Patents

Literature

285results about How to "Reduce vibration force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

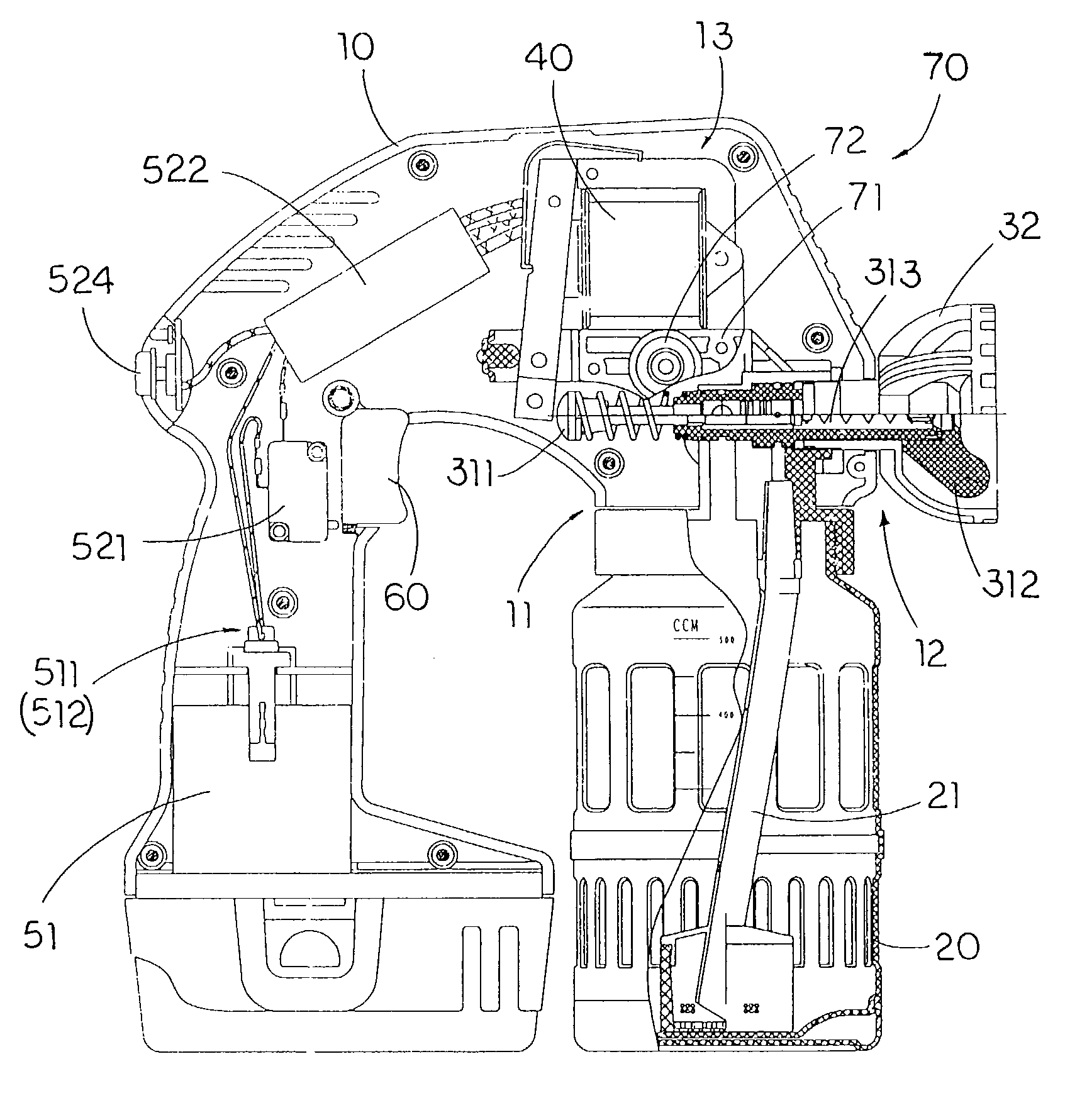

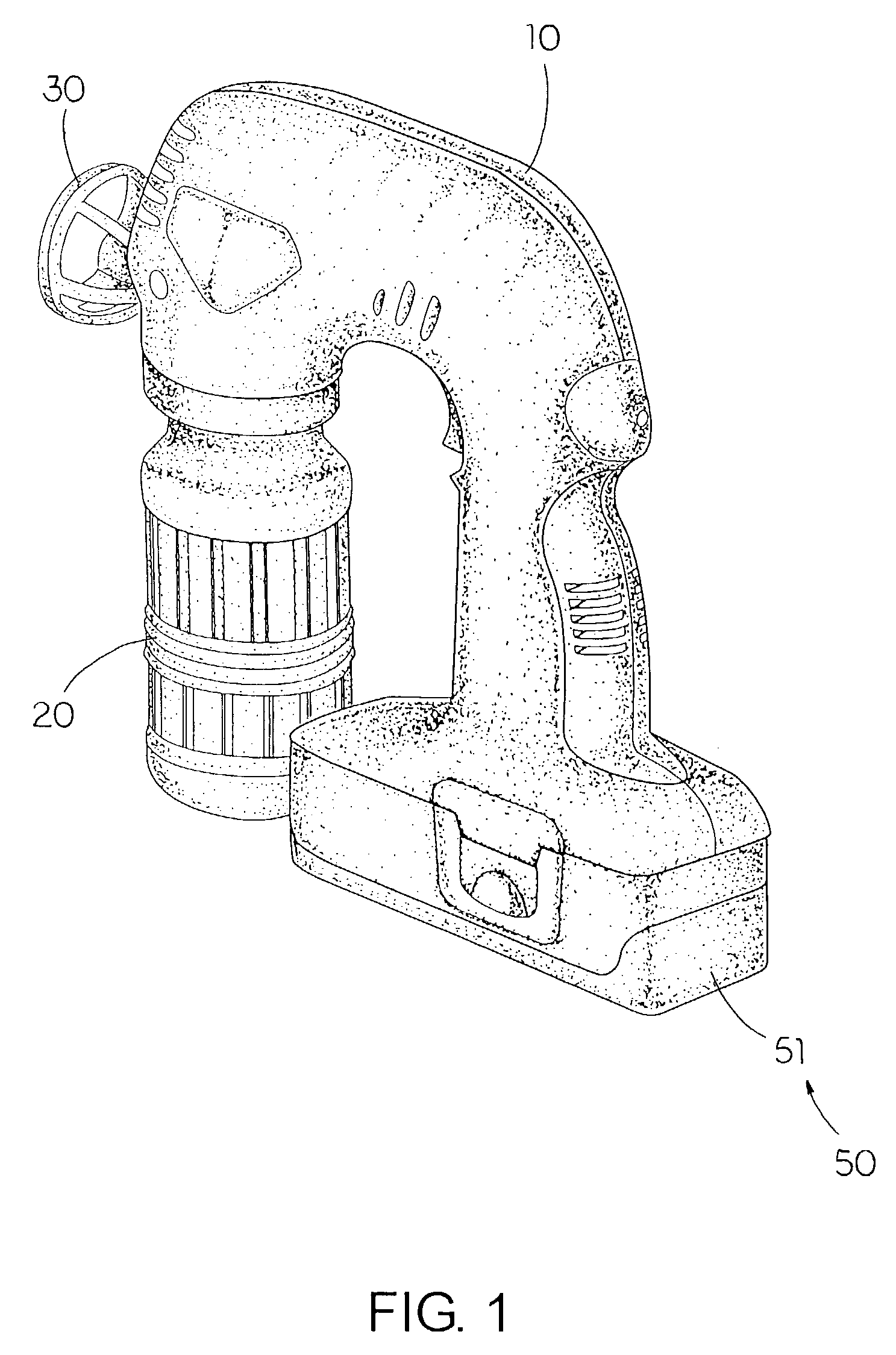

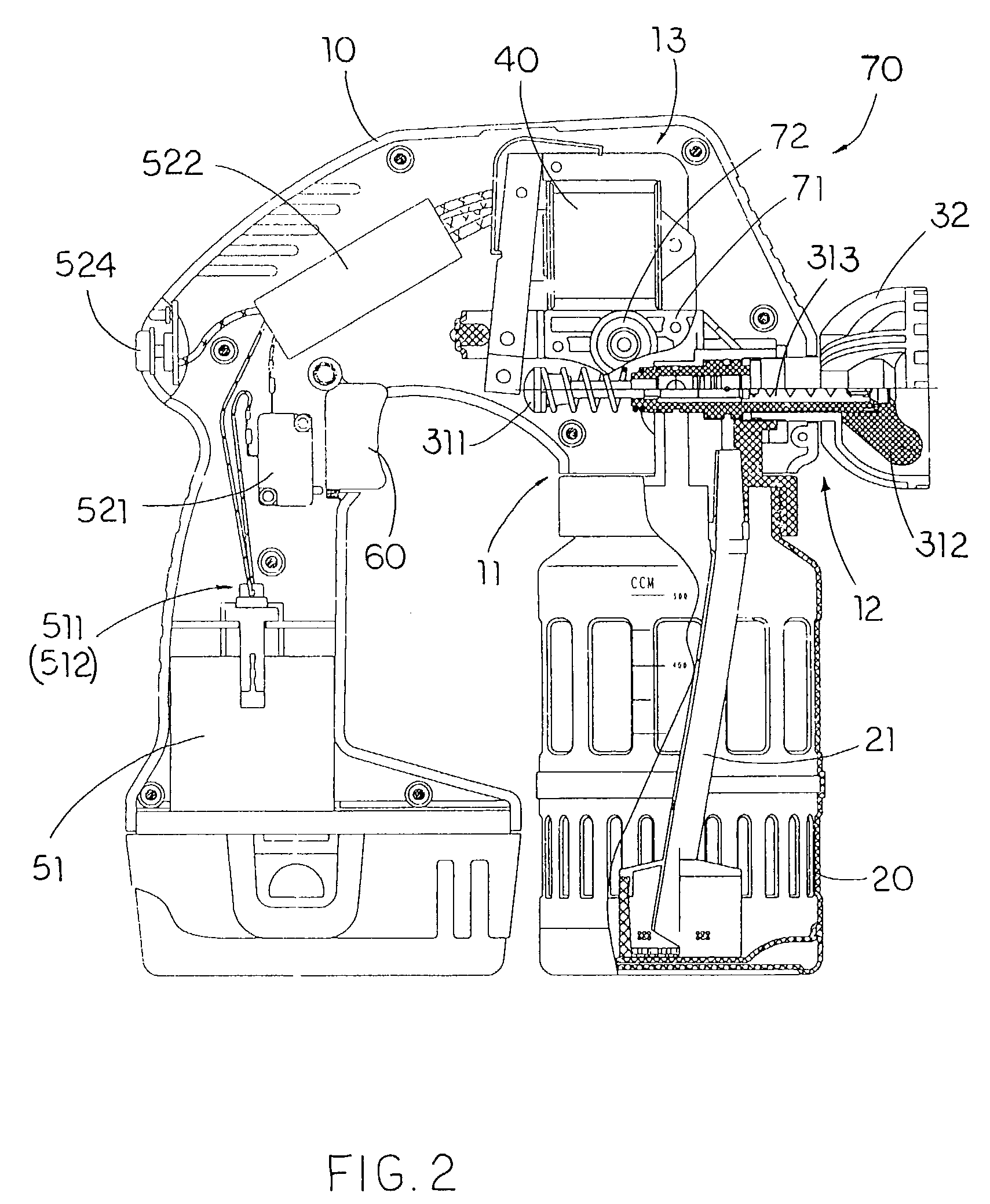

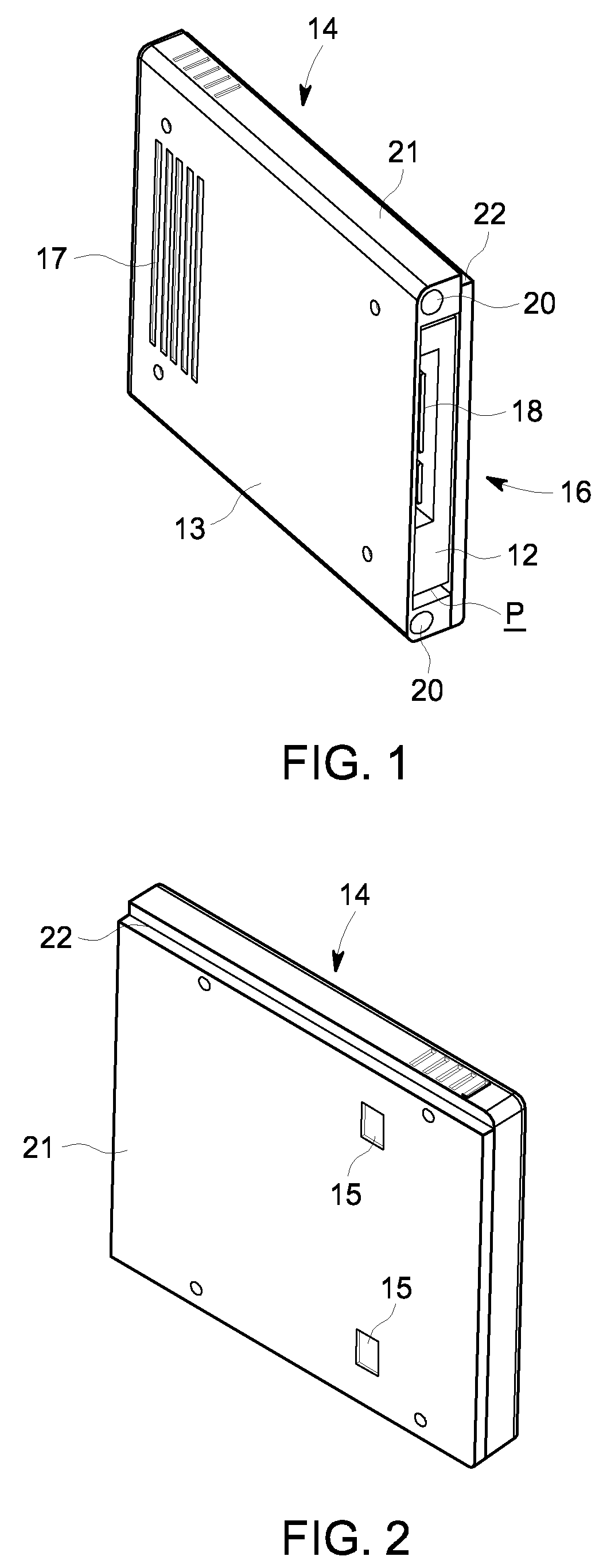

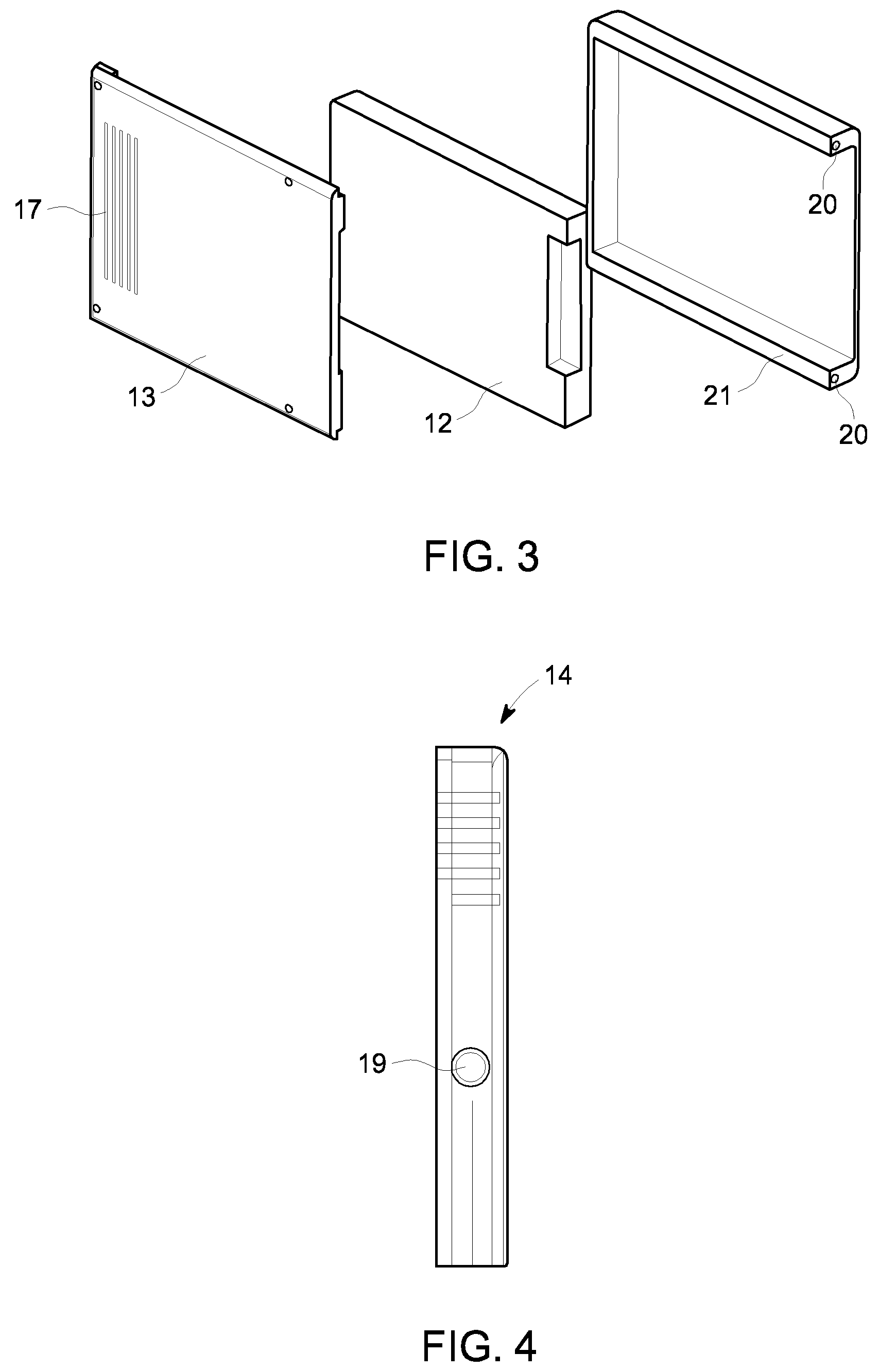

DC power spraying tool

ActiveUS7182280B2Improve portabilityEasy to operateLarge containersVolume meteringVacuum pressurePower flow

A DC power spraying tool includes a housing having an inlet opening, a discharging opening, and a motor cavity, a liquid container for containing a liquid colorant therein communicatively connected to the inlet opening of the housing, a spray nozzle extended from the discharging opening of the housing to communicate with the liquid container, and an electric motor supported within the motor cavity of the housing for applying a vacuum pressure on the liquid container to pump the colorant towards the spray nozzle. A DC power source includes a rechargeable battery supported by the housing for applying a DC current and a control circuitry electrically connected the rechargeable battery with the electric motor for transforming the DC current to an impulse current so as to drive the electric motor to operate.

