Pulsation air current vibration-damping arrangement

A pulsating airflow and vibration damping technology, applied in the direction of muffler, fluid flow, engine components, etc., can solve the problem of not finding a solution, and achieve a good vibration damping effect and the effect of reducing the excitation force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

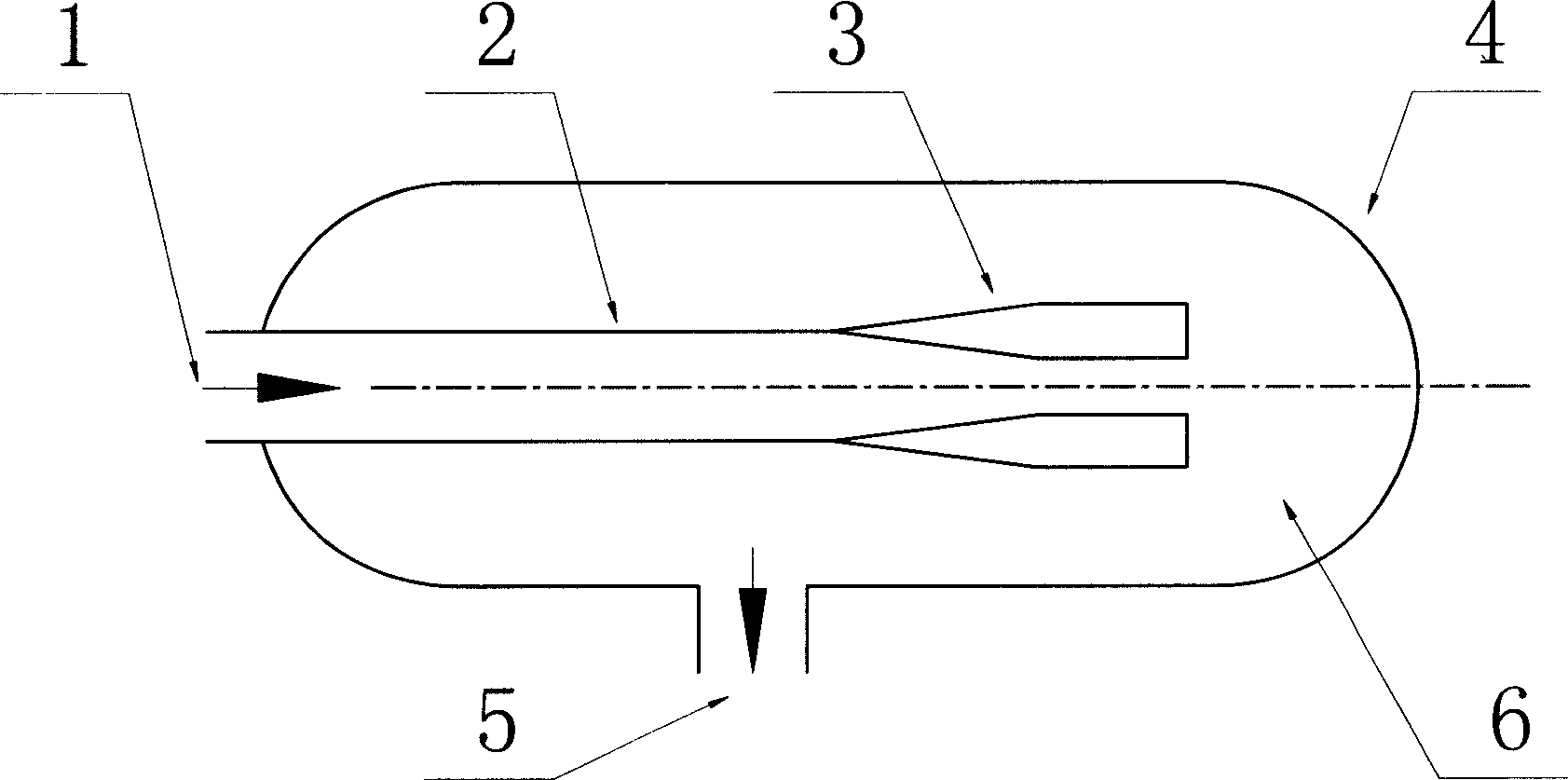

[0015] The present invention is further described with reference to the embodiments given in the accompanying drawings: figure 1 As shown, the device of the present invention is mainly composed of an outer casing 4, an inner member and an airflow expansion space 6; the inner member is composed of a transition section 2 and a nozzle 3; the outer casing has an air outlet 5; An airflow expansion space 6 is formed; the outlet of the nozzle 3 communicates with the airflow expansion space between the inner member and the outer casing 4 .

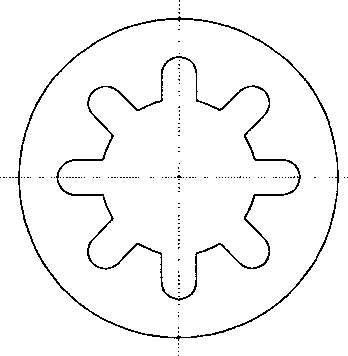

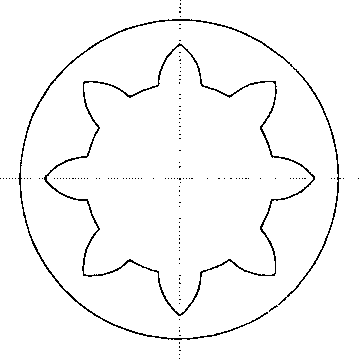

[0016] The cross-sectional shape of the nozzle - it is composed of a straight line segment or a circular arc segment or a parabola segment or a hyperbola segment or an unfolded segment and a periodic segment consisting of a straight line segment and a circular arc segment or a parabola segment or a hyperbola segment or an unfolded segment. The space plane curve structure is extended and arranged in the circumferential direction, or along the direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com