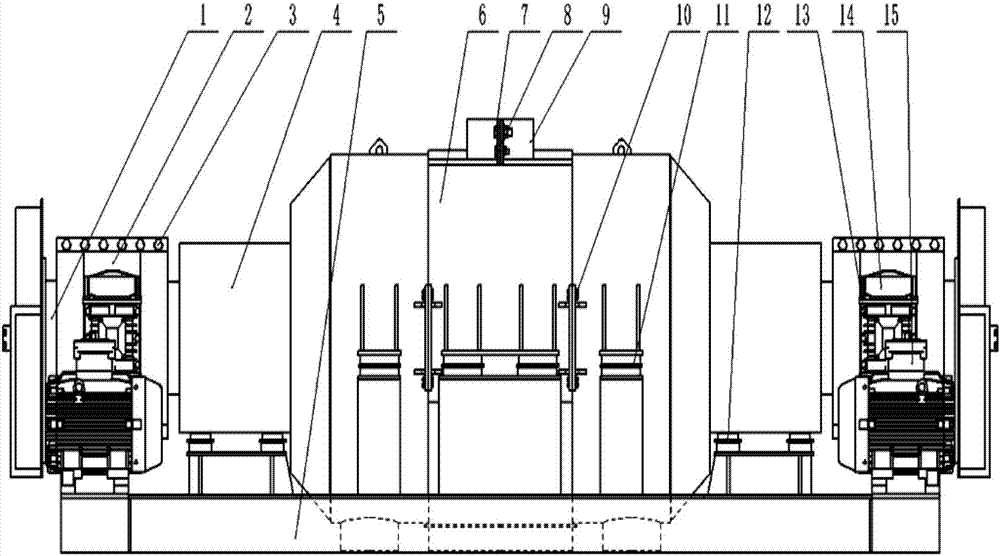

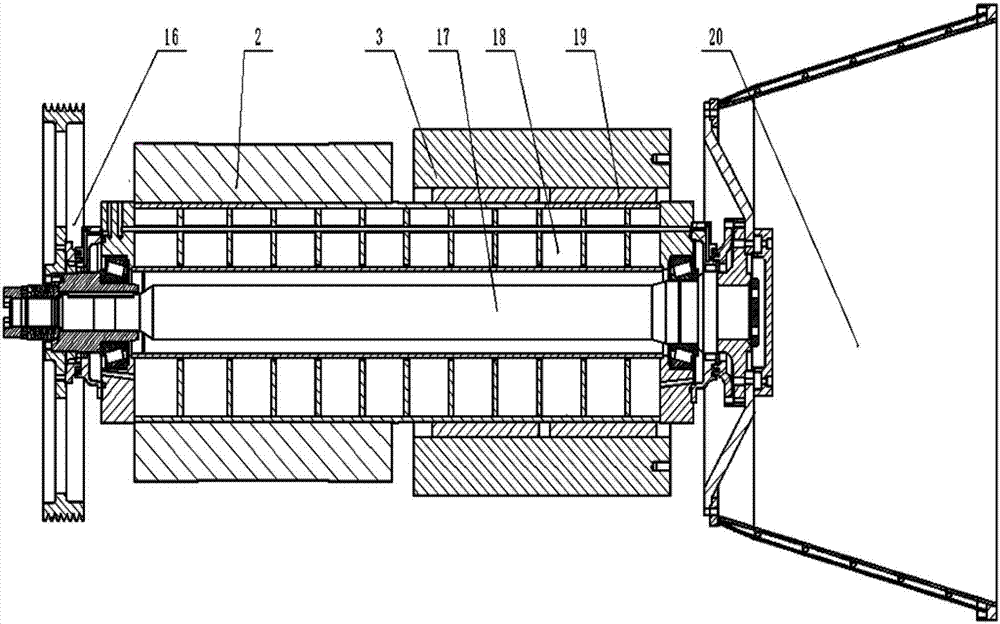

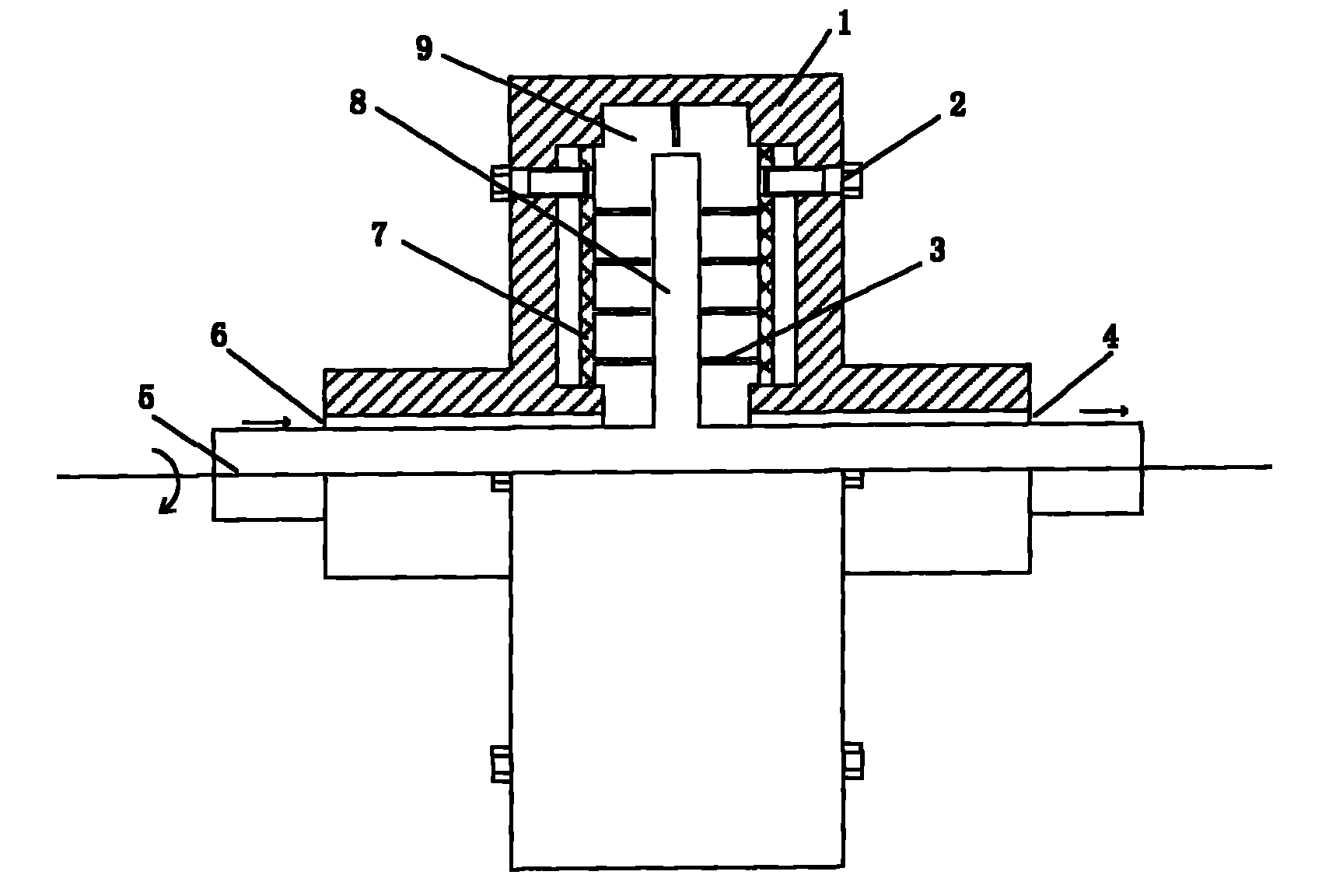

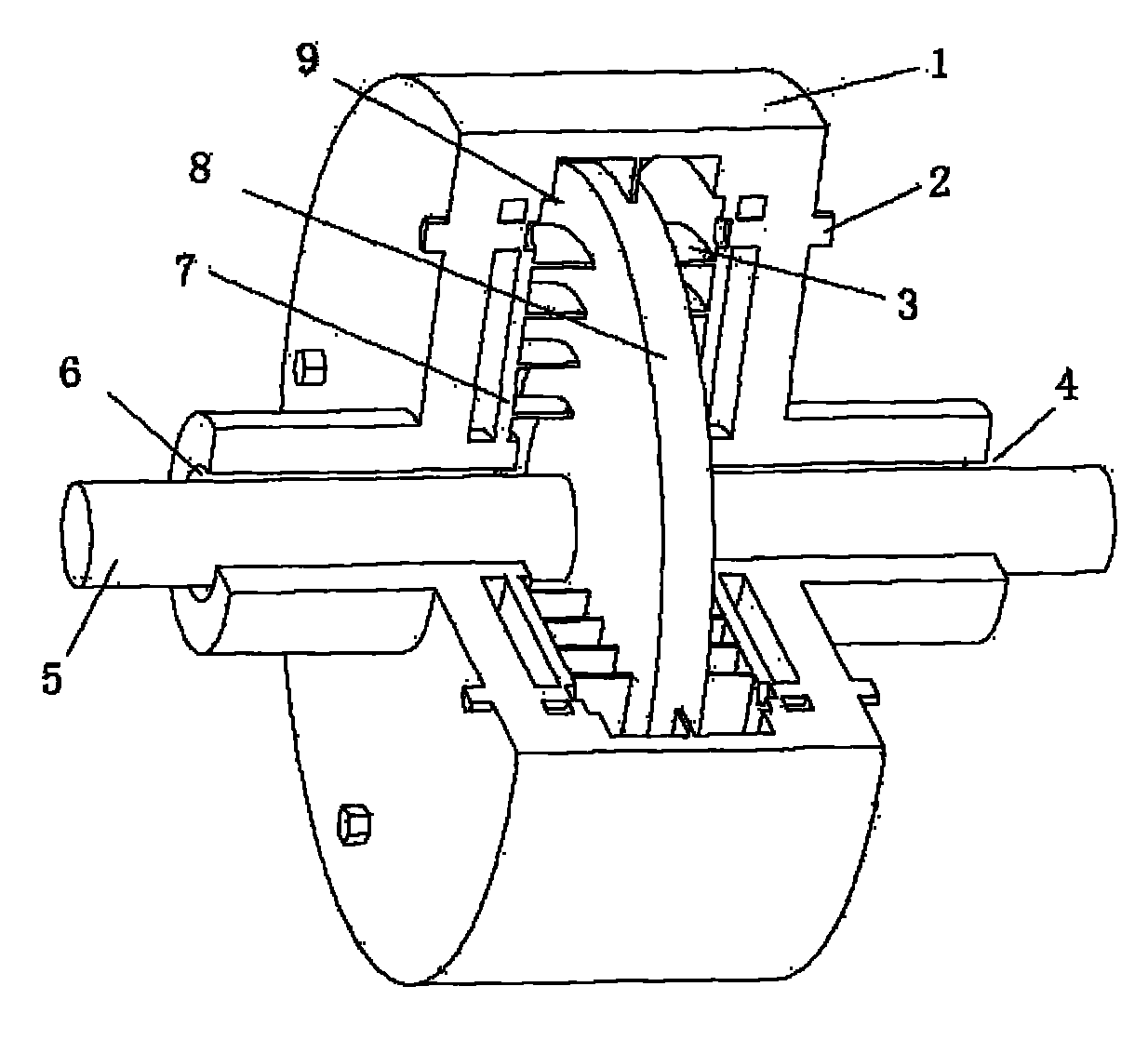

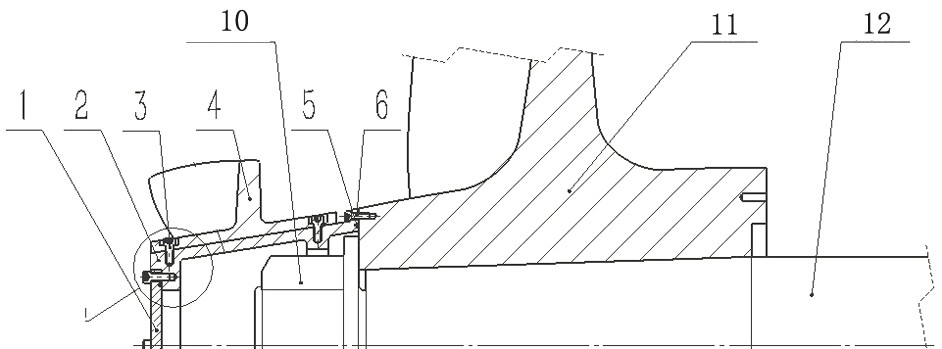

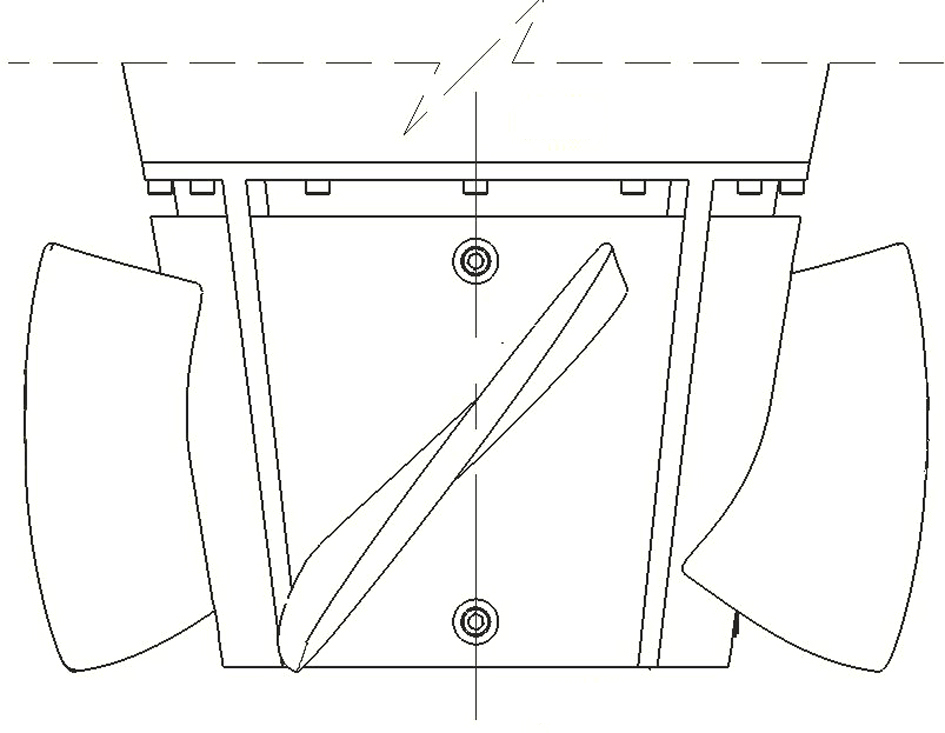

Vibration-type wolfberry fruit picking mechanism

ActiveCN105594374AEliminate avoidance of vibrating rodsReduce harmPicking devicesHydraulic motorFixed frame

The invention relates to a vibration-type wolfberry fruit picking mechanism and belongs to the technical field of agricultural machinery. A fixed frame of the mechanism is formed by fixedly connecting door-shaped brackets on the left and right sides, front and rear slide ways and a middle connecting beam; the two sides of the front and rear slide ways, and left and right hoisting opening / closing frames from left and right horizontal movement pair respectively; two opening / closing air cylinders are mounted in the middle of the middle connecting beam; stretching-out piston rod ends of the opening / closing air cylinders are fixedly connected with the left and right hoisting opening / closing frames respectively; each hoisting opening / closing frame is a rectangular framework; front and rear vertical beams, and upper and lower vibration rod mechanisms with opposite vibration directions form vertical movable pairs respectively; a hoisting air cylinder is mounted in the middle of an upper transverse beam; a piston rod end of the hoisting air cylinder is fixedly connected with the vibration rod mechanisms; each vibration rod mechanism comprises horizontal slide rails, and the horizontal slide rails, and upper and lower rows of vibration rod rows form front and rear horizontal movement pairs; the vibration rod rows are in transmission connection with an output shaft mounted on a hydraulic motor. By virtue of the vibration-type wolfberry fruit picking mechanism, the picking efficiency and the picking rate are effectively improved; a needed excitation force is relatively small, and injuries to branches, caused by the picking excitation force, is remarkably reduced.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