Owner:JINHUA JINSHUN TOOLS

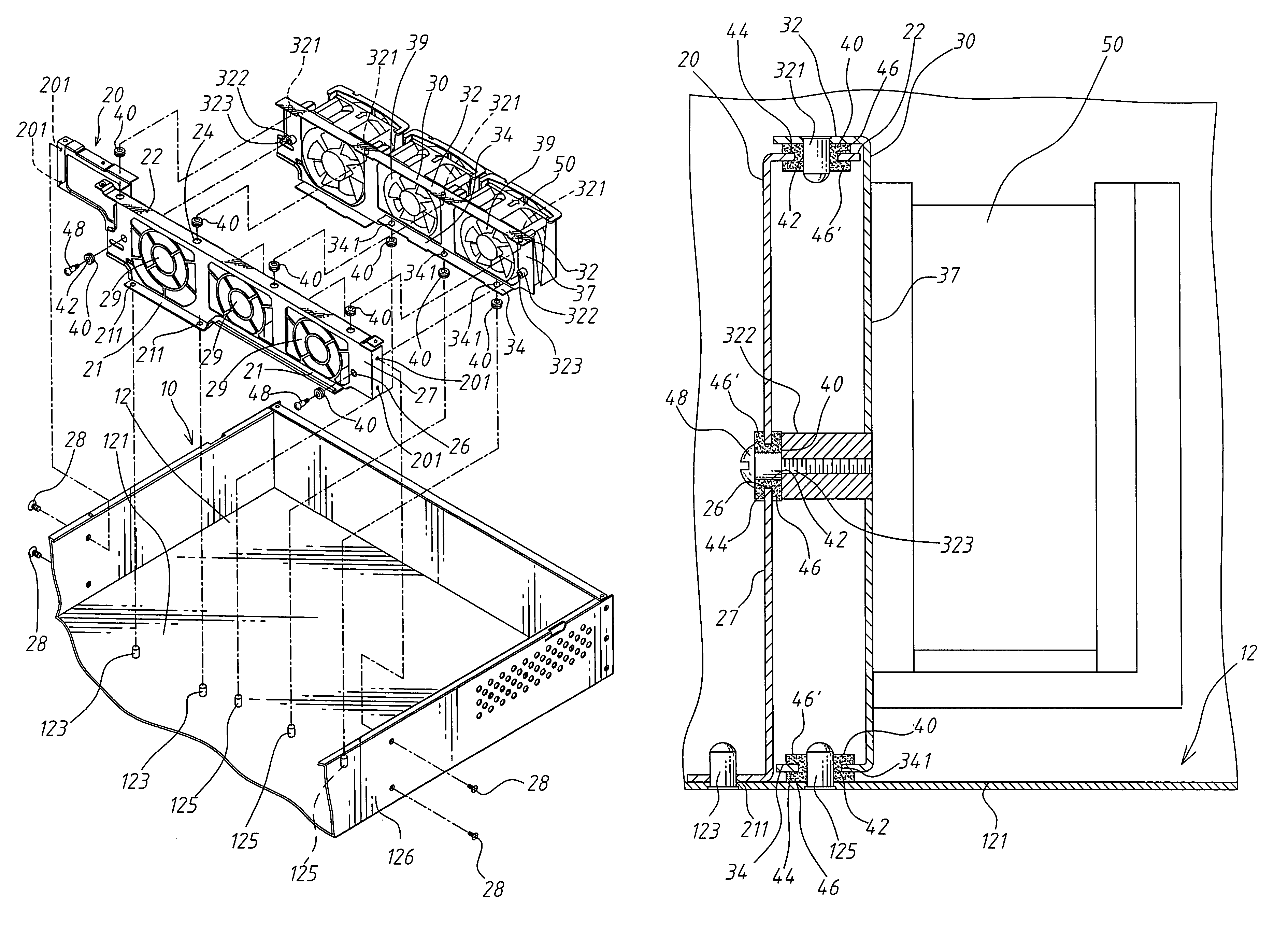

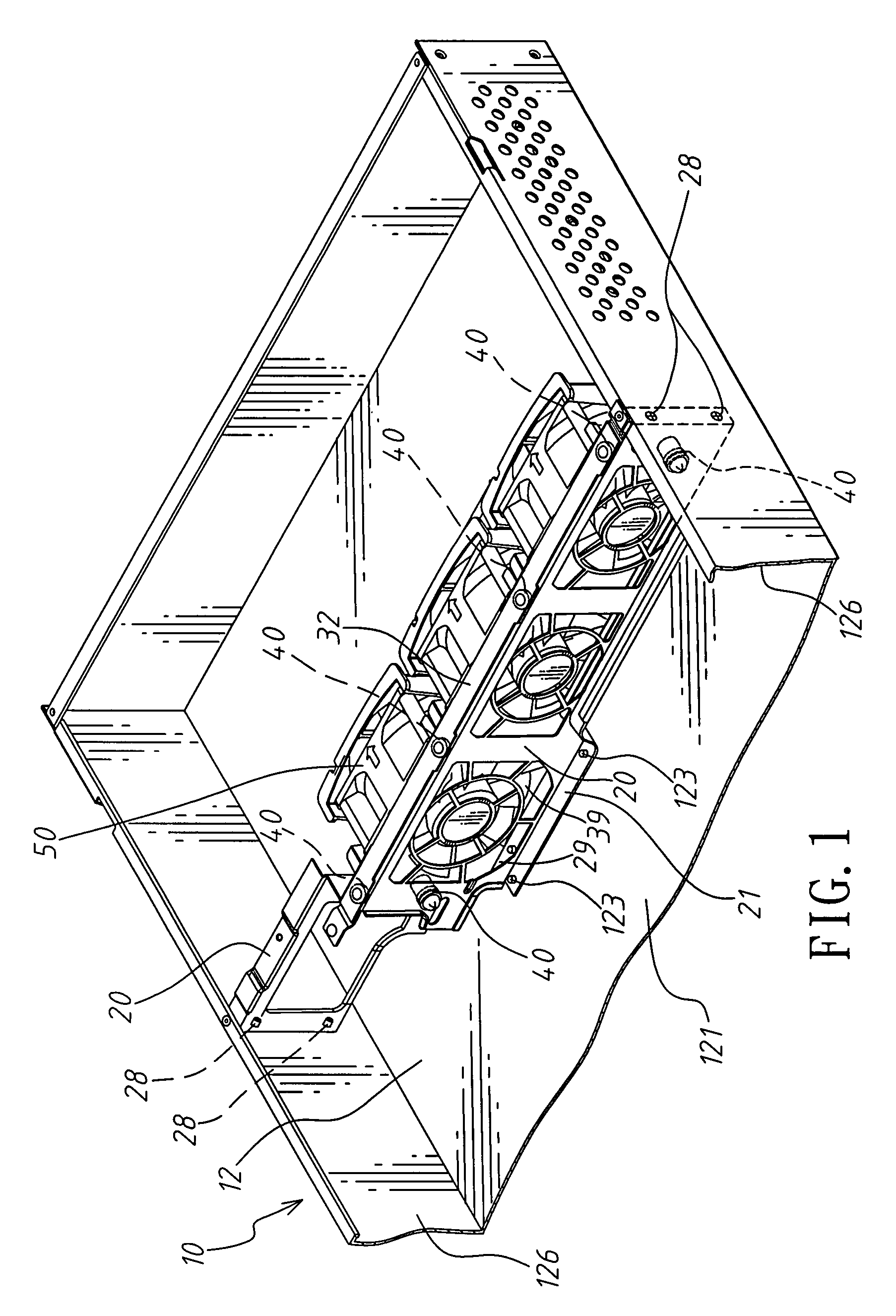

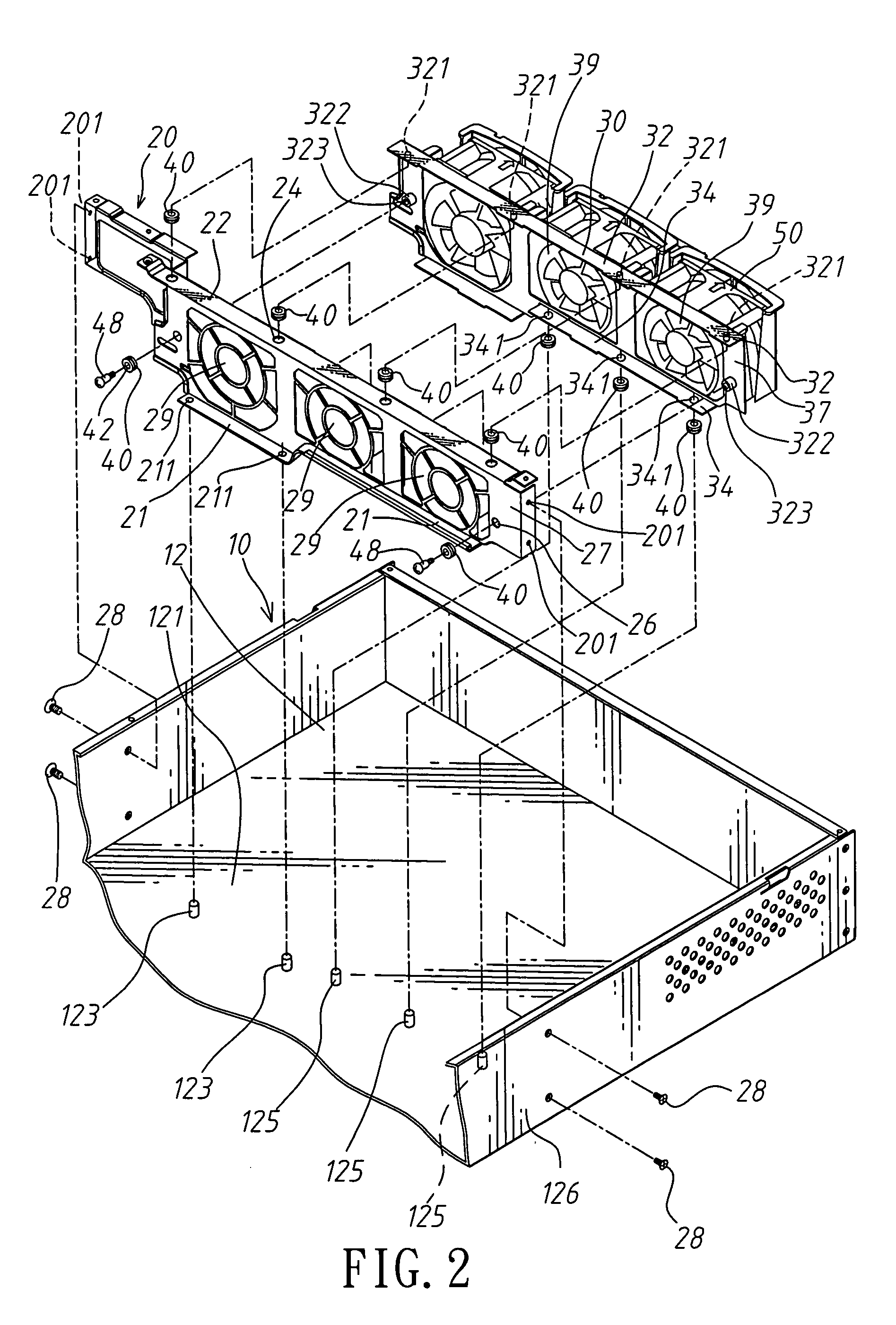

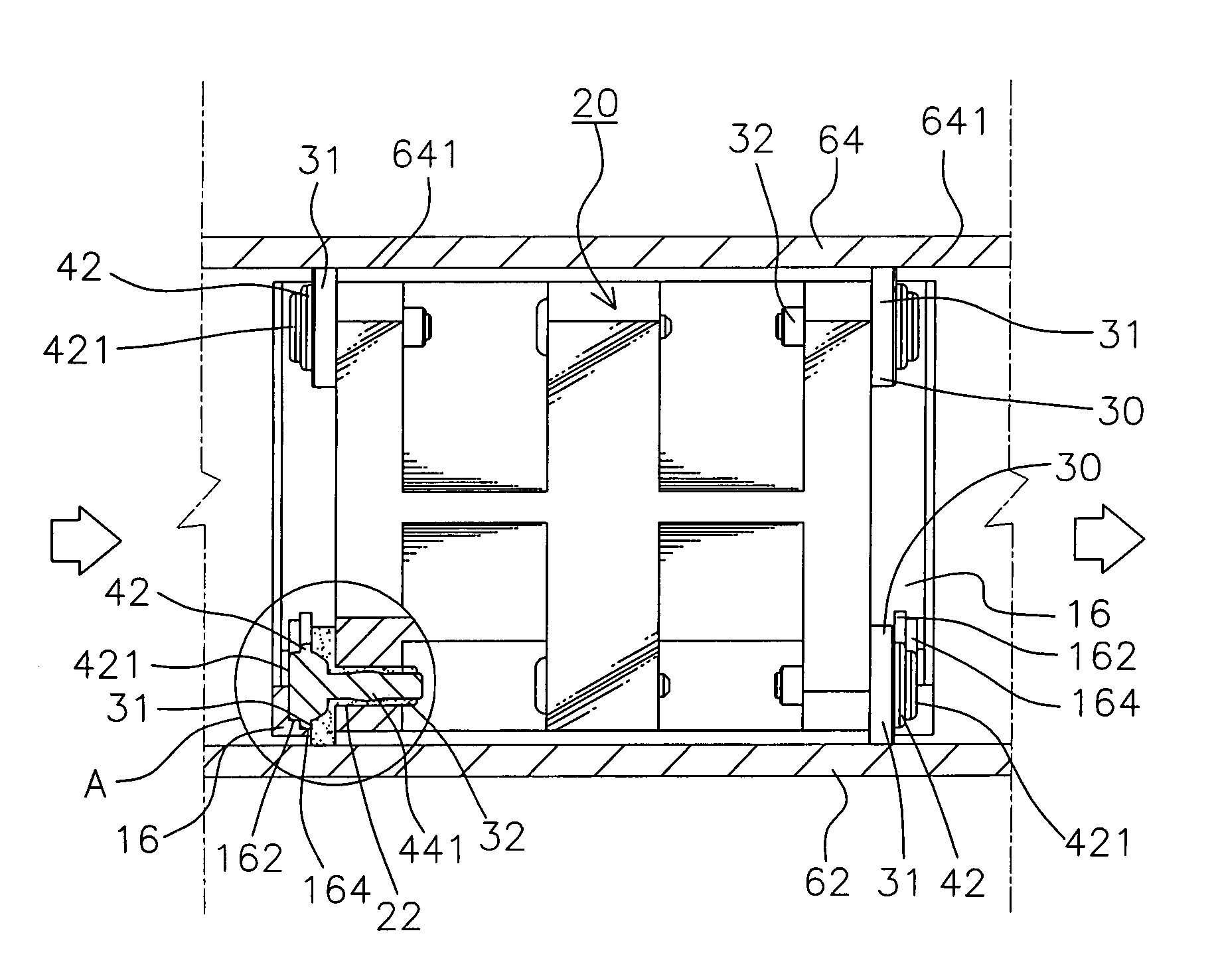

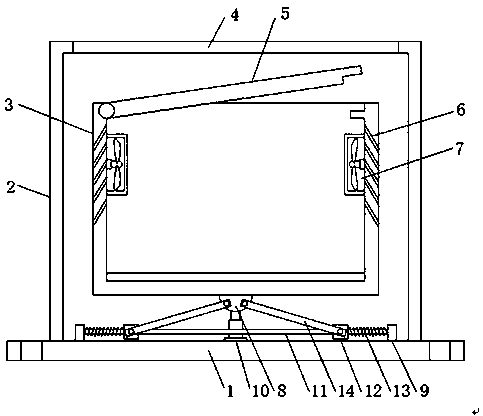

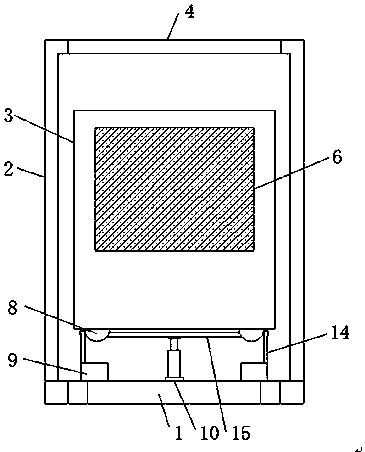

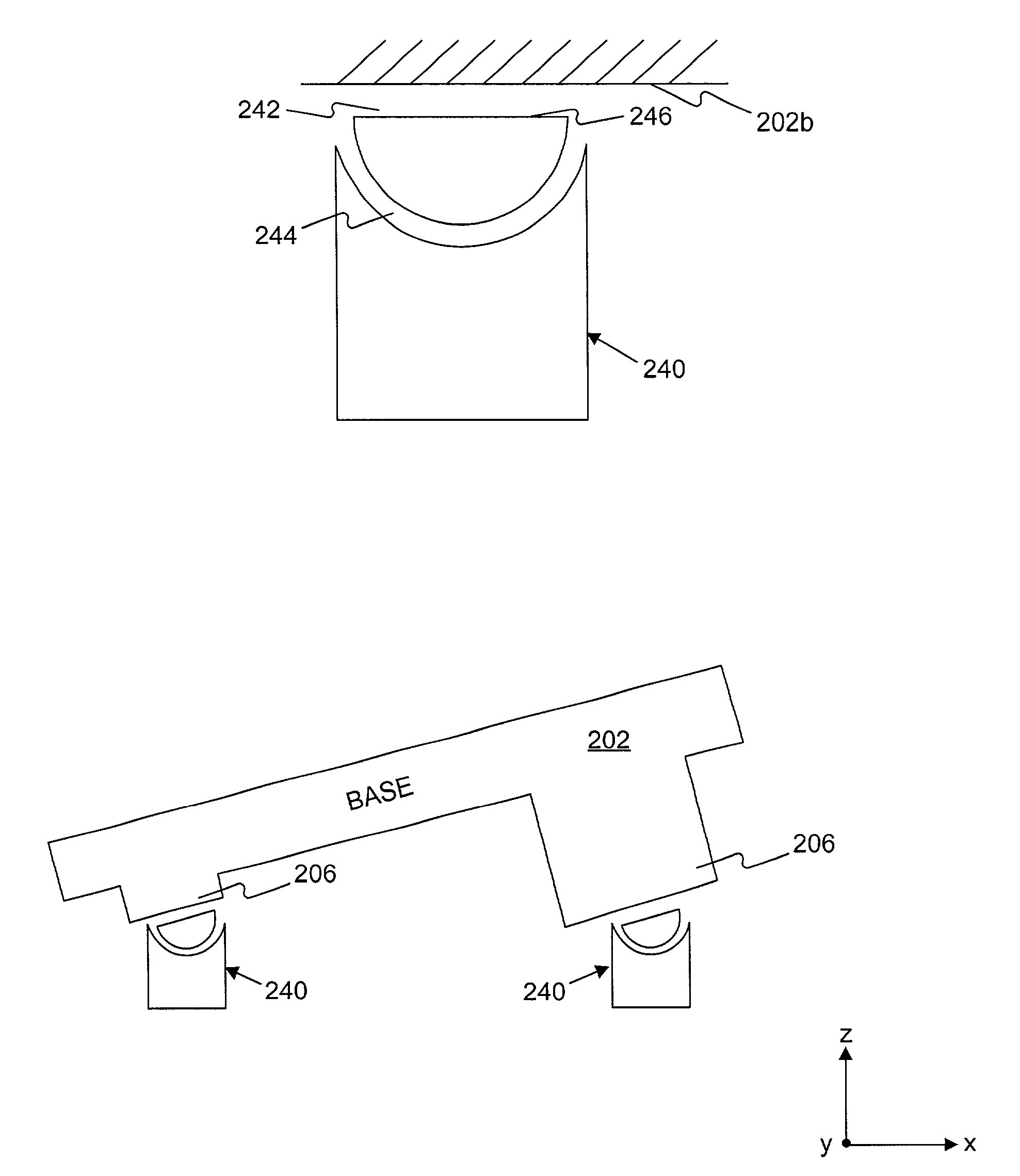

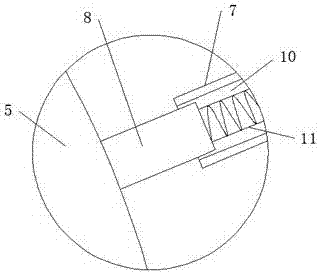

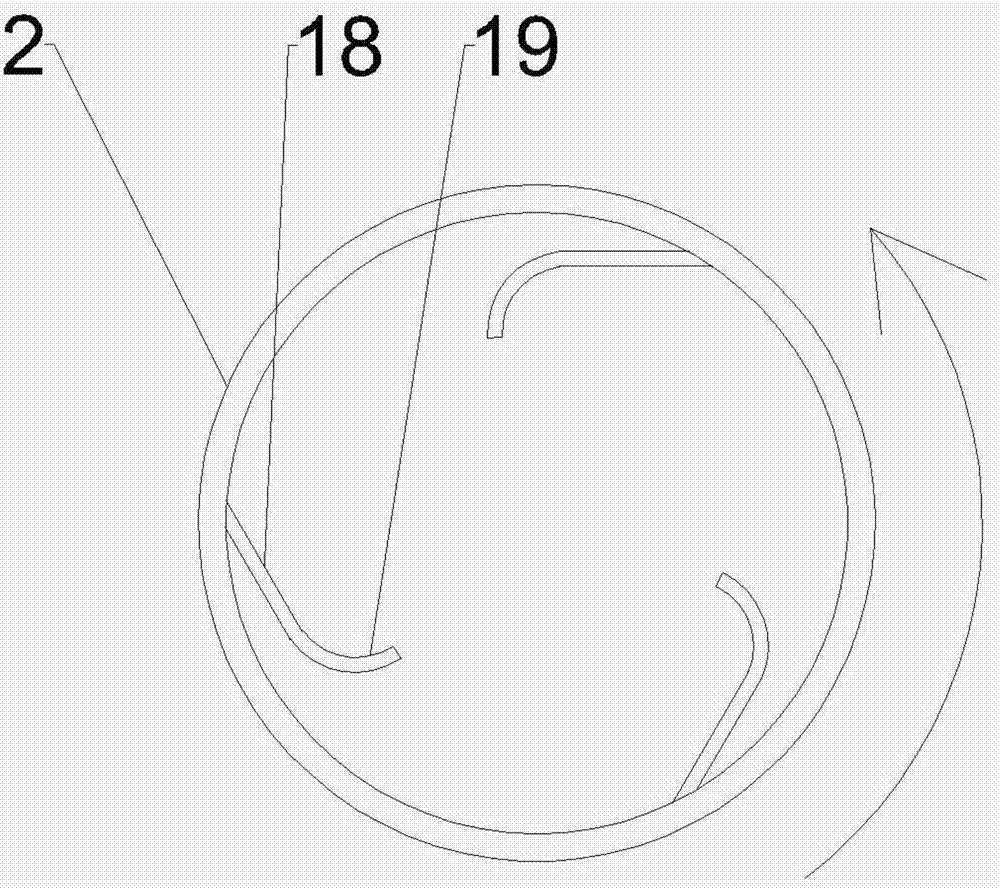

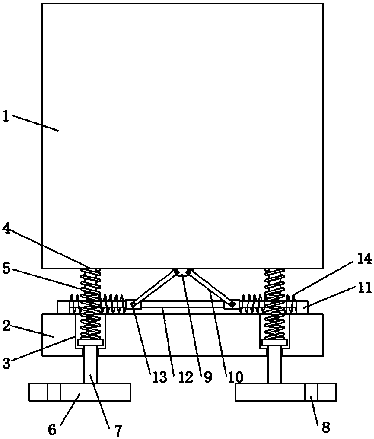

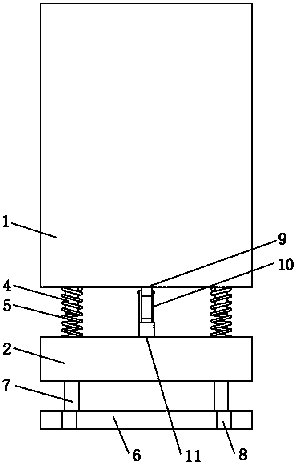

Computer housing shock absorber device for a vibration source frame

ActiveUS7545641B2Reduce riskReduce vibration forcePump componentsDigital data processing detailsFixed frameEngineering

A computer housing shock absorber device for a vibration source frame, which includes:a computer housing provided with a U-shaped holding space;an inner fixing frame fixed within the U-shaped holding space;an outer fixing frame;The shock absorber elements mounted on circumferential edge walls of the connecting holes of the inner fixing frame. Upper and lower portions of each of the recessed circular grooves of the shock absorber elements are respectively provided with a cylindrical body, and one of the cylindrical bodies of each of the shock absorber elements lies between the upper surface of the outer