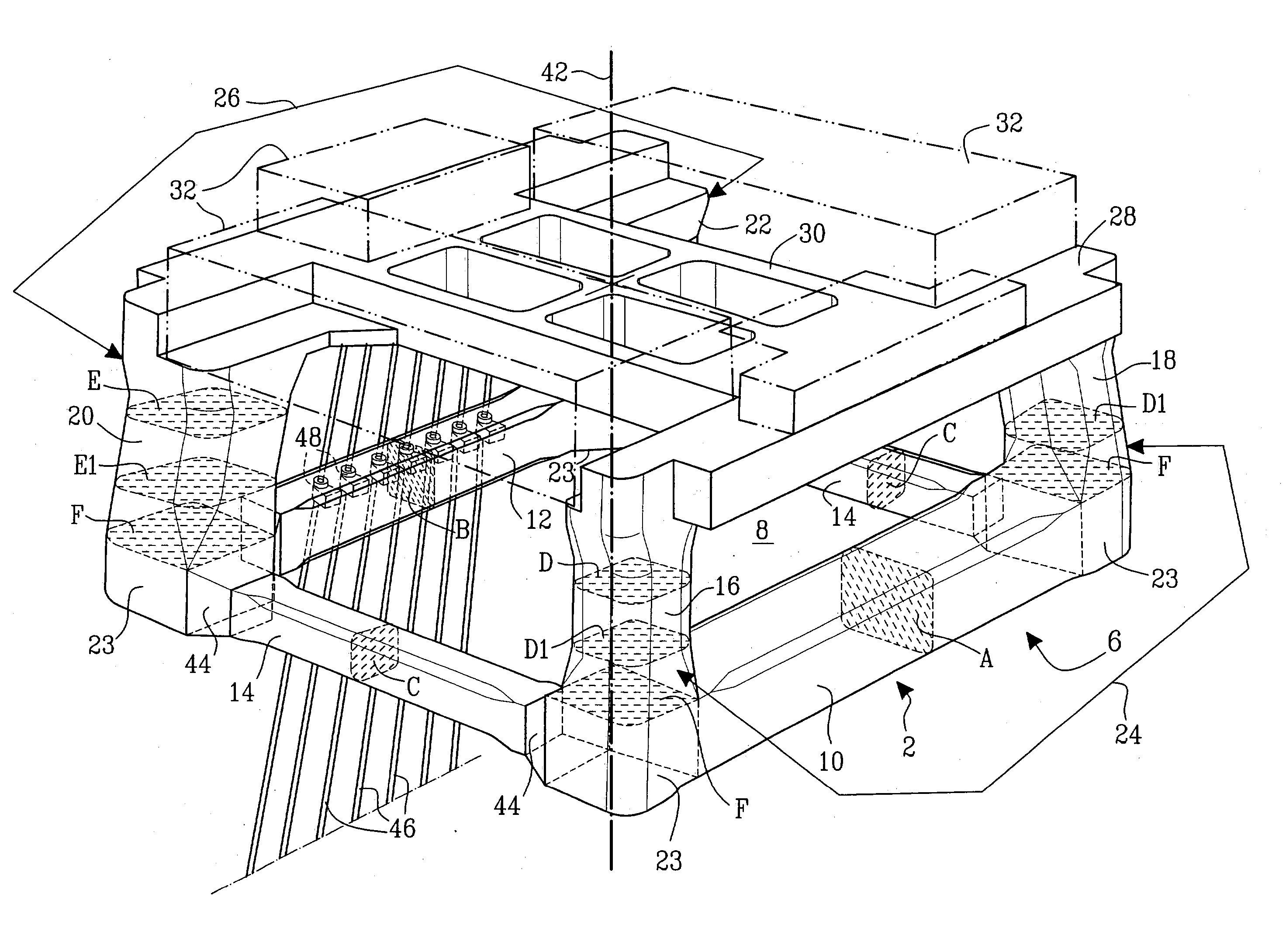

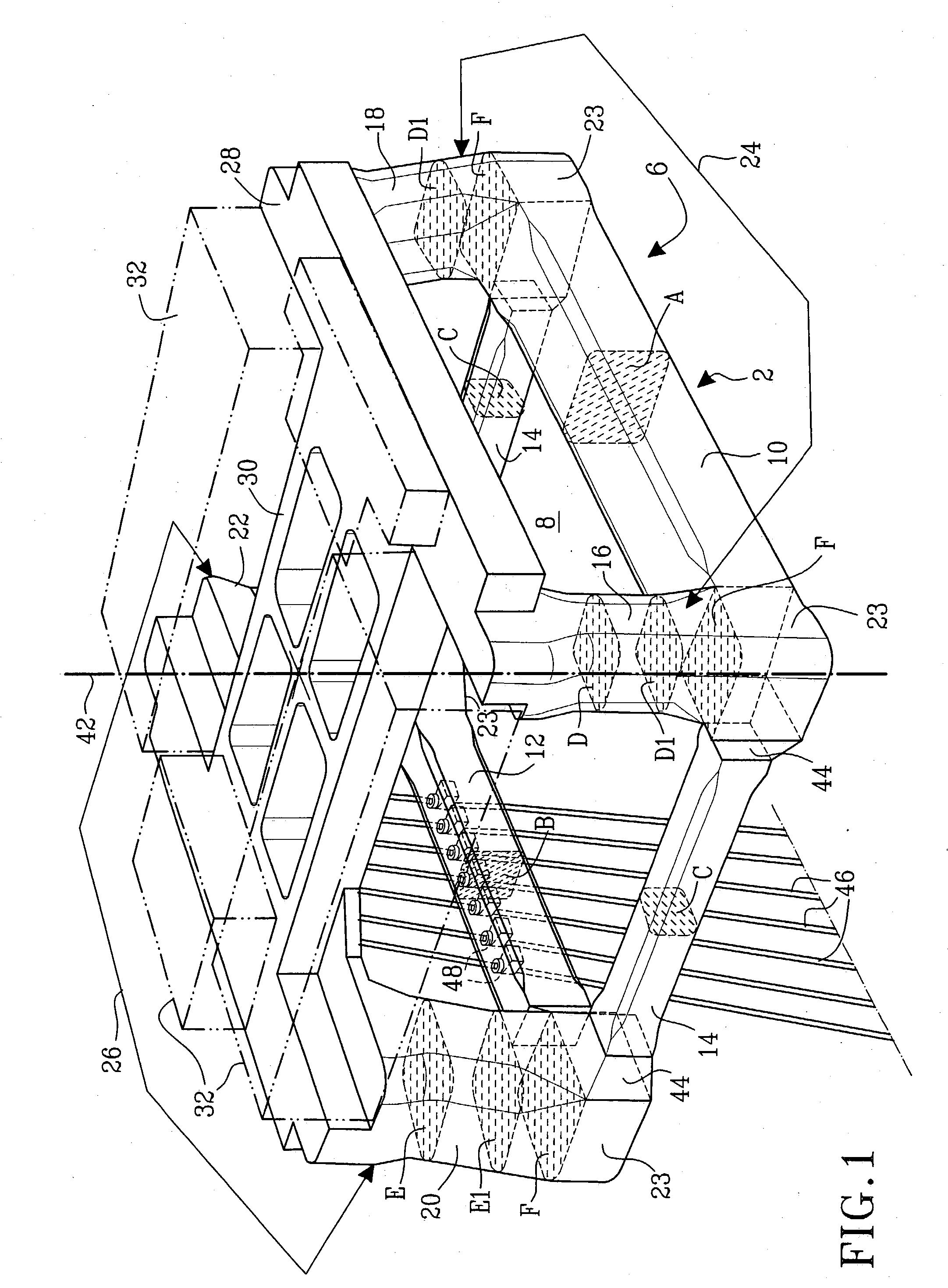

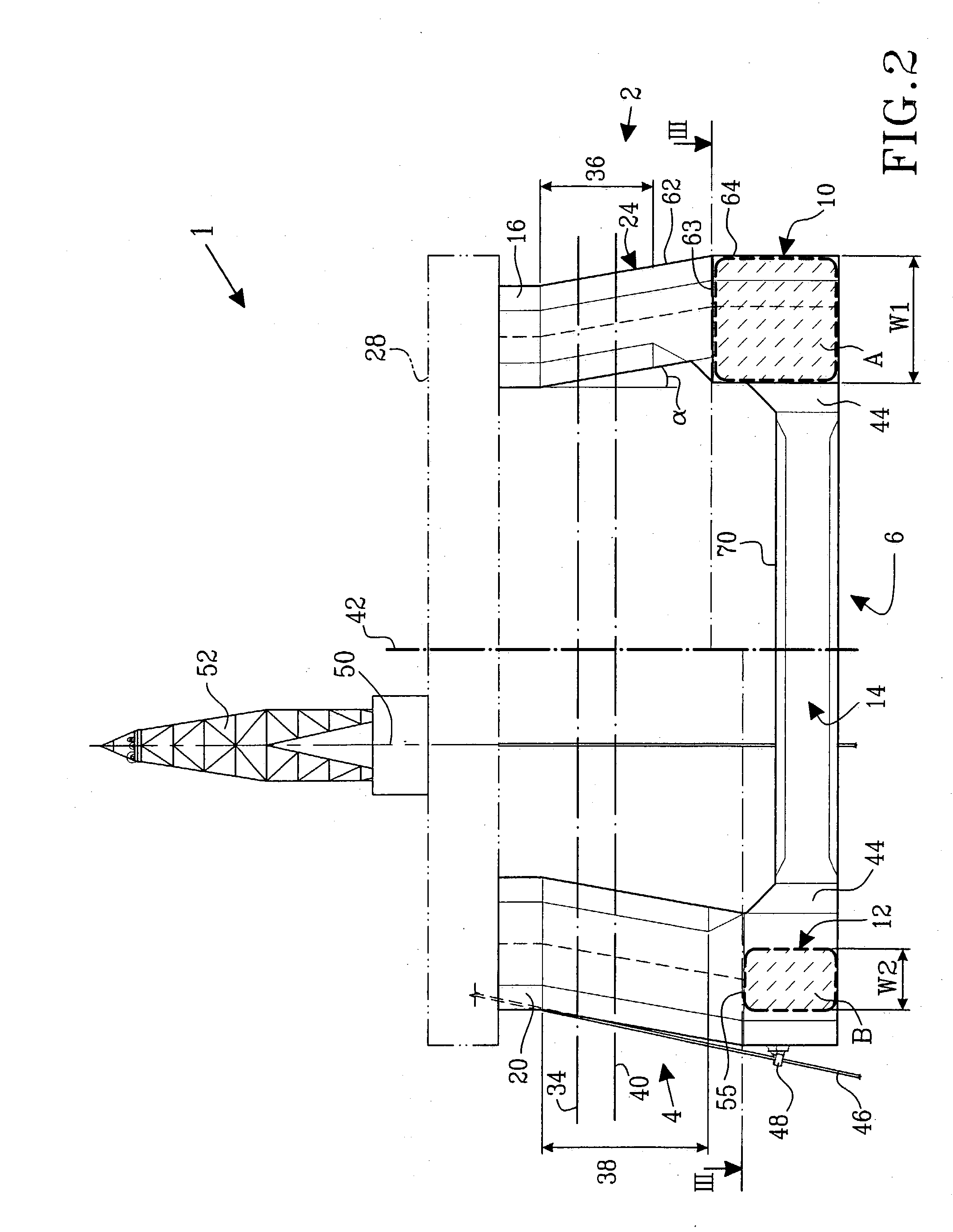

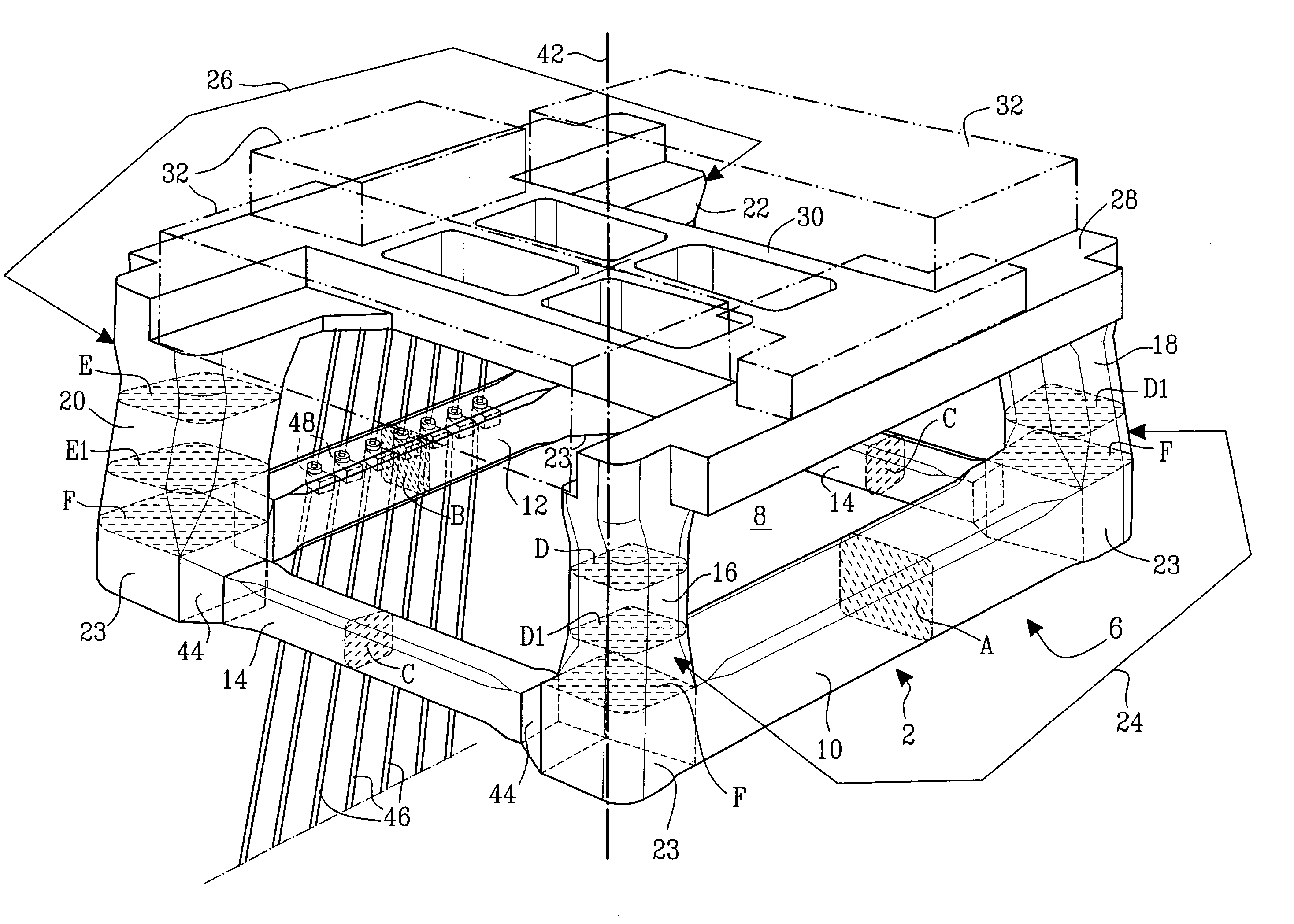

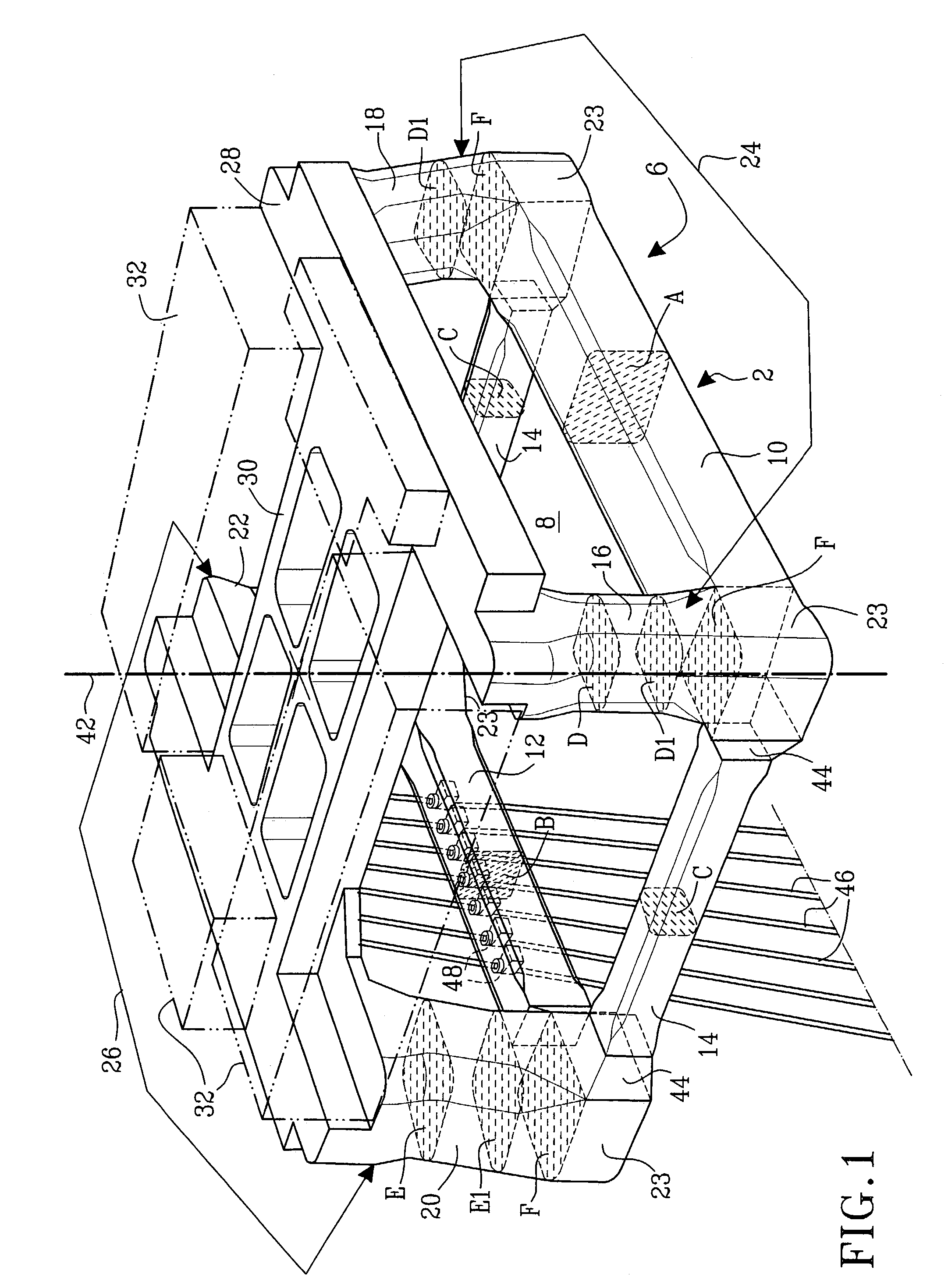

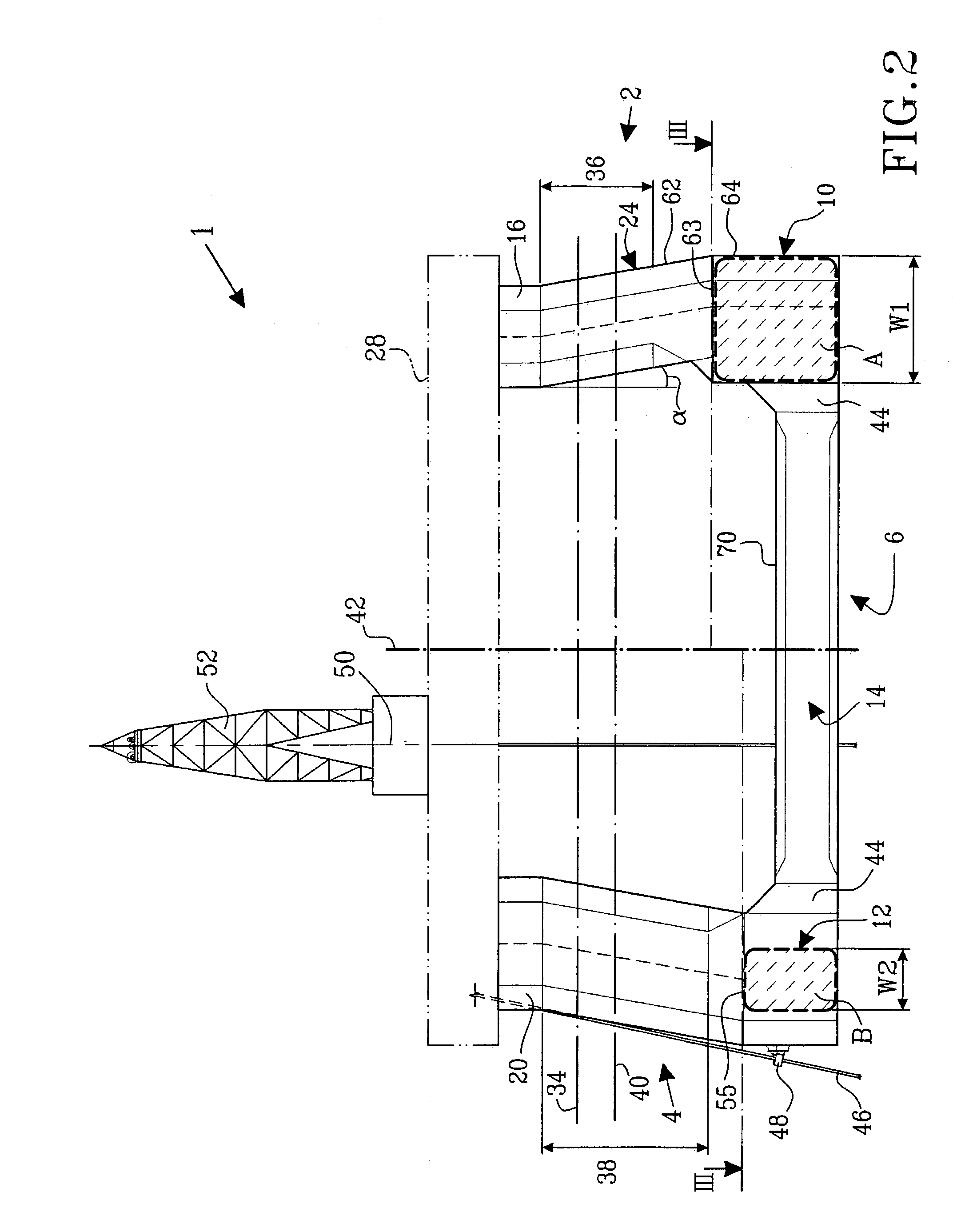

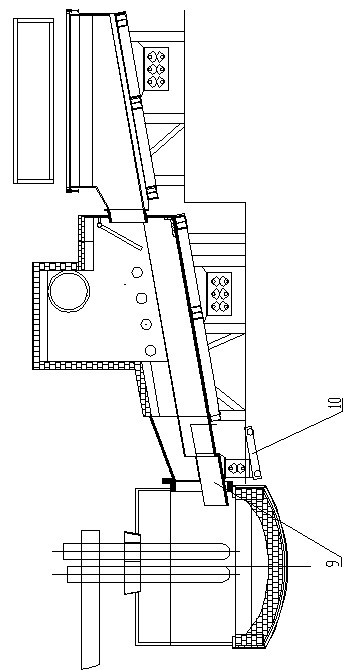

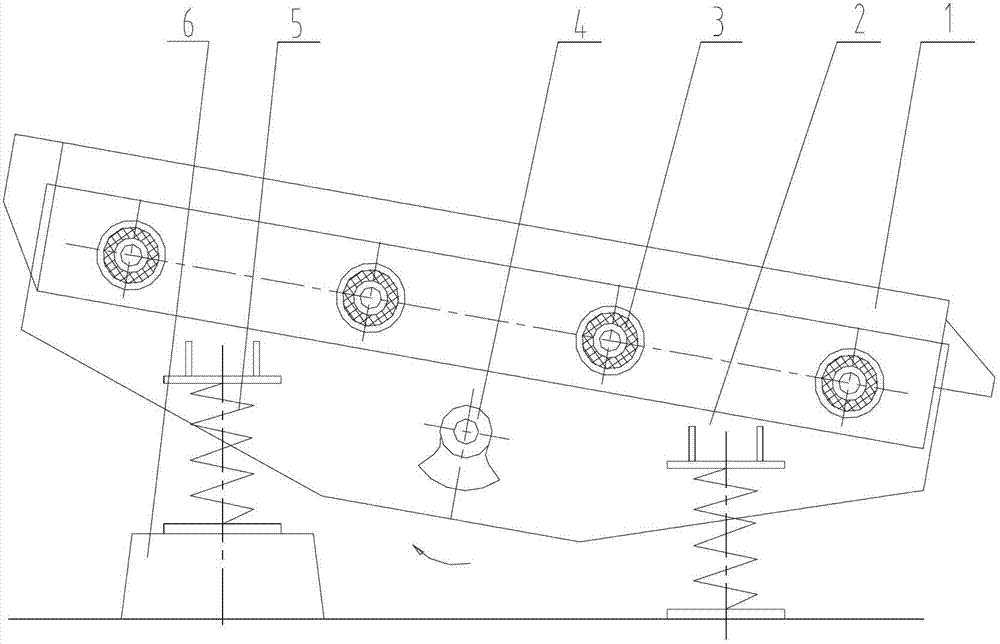

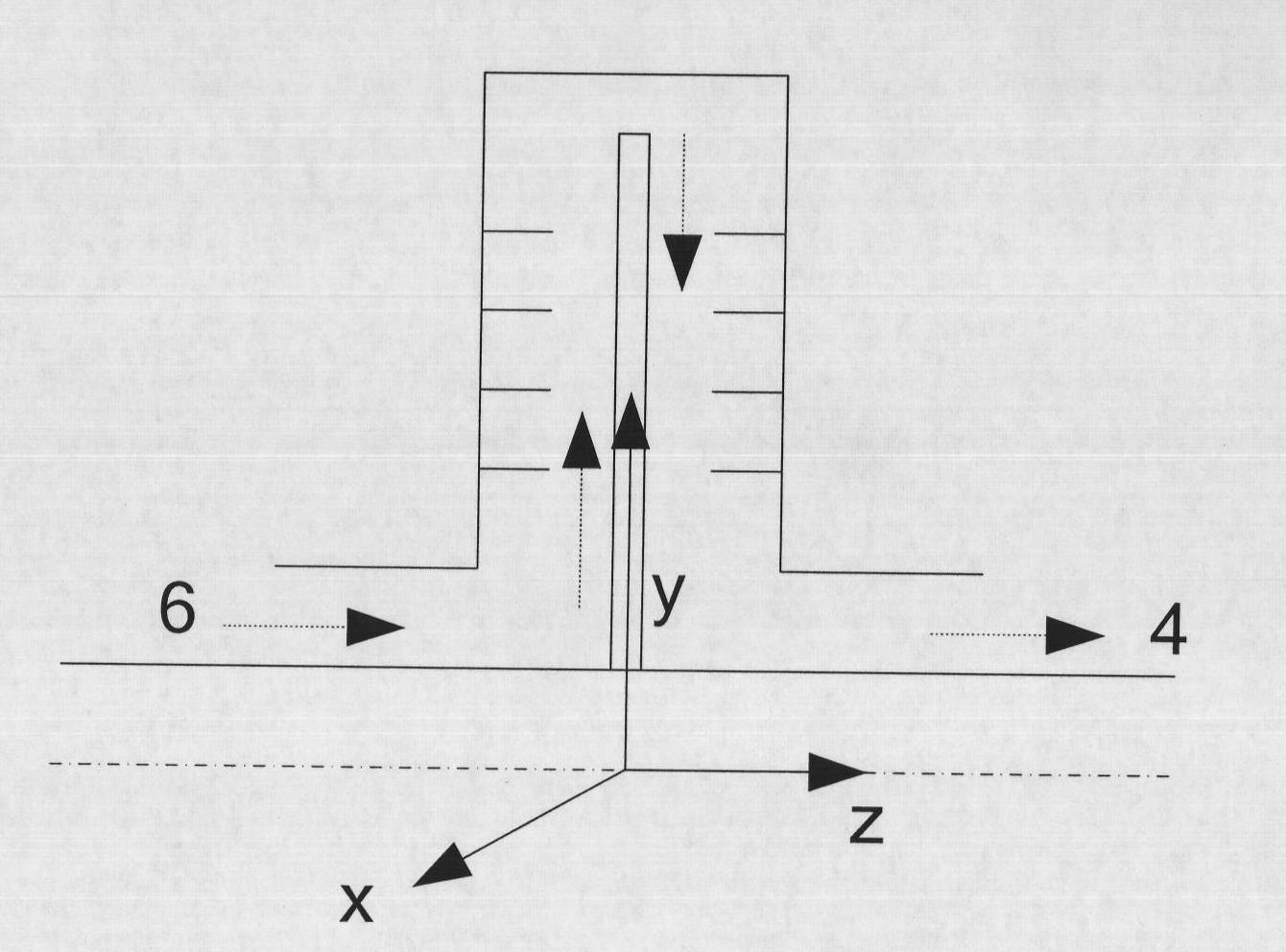

Semi-submersible offshore vessel

ActiveUS20050058513A1Reduce the excitation forceIncrease the exciting forceDrilling rodsHydraulic engineering apparatusPontoon bridgeBoard structure

A semi-submersible offshore vessel (1) exhibiting a first end (2), for example constituting the forward end of the vessel, and a second end (4), for example constituting the aft end of the vessel (1), or vice versa, wherein the vessel (1) includes a substantially rectangular ring-pontoon (6) including a first transverse pontoon section (10) located at the first end (2) of the vessel (1); a second transverse pontoon section (12) located at the second end (4) of the vessel (1), the second transverse pontoon section (12) being parallel to the first transverse pontoon section (10), the ring-pontoon (6) further including two mutually parallel longitudinal pontoon sections (14) extending between the first (2) and the second end (4) of the vessel (1); at least four support columns (16, 18, 20, 22) extending upwardly from respective edge-portions (23) of said ring-pontoon (2), the support columns (16, 18, 20, 22) being arranged in a first column pair (24) located at the first end (2) of the vessel (1) and a second column pair (26) located at the second end (4) of the vessel (1); and an upper deck structure (28) positioned upon the support columns (16, 18, 20, 22). The first transverse pontoon section (10) may also include a vertical mean cross-section area (A) which exceeds the corresponding vertical mean cross-section area (B) of the second transverse pontoon section (12), and the support columns (20, 22) in the second column pair (26) each has a water-plane area (E) which exceeds the water-plane area (D) of each of the support columns (16, 18) in the first column pair (24).

Owner:GVA GONSULTANTS

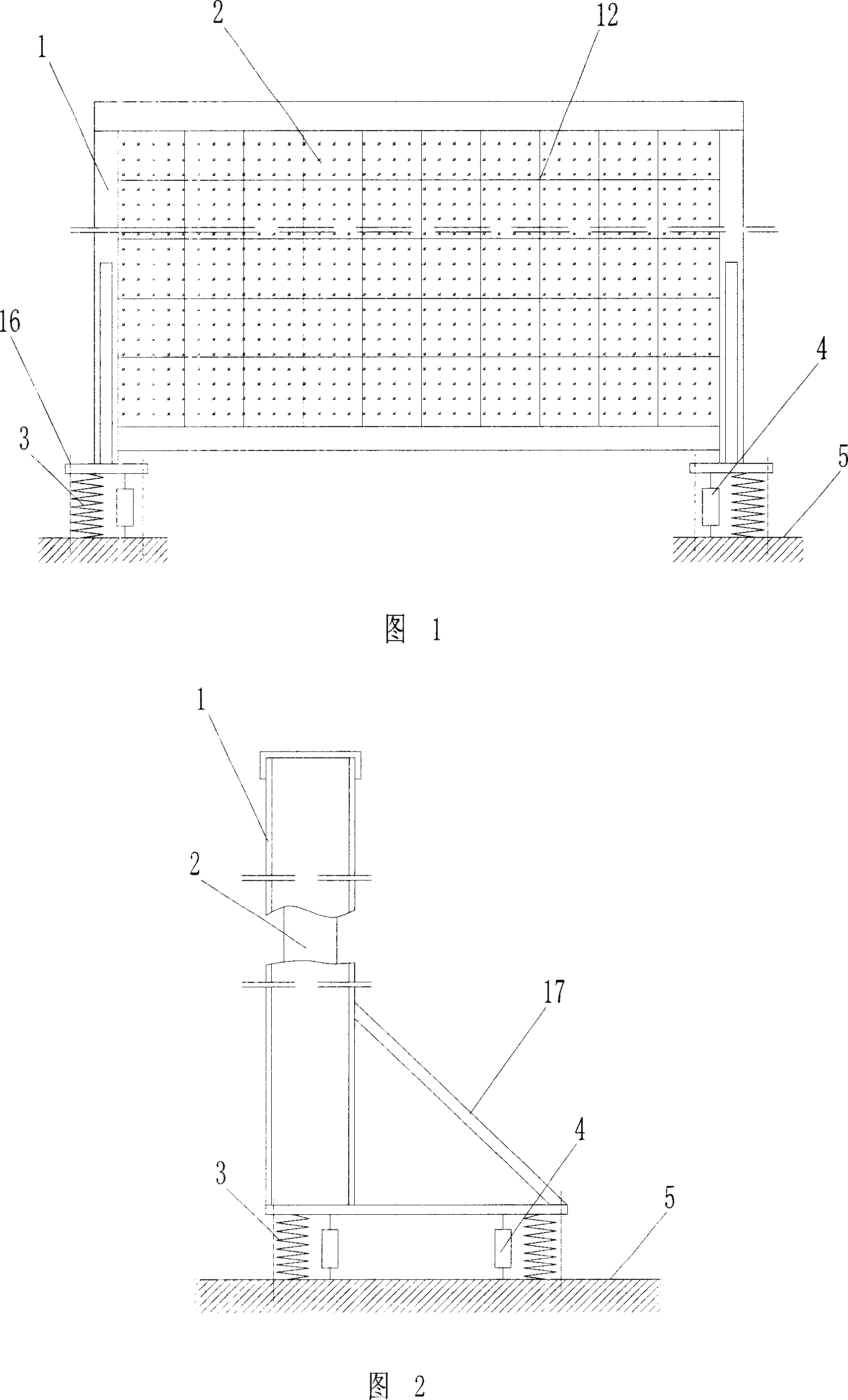

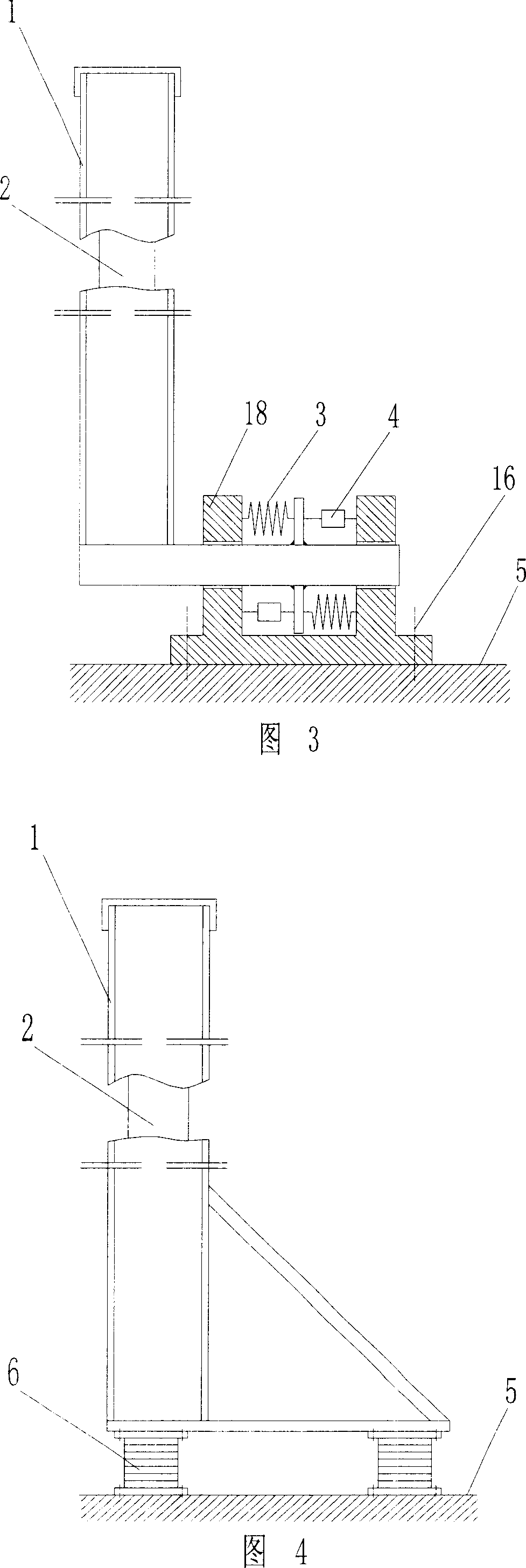

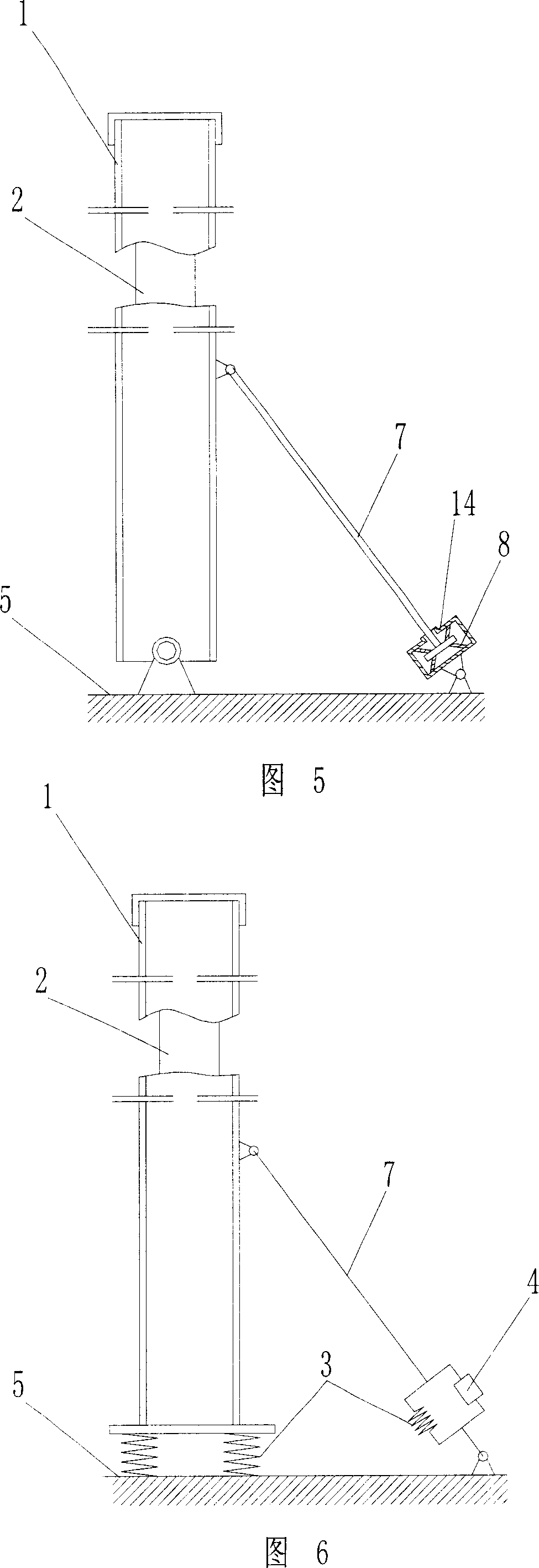

Sound absorbing and insulating barrier

ActiveCN101016729AReduced number of fatigue stress cyclesReduce the excitation forceNoise reduction constructionEngineering

The invention relates to a shield besides road to adsorb noise, which comprises a sound adsorption shield and a support frame, wherein the shield plate and the support frame or / and support frame and the base are connected via flexible element or / and damping element, the flexible element and the damping element can be serially, parallel or integrally connected. The invention can improve sound adsorption ability and protect the base, with long service life, less increase on the load of road, and high safety or the like.