fixing frame and the upper surface of the inner fixing frame. Accordingly, the vibratory moment on the outer fixing frame produced by rotation of the fans is absorbed by the shock absorber elements.

Owner:SUPER MICRO COMP

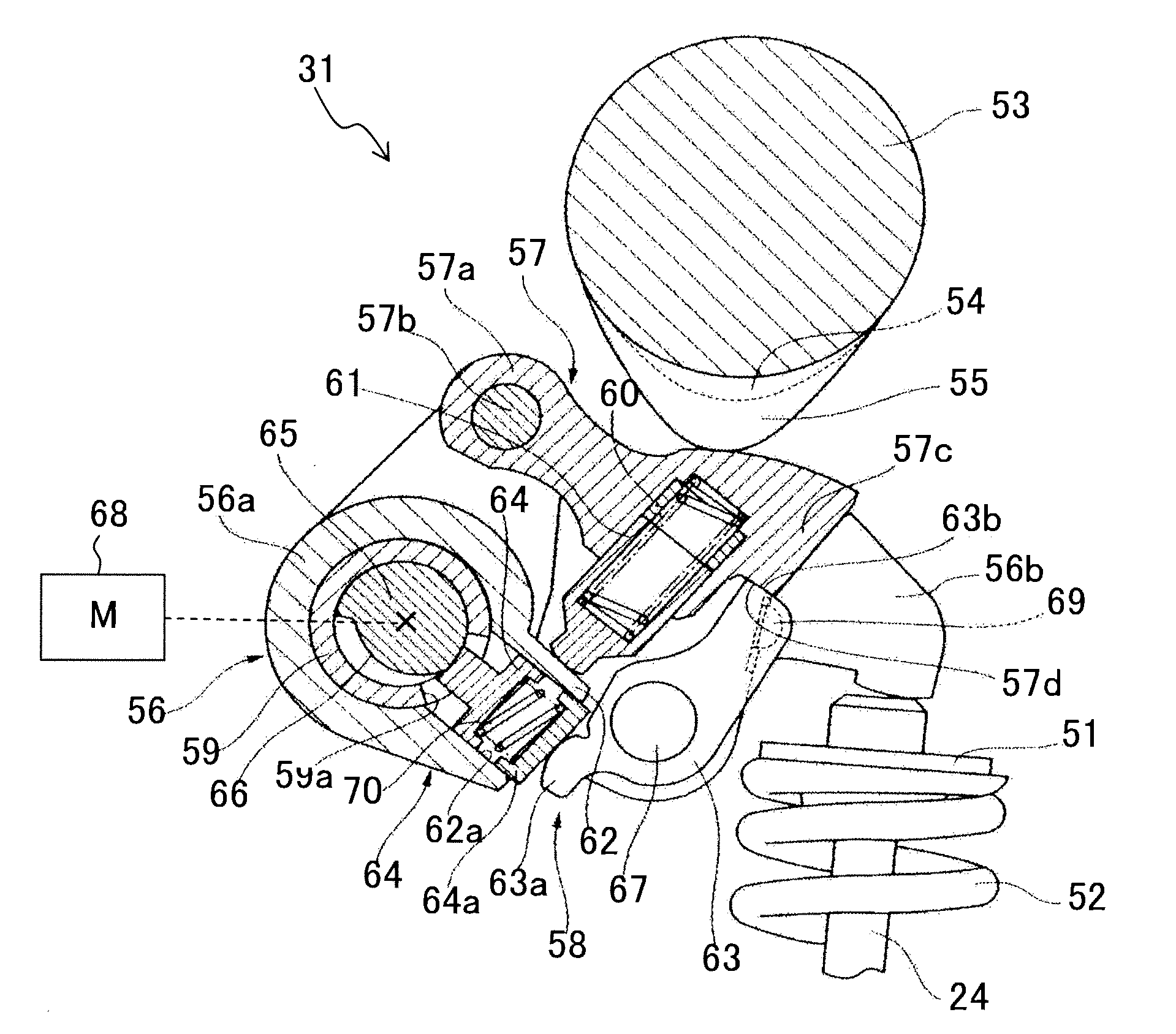

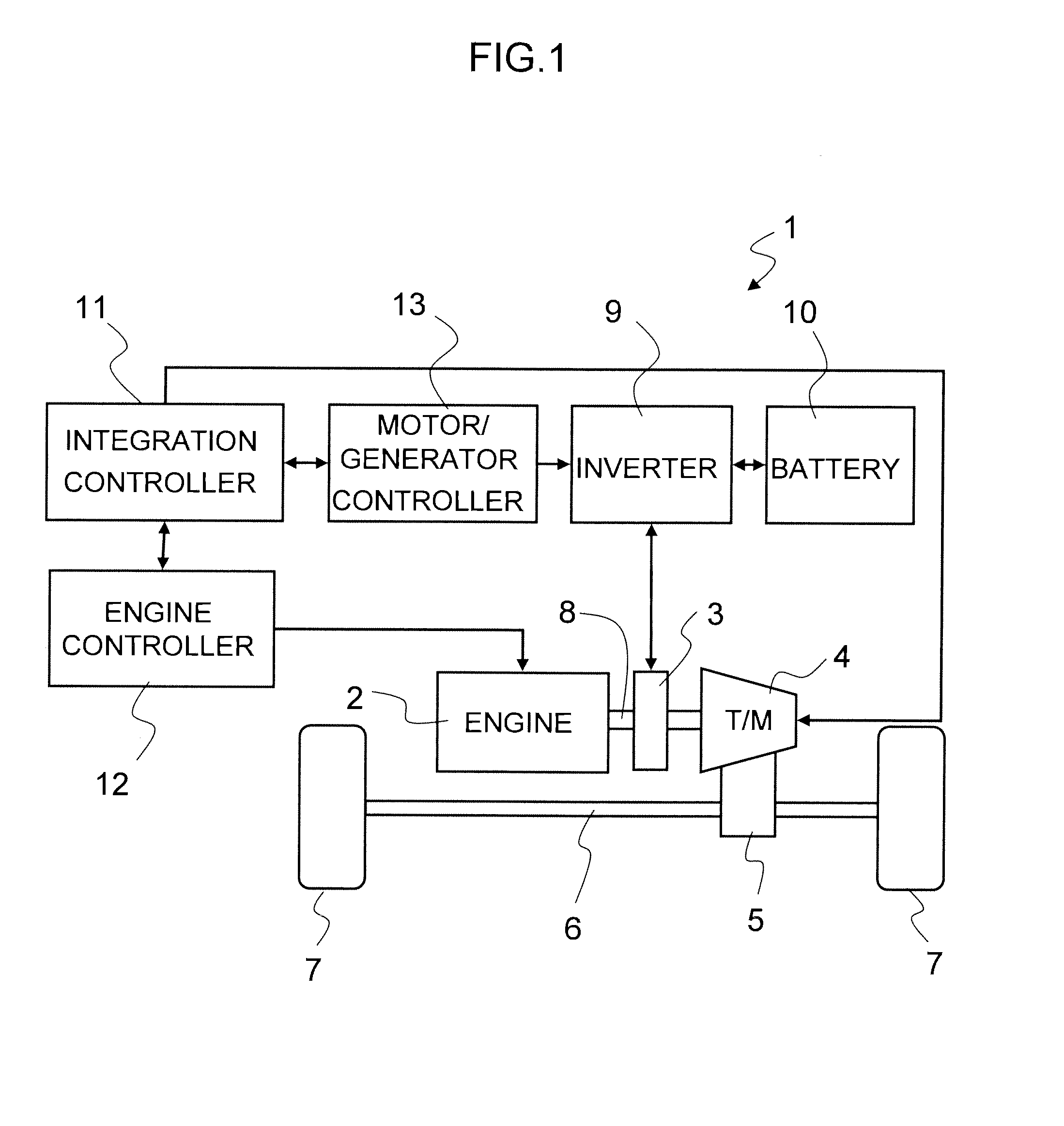

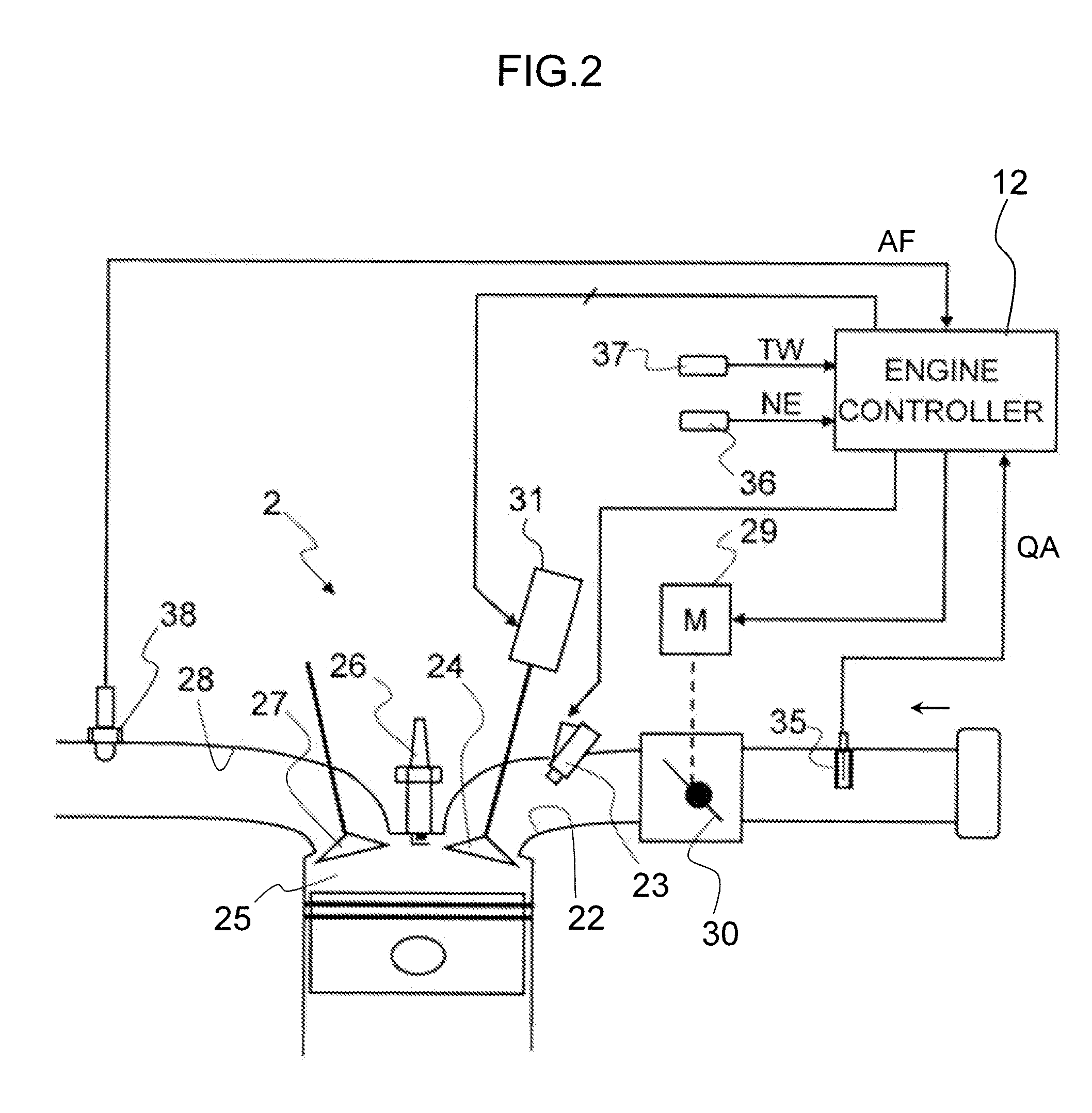

Apparatus for and method of controlling variable valve timing mechanism

InactiveUS20120067309A1Reduce power consumptionReduce vibration forceValve arrangementsElectrical controlVariable valve timingInlet valve

The present invention relates to an apparatus for and a method of controlling a variable valve timing mechanism. The valve timing mechanism changes over between a first cam for which the closing timing IVC of the intake valve is after intake bottom dead center, and a second cam for which the closing timing IVC is closer to intake bottom dead center than the closing timing IVC with the first cam. Here at the time of stopping the internal combustion engine, the valve timing mechanism changes over to the first cam, and the initial intake stroke performs operation at low effective compression ratio. In the second and subsequent intake strokes, the valve timing mechanism changes from the first cam to the second cam.

Owner:HITACHI ASTEMO LTD

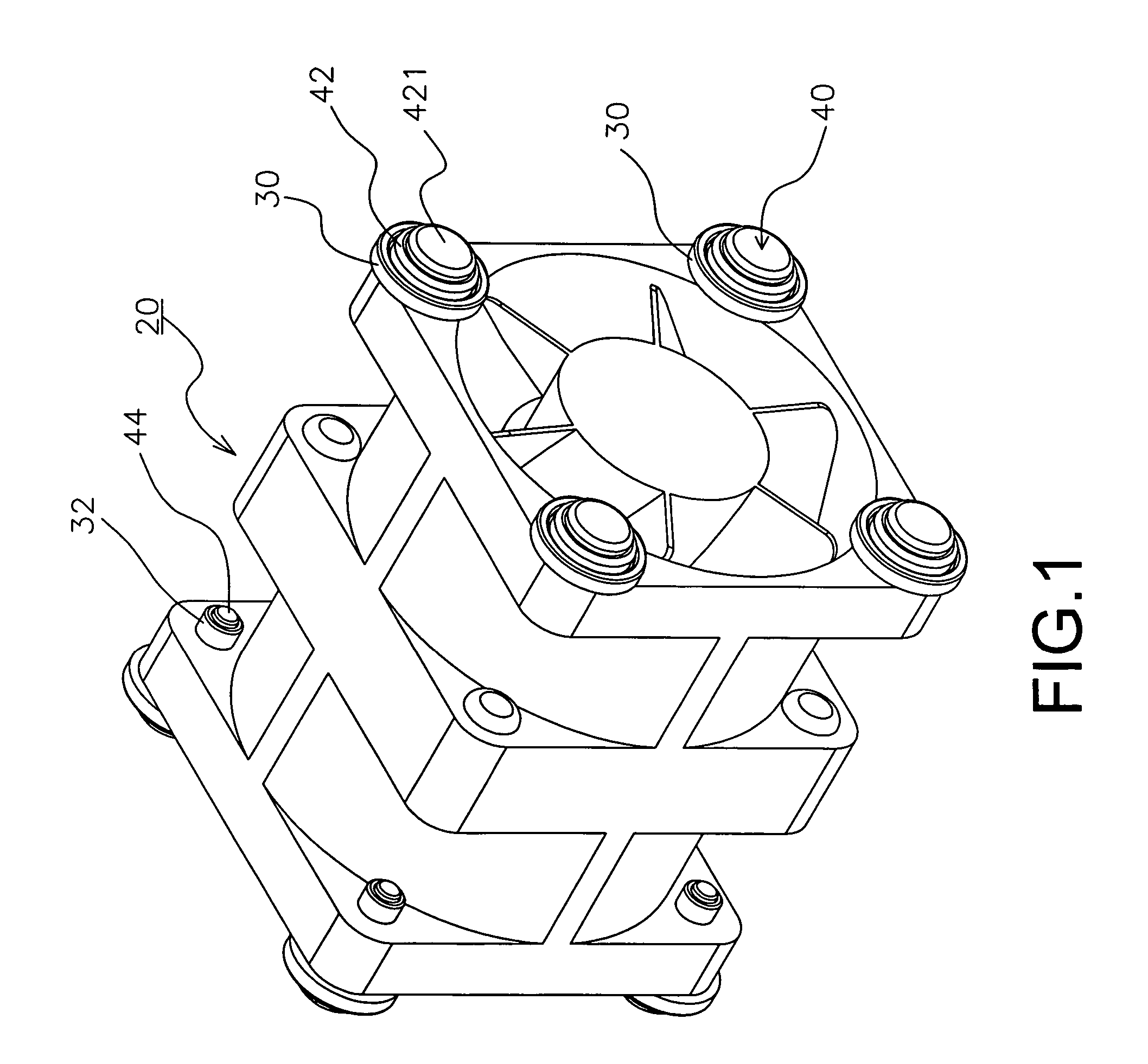

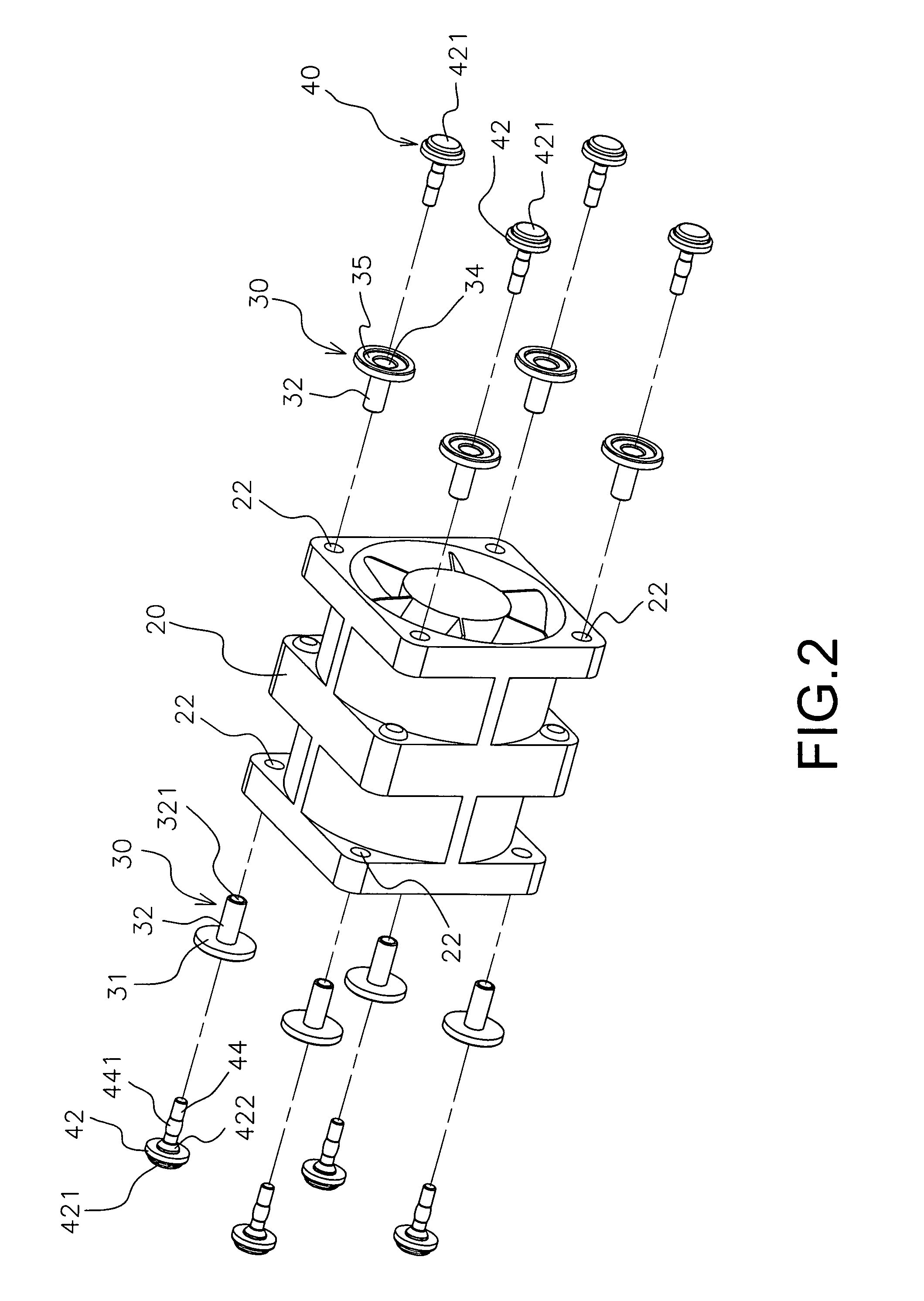

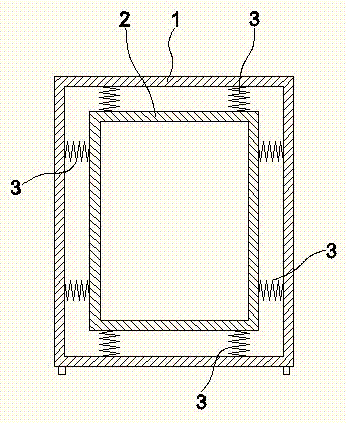

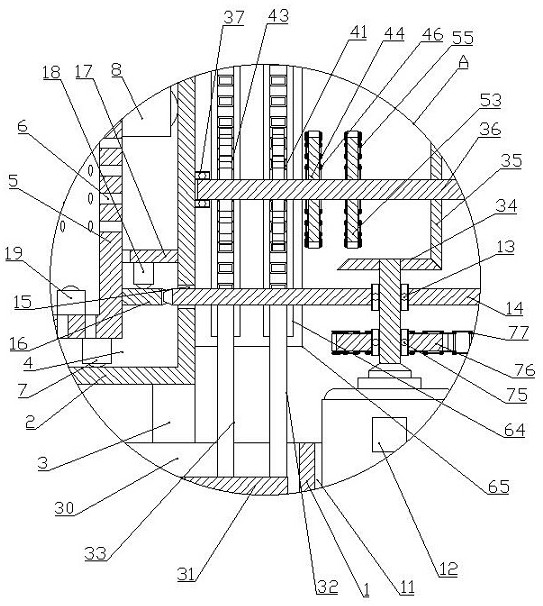

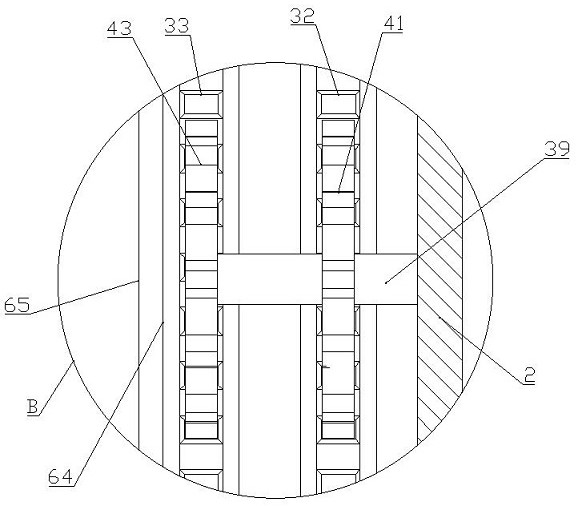

Vibration absorption device for a fan

ActiveUS7488152B2Increase ratingsIncrease speedPump componentsBlade accessoriesEngineeringVibration absorption

A vibration absorption for a fan includes a frame, fans, positioning outer jackets, and pins, wherein the positioning outer jacket is inserted into a latching hole of fan, an outer-projected circular ring of pin is attached to a first groove of frame, and a circular ring of ping is attached to a second groove of frame, so as to reduce a vibration force of fans and to increase a flow rate and a flow speed of air flowing out of the fans.

Owner:SUPER MICRO COMP

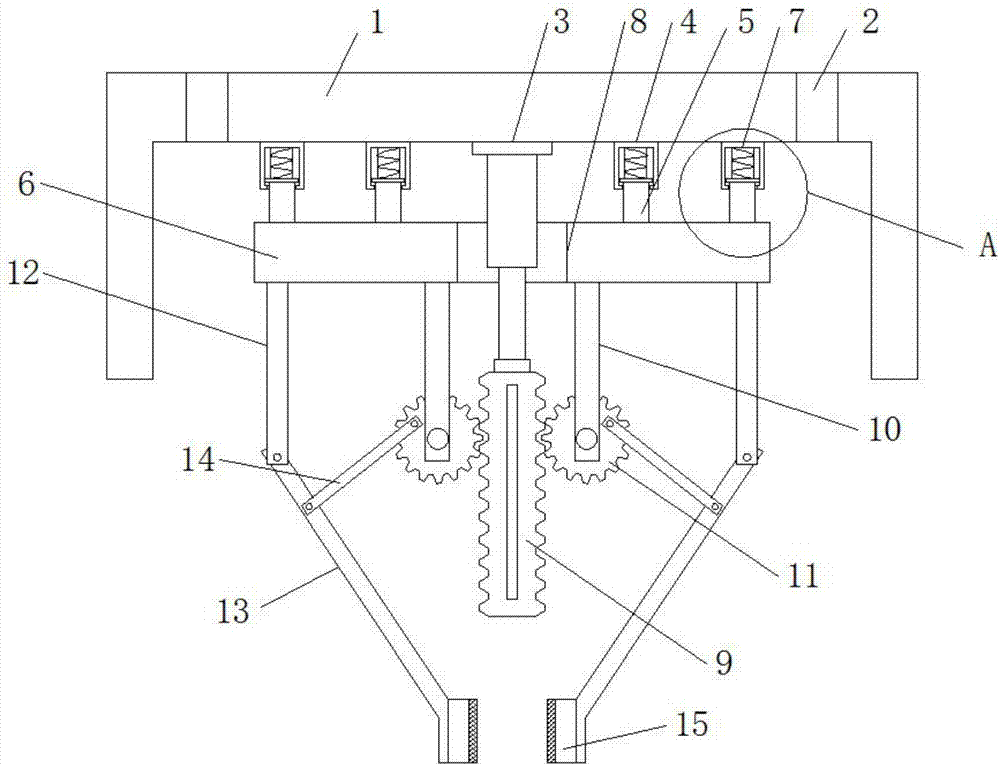

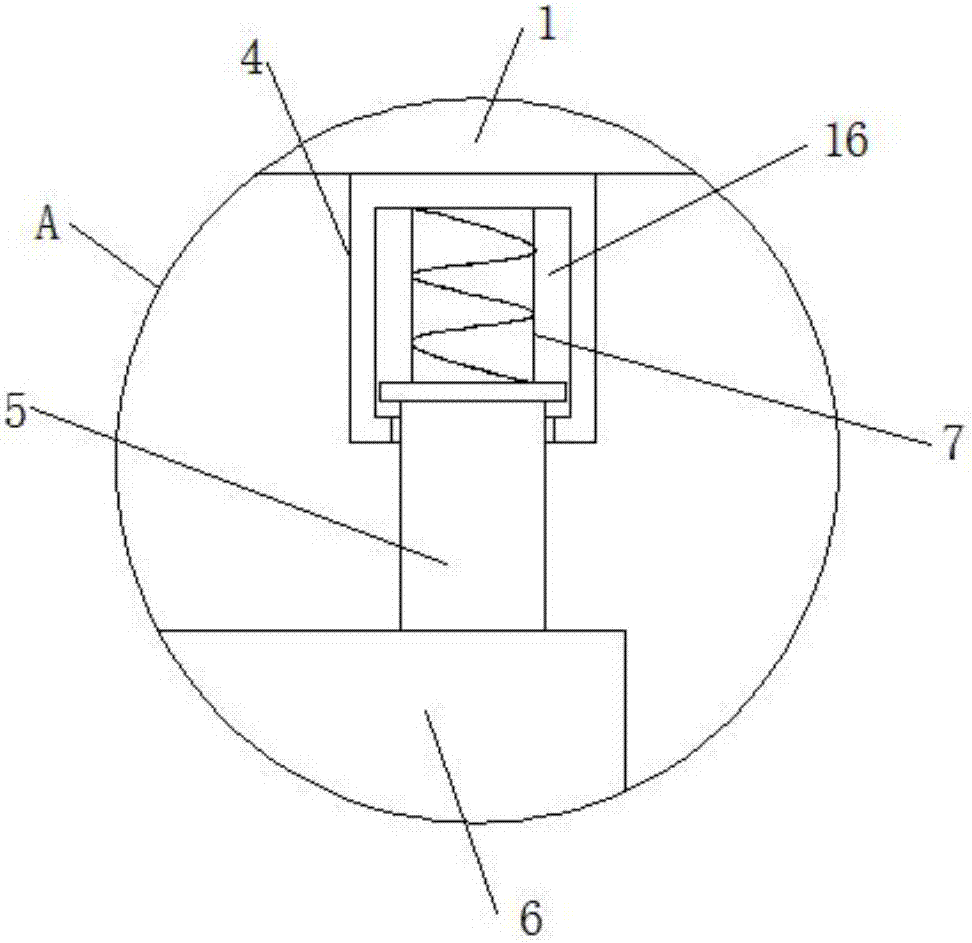

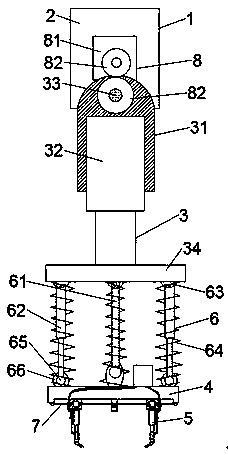

Clamping device of walking agricultural machine

InactiveCN107336254AEasy to holdReduce vibration forceGripping headsWork holdersAgricultural engineeringPiston rod

The invention discloses a clamping device of a walking agricultural machine. The clamping device comprises a fixed base. A plurality of mounting holes are formed in each of the two sides of the fixed base. An air cylinder and supporting rods are fixedly mounted at the bottom of the fixed base. The supporting rods are located on the two sides of the air cylinder. Buffering rods and buffering plates are arranged under the supporting rods correspondingly. A storage groove is formed in the side, close to the corresponding buffering rod, of each supporting rod. The inner wall of the top end of each storage cavity is fixedly connected with one end of a spring. The other end of each spring is connected with one end of the corresponding buffering rod. The other end of each buffering rod is perpendicularly connected with the corresponding buffering plate. A through hole is formed in the middle of each buffering plate. A rack is arranged at the bottom of the air cylinder and fixedly connected with a piston rod of the air cylinder. Supports are arranged on the two sides of the rack correspondingly and fixedly welded to the bottom ends of the buffering plates. The bottoms of the supports are sleeved with gears, and the gears are engaged with the racks. The clamping device is reasonable in design and high in clamping precision, and the operating quality of the machine is effectively improved.

Owner:HEFEI XIONGCHUAN MACHINERY SALE CO LTD

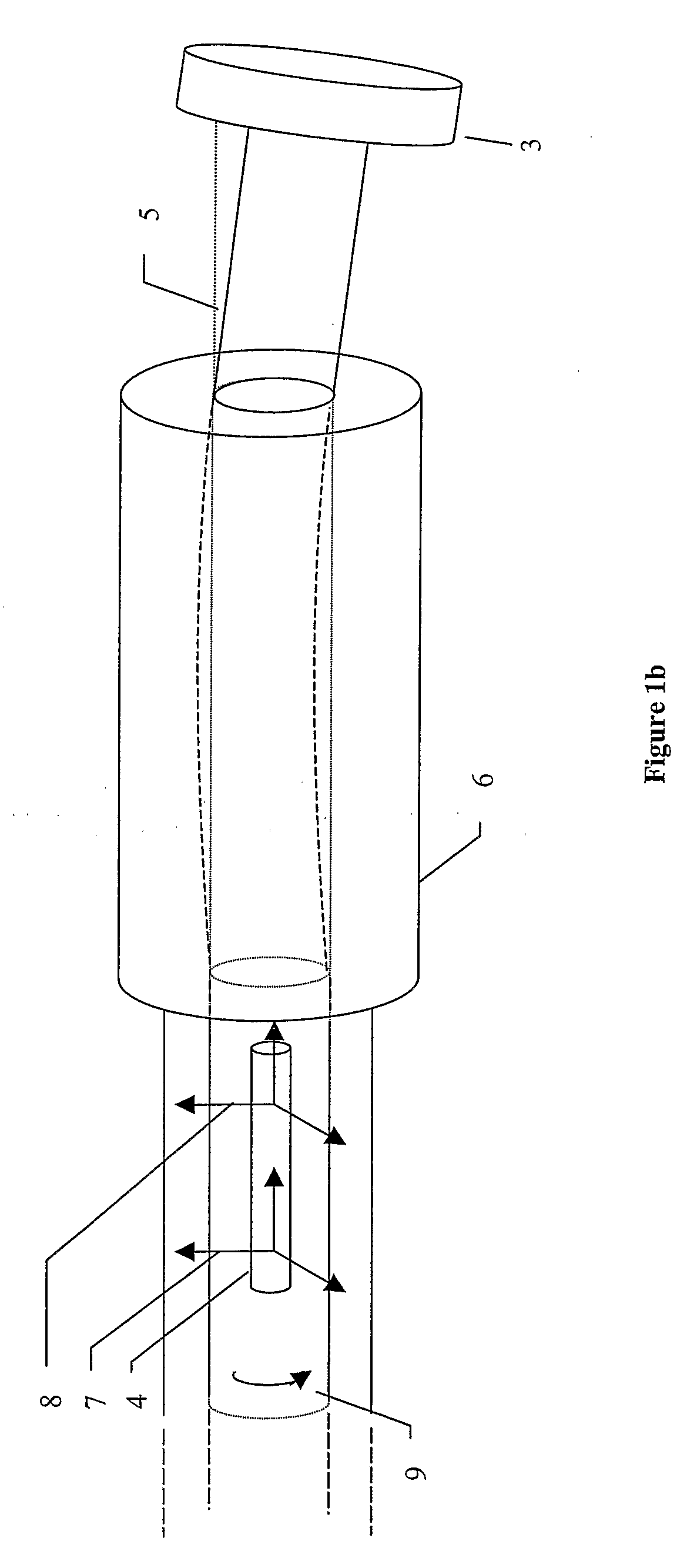

Closed Loop Control Bore Hole Drilling System

ActiveUS20080128171A1Improve outputReduce relative motionSurveyDirectional drillingDrill holeDrilling system