Owner:QINGDAO CREATE ENVIRONMENT CONTROL TECH

Semi-submersible offshore vessel

InactiveUS7011472B2Reduce the excitation forceIncrease the exciting forceVessel safetyVessel movement reduction by mass displacementPontoon bridge

Owner:GVA GONSULTANTS

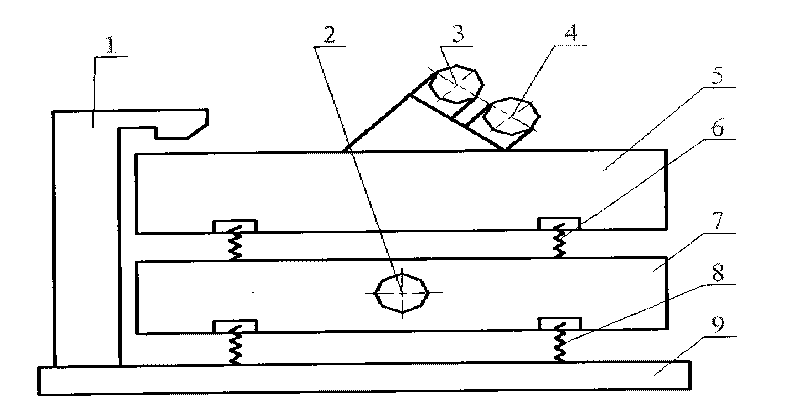

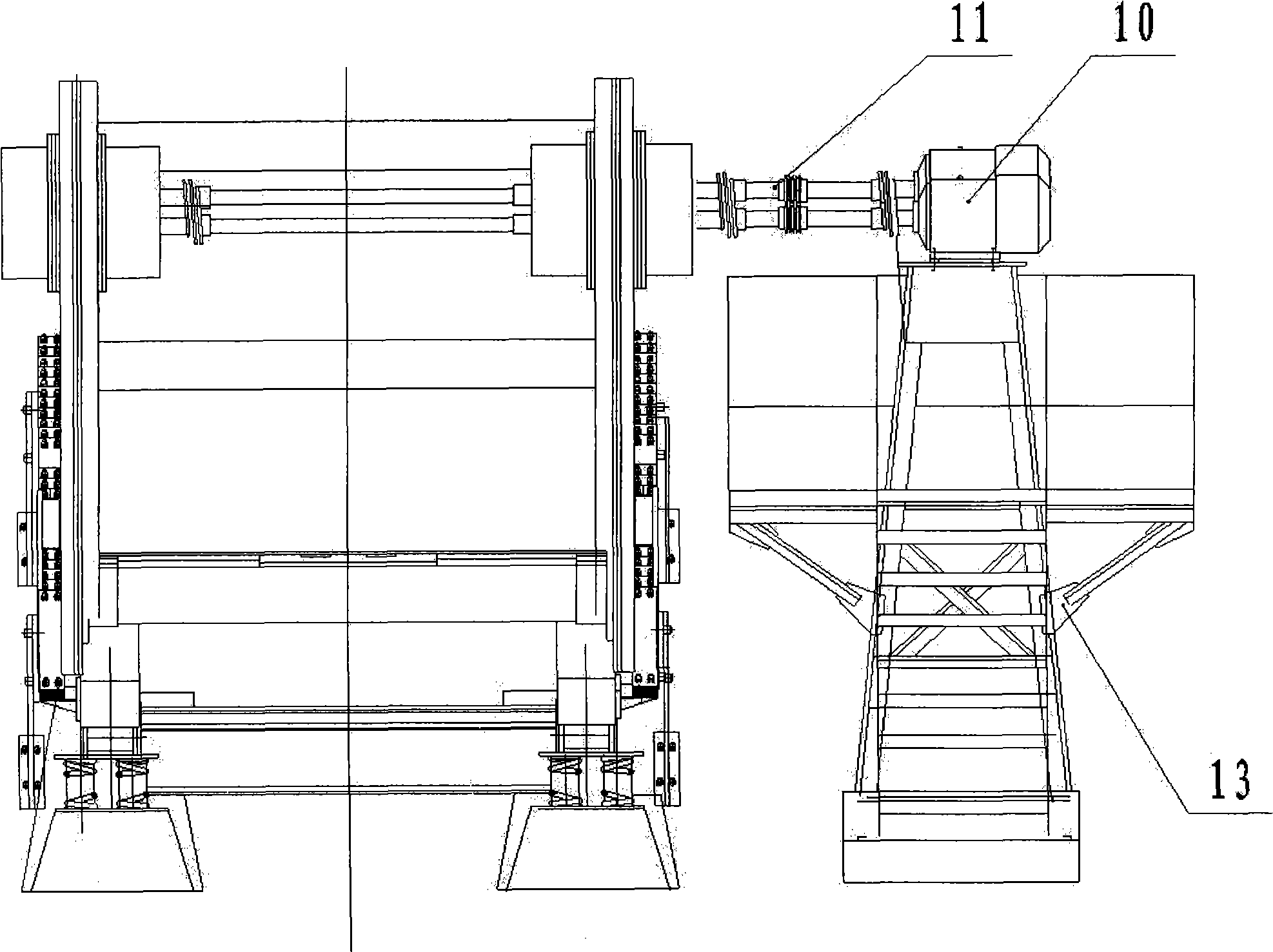

Differential motion airtight feeding electric furnace smelting device and feeding method thereof

ActiveCN102181601AShorten the lengthIncrease the feeding speedCharge manipulationElectric furnaceEngineeringHeat losses

The invention discloses a differential motion airtight feeding electric furnace smelting device and a feeding method thereof. The device comprises an electric furnace and a charging device, wherein the charging device comprises a cold receiving conveying trough and a heat conveying trough; the lower sides of the cold receiving conveying trough and the heat conveying trough are provided with an independently-controlled excitation device respectively; the outlet of the cold receiving conveying trough is provided with a conveying throat opening which is extended into the heat conveying trough; and the distance between the conveying throat opening and the bottom of the heat conveying trough is greater than or equal to the depth of the heat conveying trough. By the feeding method, shock excitation at different frequencies is applied to the two conveying troughs to realize the differential motion conveying of raw materials, so that a thicker material layer can be laid on the cold receiving conveying trough, and the material loading speed is increased; simultaneously, a shorter cold receiving conveying trough and a shorter material-conveying bottom elongated slot can be designed, so that the device and the method make project implementation convenient. In addition, due to the adoption of the throat opening and a sealed door structure, the possibility of material blocking and the air leakage rate are greatly reduced, and the device has low heat loss and a good dedusting effect, and is high-efficient, energy-saving and environment-friendly during smelting.