Owner:HALLIBURTON ENERGY SERVICES INC

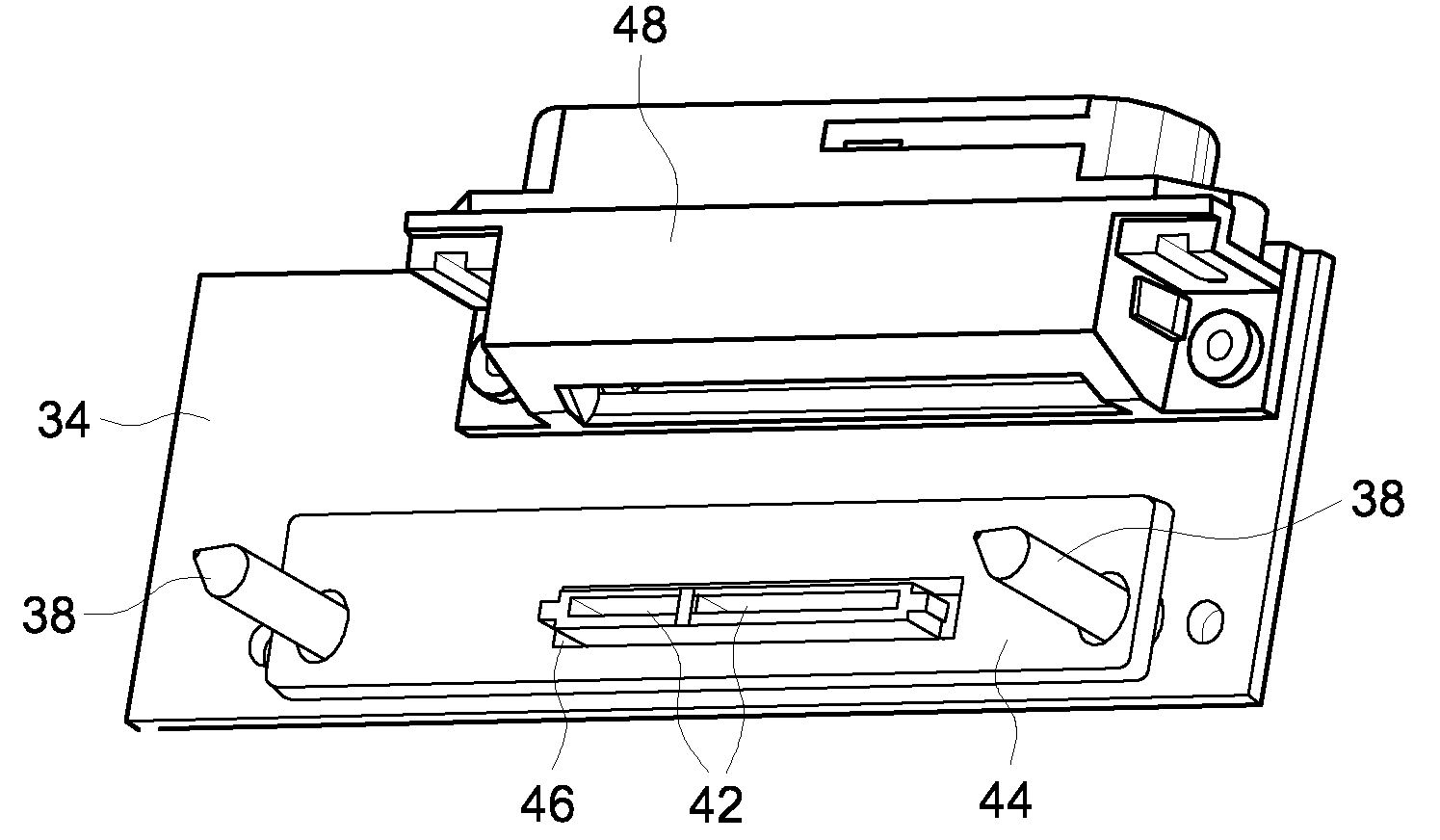

Apparatus for securing electronic equipment

ActiveUS8331084B2Facilitate electrical communicationFacilitates electrical communicationDigital data processing detailsPrinted circuit board receptaclesElectricityEngineering

An apparatus for securing electronic equipment. The apparatus includes an electronic device having a first mating portion. The device is removably secured within a shell, which has an open end allowing access to the first mating portion. The apparatus further includes a dock having a second mating portion and an output connector in electrical communication with the second mating portion. The dock removably receives the shell to facilitate electrical communication between the first and second mating portions. The output connector facilitates electrical communication between the electronic device and a device external to the dock. The apparatus also includes a damping mechanism to reduce vibratory forces on the first and second mating portions and relative movement between the portions.

Owner:GE GLOBAL SOURCING LLC

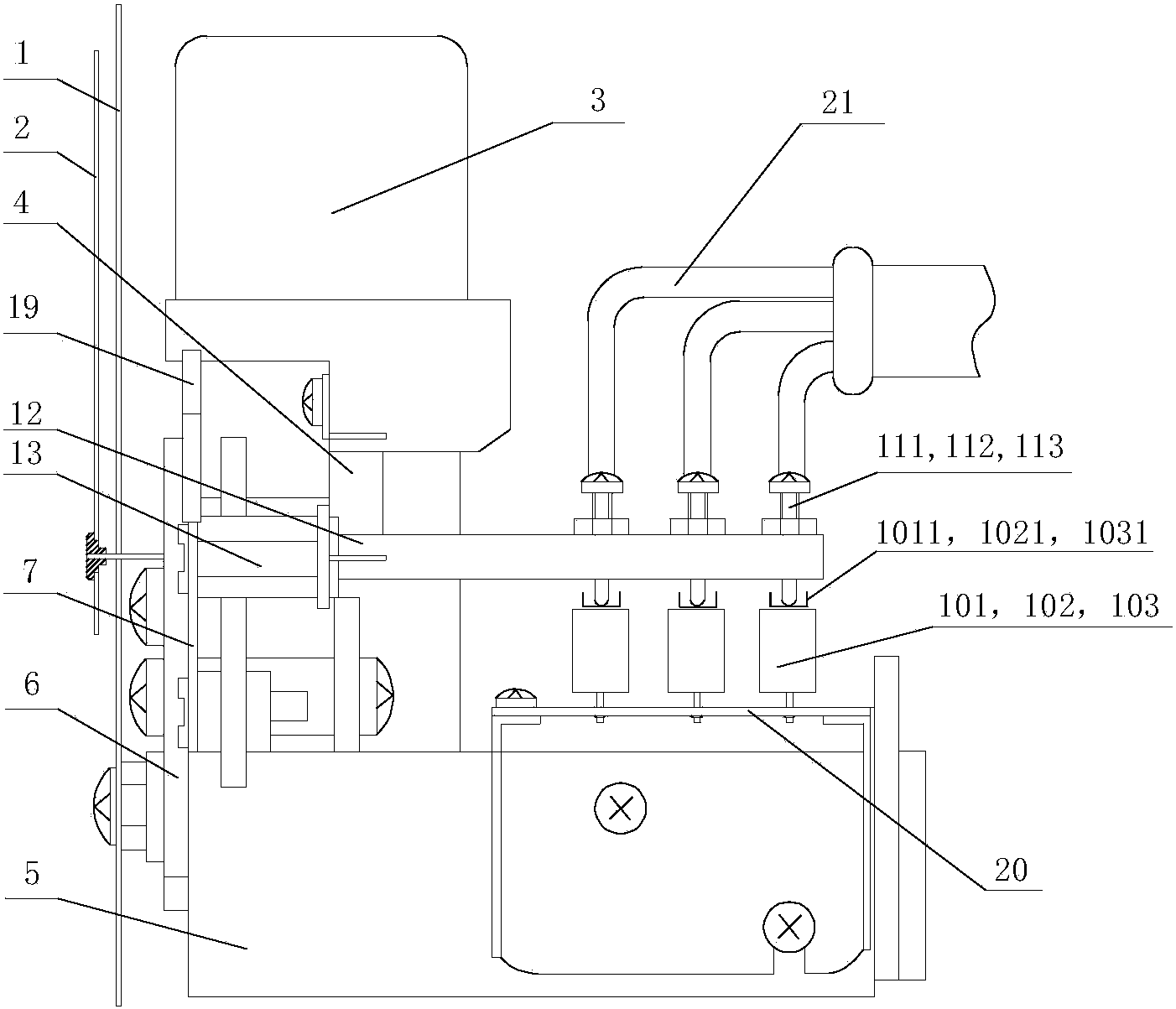

Protection device for charging pile power supply

InactiveCN107696887AAvoid dust accumulationProtection from damageCharging stationsModifications for power electronicsComputer fanEngineering

The invention discloses a protection device for a charging pile power supply. The protection device comprises a fixed seat, a housing and a device body, wherein the housing and the device body are both in a cavity structure; the fixed seat is fixed on the bottom end of the housing; the device body is disposed in the housing; a ventilating port is formed in the top end of the housing; a top lid ishinged to the top end of the device body; a plurality of heat radiation holes arrayed in a straight way are formed on the tops of the two sides of the device body; heat radiation fans are mounted on the inner walls of the two sides of the device body; the heat radiation fans are corresponding to the heat radiation holes; two fixing blocks are arranged in the middle of the bottom end of the devicebody; the fixing blocks are arranged on two sides of the bottom of the device body; an elevating plate is horizontally connected between the two fixing blocks; and a vertically-arranged air cylinder is fixed in the middle of the top end of the fixed seat. The protection device is rationally designed and simple to operate, has obvious heat radiating effect, protect the power supply from damages, and can effectively prolong service life of the power supply.

Owner:ANHUI MINGRUI INTELLIGENT TECH CO LTD

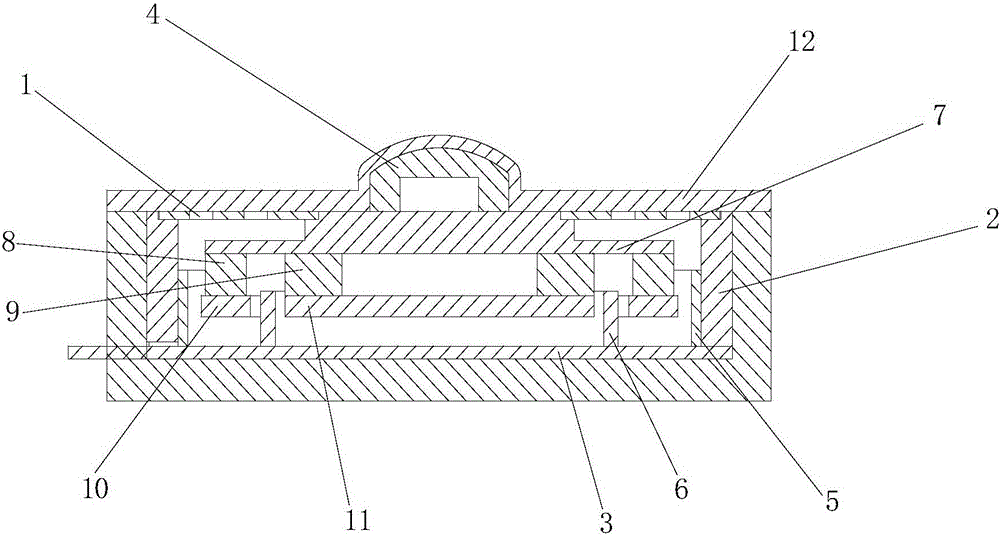

Touch prompting device and wireless earphone

InactiveCN103402152AExtended service lifeSolve Vibration ProblemsEarpiece/earphone attachmentsReciprocating motionElectrical polarity

The invention relates to a touch prompting device and a wireless earphone. The touch prompting device comprises a power drive, a first magnet, a second magnet and a touch part, wherein the power drive is connected with electromagnets in the first and second magnets and used for generating an electromagnetic field through driving the electromagnets according to trigger signals; the first magnet is fixed in a shell, and the second magnet repeats a reciprocating motion of approaching and keeping away from the first magnet according to the polar variation of a self electromagnetic field or the polar variation of the electromagnetic field of the first magnet; and the touch part is connected with the second magnet, protrudes out of the shell and touches the skin of a user according to the reciprocating motion of the second magnet. The touch prompting device and the wireless earphone provided by the invention can be worn by users and can also be arranged on various electronic equipment which can be worn by the users; the touch prompting device prompts the users in a skin touching manner and can be used for solving problems which are not easily found out by users in a vibration prompting manner; and the triggered vibration force is small, the service life of the electronic equipment cannot be shortened when the touch prompting device is arranged on the electronic equipment, and the touch prompting device is energy-saving and environmental-friendly.

Owner:1MORE ACOUSTIC TECH CO LTD

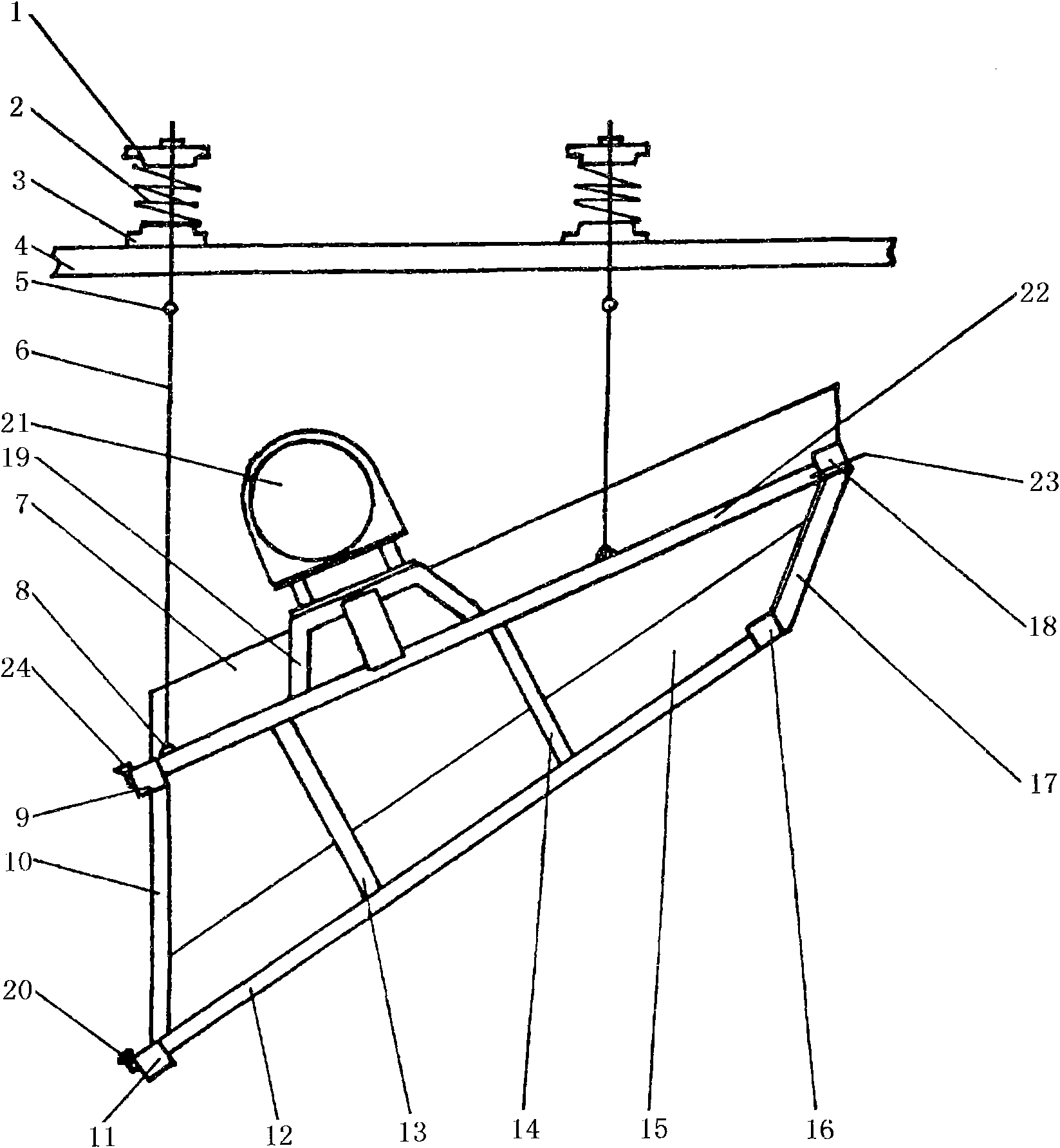

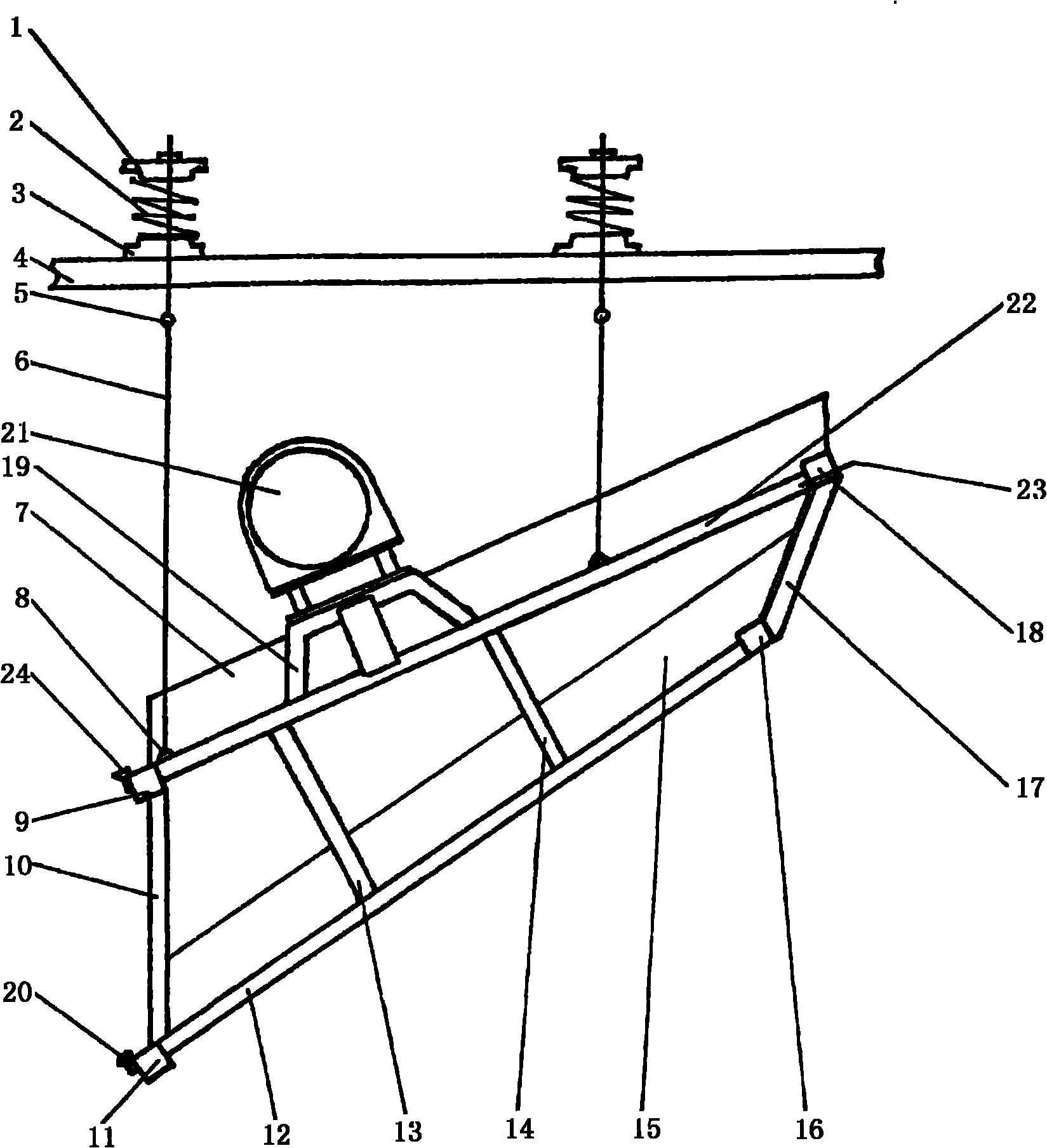

Water retaining device

ActiveCN103015375AReduce forced vibrationWon't flipBarrages/weirsAgricultural irrigationSystems management

The invention discloses a water retaining device in the field of water conservancy facilities. The water retaining device comprises at least one group of water retaining boards which are integrally arranged in a watercourse, gate walls are arranged on two sides of the watercourse, a concrete foundation is arranged at the bottom of the watercourse, supporting piers are arranged on one sides of back faces of the water retaining boards in each group, rollers are arranged at the bottoms of the water retaining boards and supported on the concrete foundation, an oil cylinder is arranged between each water retaining board and the corresponding supporting pier, an oil cylinder block is hinged onto the corresponding supporting pier, and an extending end of an oil cylinder piston rod is hinged to the lower portion of the corresponding water retaining board. A hinge rod is further arranged on one side of the back face of each water retaining board, the upper end of each hinge rod is hinged to the upper portion of the corresponding water retaining board, and the lower end of each hinge rod is hinged onto a hinge seat which is fixed onto the concrete foundation. The water retaining device is high in structural strength, low in energy consumption, flexible in operation and investment-saving and can be used for various water conservancy constructions such as reservoir construction, watercourse flood flowing, urban water system management and agricultural irrigation.