Owner:CISDI ENG CO LTD

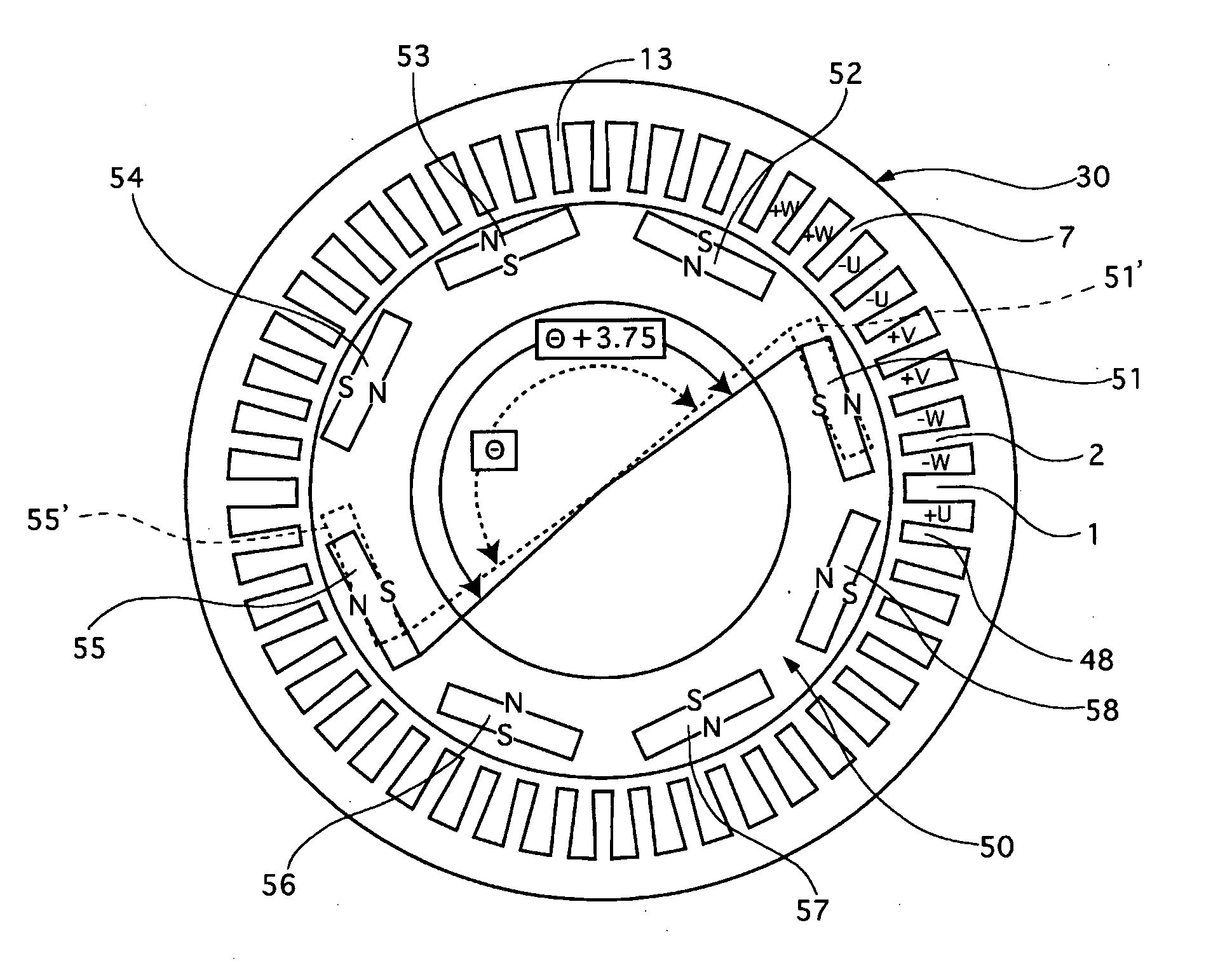

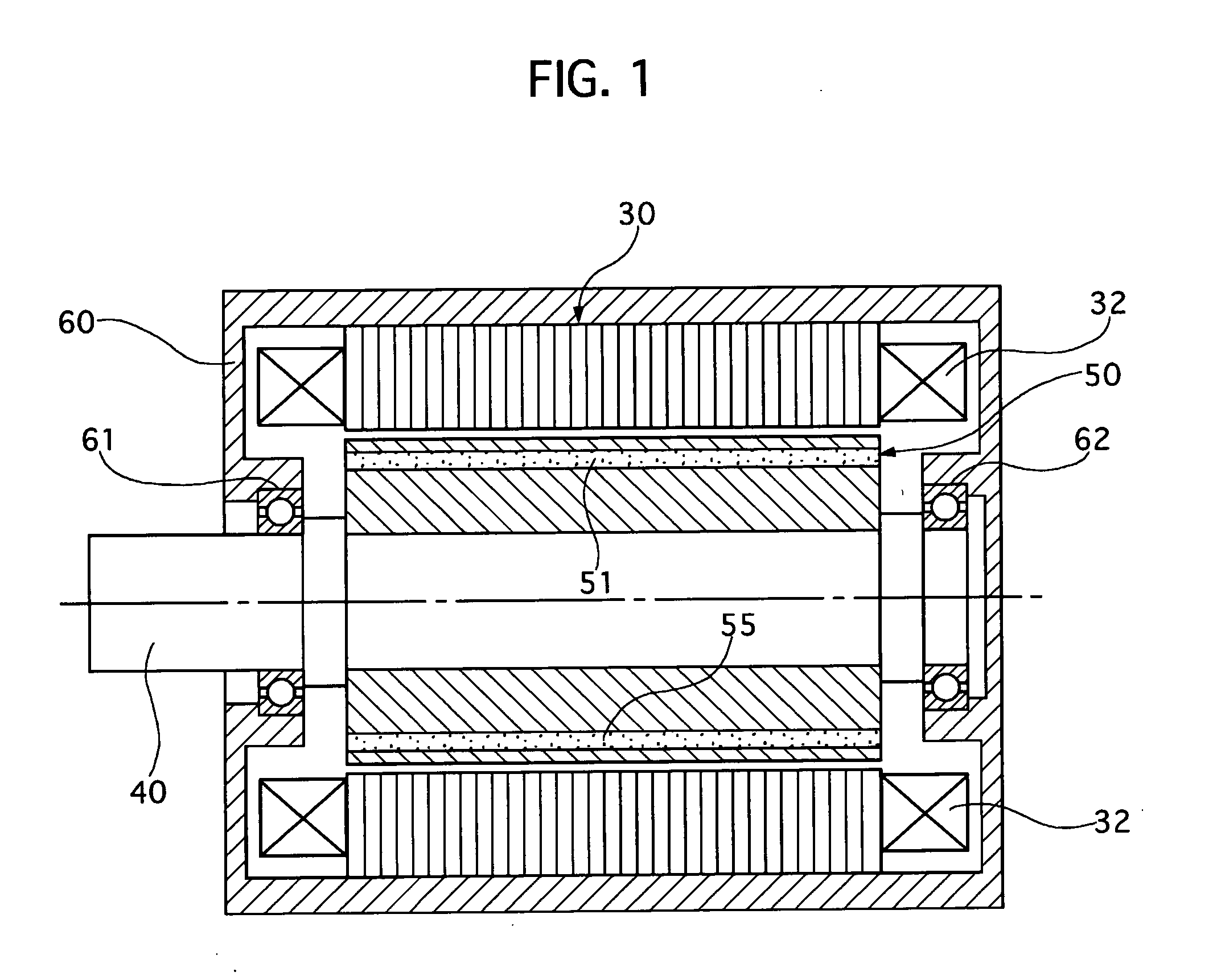

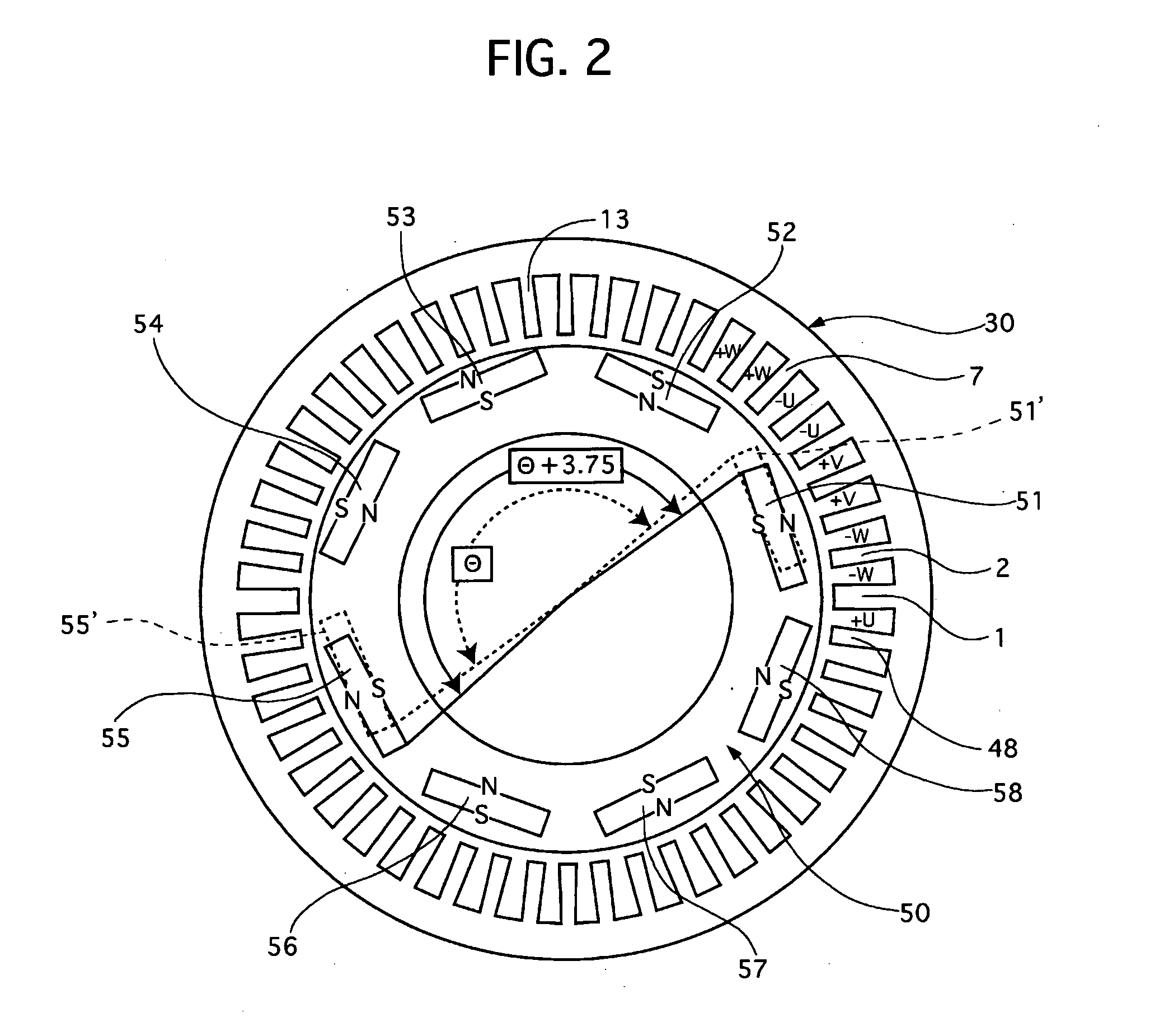

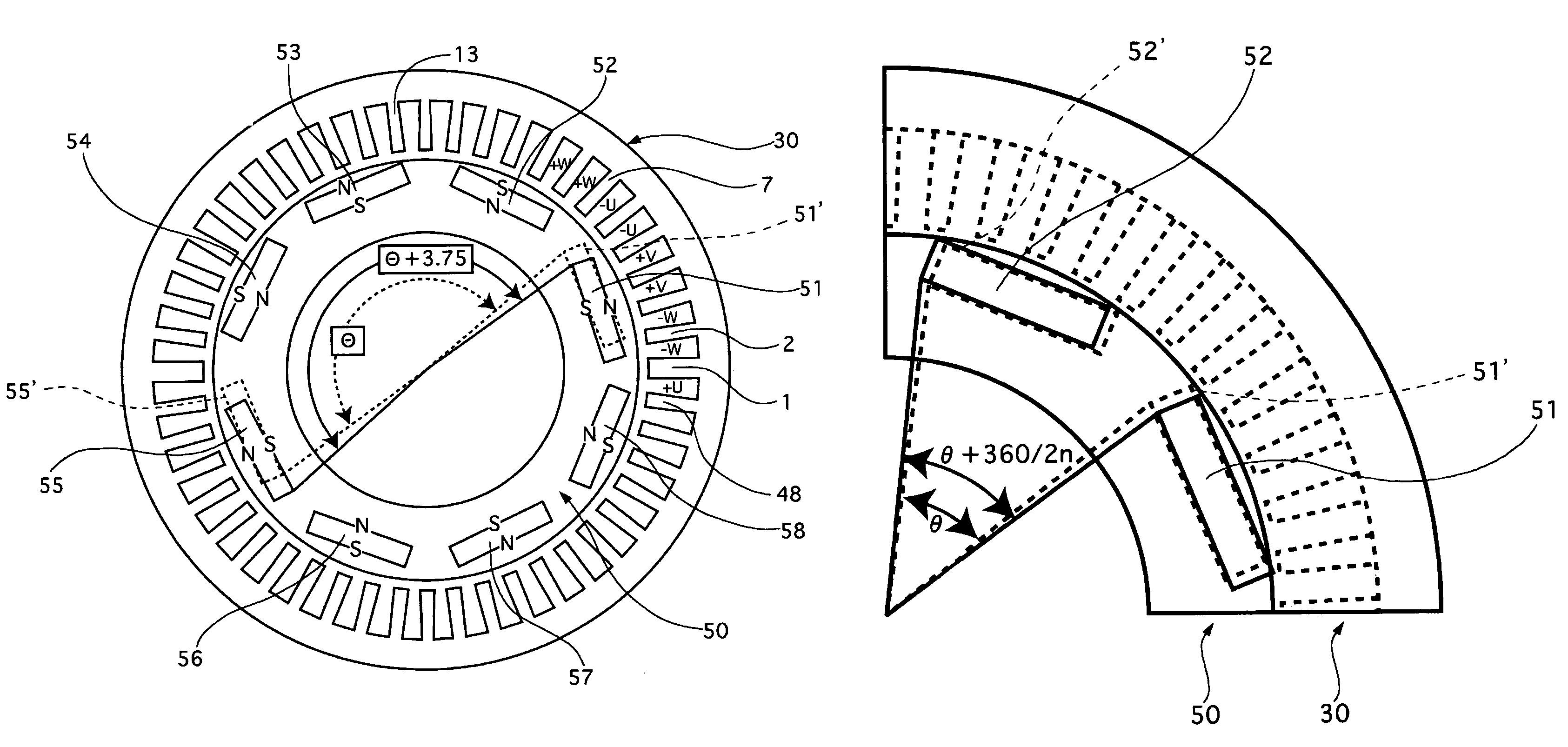

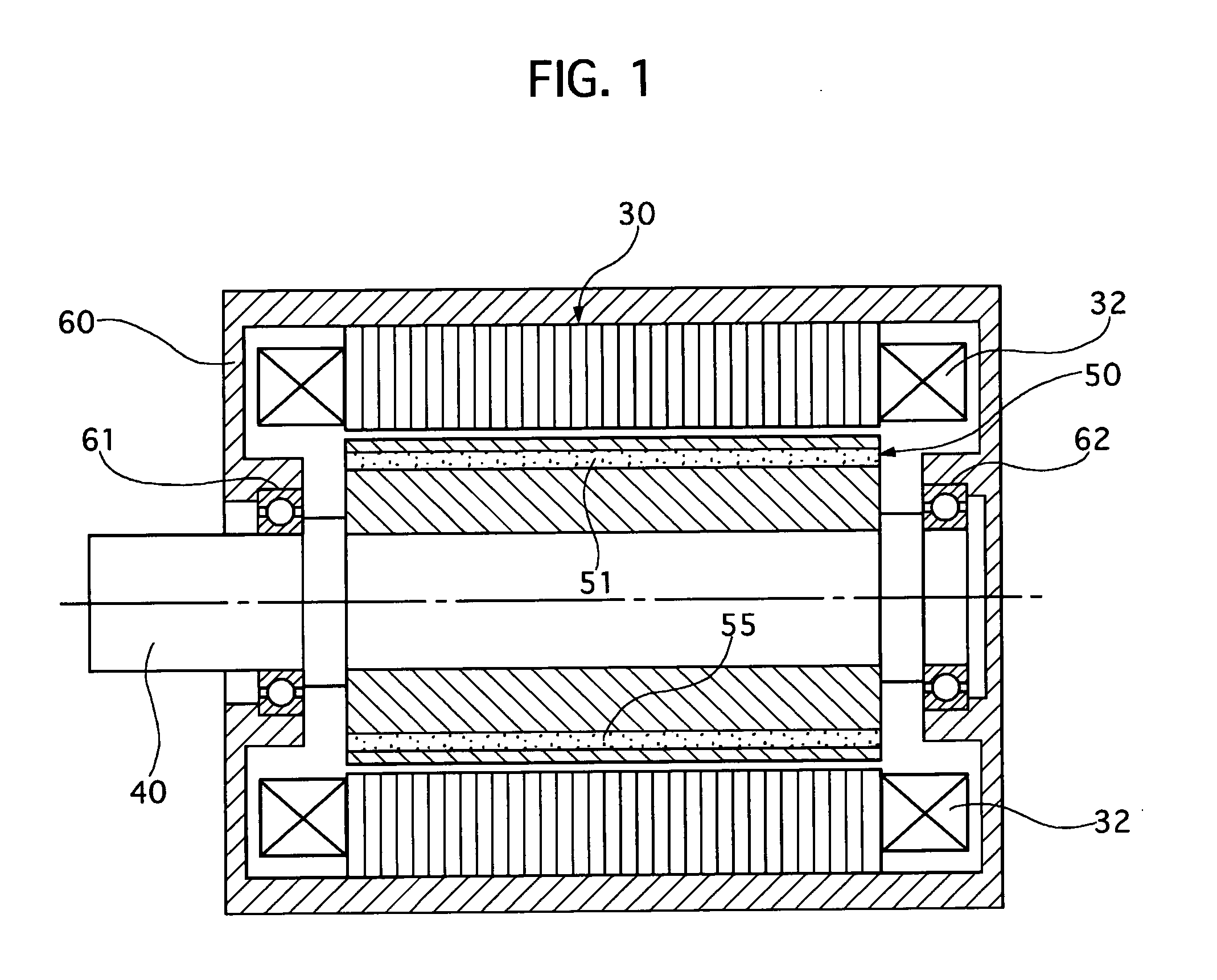

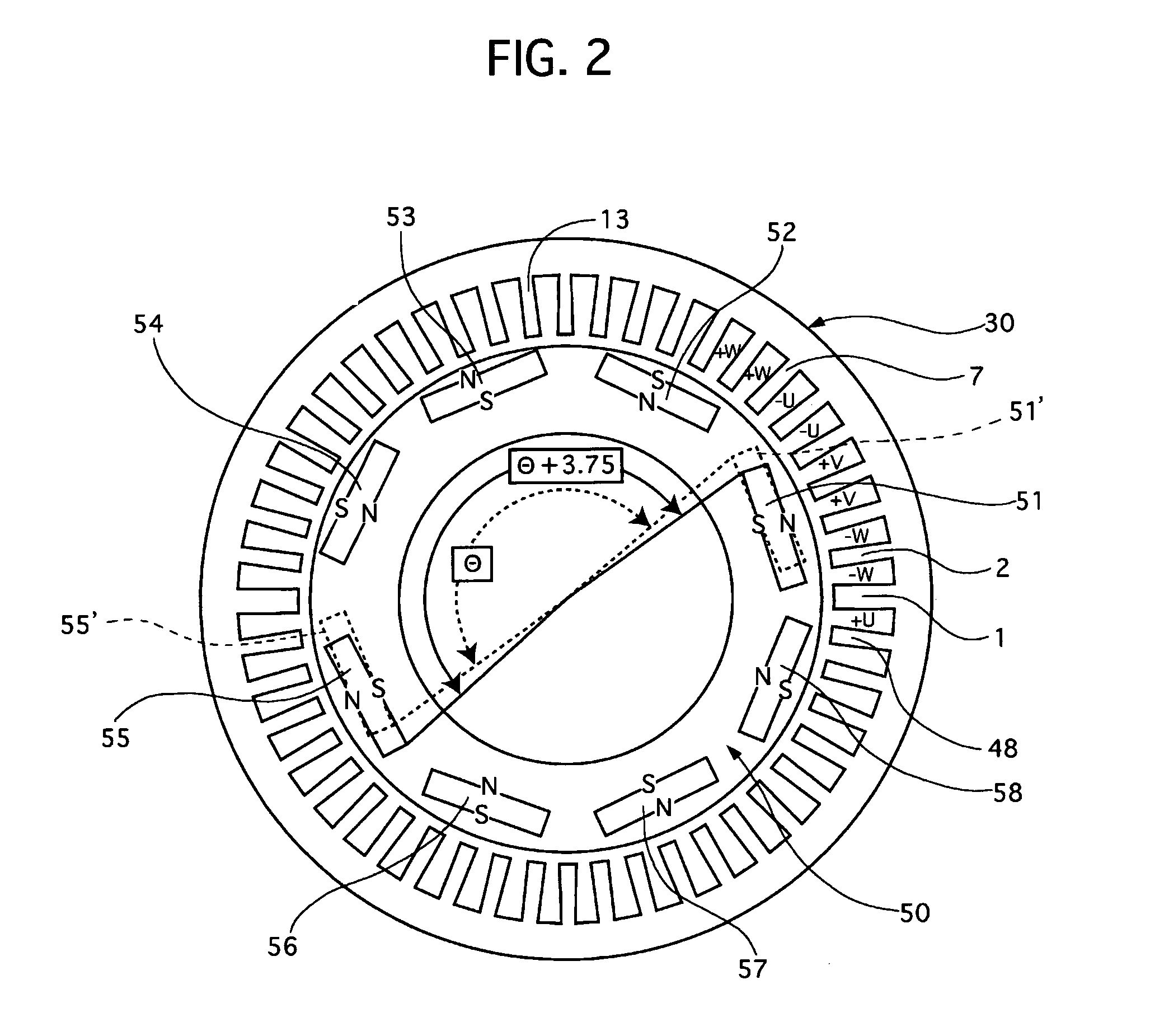

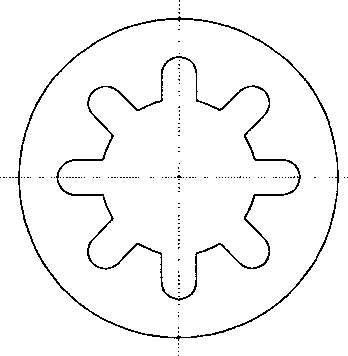

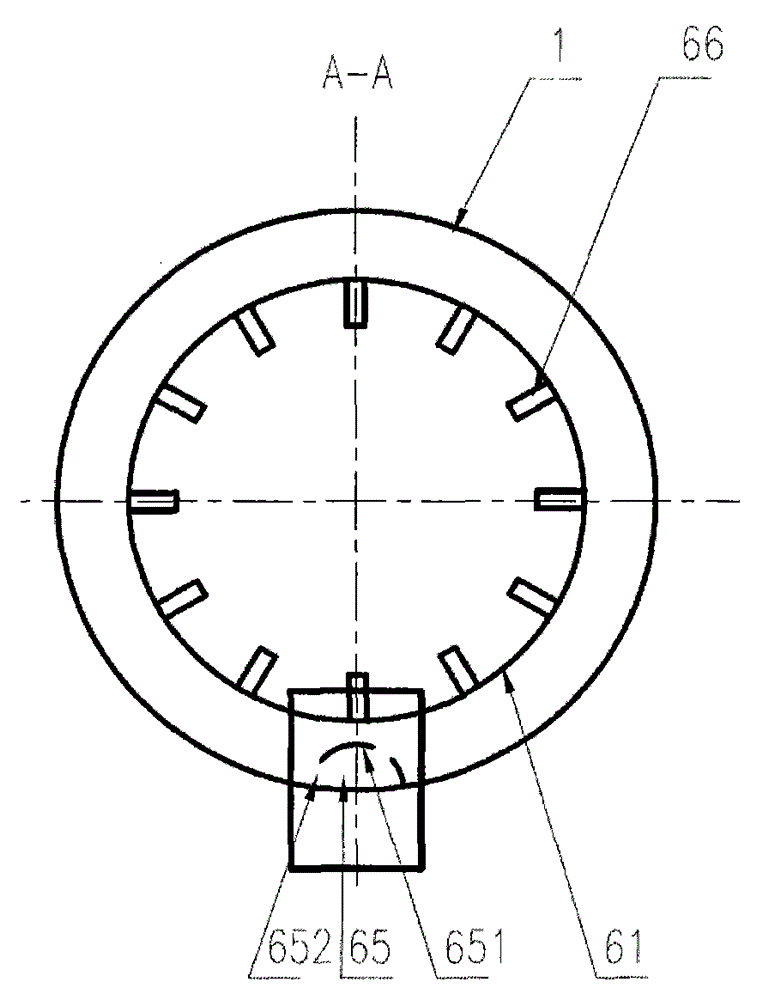

Synchronous electric machine

ActiveUS20050200222A1Weaken the electromagnetic excitation forceReduce the excitation forceMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsElectric machineElectromagnetic field

A synchronous electric machine includes a stator and a rotor. The stator is provided with teeth, which are wound around to establish electromagnetic fields. The rotor is provided with permanent magnets to generate magnetic fields, so that the rotor can rotate by interaction of the magnetic fields of the windings and the permanent magnets of the magnets. At least one pair of the permanent magnets is dislocated by a predetermined angle from positions where the permanent magnets is arranged at even pitch, and the predetermined angle being set to reduce electromagnetic excitation force acting on said teeth.

Owner:NISSAN MOTOR CO LTD

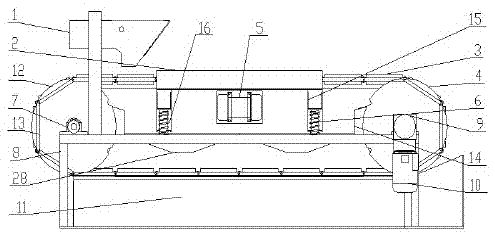

Continuously-circulating screen vibrating sieve

ActiveCN105436067AStrong self-cleaning abilityExtended service lifeSievingScreeningTransmitted powerReduction drive

The invention discloses a continuously-circulating screen vibrating sieve. The continuously-circulating screen vibrating sieve is mainly composed of a screen circulation system, a screen excitation system and a screen circulation driving system. The screen circulation system is formed by assembling screen trays, a chain and chain wheels. The screen trays are hinged together through connecting shafts. The screen excitation system is composed of funnels, excitation motors and supporting springs, wherein the funnels are provided with groove-shaped tracks. The funnels are arranged below the circulating screen trays on the screen circulation system. Rollers supporting the circulating screen trays roll in the groove-shaped tracks. The screen circulation driving system is composed of a chain transmission motor and a speed reducer. The chain transmission motor transmits power to the driving chain wheel through the speed reducer, and the driving chain wheel drives the whole screen circulation system to move. The continuously-circulating screen vibrating sieve is simple in structure and convenient to manufacture; the screen can circulate continuously, the self-cleaning capacity is high, and the defects that the self-cleaning capacity of an existing drilling fluid vibrating screen is poor, screen blocking and screen burning are likely to occur, and the solid-phase liquid content after separation is high can be effectively overcome.

Owner:SOUTHWEST PETROLEUM UNIV

Synchronous electric machine

ActiveUS7109624B2Reduce the excitation forceMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsElectric machineElectromagnetic field

A synchronous electric machine includes a stator and a rotor. The stator is provided with teeth, which are wound around to establish electromagnetic fields. The rotor is provided with permanent magnets to generate magnetic fields, so that the rotor can rotate by interaction of the magnetic fields of the windings and the permanent magnets of the magnets. At least one pair of the permanent magnets is dislocated by a predetermined angle from positions where the permanent magnets is arranged at even pitch, and the predetermined angle being set to reduce electromagnetic excitation force acting on said teeth.

Owner:NISSAN MOTOR CO LTD

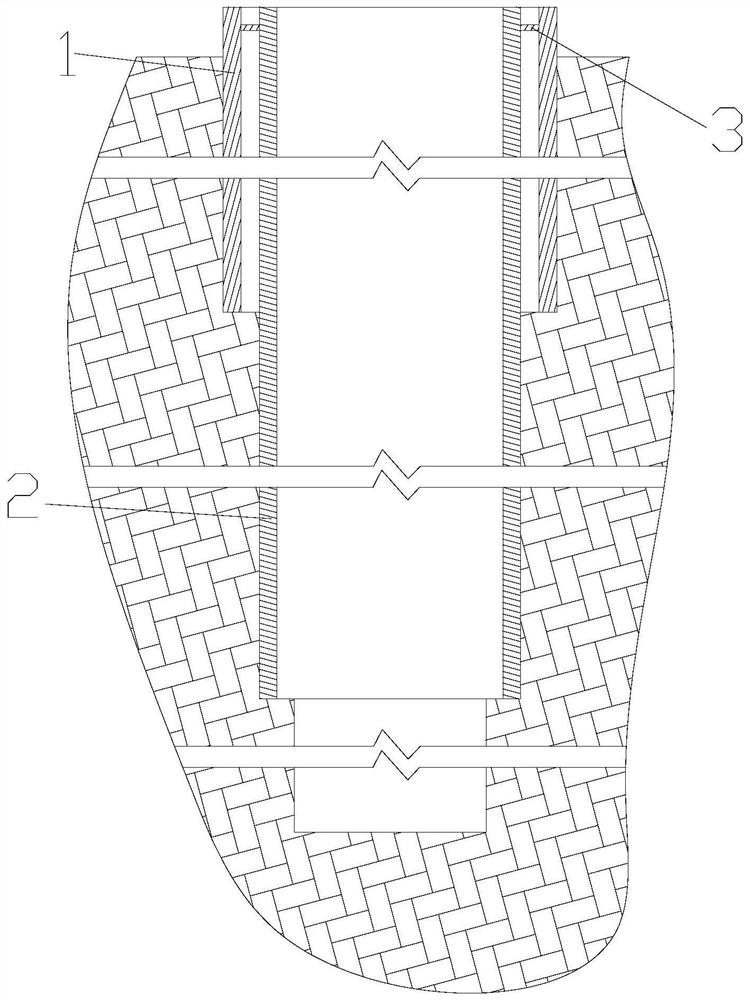

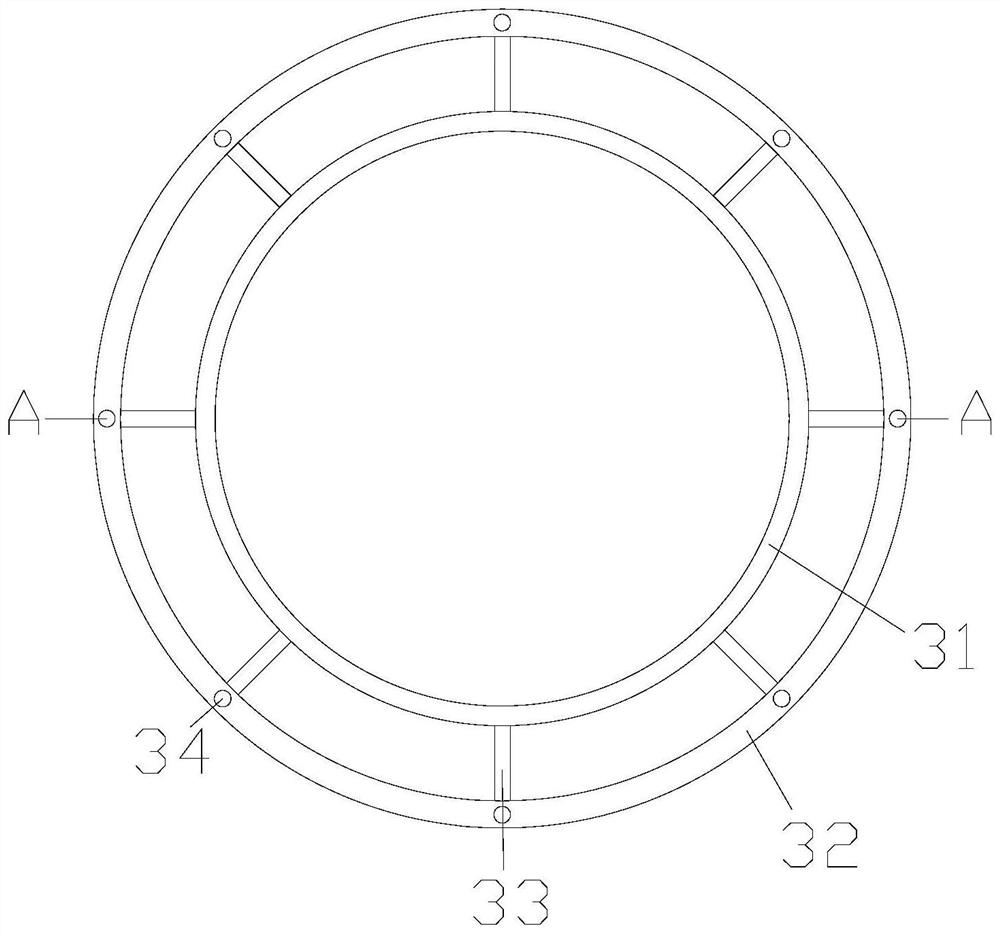

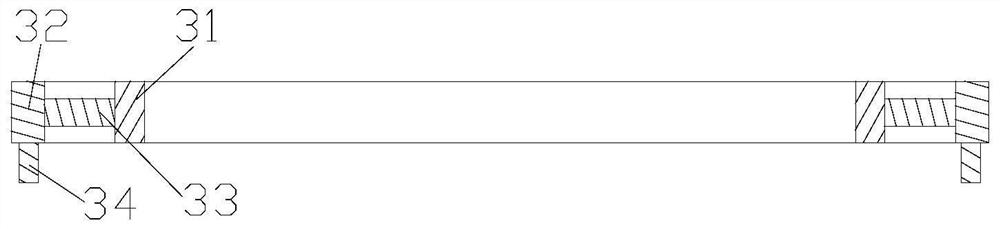

Double-mass self-synchronization elliptical vibrating screen based on motion synthesis

InactiveCN101693237AIncrease the screening areaSmall footprintSievingScreeningCounter rotationLow Mass

The invention relates to a double-mass self-synchronization elliptical vibrating screen based on motion synthesis, mainly comprising a feeding hopper, exciting motors, an upper mass, an upper mass-supporting spring, a lower mass, a lower mass-supporting spring and a base, wherein the two exciting motors with the same mass moment are mounted at the top of the upper mass in such a way that the axes of the two exciting motors are parallel and do uniform-speed reverse rotation to generate linear vibrating motion; an exciting motor which is bridged and mounted on the lower mass also does uniform-speed rotation to generate uniform-frequency circular vibrating motion; the linear vibrating motion and the circular vibrating motion are transferred by the upper mass-supporting spring and synthesized on the upper mass and the lower mass to form the elliptical motion of the upper mass and the lower mass; and the two exciting motors on the upper mass can be bridged and mounted at the top of the upper mass or on two lateral plates of the upper mass in such a way that the axes of the two exciting motors are parallel. The invention has the advantages of great screening area, great processing capability and high screening efficiency and can satisfy the production requirements of petroleum, chemical, coal, metallurgy, and the like.

Owner:SOUTHWEST PETROLEUM UNIV

Pulsation air current vibration-damping arrangement

InactiveCN1755070AReduce vibration forceGood vibration reduction effectSilencing apparatusFluid dynamicsInjectorLine segment

The invention discloses a pulse air-flow damping device in the vibration damping and damageproof technique domain, which comprises the following parts: outer case, inside component and air-flow expansion space, wherein the inside component contains transition section and injector whose exit connects the air-flow expansion space between inside component and outer case; the cross-section shape of injector is periodic plane curve structure in space along the circle direction or quadrangle, triangle and regular polygon direction to extend arrangement, which is composed of straightway, arc segment or parabolic segment or hyperbolic segment or expansion segment; forming a closed plane curve in space; stretching the section shape along the axial direction of outer case; forming hollow channel with two end opening; the outlet of condenser sprays out through transition section and forms current direction vortex, extension vortex structure in the gas flow expansion space, which turns the pulse air-flow as stable air-flow.

Owner:刘友宏 +2

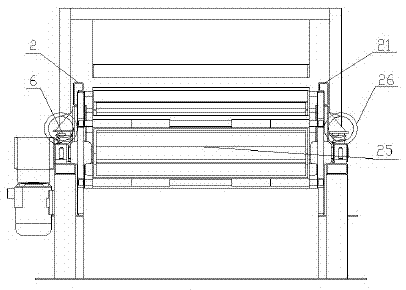

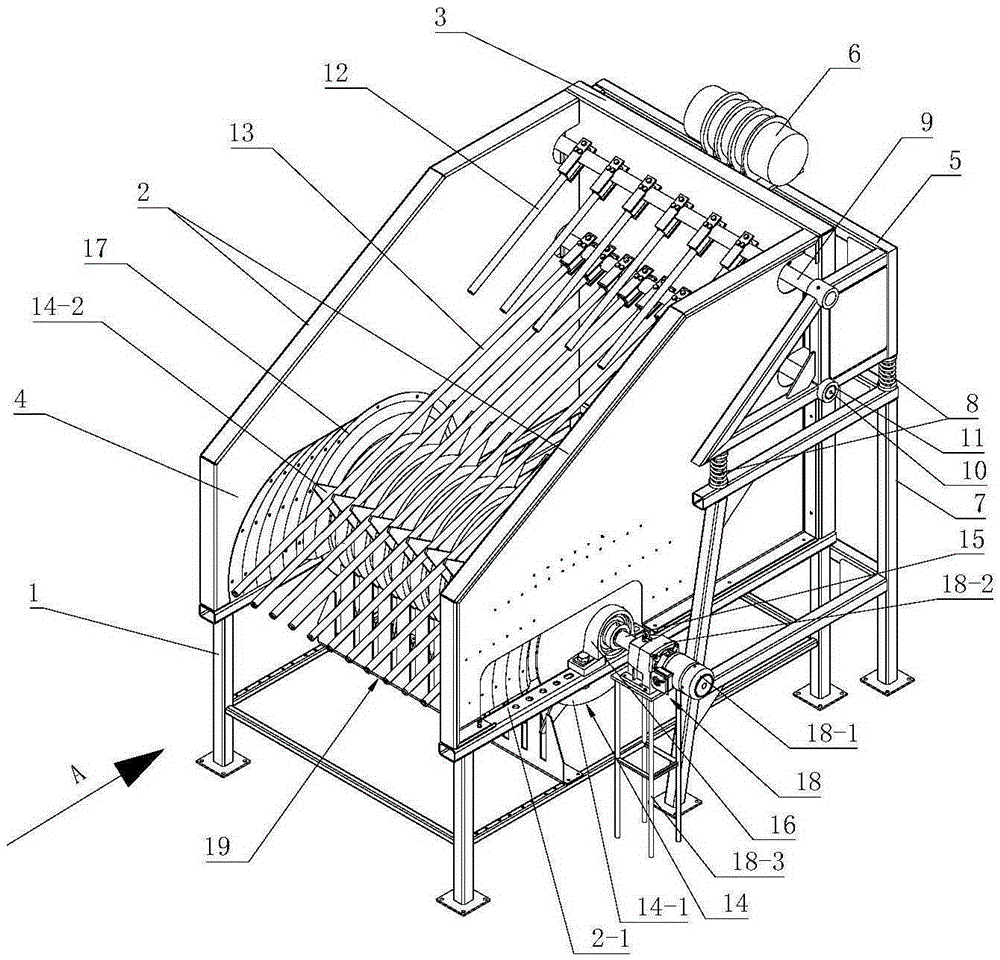

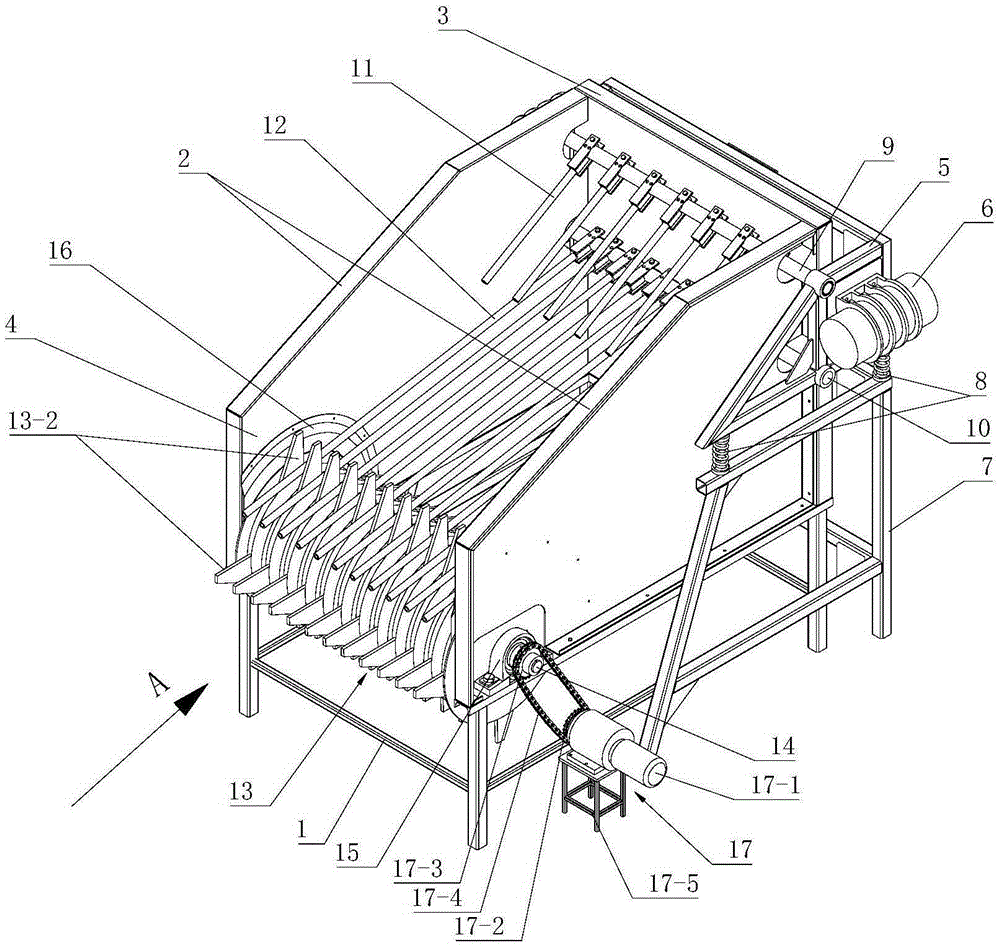

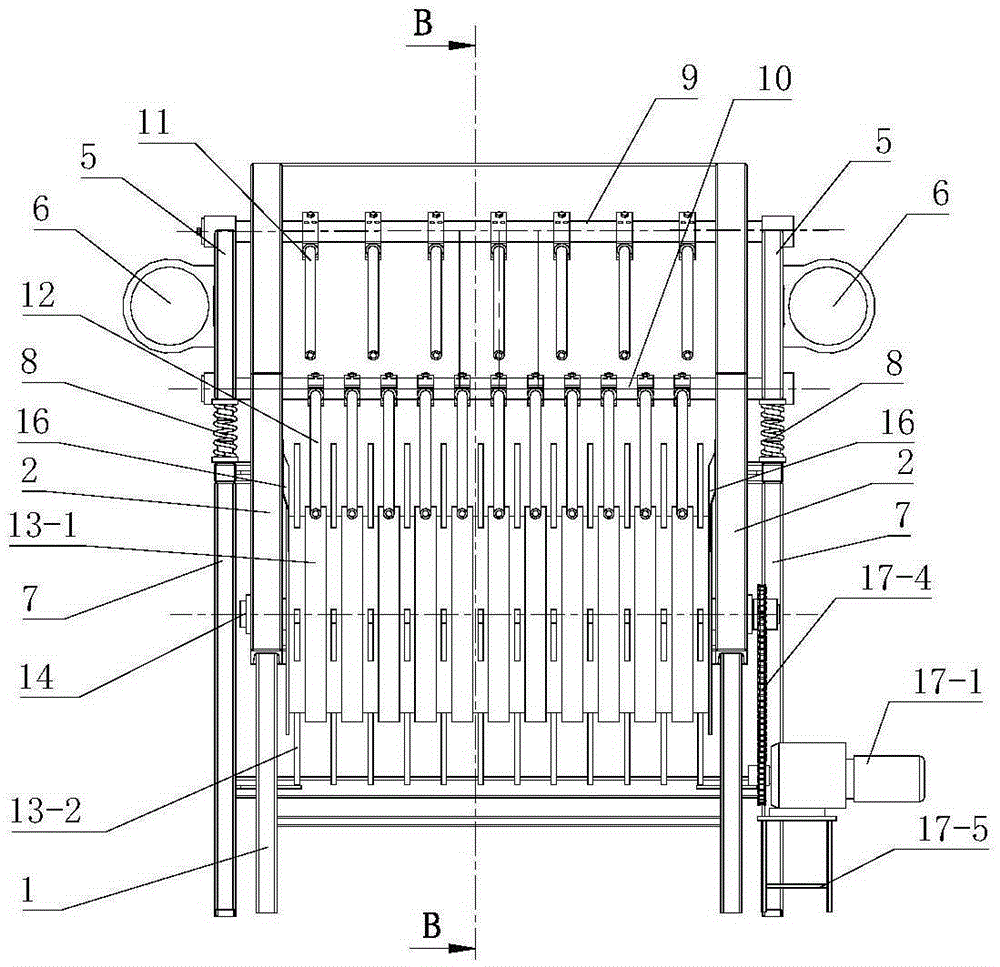

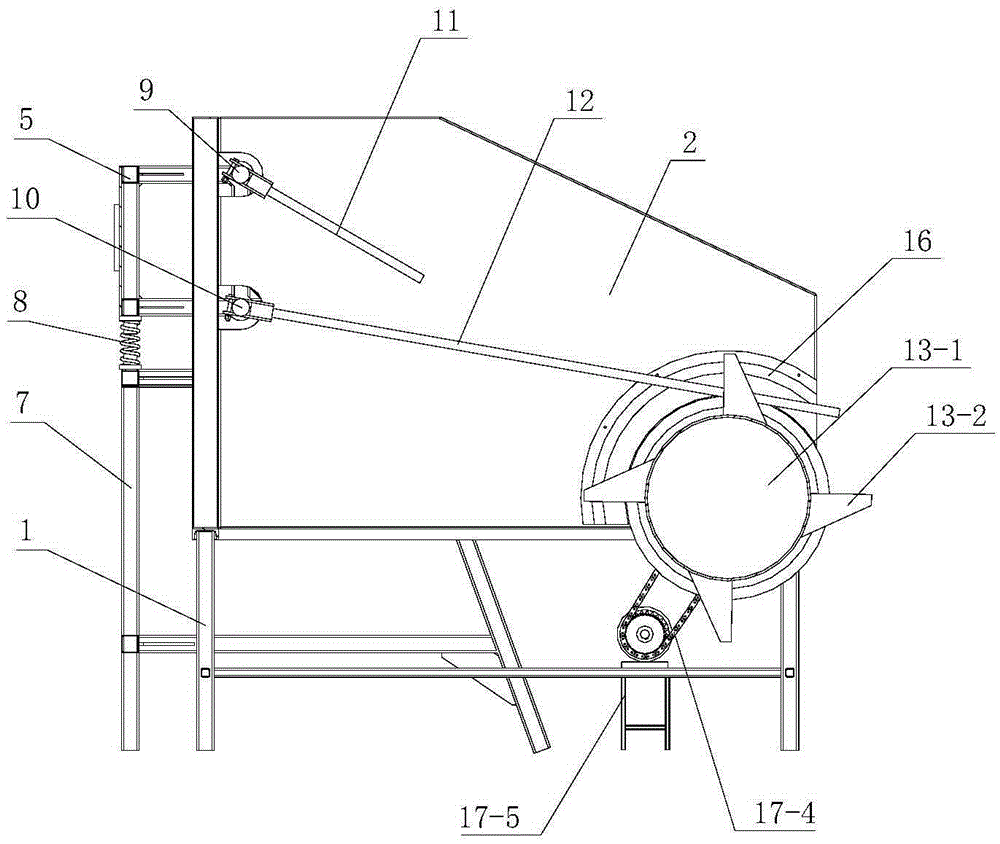

Adjustable vibration type bar screening equipment

The invention discloses adjustable vibration type bar screening equipment. The adjustable vibration type bar screening equipment comprises a frame, wherein two side plate and a back baffle plate are arranged at the upper end of the frame; the front ends of the two side plates are large material discharge ends; a vibration frame is arranged at the outer peripheries of the two side plates and the back baffle plate, and is supported on a vibration support frame in a floating manner through multiple vibration reducing springs; a vibration motor and first and second shafts, vertically arranged, are mounted on the vibration frame; multiple short bars are mounted on the first shaft to form an upper-layer bar screen; multiple long bars are mounted on the second shaft to form a lower-layer bar screen; poking drums consisting of drum bodies and multiple sets of poking teeth are arranged in the positions of the large material discharge ends, and are fixedly supported on the frame in a front-back adjusting manner; the two ends thereof are respectively provided with baffle plates; a driving mechanism is arranged outside the side plate at one side; and the lower ends of the multiple long bars are freely arranged on the drum bodies, and are inserted between the axially arranged poking teeth one by one. The equipment prolongs the service life of the bar screens, reduces the exciting force, the vibration frequency and the power of the vibration motor, and improves the large material discharge speed of the bar screens.

Owner:天津百利阳光环保设备有限公司

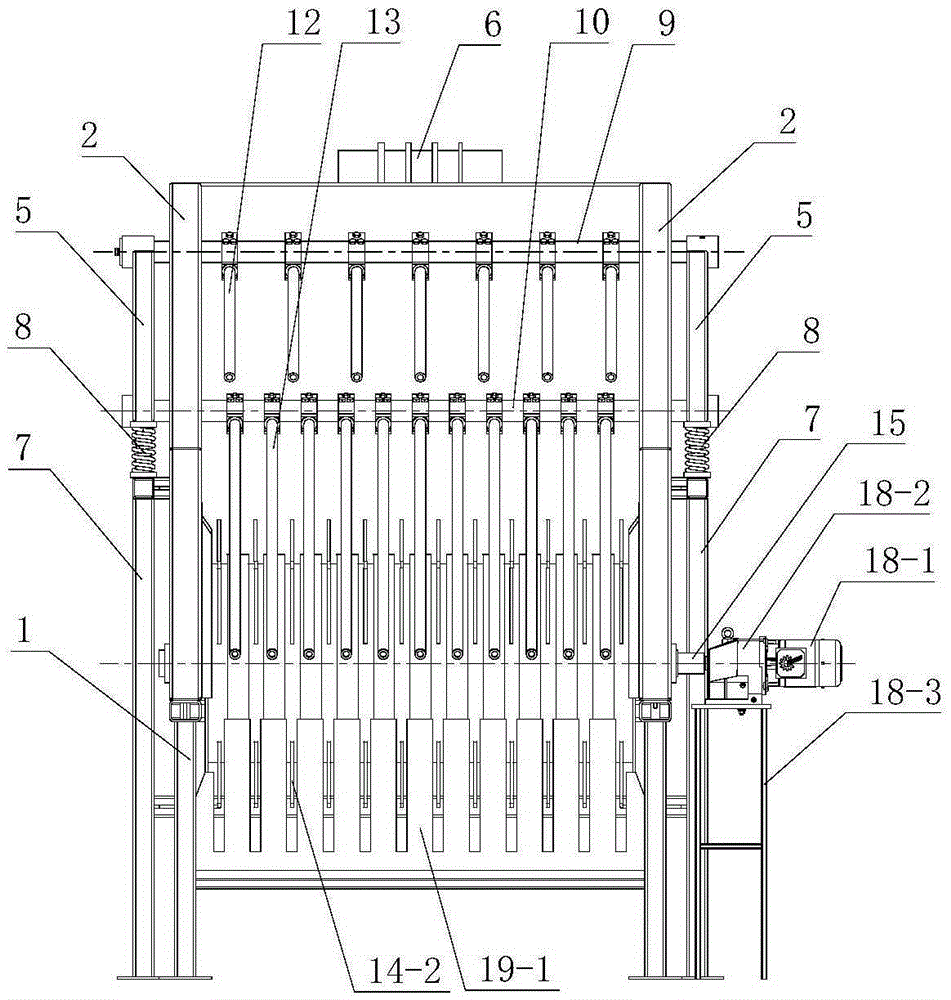

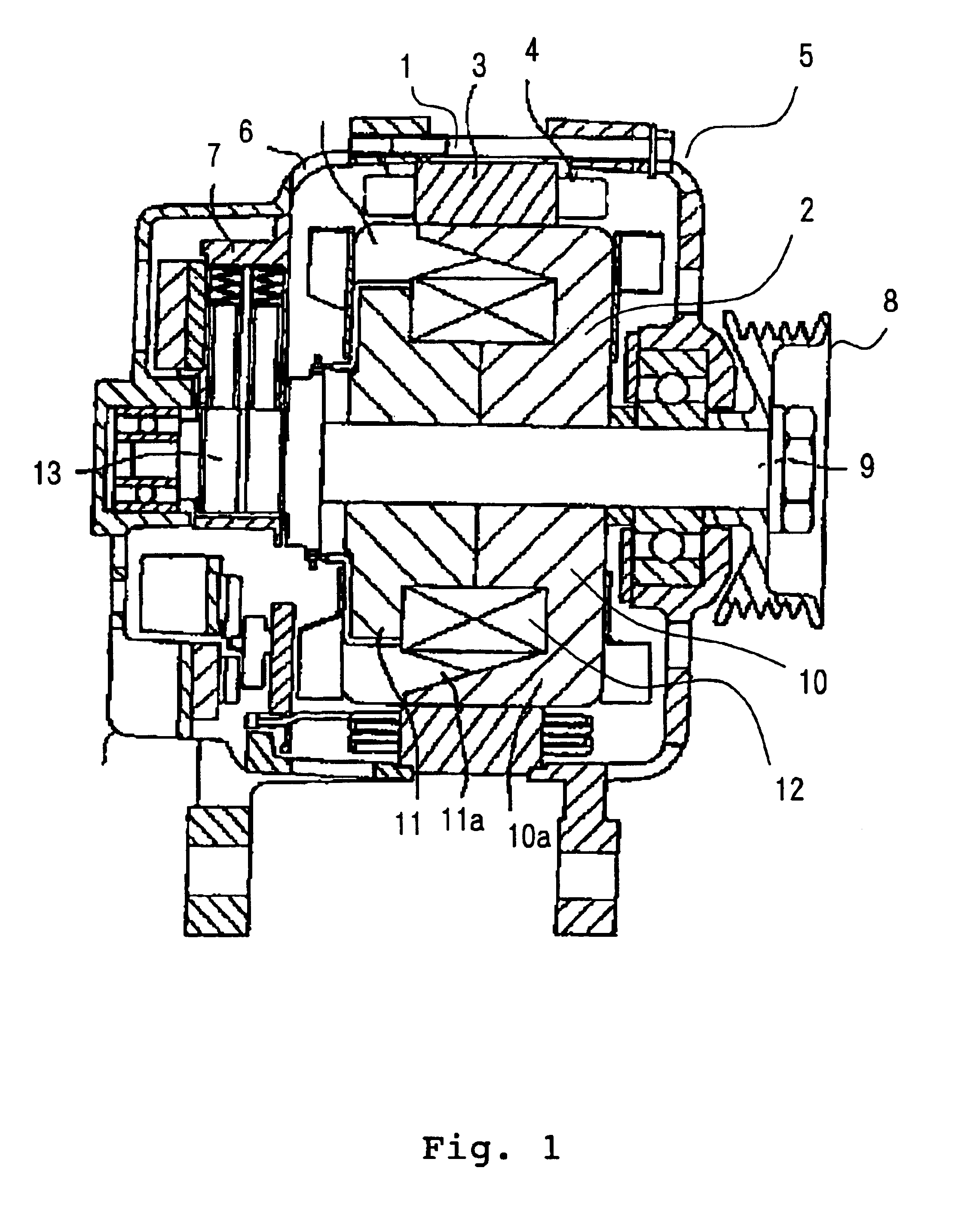

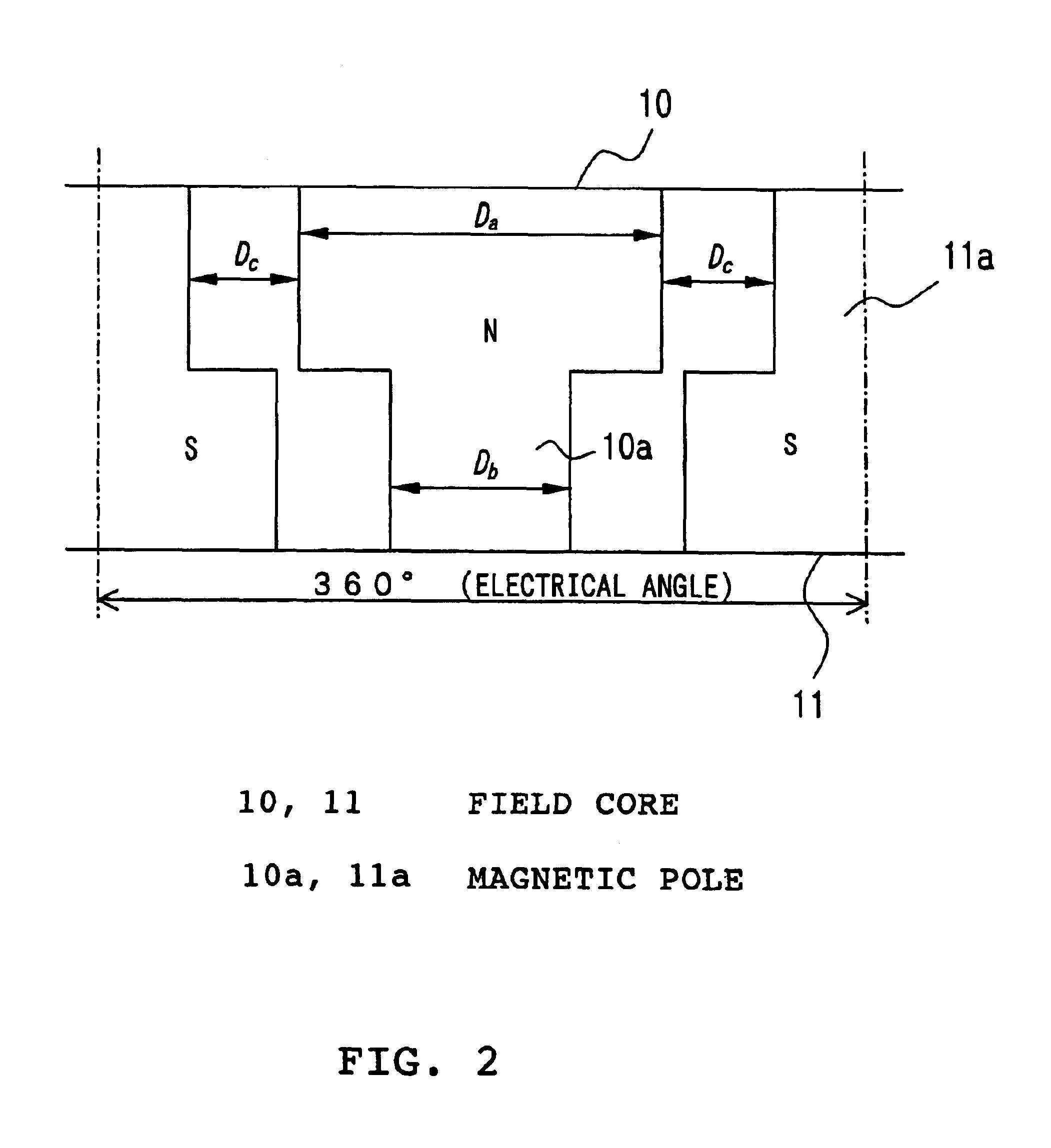

Rotating electrical machine for vehicle

InactiveUS6847150B2Increase production capacityReduce the excitation forceSynchronous generatorsMagnetic circuit rotating partsProduction rateElectric machine

A rotating electrical machine for a vehicle includes a stator having a multi-phase armature winding, a rotor having a pair of field cores which rotate together with a rotating shaft, and a field winding for magnetizing the pair of field cores, the pair of field cores respectively includes magnetic poles extending in an axial direction of the rotating shaft and being arranged to alternately engage with each other through a predetermined clearance Dc, each of the magnetic poles having a width in a rotation direction thereof is formed in a stair shape to be smaller toward a tip of the width, and the clearance Dc between adjacent the magnetic poles is set within a range from 50° to 70° in electrical angle. As a result, the rotating electrical machine for a vehicle can be obtained in which exciting force of harmonic components is reduced, electromagnetic noise, torque ripple and the like are effectively suppressed, and the productivity is excellent.

Owner:MITSUBISHI ELECTRIC CORP

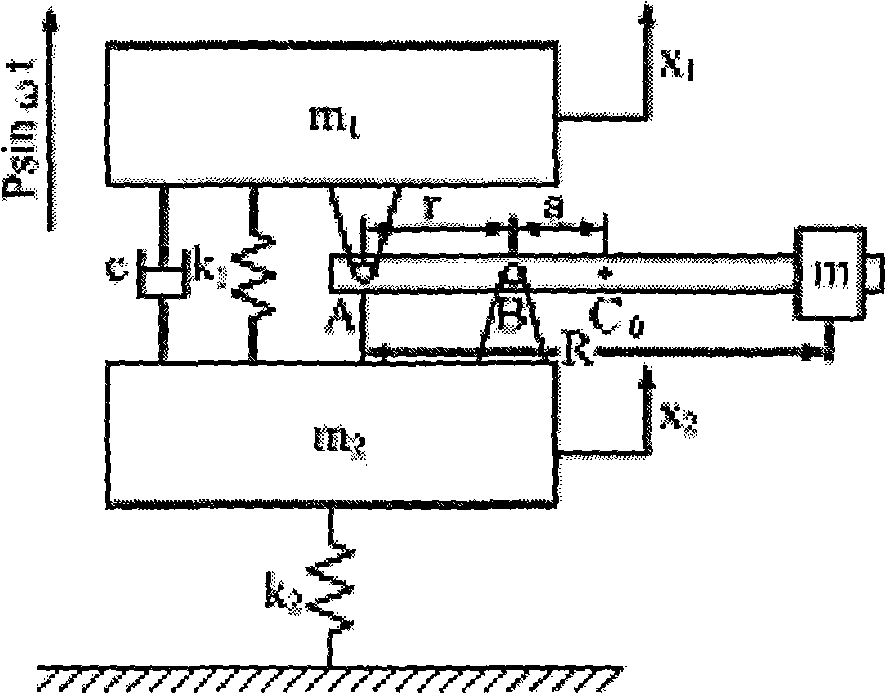

Anti-resonance type resonance screen

InactiveCN101530847ASolve vibration isolation problemsGood vibration isolationSievingScreeningDrive shaftResonance

The invention relates to an anti-resonance type resonance screen, which belongs to the technical field of oscillating machinery. The anti-resonance type resonance screen comprises an upper mass body, a lower mass body, a main vibrating spring, a vibration exciter, a vibration isolation spring, levers, balance weights, a base, a motor, a driving shaft, and a motor bracket. The upper mass body is provided with the vibration exciter, the upper mass body is connected with the lower mass body through the main vibrating spring, the lower mass body is arranged on the base through the vibration isolation spring, at least four levers vertical to the vibrating direction are arranged symmetrically between the upper mass body and the lower mass body through hinges, and one end of each lever is provided with the balance weight. The anti-resonance type resonance screen can be operated in a resonance state and an anti-resonance state simultaneously, has good vibration isolation effect and solves the vibration isolation problem of the prior resonance screen, and the mass of the lower mass body can be much far less than that of the prior resonance screen so that the weight of the complete machine can be greatly reduced. Because of the principle of resonance, the required exciting force can be greatly reduced, and the mass of the exciter can be reduced in favor of saving energy and improving the service life of a screening machine.

Owner:NORTHEASTERN UNIV

Vibrating type bar screening equipment

Vibrating type bar screening equipment comprises a frame; two side plates and a rear baffle are arranged at the upper end of the frame; the front ends of the two side plates are large material discharging ends; a vibrating frame is arranged at the peripheries of the two side plates and the rear baffle, and is supported by a vibrating support frame in a floating manner through a plurality of damping springs; vibrating motors, a first shaft and a second shaft are mounted on the vibrating frame; the first shaft and the second shaft penetrate the two side plates and are arranged up and down; a plurality of short bars are mounted on the first shaft to form an upper bar screen; a plurality of long bars are mounted on the second shaft to form a lower bar screen; a kick-off drum comprising a drum body and groups of kick-off teeth is arranged at the positions of the large material discharging ends; striker plates are respectively arranged at two ends of the kick-off drum; the kick-off drum is supported by the frame; a driving mechanism is arranged outside the side plate on one side; and the long bars are suspended and inserted one by one between the kick-off teeth arranged axially on the kick-off drum. The vibrating type bar screening equipment has the advantages that the service lives of the bar screens are prolonged, the excitation force, the vibration frequency and the power of the vibrating motors are reduced, and the discharging speed of large materials on the bar screens is increased.

Owner:天津百利阳光环保设备有限公司

Rotary excavating pile foundation double-steel-casing construction method

InactiveCN112227357AIncrease sinking depthReduce friction areaBulkheads/pilesArchitectural engineeringEngineering

The invention discloses a rotary excavating pile foundation double-steel-casing construction method. The rotary excavating pile foundation double-steel-casing construction method comprises the following steps that step 1, positioning and setting-out are constructed on site according to a construction drawing, a measuring grid is established, and points are measured and set out; step 2, after the position is adjusted, a guide hole is excavated; step 3, whether the pile position is consistent with the center of an outer steel casing or not is checked, the periphery of the outer steel casing is filled with soil and tamped after correction, and the outer steel casing is sunken to the height H1 through a crawler-type vibratory hammer; step 4, a positioning hoop is installed at an orifice of theouter steel casing, and then the crawler-type vibratory hammer is adopted to enable an inner steel casing to sink from the interior of the positioning hoop and penetrate through the outer steel casing to reach a dense soil layer or a strong weathered layer; step 5, a hole is formed through drilling, the hole is cleaned, and a reinforcement cage is installed; and step 6, concrete is poured, and the inner steel casing and the outer steel casing are pulled out. Compared with the prior art, the construction efficiency of the rotary excavating pile in the high backfill area is improved, and the processing quality and economic benefits of a pile foundation are improved.

Owner:CHONGQING CONSTR NINTH ENG

Elliptic or circular motion antiresonance vibrating screen

An elliptic or circular motion antiresonance vibrating screen belongs to the technical field of vibrating machines. The vibrating screen comprises a screen box, a vibrating excitation body, a master vibrating spring, a vibrating exciter, an isolation spring, a foundation and a motor, wherein the screen box is an upper plastid; the vibrating excitation body is a lower plastid; the vibrating excitation body is arranged on the foundation by the isolation spring; the screen box is connected with the vibrating excitation body by the master vibrating spring; the vibrating screen is characterized in that the vibrating exciter is mounted on the vibrating excitation body and is of a single-shaft, double-shaft or three-shaft structure; the motor is connected with the vibrating exciter by a transmission shaft; two shafts in the double-shaft structure slew in the same rotation direction; two shafts in the three-shaft structure slew in the same rotation direction, while another shaft slews in the direction opposite to the rotation direction of the two shafts; the master vibrating spring consists of an inner spring seat, an outer spring seat and a spring arranged between the inner spring seat and the outer spring seat; the master vibrating spring has the same rigidity in all directions in a working plane; and the working frequency of the elliptic or circular motion antiresonance vibrating screen is equal to the antiresonance frequency.

Owner:NORTHEASTERN UNIV

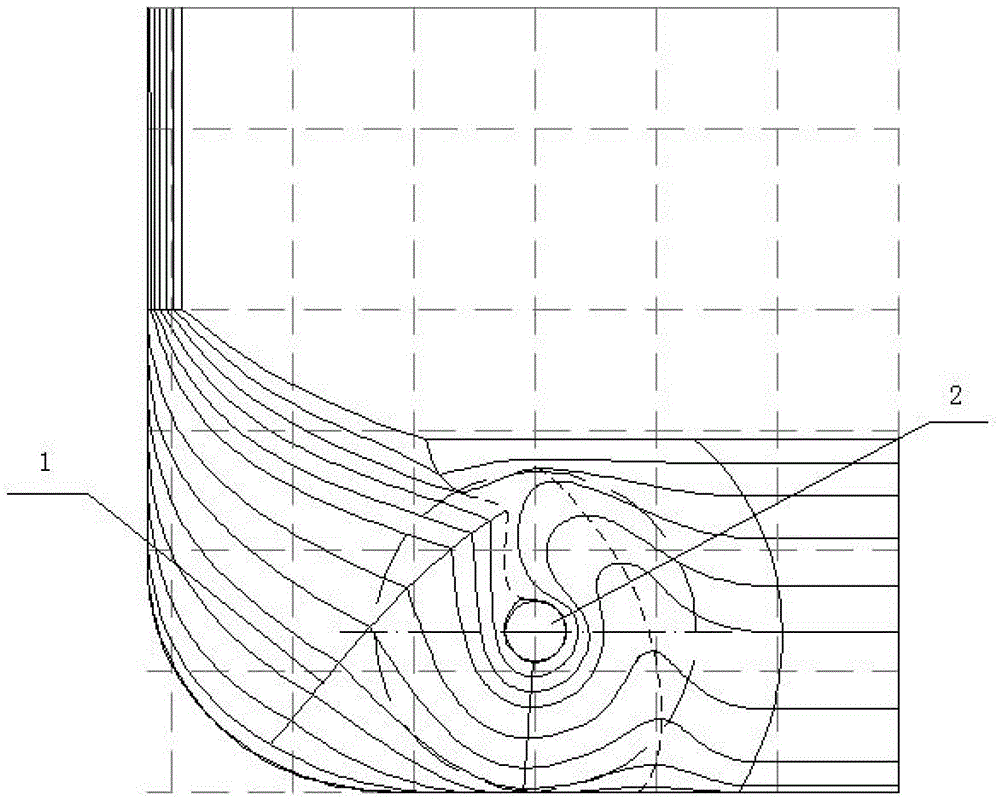

Ship with knuckle line and internal rotational fin tail

InactiveCN102745304AReduce resistanceSolve the resistanceWatercraft hull designStern postsPropellerInternal rotation

The invention discloses a ship with a knuckle line and an internal rotational fin tail, and belongs to the technical field of ships. The ship comprises a propeller, and the knuckle line is arranged on the basis of a ship with an internal rotation fin tail and positioned on the outer side of a shaft of the propeller along the length direction of the ship. The ship has the advantages that longitudinal flow and lateral flow can be guided, and a flow regulating effect can be achieved.