Owner:YANGZHOU CHUMEN ELECTROMECHANICAL DEVICES MFG

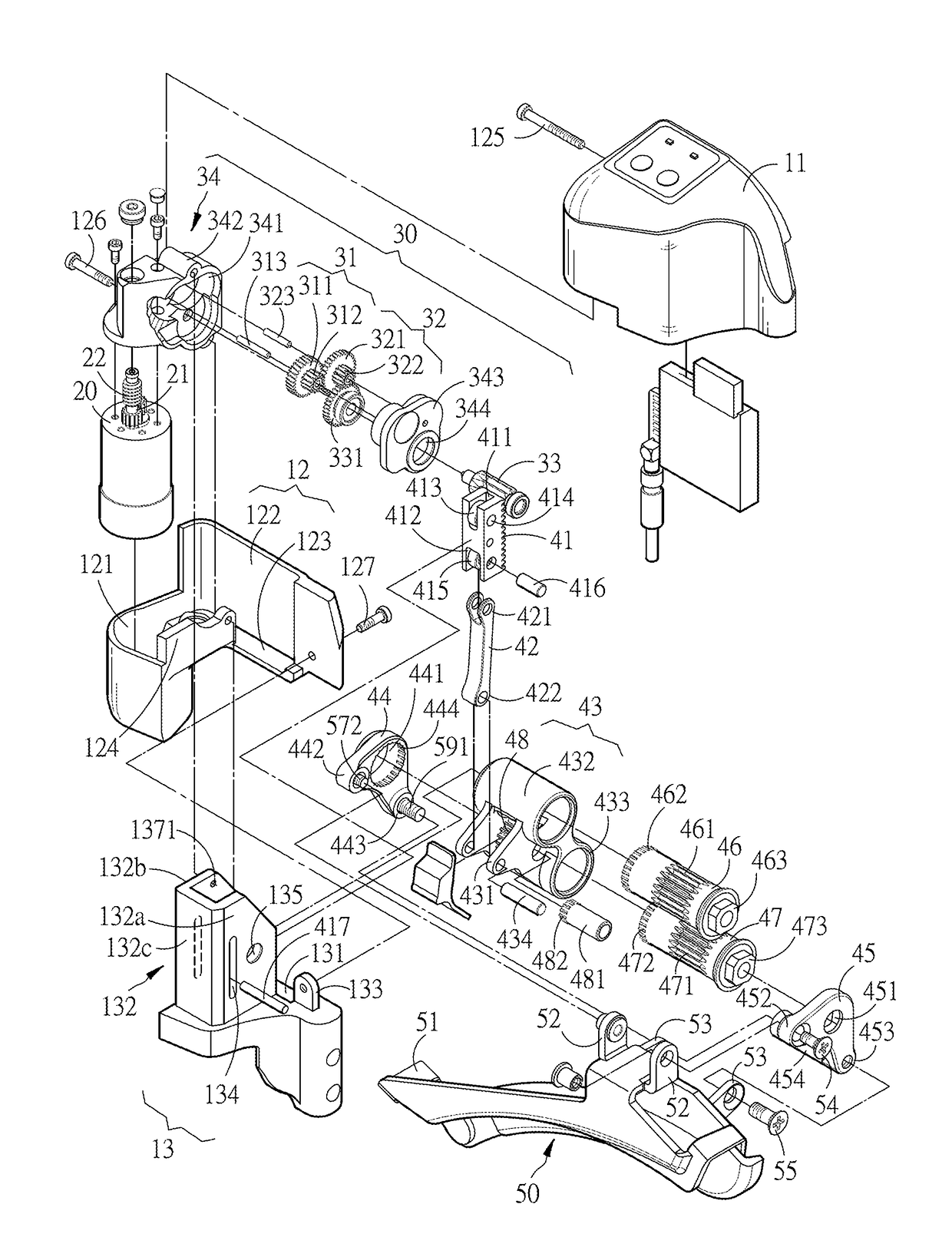

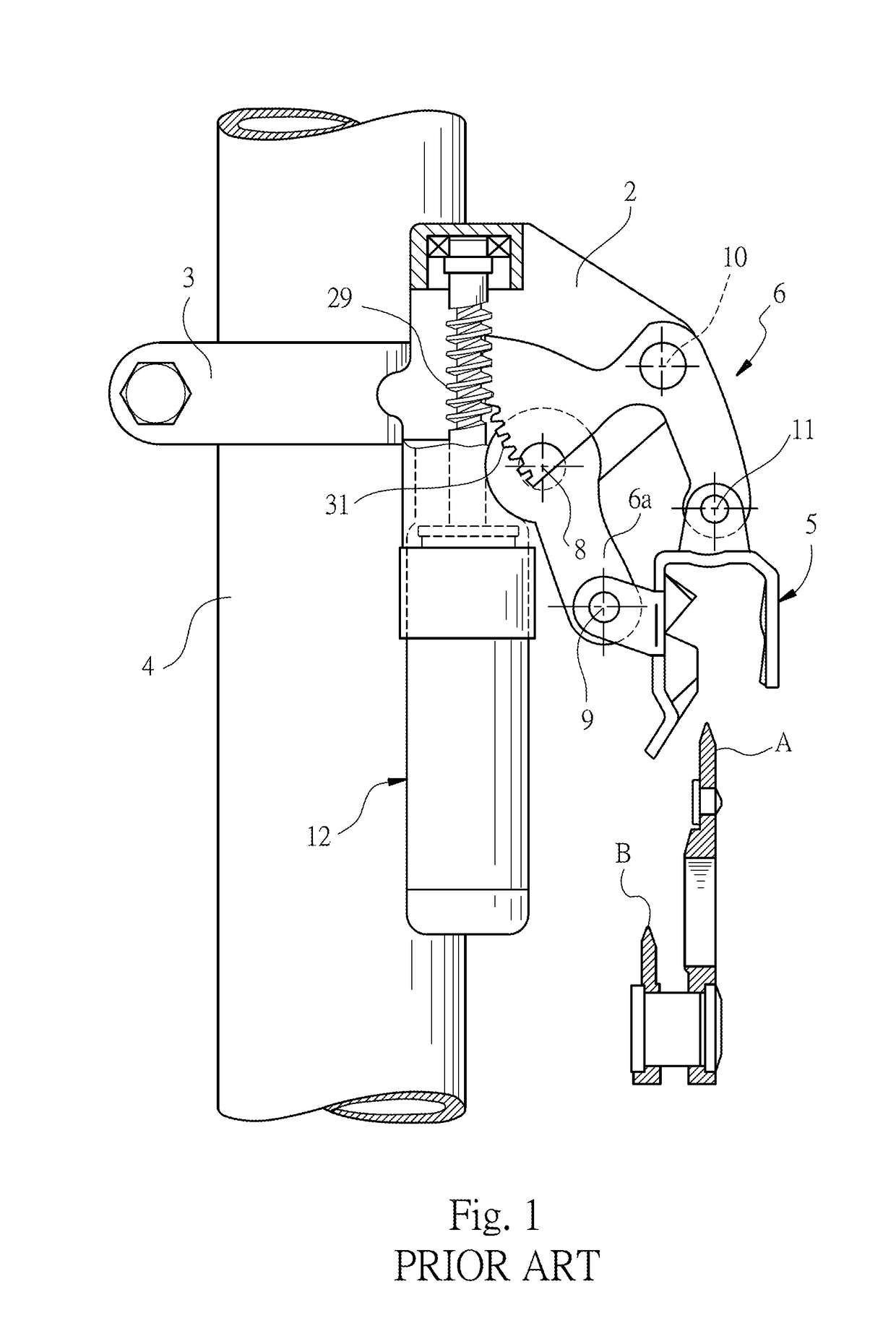

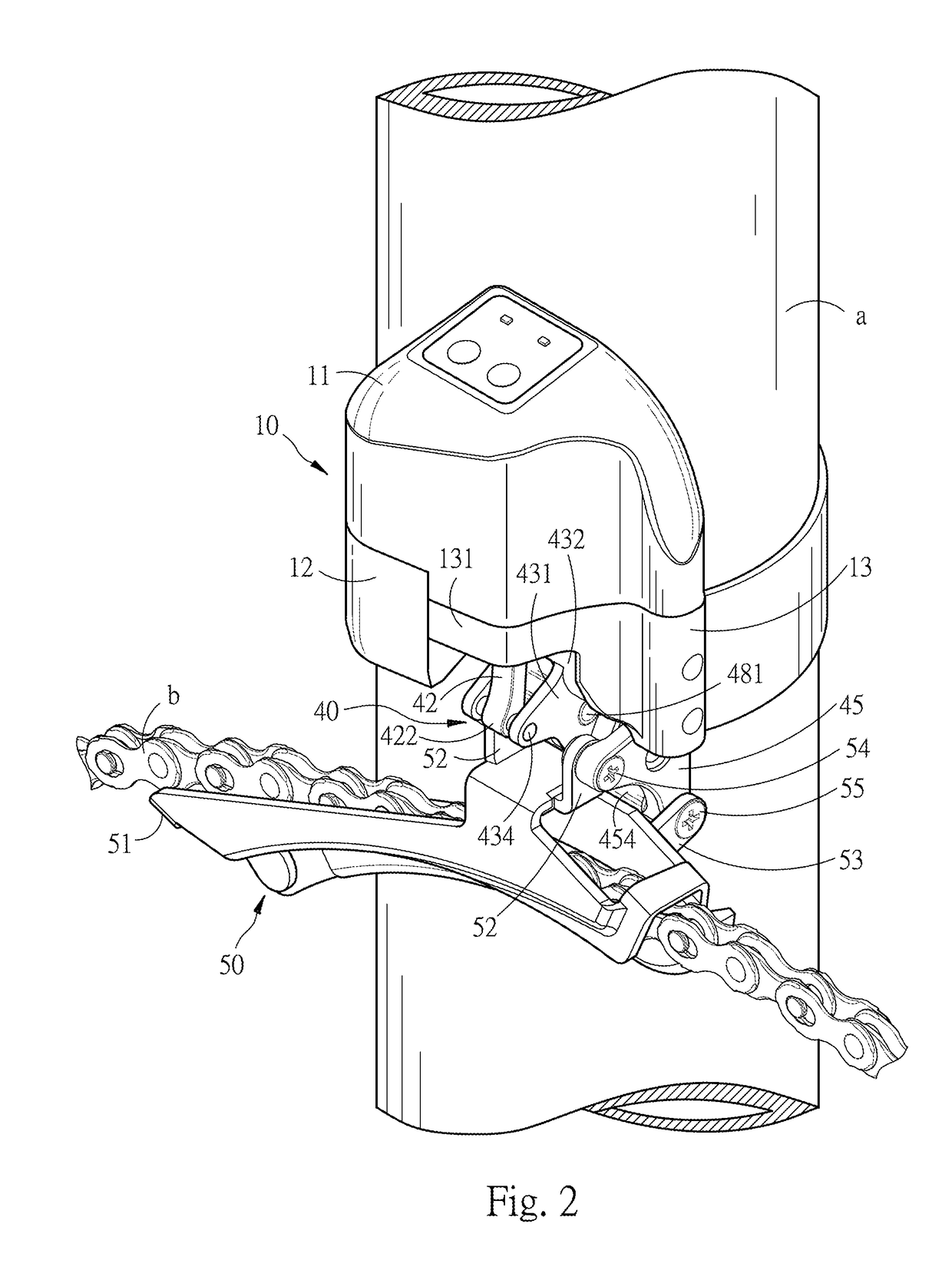

Electric front derailleur

ActiveUS20170334519A1Reduce vibration forceAvoid problemsChain/belt transmissionCycle actuatorsMechanical engineeringRack and pinion

Owner:TIEN HSIN INDS

Intelligent material carrying mechanical arm and carrying method

InactiveCN109677905AIncrease the lengthIncrease the efficiency of grabbing materialsConveyor partsEngineeringManipulator

The invention discloses an intelligent material carrying mechanical arm and carrying method. The mechanical arm comprises a mechanical carrying hand, the mechanical carrying hand comprises a first supporting arm, a second extension arm, a mechanical palm and a four-finger grabbing device; the first supporting arm is connected with the second extension arm through a hinge shaft, the second extension arm is connected with the mechanical palm through a palm turning mechanism, and the bottom end of the mechanical palm is connected with the four-finger grabbing mechanism through a four-shaft synchronous driving mechanism. The method comprises the steps that a walking carrying trolley walks to the position nearby the material, the first supporting arm, the second extension arm, the mechanical palm and the four-finger grabbing device are matched, the material is grabbed, the trolley and the mechanical arm cooperate to convey the material to the designated position, the material is loosened, the mechanical arm returns to the grabbing point to continuously grab the material, an extension oil cylinder of the second extension arm can extend, the length of the mechanical arm is prolonged, themechanical grabbing ends can rapidly approach to the material, the material grabbing efficiency and accuracy are high, the structure is simple, the cost is low, the material is not prone to being damaged due to clamping, and the material transport is more stable and reliable.