Owner:CSIC WUHAN SHIP & MARINE ENG EQUIP DESIGN

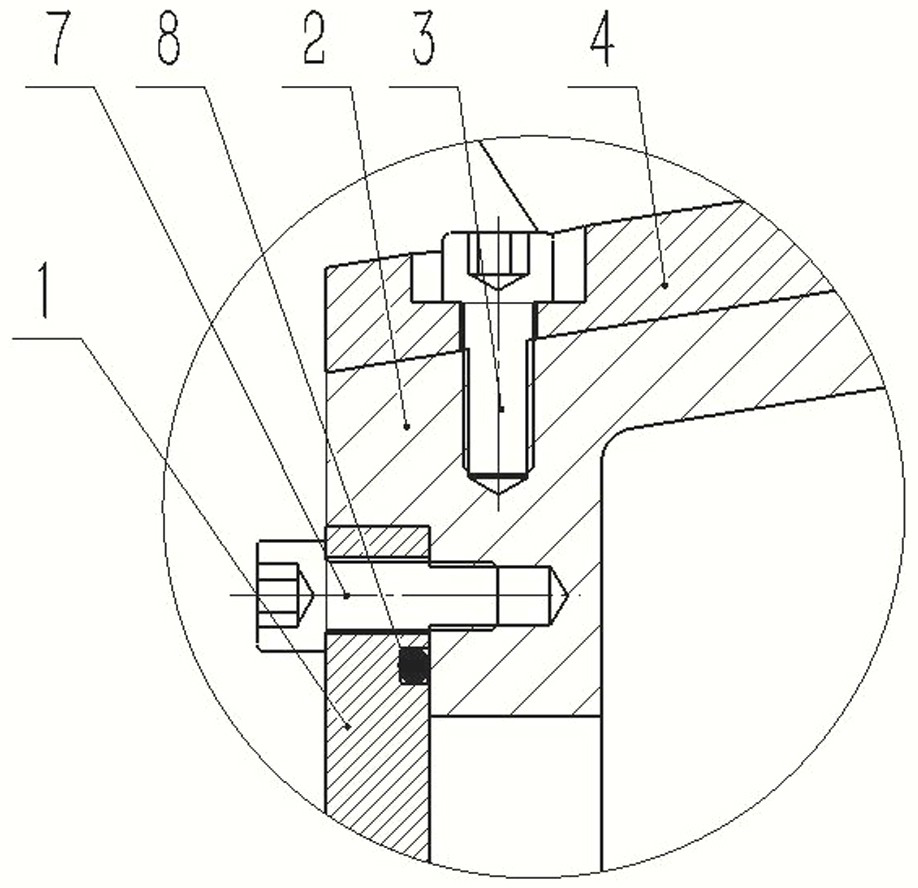

Eccentric vibration device of road roller and arranging structure thereof

PendingCN106638238AReduce manufacturing difficultyReduce installation difficultyRoads maintainenceEngineeringStructural engineering

The invention relates to an eccentric vibration device of a road roller and an arranging structure thereof. The device comprises a vibration shaft and a movable eccentric block group, wherein the movable eccentric block group is arranged on the vibration shaft; the movable eccentric block group comprises movable eccentric blocks, limiting rings and fixing keys; the limiting rings are fixed to the vibration shaft through the fixing keys, limiting grooves being matched with limiting convex blocks on the limiting rings are formed in the movable eccentric blocks, and the central angles of the limiting grooves are equal to or larger than those of the limiting convex blocks; and when the central angles of the limiting grooves are larger than those of the limiting convex blocks, the limiting grooves are matched with the limiting convex blocks, so that when the vibration shaft positively rotates or negatively rotates, the movable eccentric blocks provided with two vibration limitation positions correspondingly. According to the eccentric vibration device of the road roller and the arranging structure thereof, structures of the movable eccentric blocks are greatly simplified, and manufacturing and installing difficulties of the eccentric blocks are lowered; and meanwhile, the movable eccentric blocks are integrally formed, thus the movable eccentric blocks are not prone to being damaged during using, and during working, stability and reliability are highly maintained.

Owner:合肥永安绿地工程机械有限公司

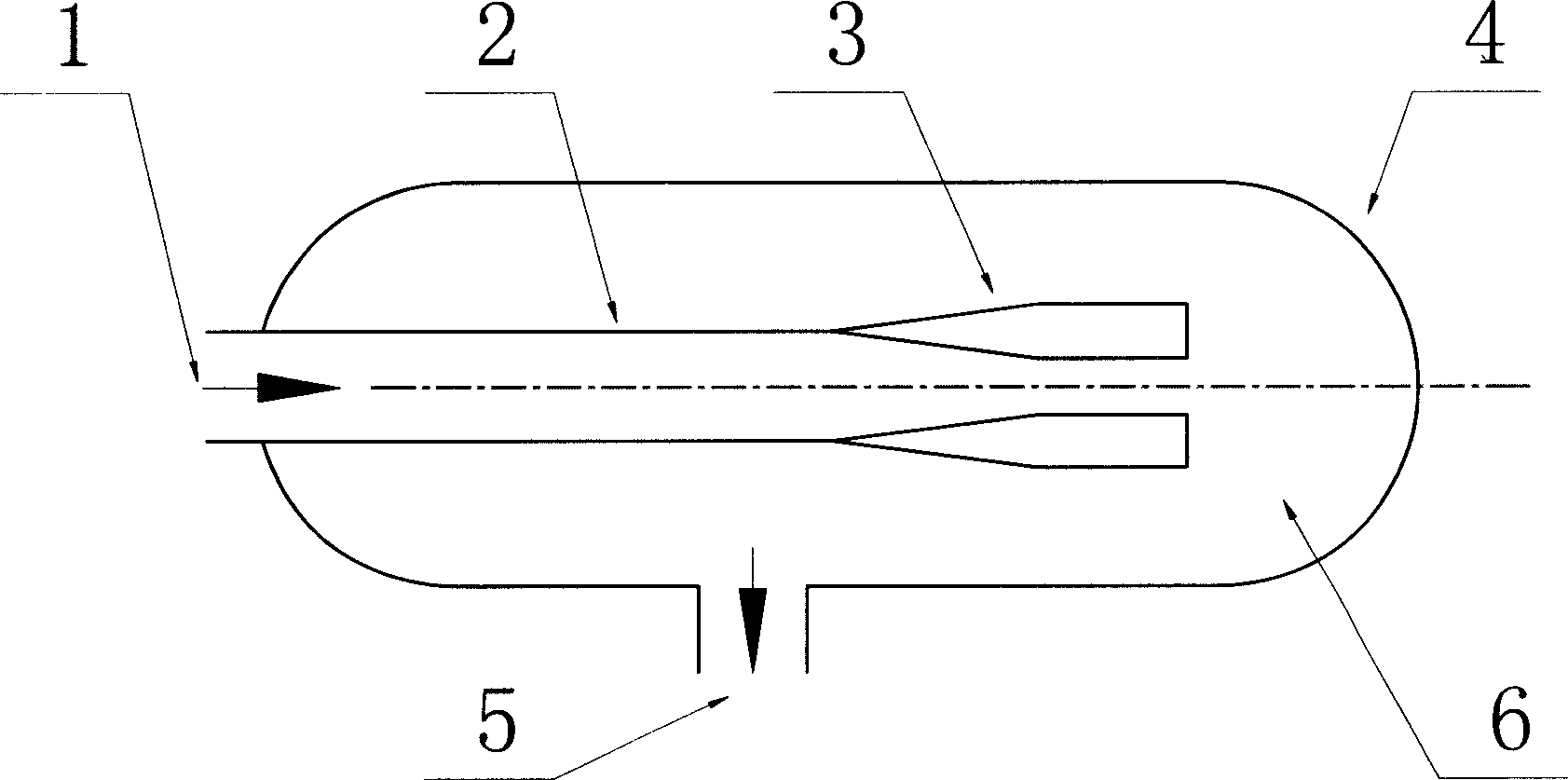

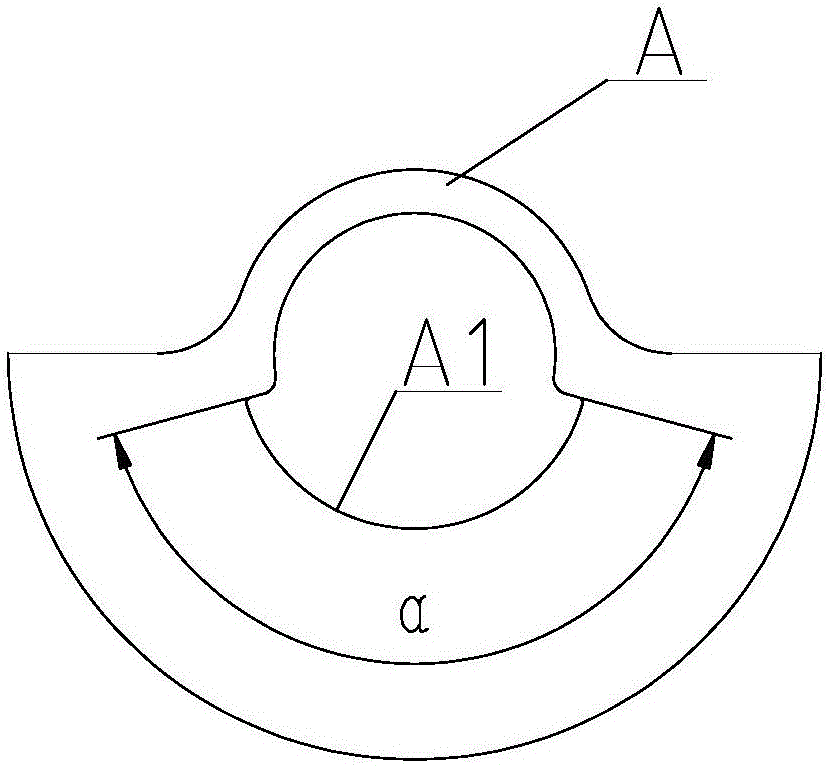

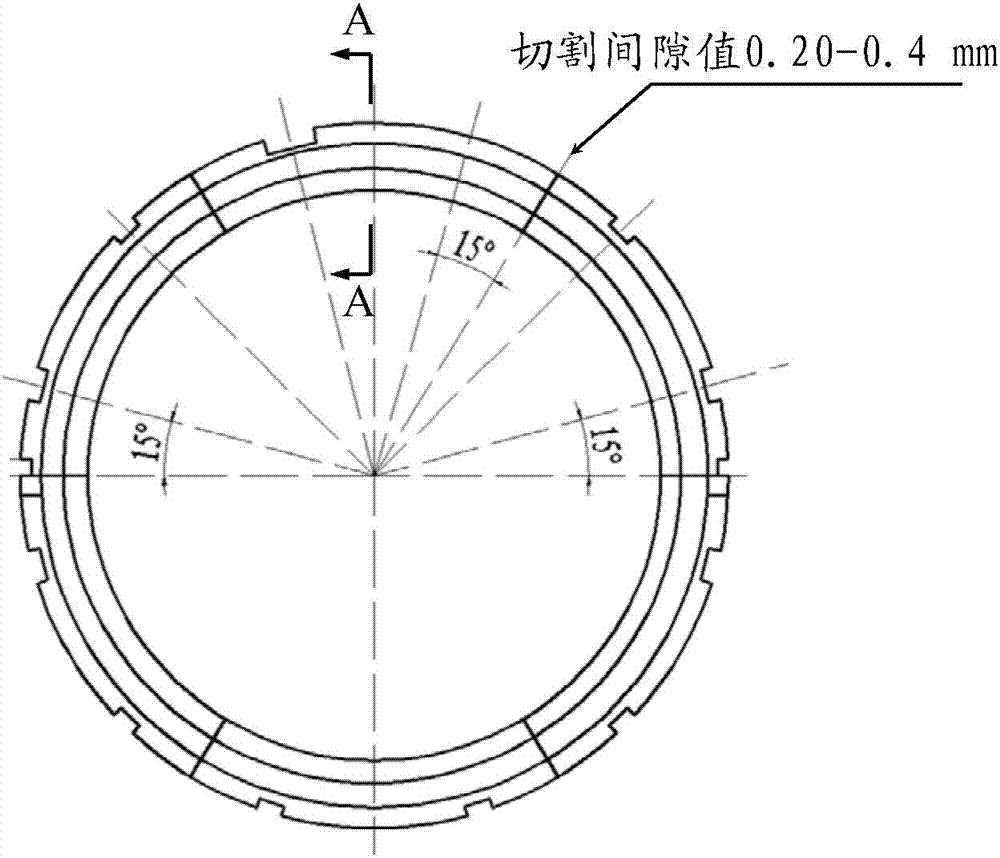

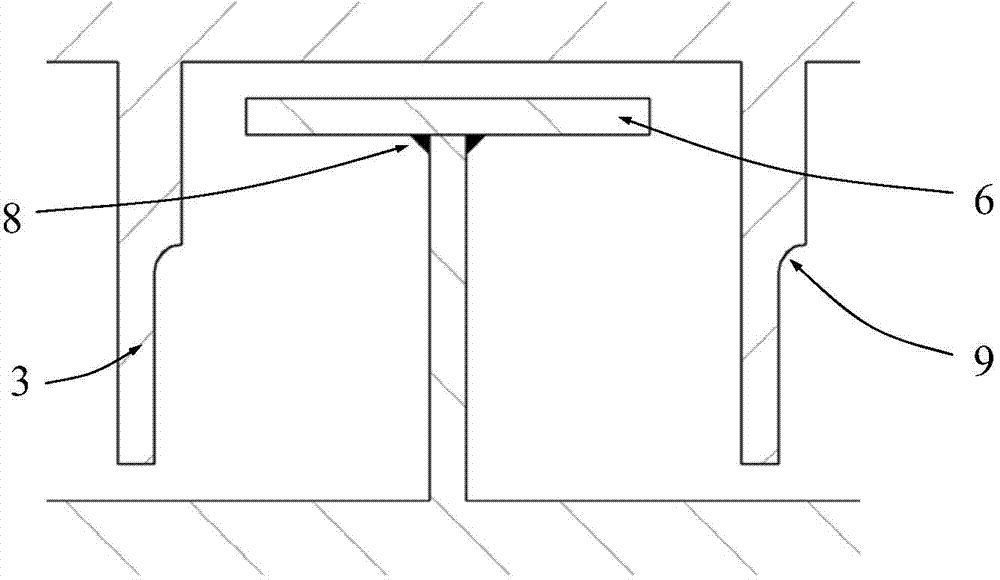

T-shaped staggered-type labyrinth seal capable of eliminating rotor exciting force

ActiveCN103899758ASolve Vibration ProblemsReduce vibrationEngine sealsMechanical engineeringLabyrinth seal

The invention aims to provide a T-shaped staggered-type labyrinth seal capable of eliminating rotor exciting force. The T-shaped staggered-type labyrinth seal comprises fan-shaped rings. The fan-shaped rings comprise seal cavities and rotors. The seal cavities and the rotors are respectively of a fan-shaped structure, the seal cavities are located outside the rotors, high teeth are arranged arranged on the inner sides of the seal cavities, low teeth are arranged on the outer sides of the rotors, annular seal rings are installed on the low teeth, installation crowns are installed on the outer sides of the seal cavities and spring grooves are formed in the installation crowns. According to the T-shaped staggered-type labyrinth seal capable of eliminating the rotor exciting force, the seal structure formed by the annular seal rings and the low teeth is used for enabling gas forces exerted on the rotors by leaked gas to be mutually cancelled out in the radial direction. Thus, the gas exciting forces borne by the rotors can be eliminated, vibration of the rotors can be reduced and stable running of a rotation part can be guaranteed. Meanwhile, the seal structure formed by combining the high teeth and the low teeth can further greatly reduce leakage and improve the sealing performance.

Owner:HARBIN ENG UNIV

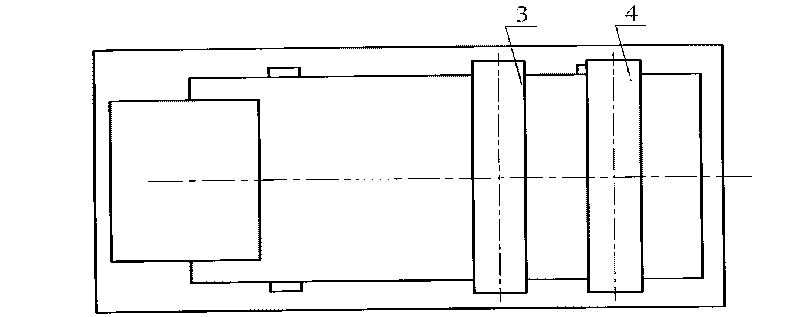

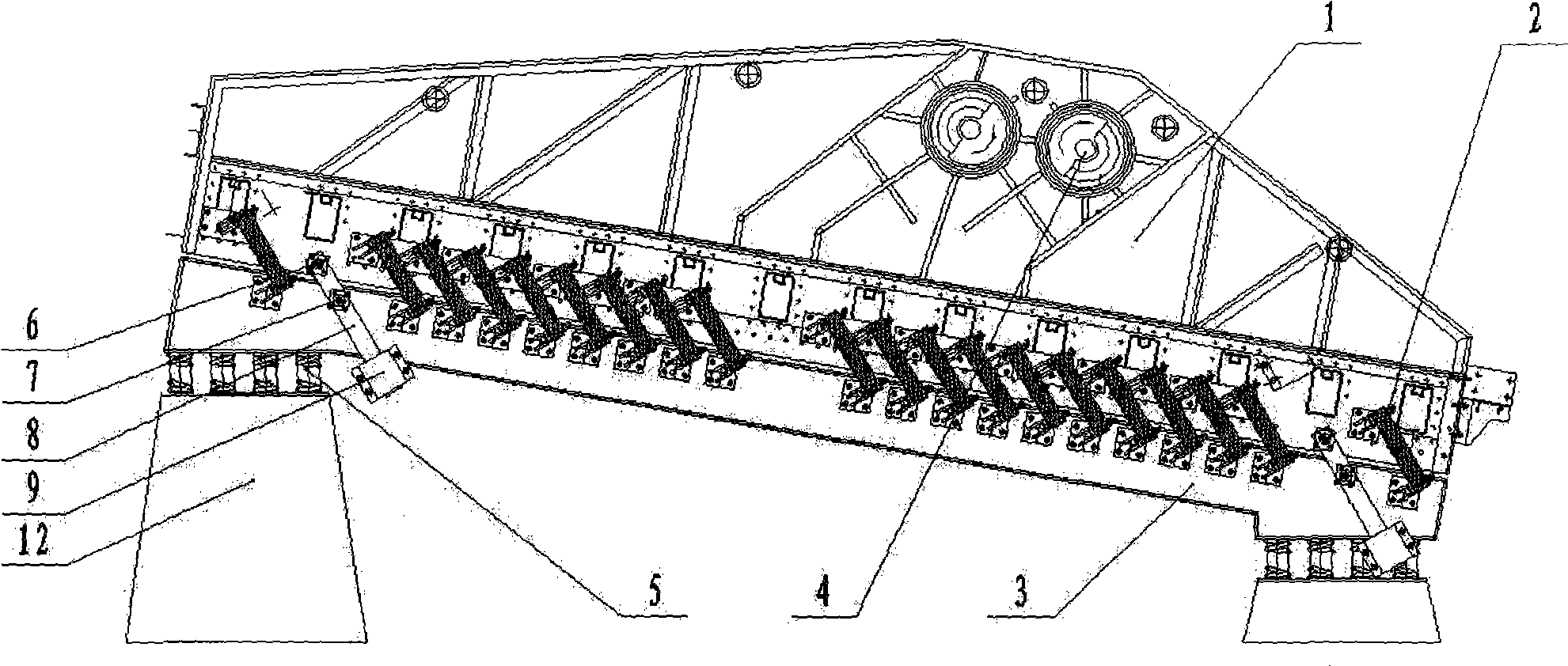

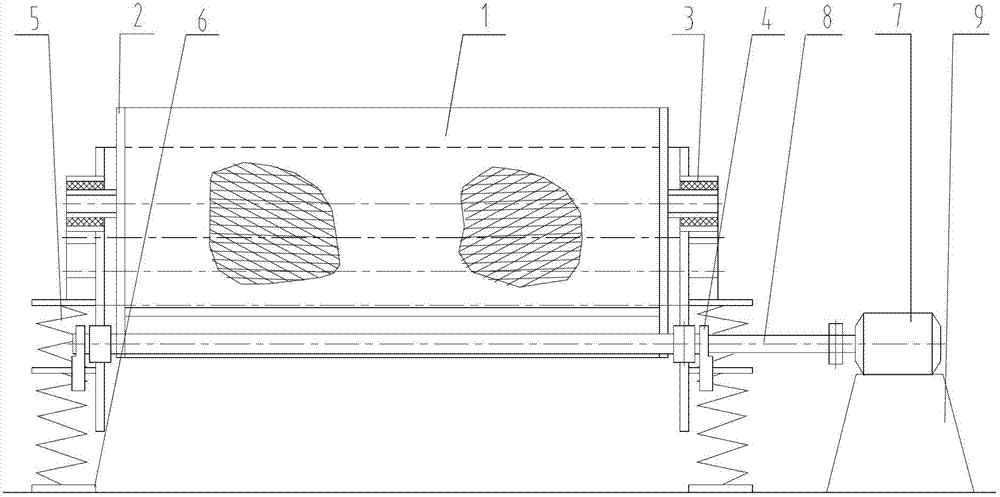

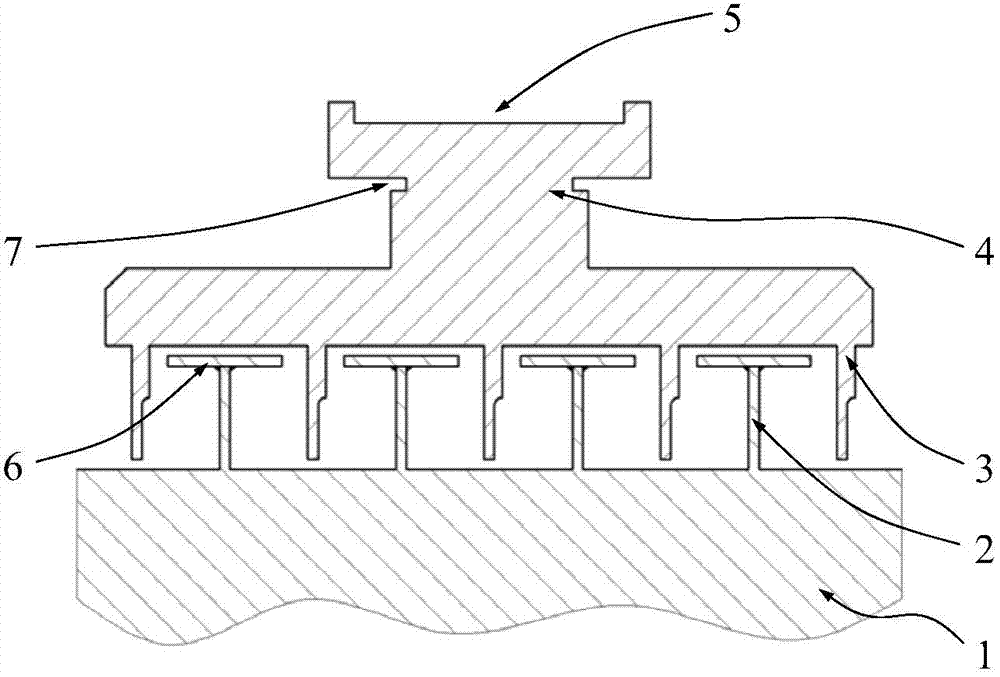

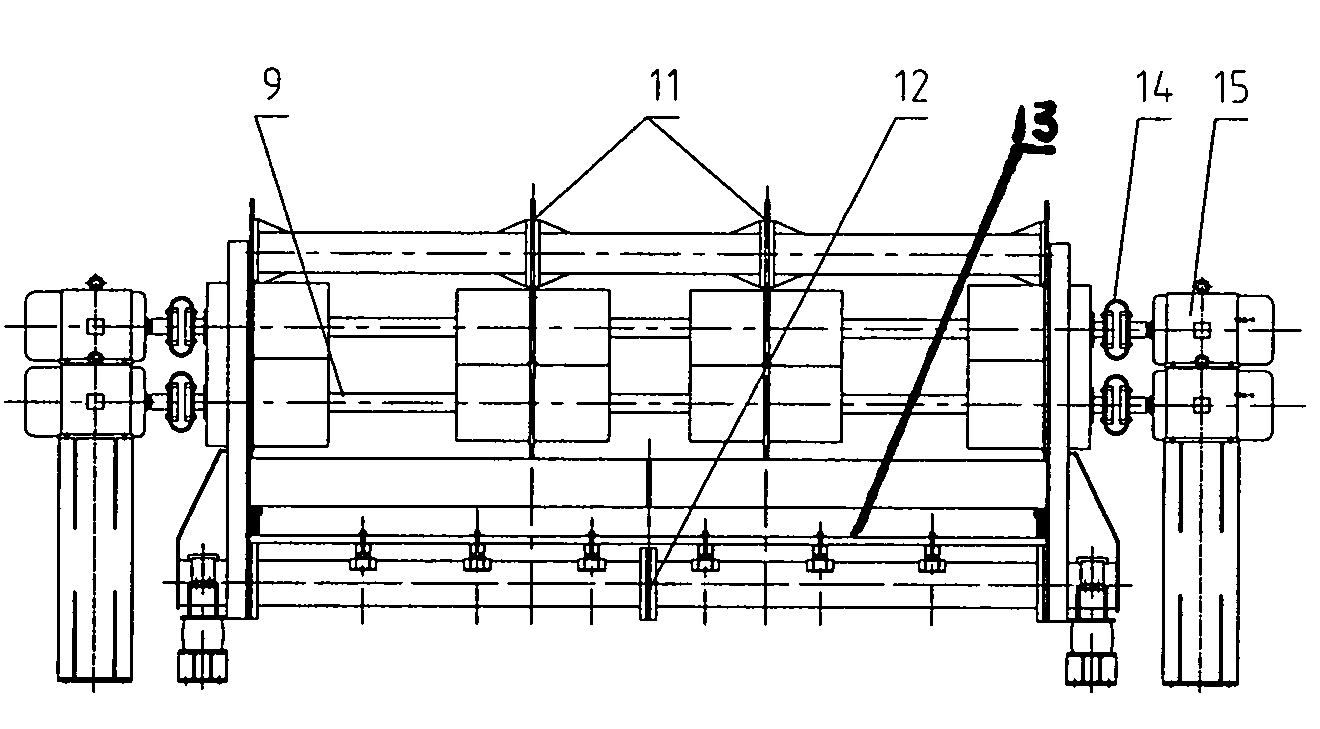

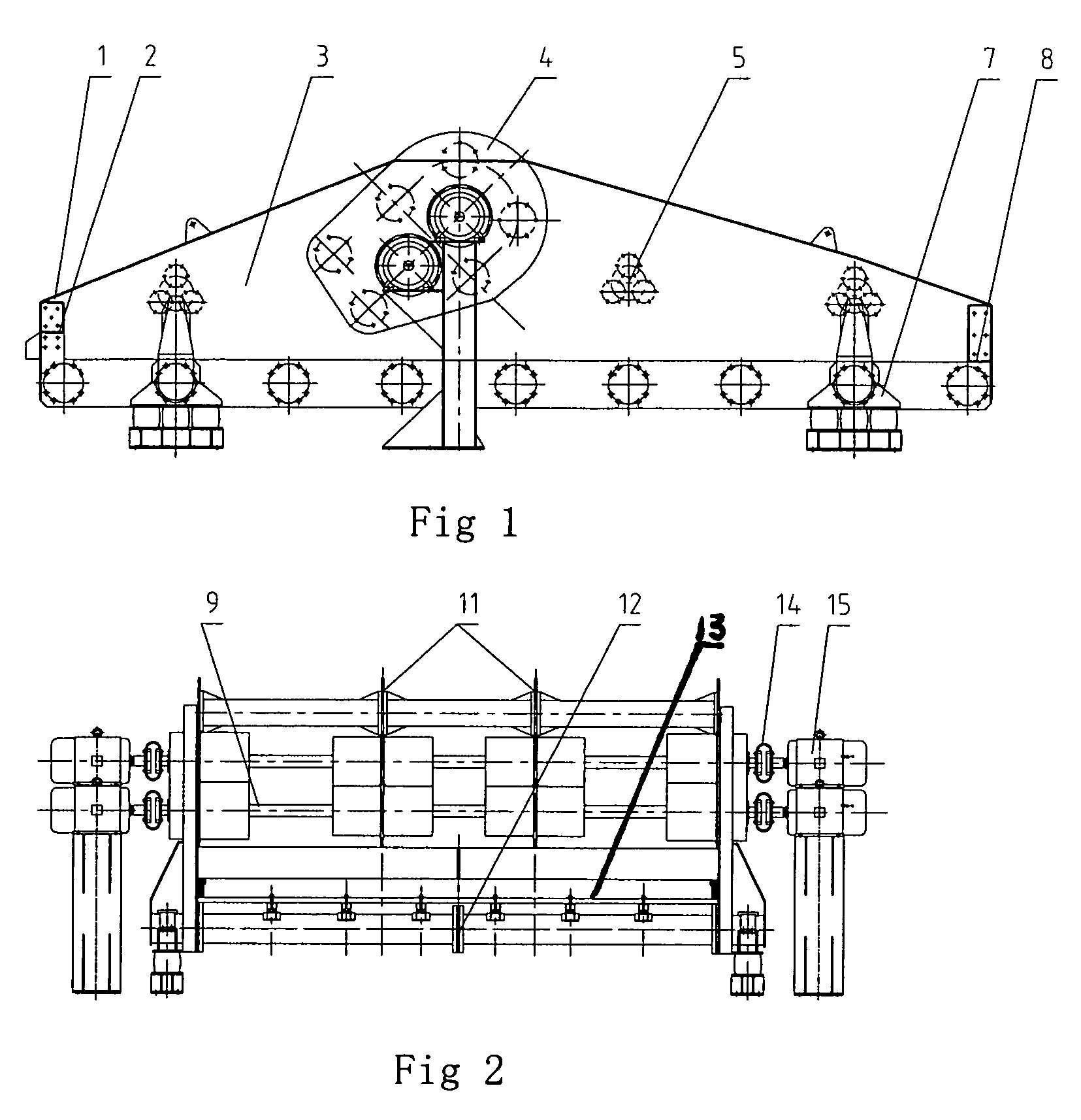

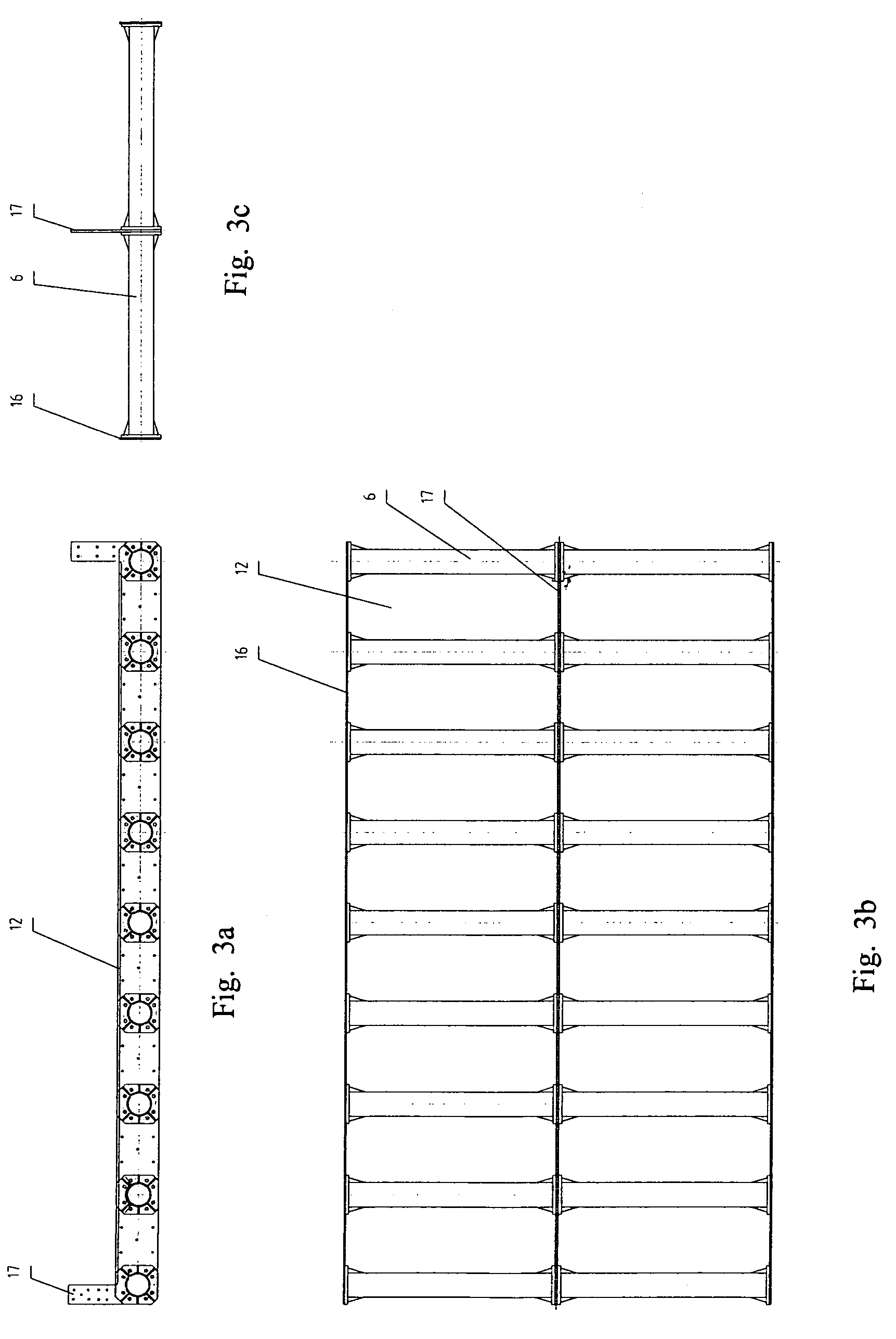

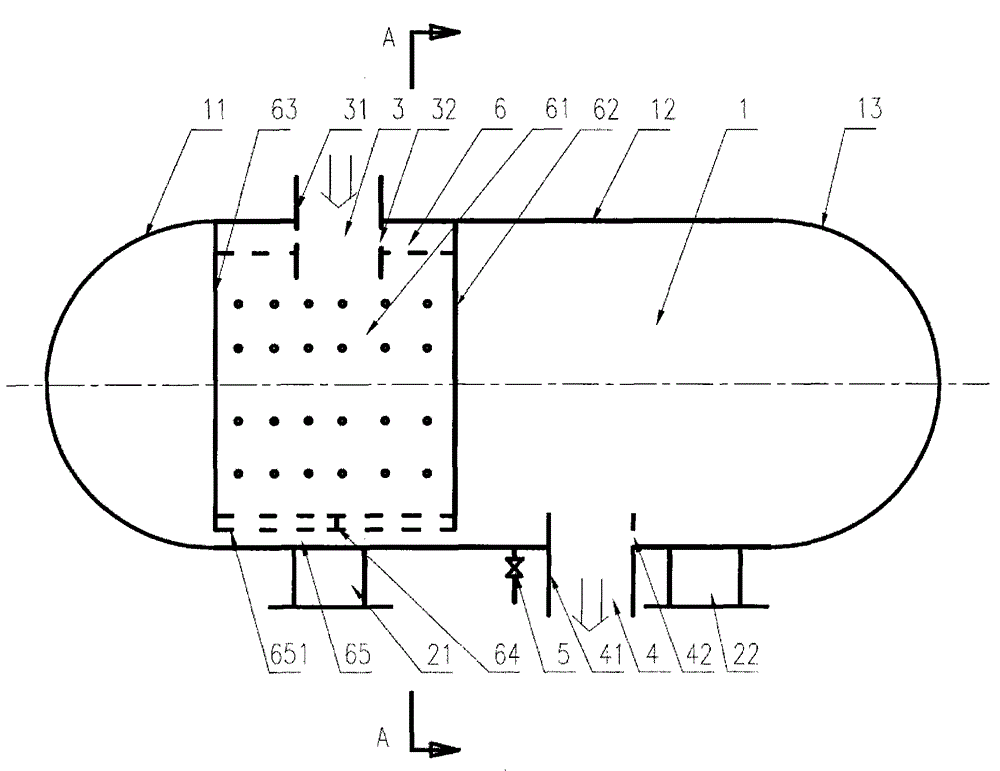

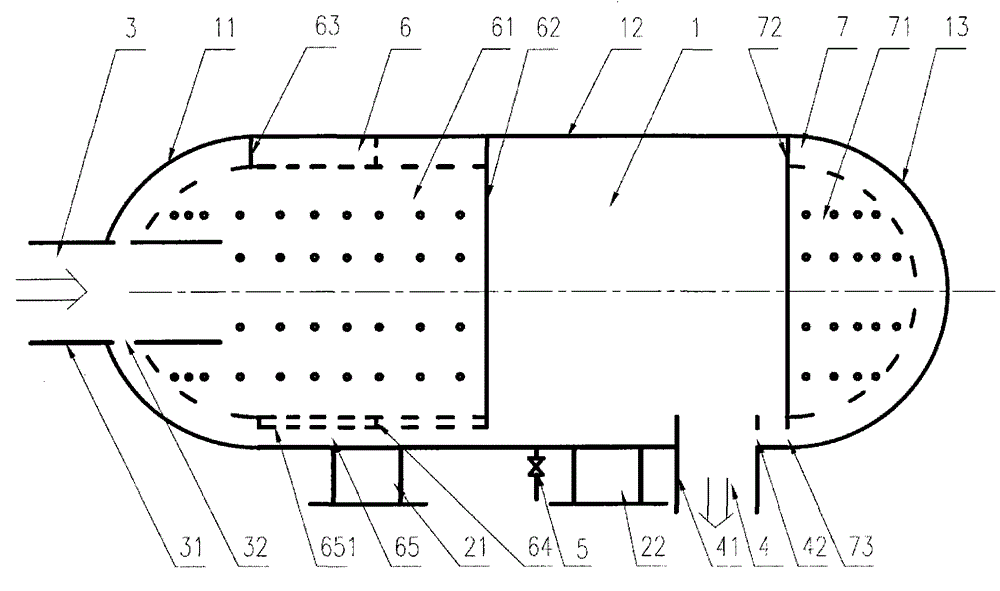

Extra-large vibrating screen with duplex statically indeterminate mesh beam

ActiveUS8074805B2Light weightReduce the excitation forceSievingScreeningStatically indeterminateCoupling

An extra-large vibrating screen with duplex statically indeterminate mesh beam excitation body and plate type combined bearing beam comprises plate type flat and rigid statically indeterminate combined bearing beam (12) arranged in a screen box (1), a plurality of Y-shaped statically indeterminate combined reinforcing beams (5) arranged on the side plates (3) of the screen box alternately, duplex statically indeterminate supporting plates (22) linking a plurality of mesh beams (21) to the statically indeterminate connecting plate (4) and the side plate (3) so as to form a container made of a beam system, the vibration exciters (10) in the statically indeterminate mesh beam unit comprising eight sets of vibration exciters, which are aligned in pair horizontally and linked together through universal couplings (9), and connected to the duplex statically indeterminate mesh beam excitation body (11) to form a highly rigid integral vibrating assembly. The vibrating screen is simple and reliable in structure, can vibrate smoothly, and therefore can be widely used in coal, metallurgical, chemical, and environmental protection industries.

Owner:CHINA UNIV OF MINING & TECH

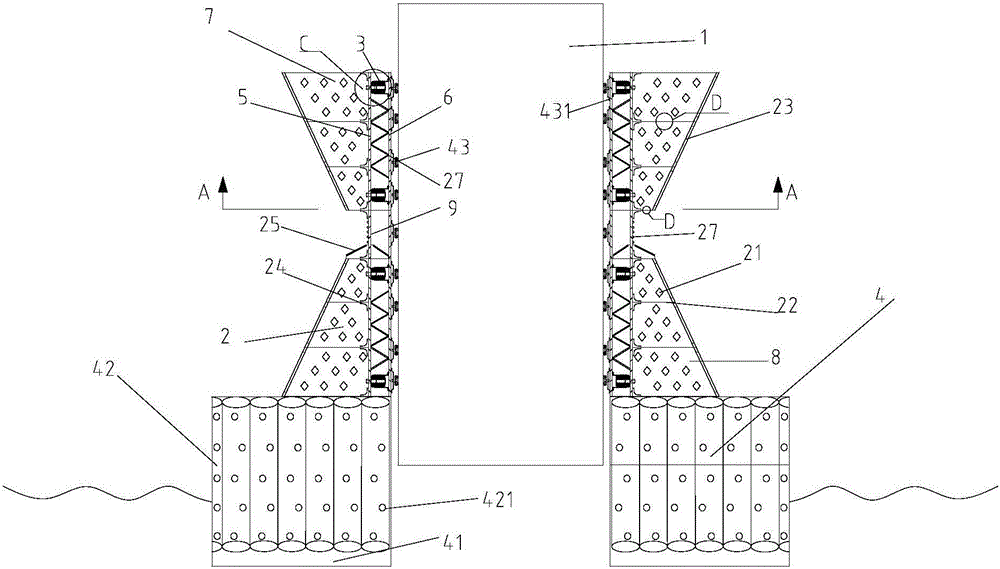

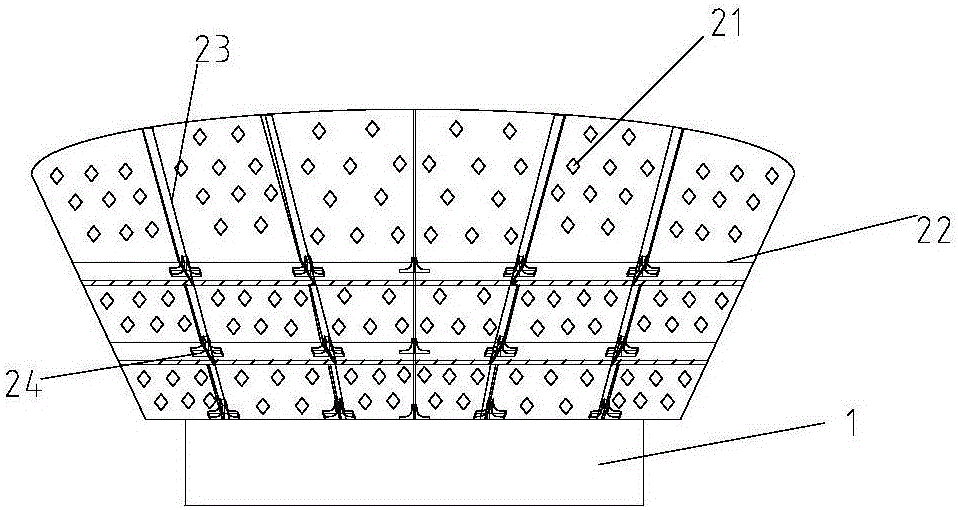

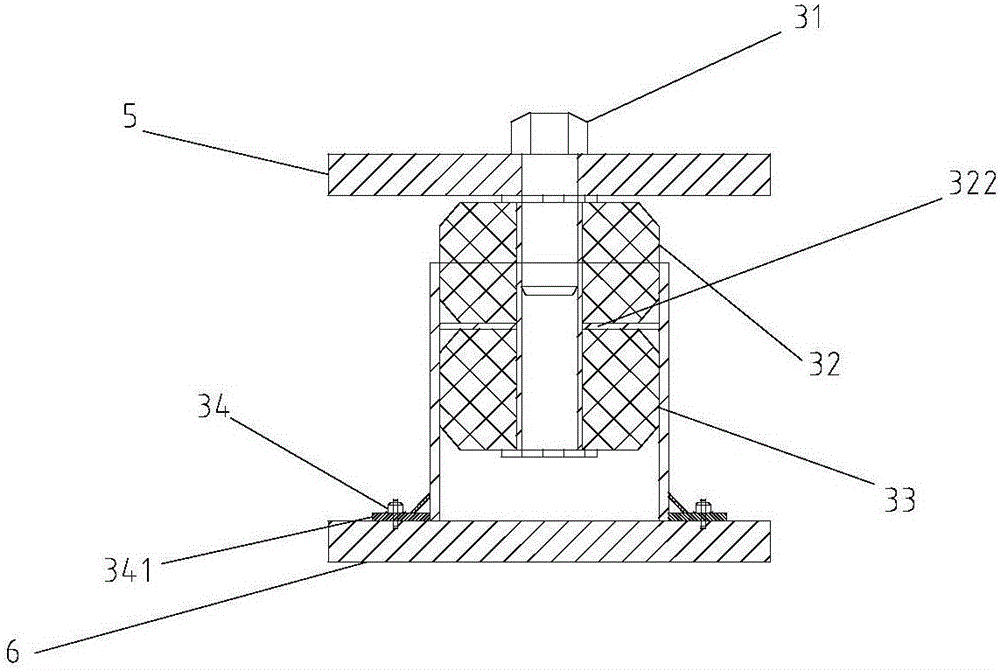

Ice-resistant device applicable to polar ice zone ocean platform

InactiveCN105756029AImprove economyImprove securityArtificial islandsUnderwater structuresCircular coneOcean sea

The invention discloses an ice-resistant device applicable to a polar ice zone ocean platform.The ice-resistant device comprises a self-adaptive tide floating type self-elevating device and a structure strengthening device, the structure strengthening device is located above the self-adaptive tide floating type self-elevating device and comprises a circular-cone-shaped lower cone, multiple wave absorbing holes are formed in the lower cone, a first partition plate is arranged on the inner side of the lower cone and connected with a second partition plate through multiple inclined struts which are mutually connected in a staggered mode, multiple damping devices are connected between the first partition plate and the second partition plate, and the second partition plate is arranged on a stand column in a sleeving mode.According to the ice-resistant device applicable to the polar ice zone ocean platform, by means of the damping device, the self-adaptive tide floating type self-elevating device and the structure strengthening device, damping and strength requirements of the structure can be effectively strengthened, and meanwhile the ice-resistant effect can be flexibly carried out by adapting to rising or falling of the tide water level.

Owner:JIANGSU UNIV OF SCI & TECH +1

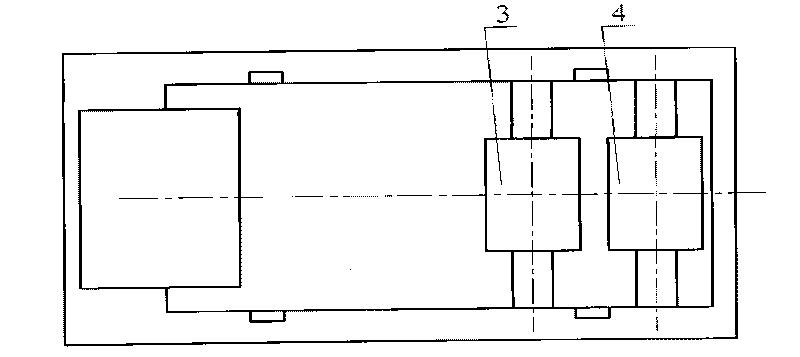

Compressor and pipeline system damping energy-saving apparatus thereof

InactiveCN104989622AReduce the excitation forceAttenuates pulsating pressure wavesPositive displacement pump componentsChemical industryUltrasound attenuationResonance

The invention relates to a compressor and a pipeline system damping energy-saving apparatus thereof. The pipeline system damping energy-saving apparatus comprises 1) a shell; 2) a left supporting seat and a right supporting seat; 3) an inlet; 4) an outlet; 5) a sewage draining outlet; and 6) an attenuation pressure pulsation and speed pulsation resonance inner member. The first part, the second part, the third part, the fourth part, and the fifth part are connected in sequence to form a hollow space structure, the sixth part is arranged in the space structure, the attenuation pressure pulsation and speed pulsation resonance inner member is formed by a cover plate and side plates, the attenuation pressure pulsation and speed pulsation resonance inner member and an inner wall surface of the shell form a hollow structure, a plurality of separating plates can be arranged or not arranged in the hollow structure, a plurality of through holes can be arranged or not arranged on the cover plate and the side plates, the through holes are connected or not connected with fine pipes with the same internal diameter, and the resonance inner member is arranged at the gravity bottom of the apparatus and is provided with a discharge drainage channel. The space of a harmonic oscillator is determined via calculation and analysis, and the resonant frequency is equal to the pulsation main frequency so that compressor main-frequency airflow pulsation waves are effectively blocked or attenuated or not reflected by the apparatus.

Owner:刘友宏

Vibrating screen

InactiveCN102029257AReduced strength requirementsReduce vibration forceSievingScreeningLow noiseEngineering

The invention relates to a vibrating screen and belongs to raw coal screening equipment. The vibrating screen consists of a power part, a screen body framework part, screening bars and a suspension part, and is characterized in that: a bracket is fixedly welded on two side beams of an upper screen frame; a transverse bolt of a crossbeam is fixed on the bracket; a vibration motor is fixed on the crossbeam; the side beams are respectively welded at two ends of an end beam to be respectively welded among a front end beam, the side beams and a rear end beam on upper and lower screen frames through four pairs of connecting posts; and the long annular screening bars are suspended on screening bar posts and screening bar hooks of the upper and lower screen frames. The vibrating screen has low amplitude and low noise, the requirement on screen intensity is low, transverse screening bars are absent, and the screen surface is not blocked.