Owner:盐城汇金科技信息咨询服务有限公司

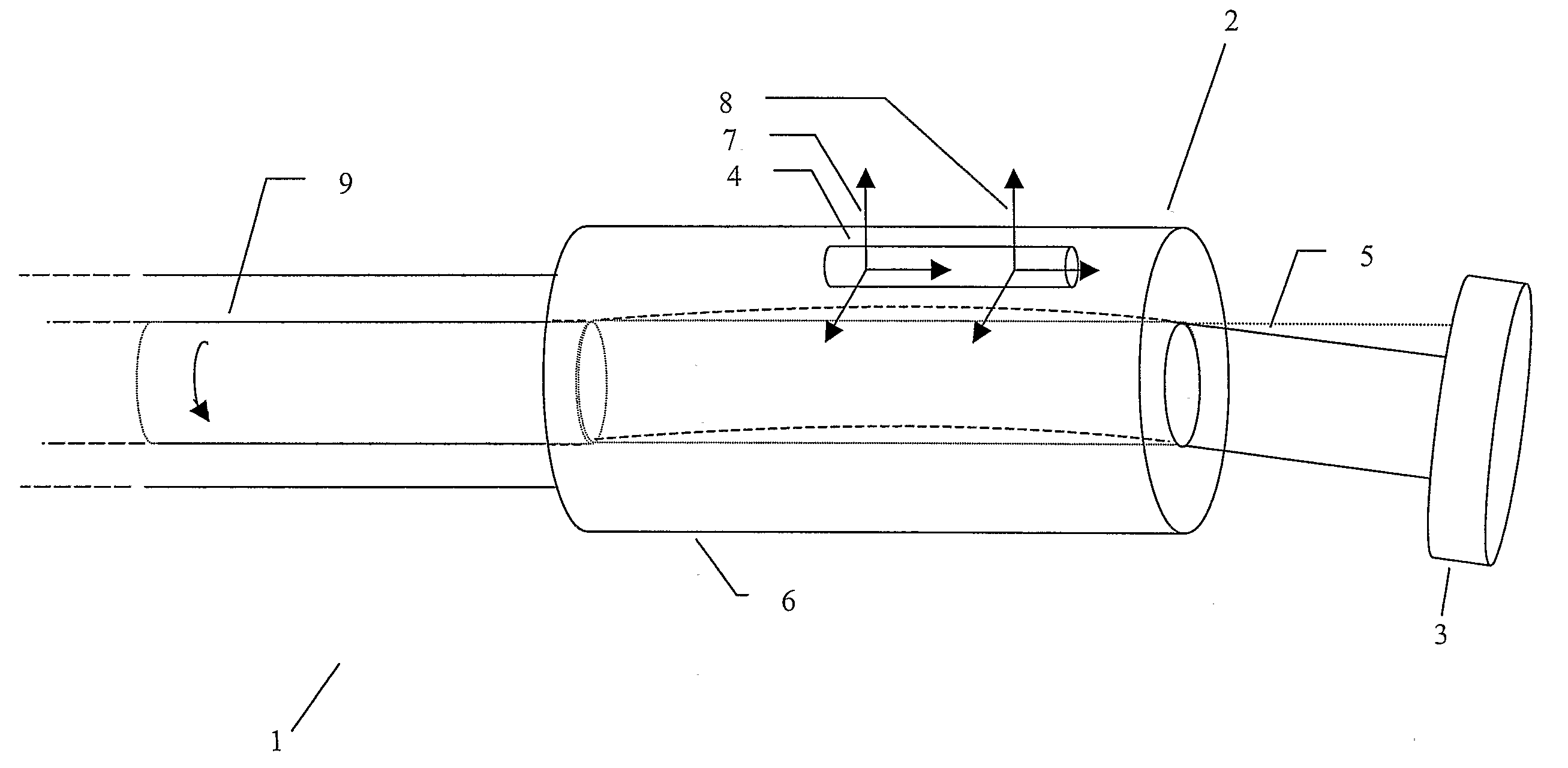

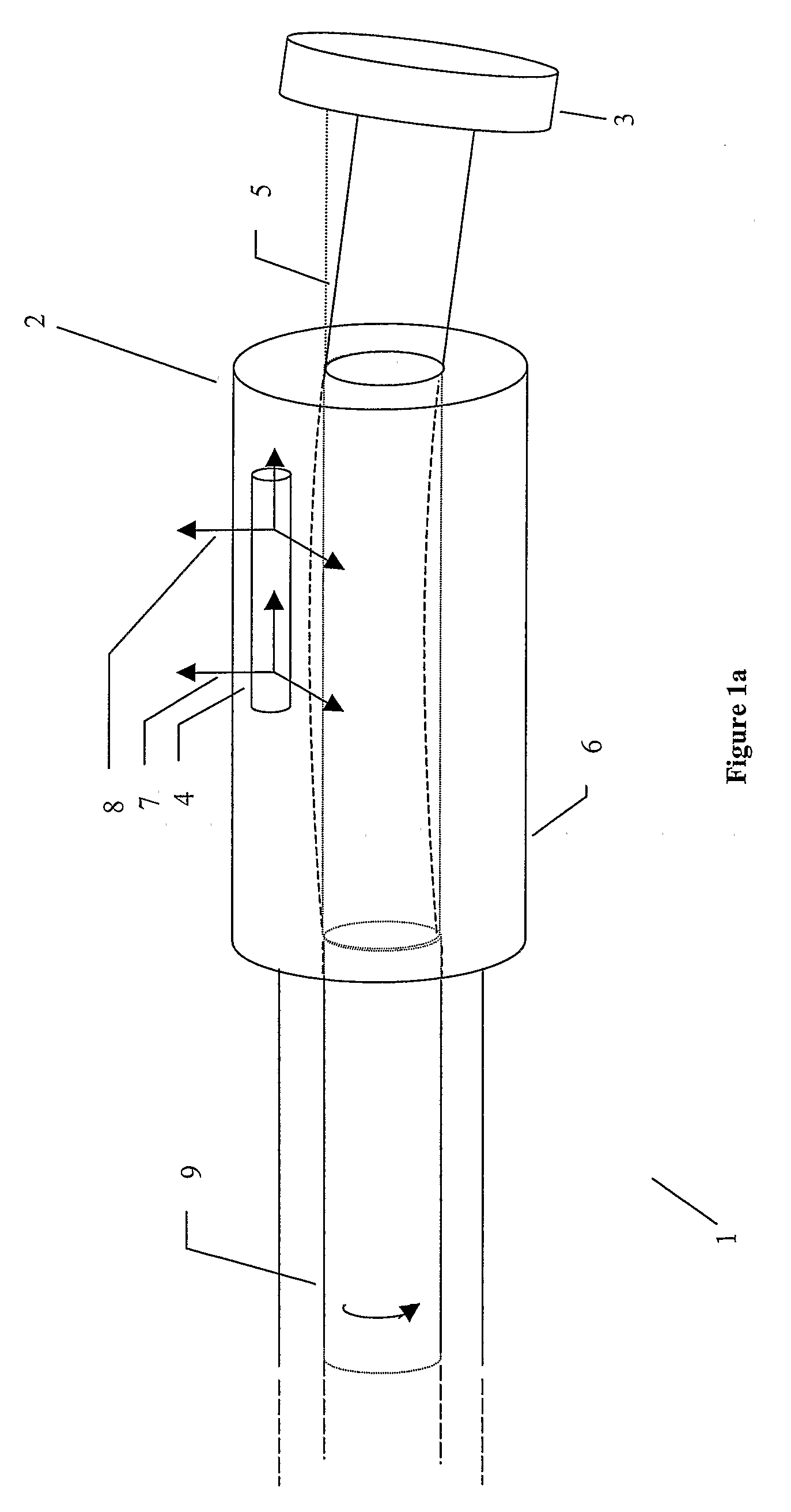

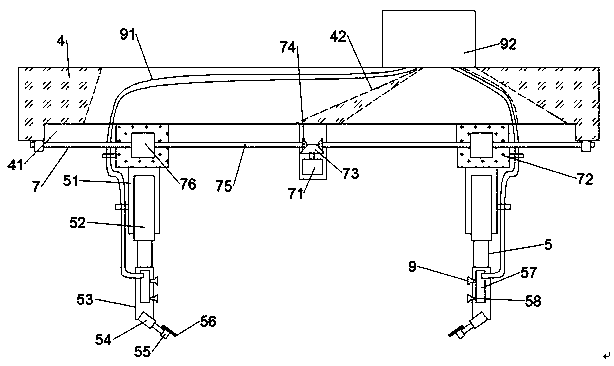

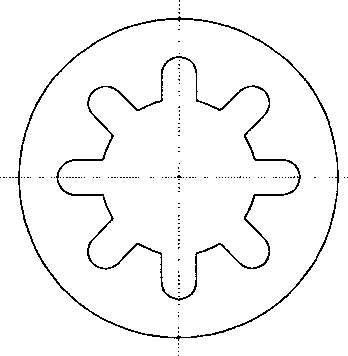

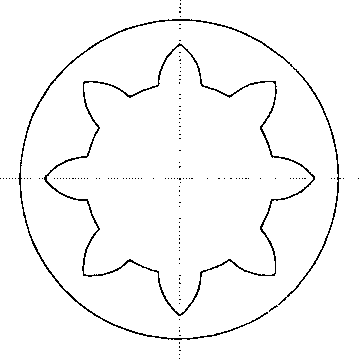

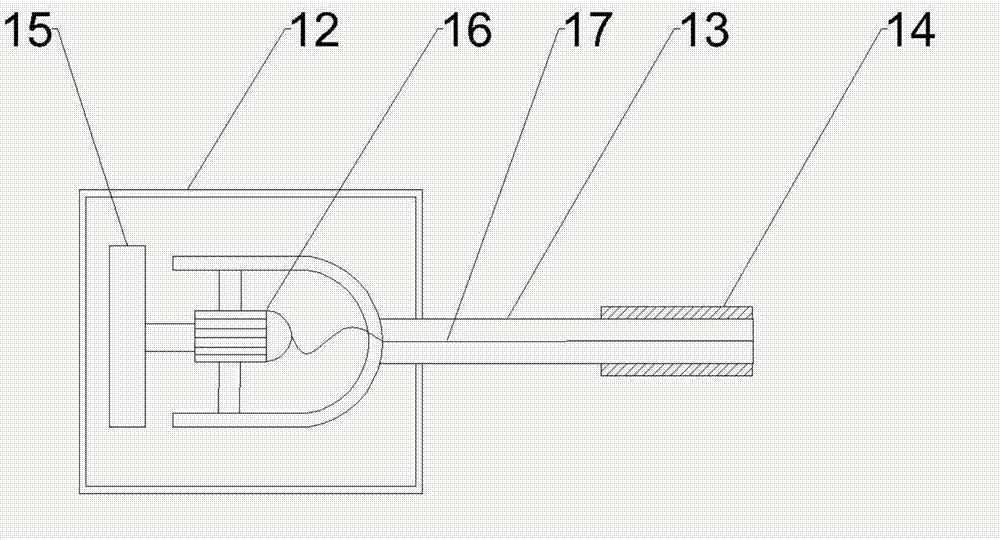

Pulsation air current vibration-damping arrangement

InactiveCN1755070AReduce vibration forceGood vibration reduction effectSilencing apparatusFluid dynamicsInjectorLine segment

The invention discloses a pulse air-flow damping device in the vibration damping and damageproof technique domain, which comprises the following parts: outer case, inside component and air-flow expansion space, wherein the inside component contains transition section and injector whose exit connects the air-flow expansion space between inside component and outer case; the cross-section shape of injector is periodic plane curve structure in space along the circle direction or quadrangle, triangle and regular polygon direction to extend arrangement, which is composed of straightway, arc segment or parabolic segment or hyperbolic segment or expansion segment; forming a closed plane curve in space; stretching the section shape along the axial direction of outer case; forming hollow channel with two end opening; the outlet of condenser sprays out through transition section and forms current direction vortex, extension vortex structure in the gas flow expansion space, which turns the pulse air-flow as stable air-flow.

Owner:刘友宏 +2

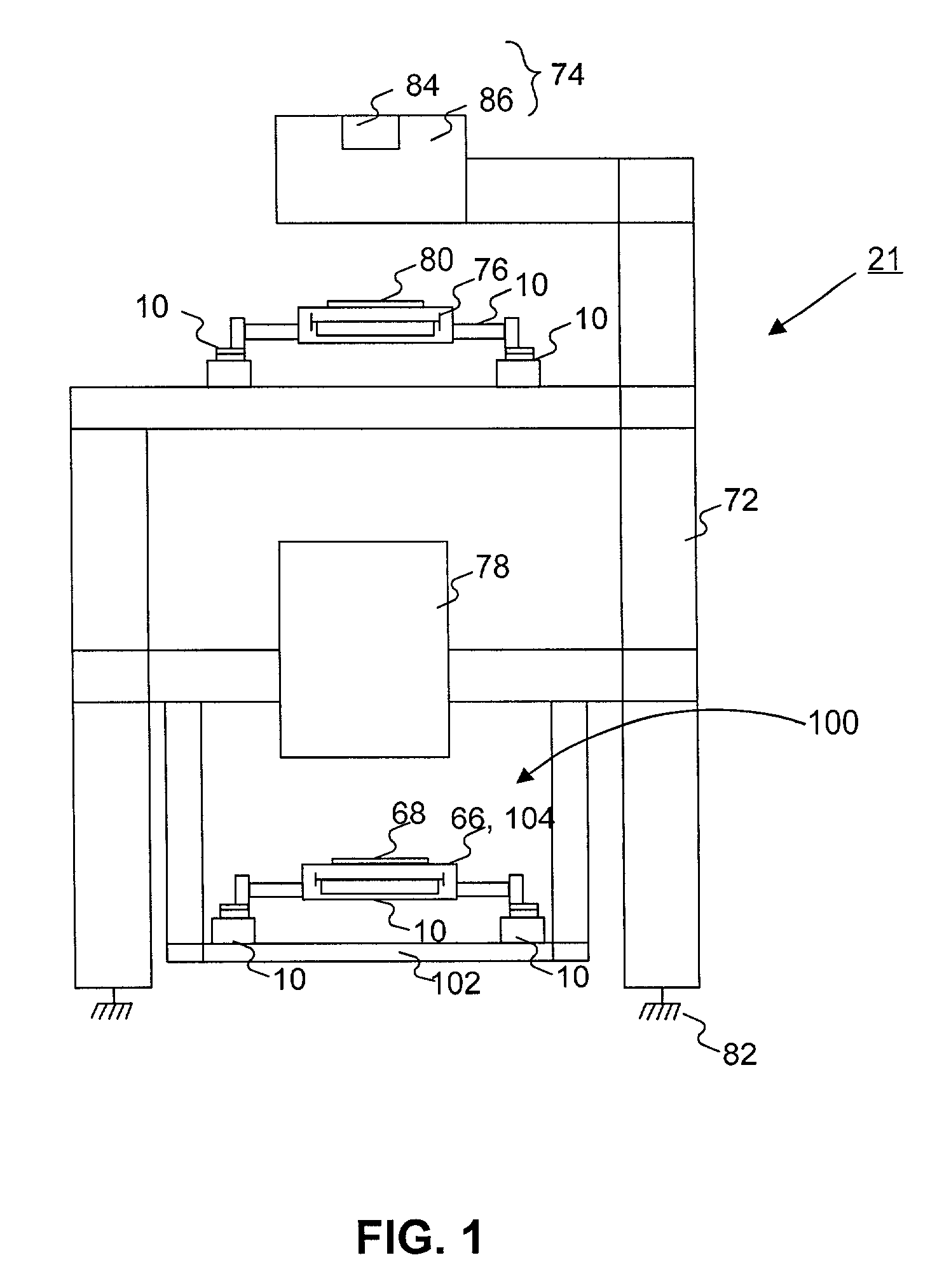

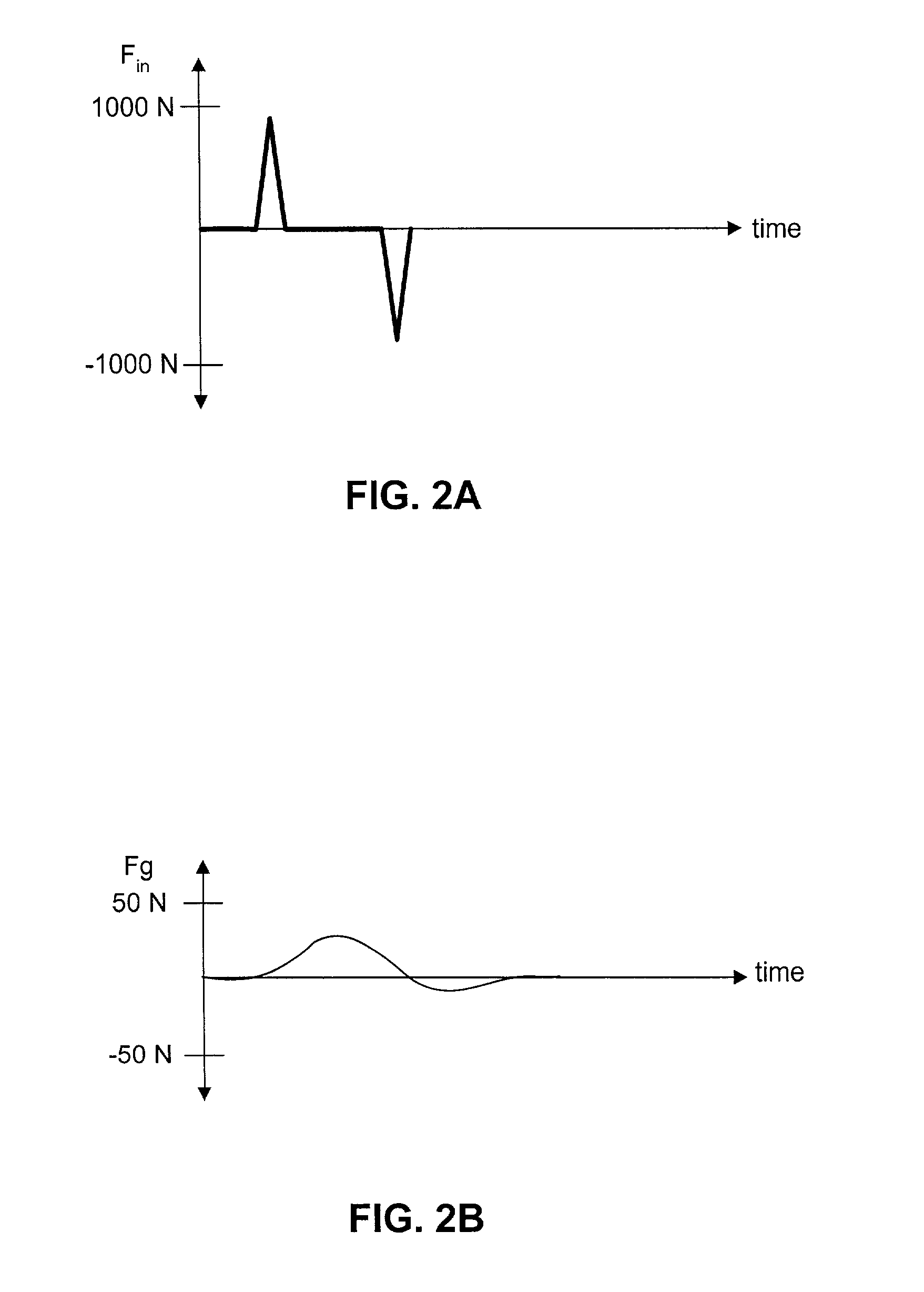

Reaction mass for a stage device

InactiveUS6987558B2Reduce vibration forceElectric controllersIgnition automatic controlSupporting systemControl system

Owner:NIKON CORP

Medium-distance bone conduction driver

InactiveCN104994457AReduce vibrating massIncrease the vibration areaElectrical transducersEngineeringBone conduction hearing

The invention relates to the field of a sounder and specifically discloses a medium-distance bone conduction driver, comprising a suspension system, a vibration system, a magnetic bowl, a back cover, a mild contactor, a first voice coil, a second voice coil and a magnetic conductive bracket, wherein the suspension system is fixedly connected with the upper surface of the magnetic conductive bracket; the mild contactor is stuck with the upper part of the magnetic conductive bracket; the magnetic bowl is ring-shaped and is used for surrounding the vibration system; the lower surface of the magnetic bowl is fixedly connected with the back cover; the upper surface of the magnetic bowl is fixedly connected with the suspension system; the first voice coil and the second voice coil are fixed on the upper surface of the back cover. Double magnetic circuits are used to drive the vibration system to work, and the suspension system is used to match with the work, so the amplitude is larger and the driving force is larger. The medium-distance bone conduction driver is more suitable for transmitting medium-distance bones, and the driving force is twice as that of a single driver.

Owner:BESTAR HLDG

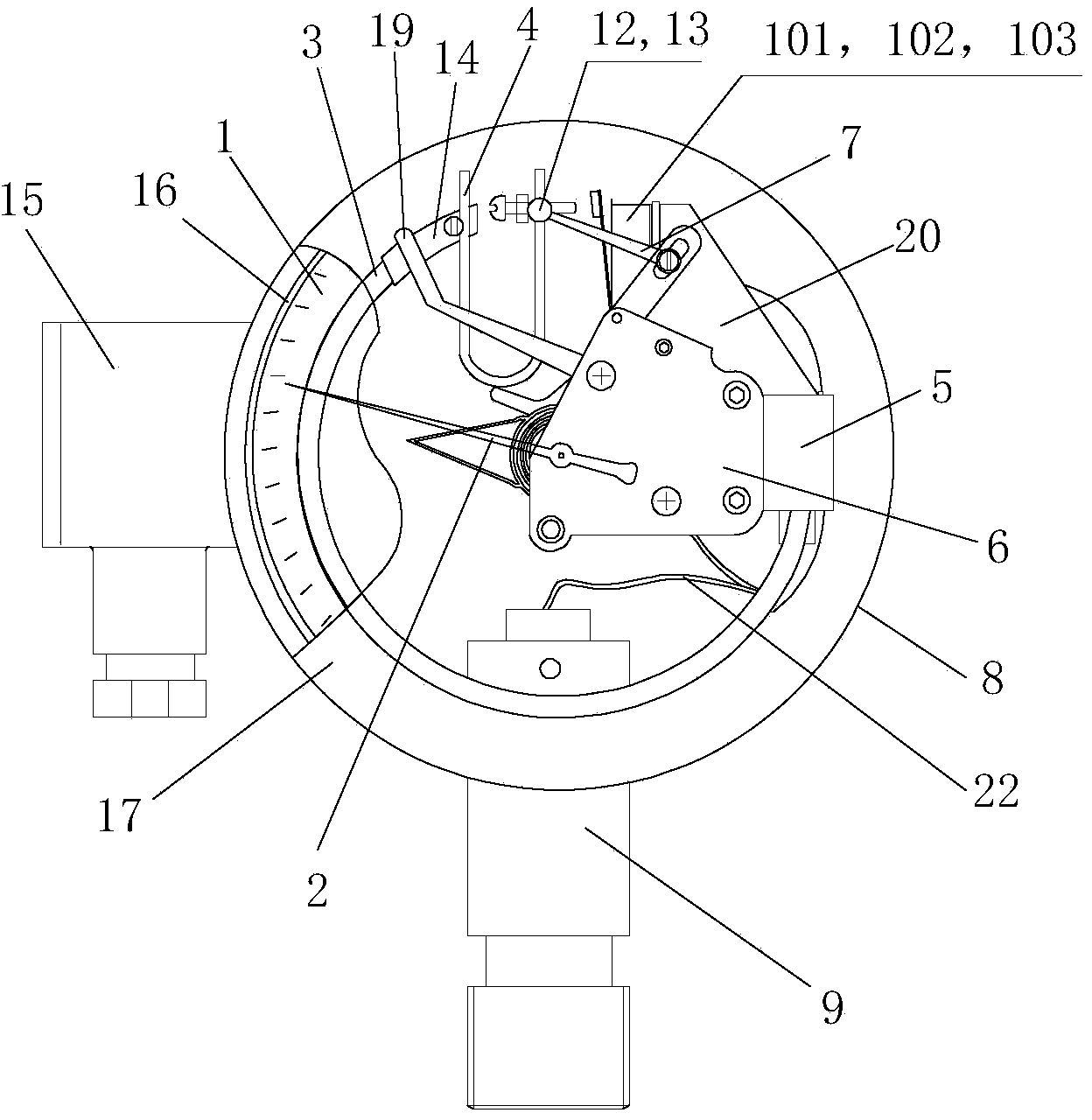

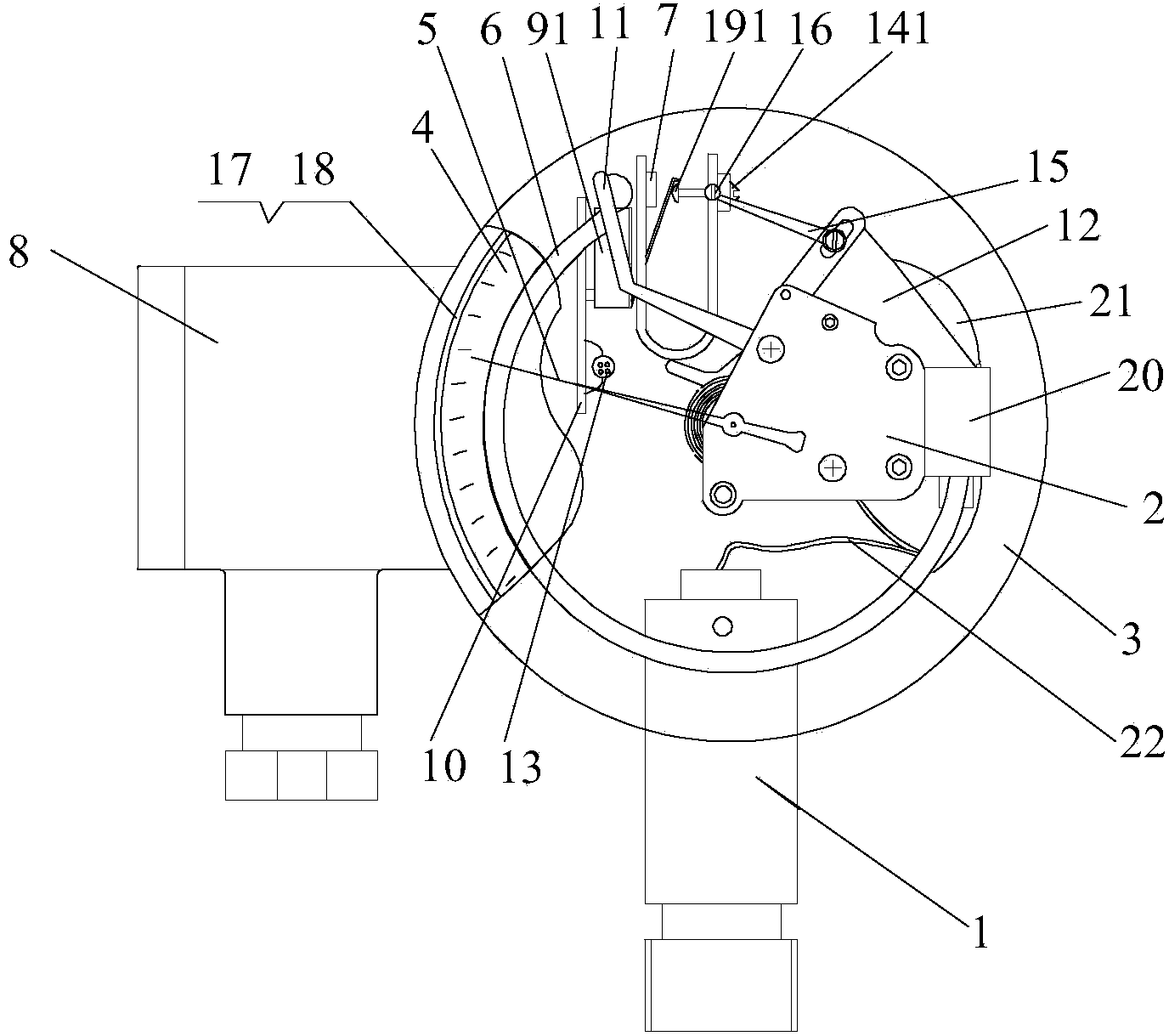

Sulfur hexafluoride gas density relay

ActiveCN103715010ARealize overpressure alarm and controlHigh precisionElectric switchesEngineeringSignal generator