Owner:薛熠 +1

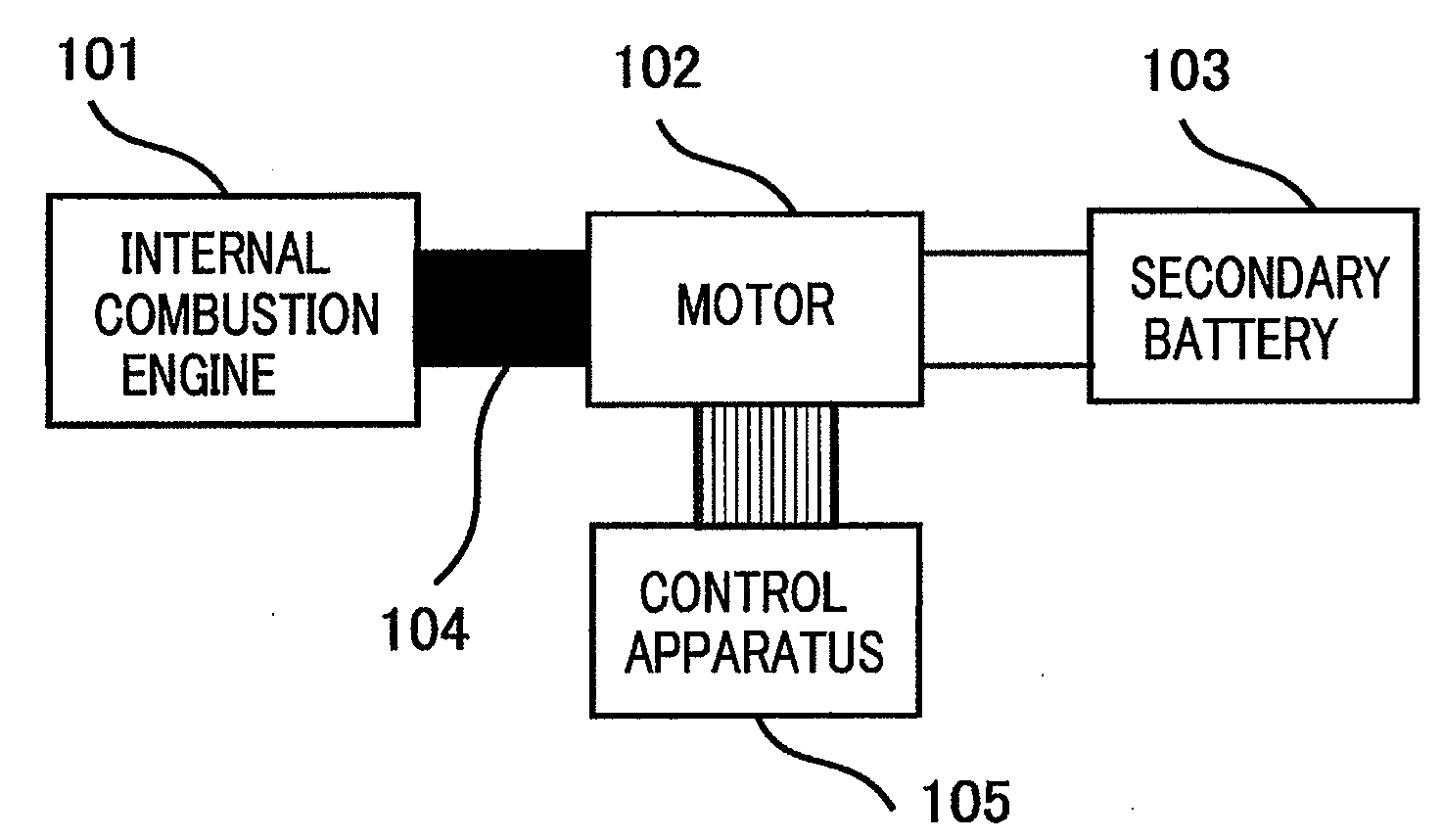

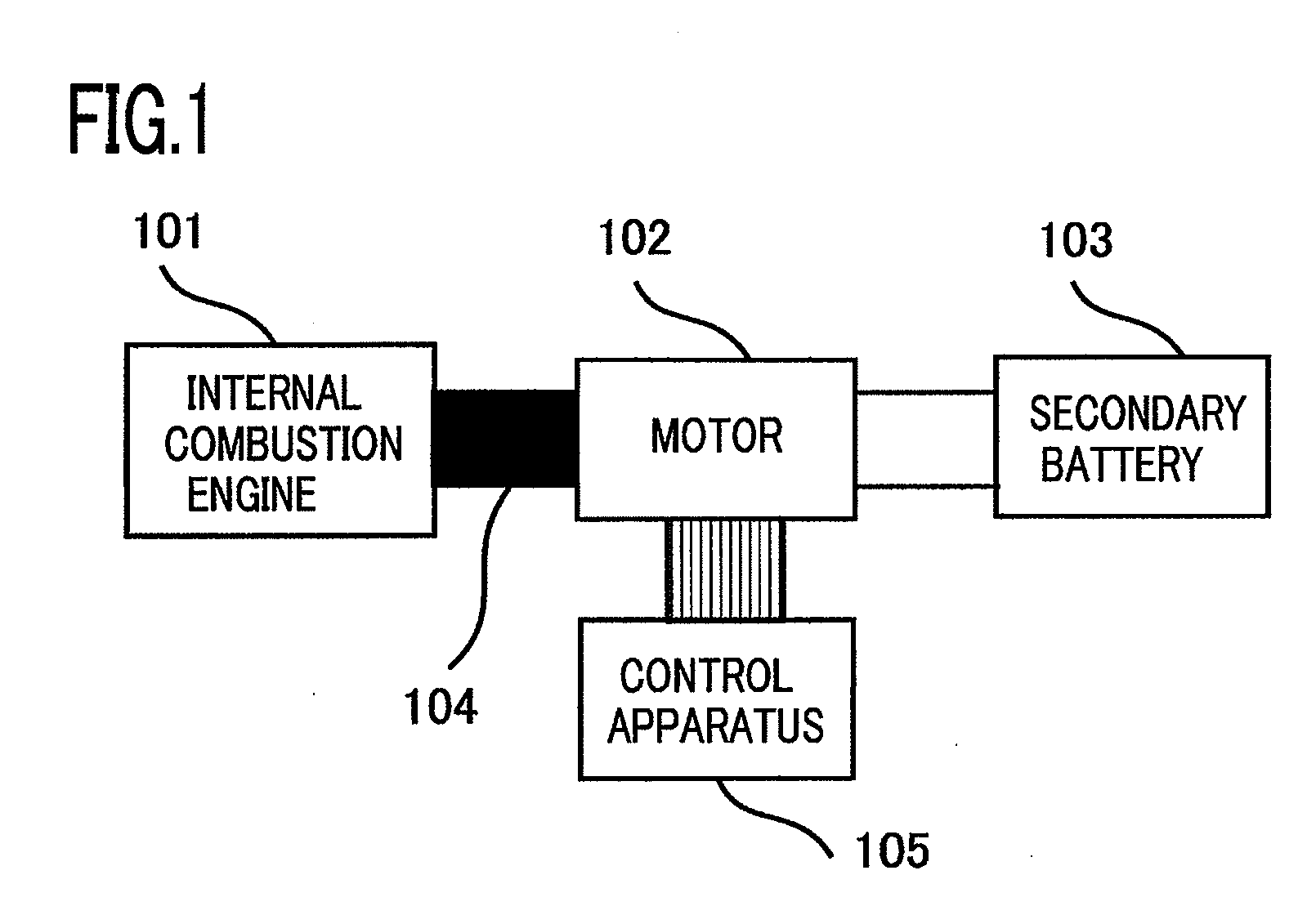

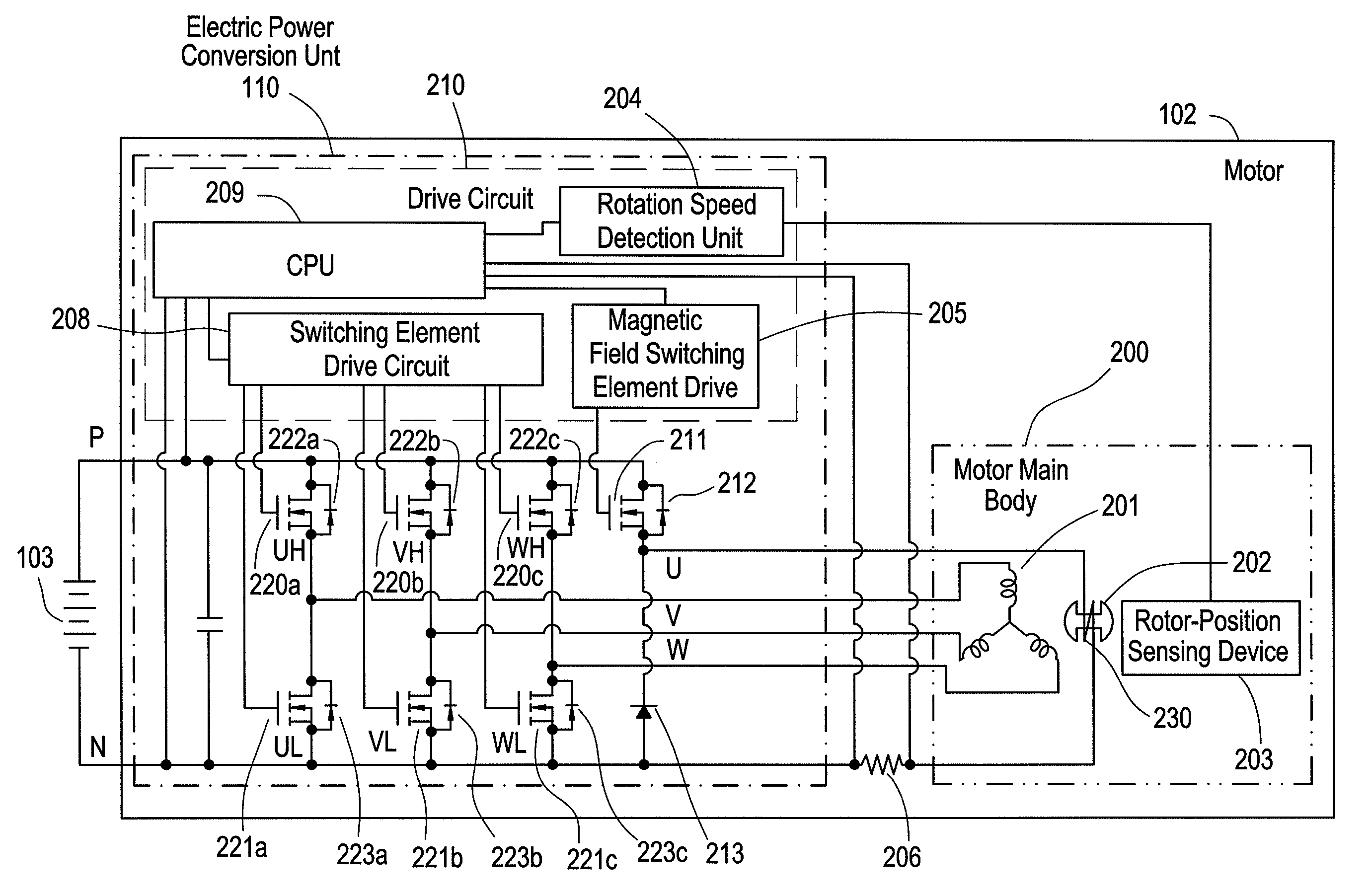

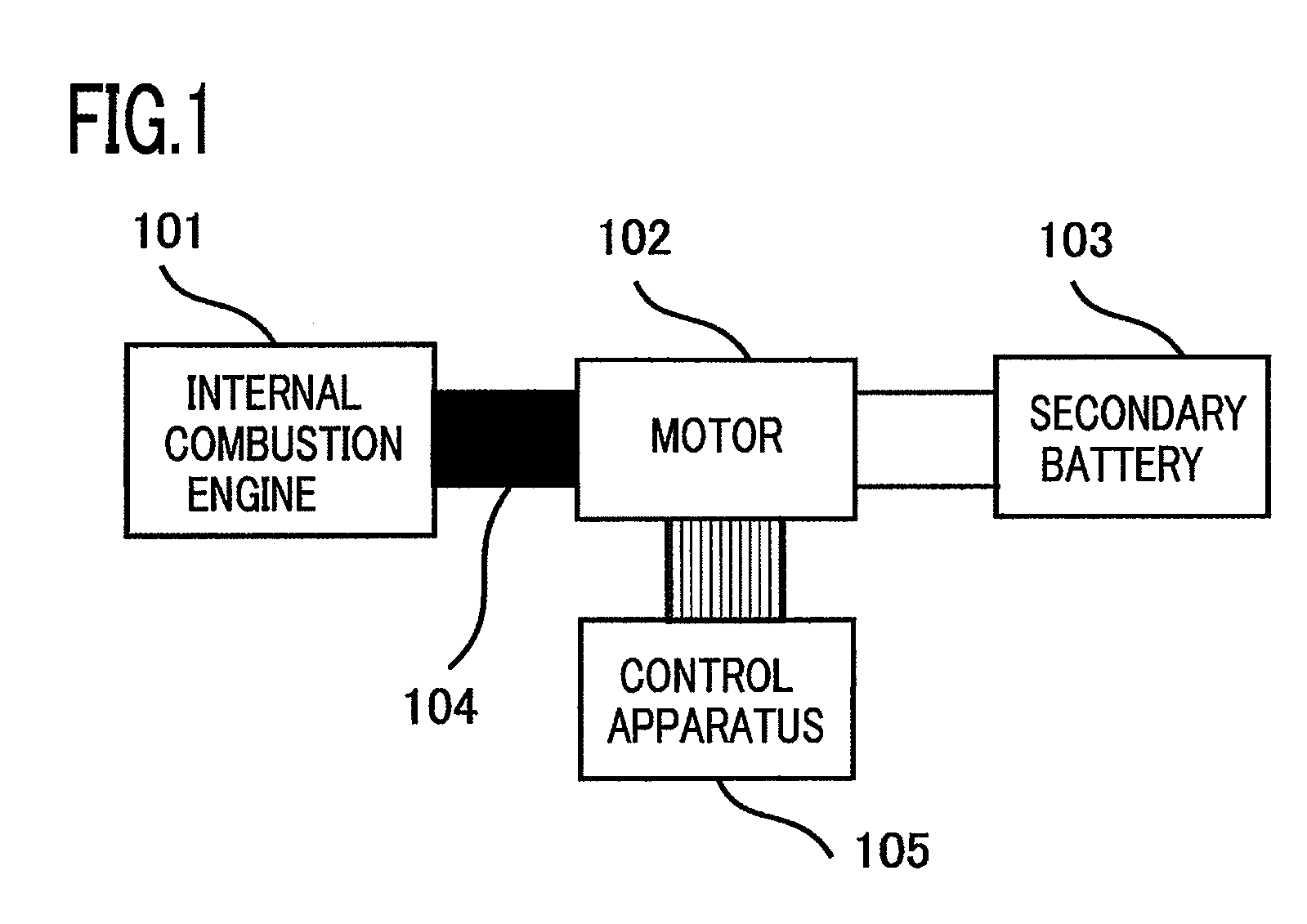

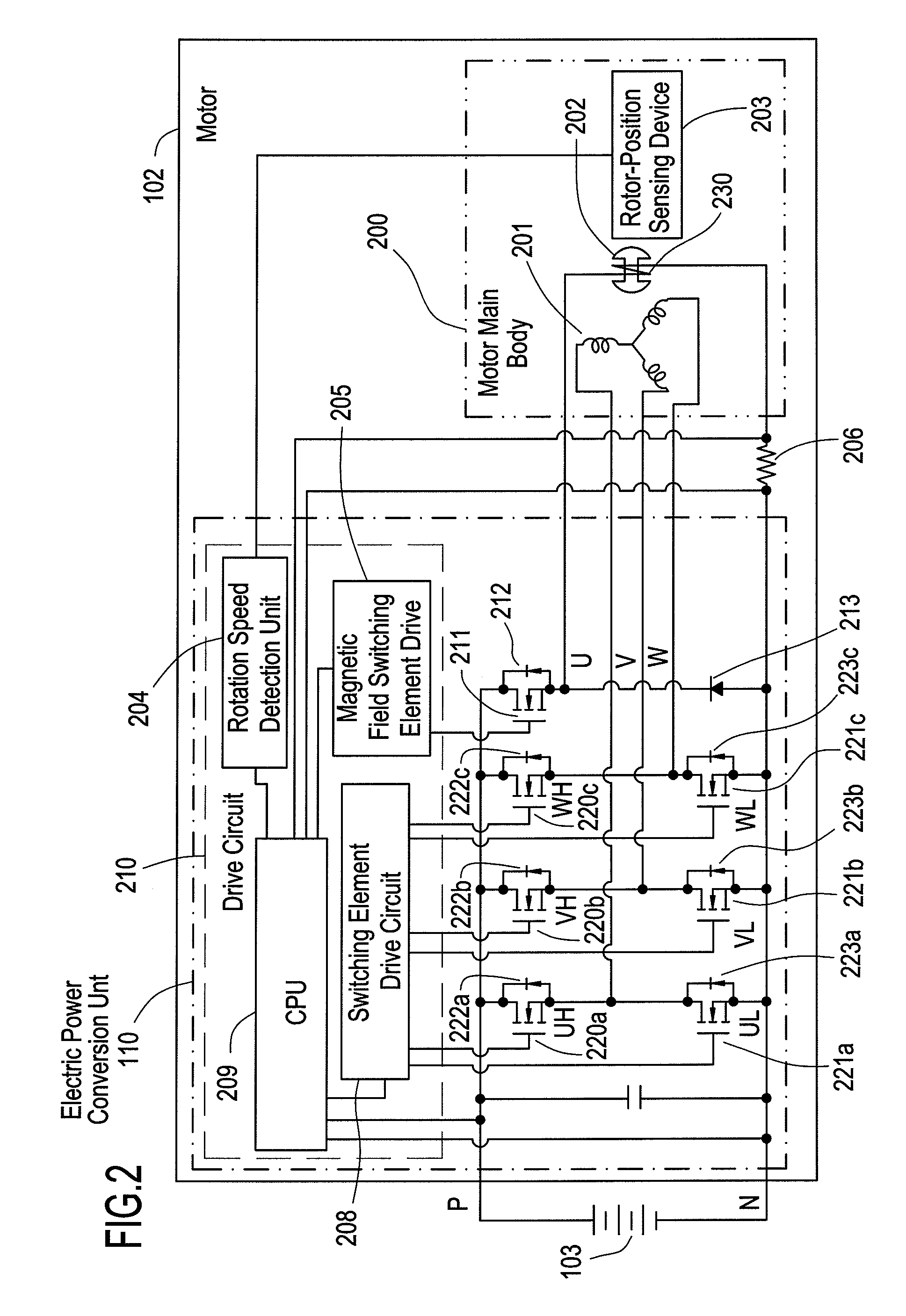

Vehicle motor control apparatus

ActiveUS20090322270A1Enhance output torqueReduce torque rippleTorque ripple controlSynchronous motors startersStatorConductor Coil

There is provided a vehicle motor control apparatus that alternately switches a first ON state in which one of the stator winding terminals is energized through an upper switch element group and another stator winding terminal is energized through a lower switch element group and a second ON state in which one of the stator winding terminals is energized through one of the upper switch element group and the lower switch element group and two other stator winding terminals are energized through the other switch element group, in one cycle period of an electric angle that changes as the rotor rotates.

Owner:MITSUBISHI ELECTRIC CORP

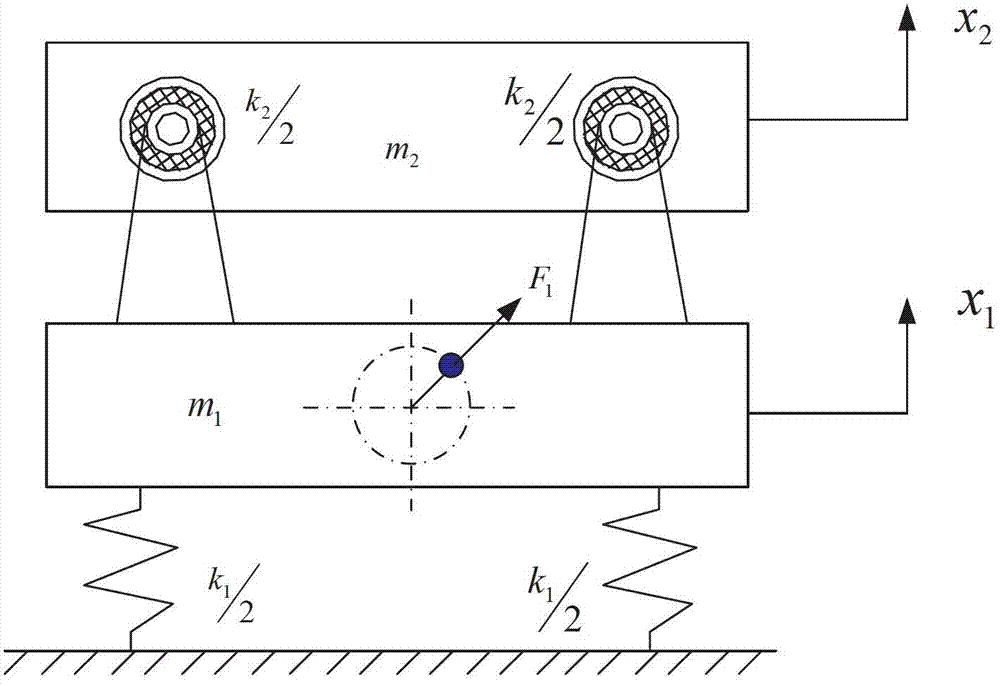

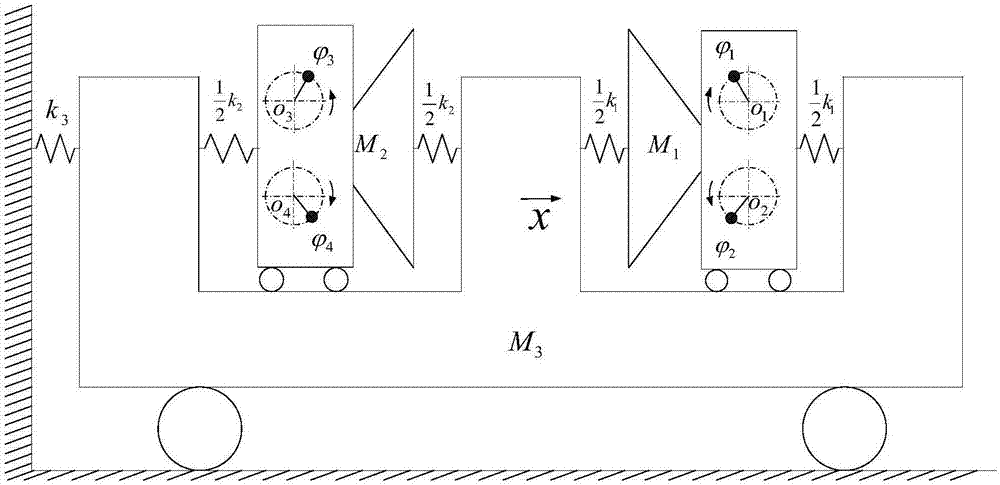

Four-motor-driving and double-screen-fence balancing type horizontal vibrating de-watering centrifuge and parameter determining method

ActiveCN107228528AReduce the excitation forceEfficient centrifugal dehydration methodDrying solid materials without heatMotor driveDynamic models

The invention provides a four-motor-driving and double-screen-fence balancing type horizontal vibrating de-watering centrifuge. The four-motor-driving and double-screen-fence balancing type horizontal vibrating de-watering centrifuge comprises a material charging and discharging mechanism, a screen fence box body mechanism, a rack, a de-watering transmission, a power mechanism, a vibration exciter and a vibration absorbing mechanism, wherein a de-watering device is mounted on the rack and is subjected to vibration isolation through the vibration absorbing mechanism; the material charging and discharging mechanism and the screen fence box body mechanism are connected as a whole to be used as an outside component being out of vibration; the de-watering transmission mechanism is connected with the screen fence box body through a shearing rubber spring, and a motor-belt wheel device is used as a power mechanism for supplying power to the de-watering transmission mechanism; a vibrating motor and a seat body form the whole vibration exciter which is mounted to the de-watering transmission mechanism to supply vibration exciting force to the de-watering mechanism. When the device is in working, materials are guided to screen fences through the material charging and discharging mechanism and are dewatered under the vibration and centrifuging effects. According to the four-motor-driving and double-screen-fence balancing type horizontal vibrating de-watering centrifuge, a three-component four-motor-driving dynamic model is used as the design model, and on that basis, a novel vibration mechanism model and a design parameter determining method thereof are provided.

Owner:NORTHEASTERN UNIV

Vehicle motor control apparatus

InactiveUS7928676B2Increase output torqueRapidly and smoothly raiseTorque ripple controlSynchronous motors startersEngineeringMotor control

There is provided a vehicle motor control apparatus that alternately switches a first ON state in which one of the stator winding terminals is energized through an upper switch element group and another stator winding terminal is energized through a lower switch element group and a second ON state in which one of the stator winding terminals is energized through one of the upper switch element group and the lower switch element group and two other stator winding terminals are energized through the other switch element group, in one cycle period of an electric angle that changes as the rotor rotates.

Owner:MITSUBISHI ELECTRIC CORP

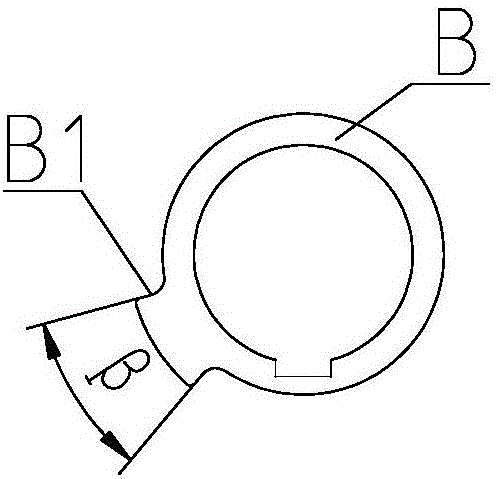

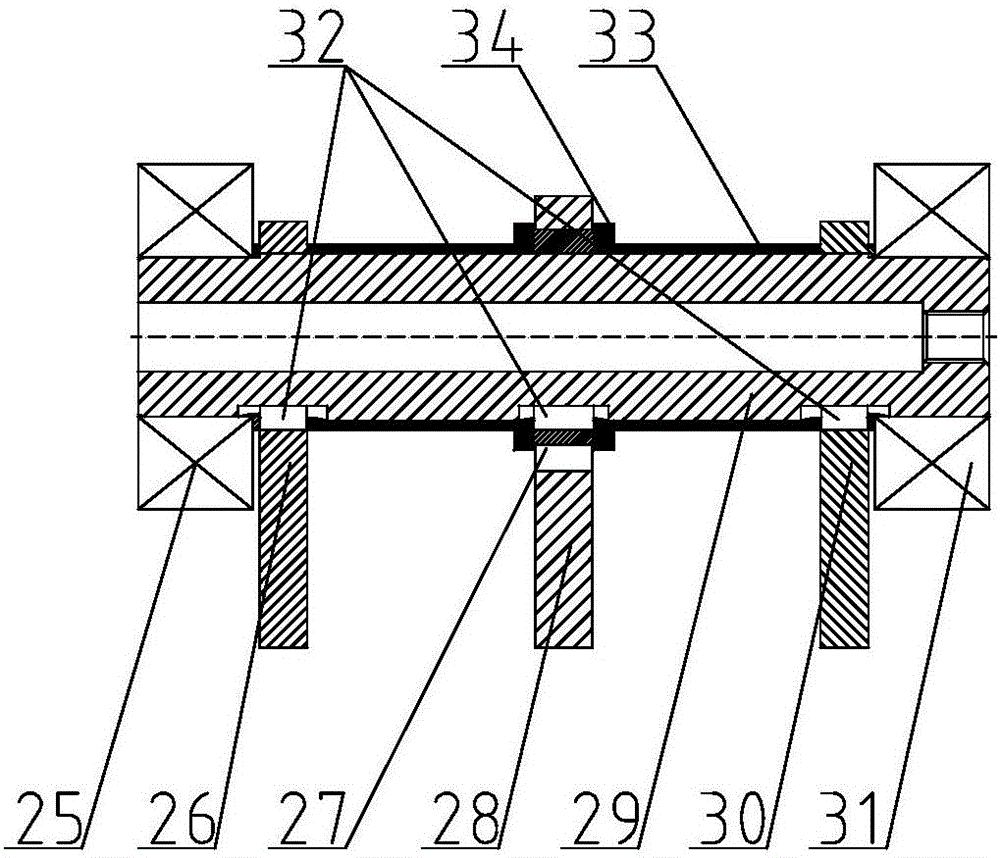

Radial ring seal

The invention discloses a radial ring seal. The radial ring seal comprises a rotor (5) and a seal sleeve (1) sleeved on the rotor (5), wherein a seal cavity (9) is formed in the seal sleeve (1) and connected with an adjusting plate (7) in a sliding way; the seal cavity (9) is provided with an adjusting screw (2); one end of the adjusting screw (2) serves as an adjusting end and is positioned outside the seal sleeve (1), and the other end of the adjusting screw (2) is rotatably connected with the adjusting plate (7); the rotor (5) is provided with a seal disc (8); and the adjusting plate (7) is provided with ring seal teeth (3) which are positioned between the seal disc (8) and the adjusting plate (7). The radial ring seal changes axial flow of gas into radial flow, eliminates the axial spiral flow and has a lower leakage rate than ordinary seal; and the flow directions of air flow forces on the two sides of the seal disc are opposite to each other and can be partially counteracted, so the air flow force in the seal is remarkably reduced.

Owner:SOUTHEAST UNIV

Electromanipulation device and method

ActiveUS7769440B2Facilitates electroporationLow powerElectrotherapyOther foreign material introduction processesChemical speciesIn vivo

The present invention is a device for electromanipulation of chemical species in vivo relative to a target tissue including a nonconductive, conformable array base adapted to be placed coincident to the target tissue, a plurality of electrode elements projecting from the array base towards the target tissue, the electrode elements addressable individually, an electrical source coupled to the plurality of electrodes, a control means interposed between the electrical source and the plurality of electrode elements and in circuit communication therein, the control means adapted to establish an electrical potential between at least two electrodes, and a delivery means adapted to introduce chemical species to the target tissue.

Owner:UNIV OF SOUTH FLORIDA

Vortex elimination fin structure with detachable fins

PendingCN111731463AEasy to disassemble and replaceImprove maintainabilityRotary propellersMarine propulsionWater flow

A vortex elimination fin structure with detachable fins comprises a flow guide body, a cavity is formed in the flow guide body, four or five grooves with one open end are formed in the outer portion of the flow guide body, the fins are installed in the grooves, a round hole is formed in the rear side of the flow guide body, a flange is arranged on the front side of the flow guide body, and a sealing groove is formed in the end face of the flange. When the propeller is installed on the propeller shaft and pressed through a fixing nut, the flow guide body is installed on the propeller hub through the bolt, grease is injected through the round hole in the rear end of the flow guide body, the rear end cover is used for sealing after the flow guide body is filled with the grease, and the situation that seawater corrodes parts, and consequently the propeller is difficult to disassemble is prevented. And finally, the fins are installed in the grooves of the flow guide body and fixed through stainless steel screws. The device has the advantages of being simple in structure, convenient to machine and manufacture, low in cost, easy to maintain, capable of reducing capacity loss of rotating water flow on the rear side of the propeller, reducing exciting force and noise of wake flow of the propeller, further reducing oil consumption of a main engine, improving ship propelling performance and the like.

Owner:HANGZHOU ADVANCE GEARBOX GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com