The invention discloses a sulfur hexafluoride gas density relay. The sulfur hexafluoride gas density relay comprises a shell, a signal control part and an indicating value display part, wherein the signal control part and the indicating value display part are arranged in the shell and are relatively independent. The signal control part comprises a control base, a control end seat, a control Burdon tube, a control temperature compensation piece, a control connecting arm, a control signal regulating piece and a plurality of control microswitches serving as signal generators. The control microswitches are arranged in the mode that the width direction of operating handles of the control microswitches is perpendicular to the width direction of the Burdon tube. The indicating value display part comprises a display Burdon tube, a display temperature compensation piece, a display base, a display end seat, a display machine core, a pointer, a display connecting arm, a display signal regulating piece and a plurality of display microswitches serving as signal generators. The sulfur hexafluoride gas density relay can achieve overpressure alarming and control, the accuracy of dense relays is improved to the maximum extent, the thickness of the dense relays is reduced, the application range of the dense relays is enlarged, and the sulfur hexafluoride gas density relay is suitable for being applied to various occasions.

Owner:SHANGHAI ROYE ELECTRICAL CO LTD

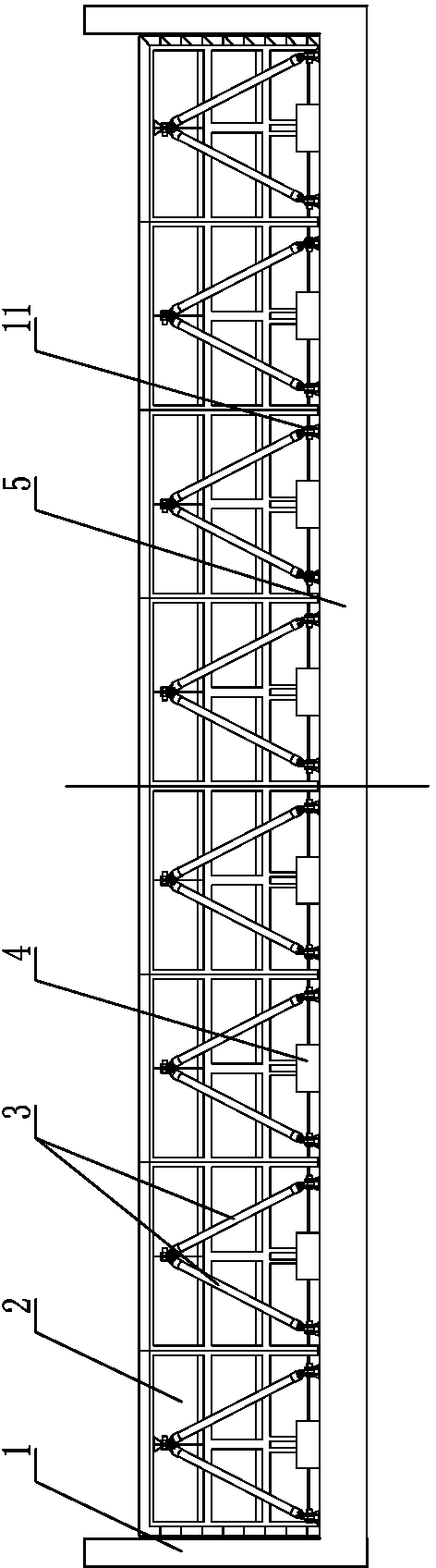

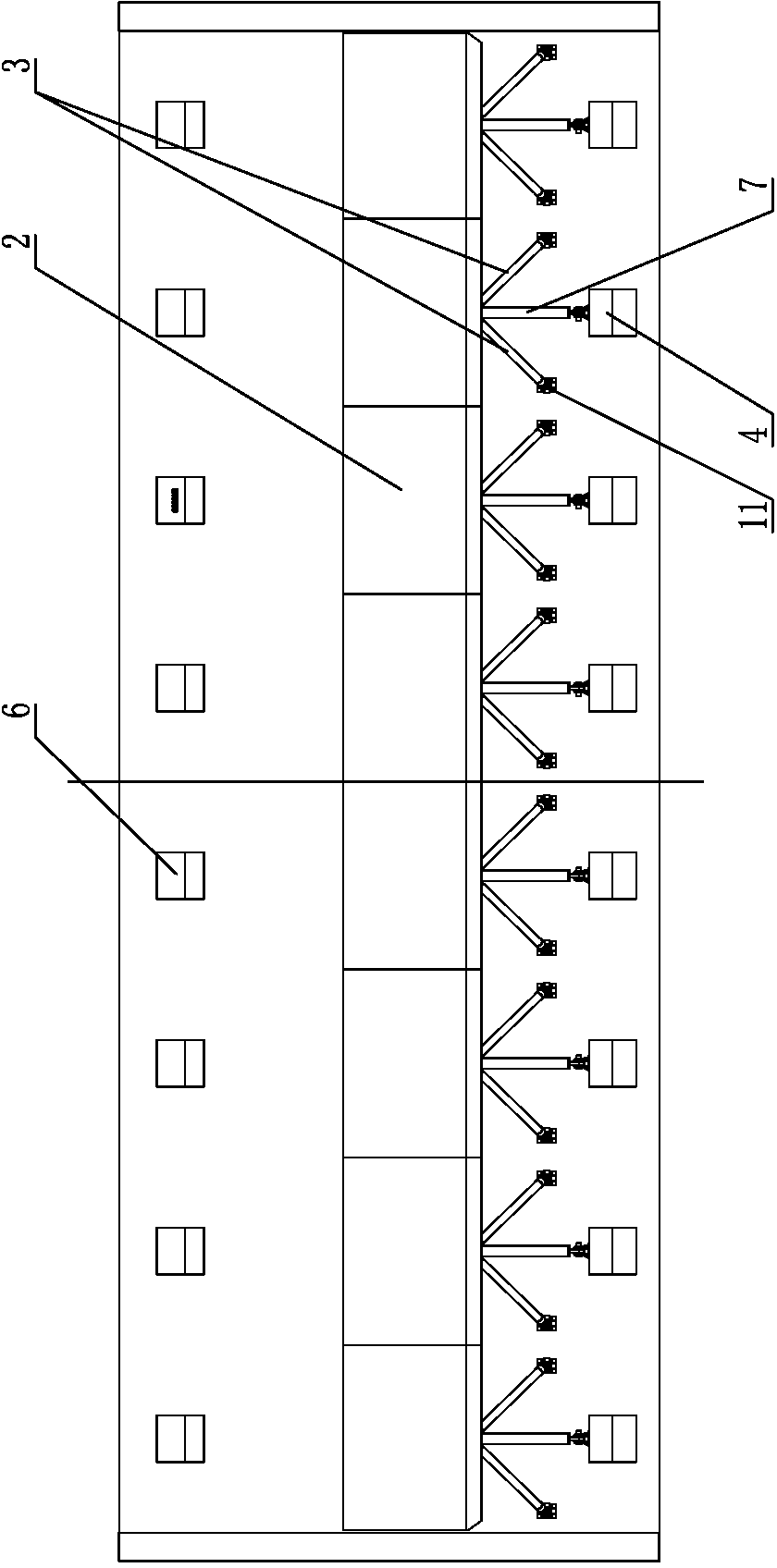

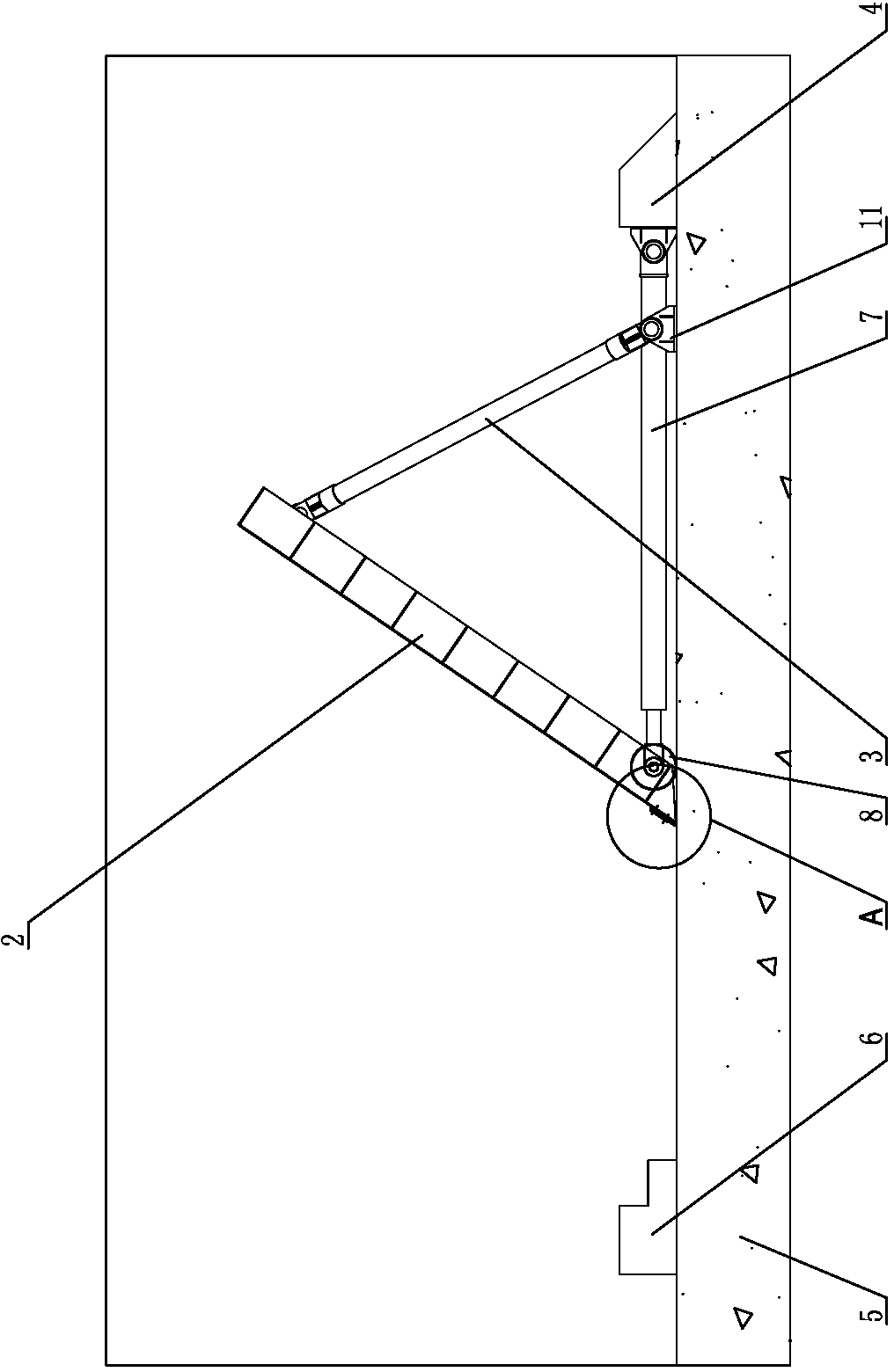

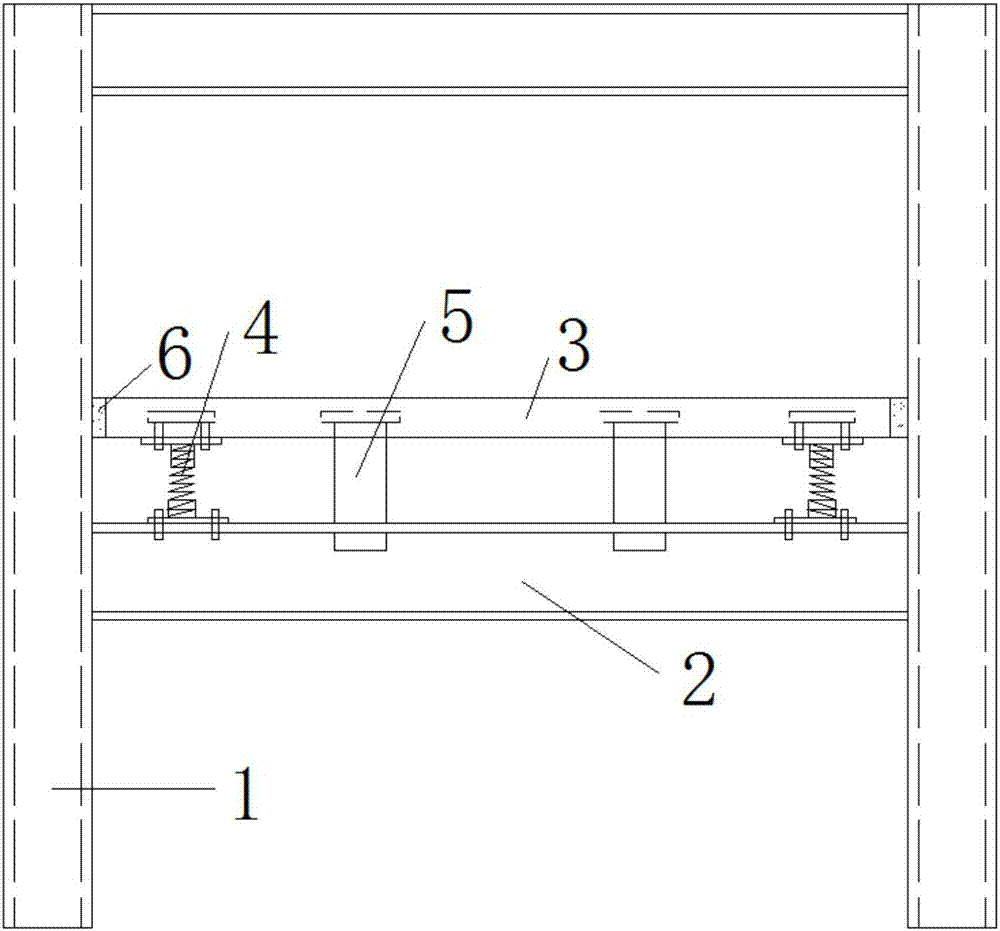

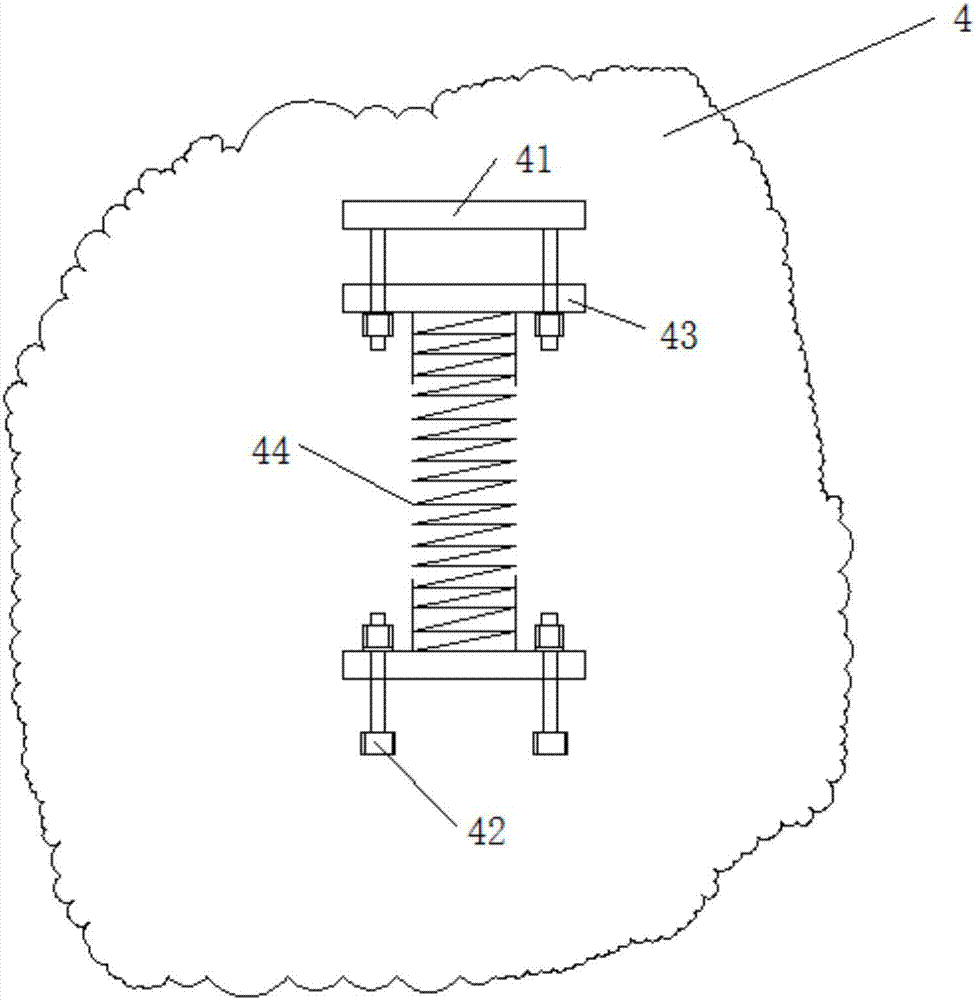

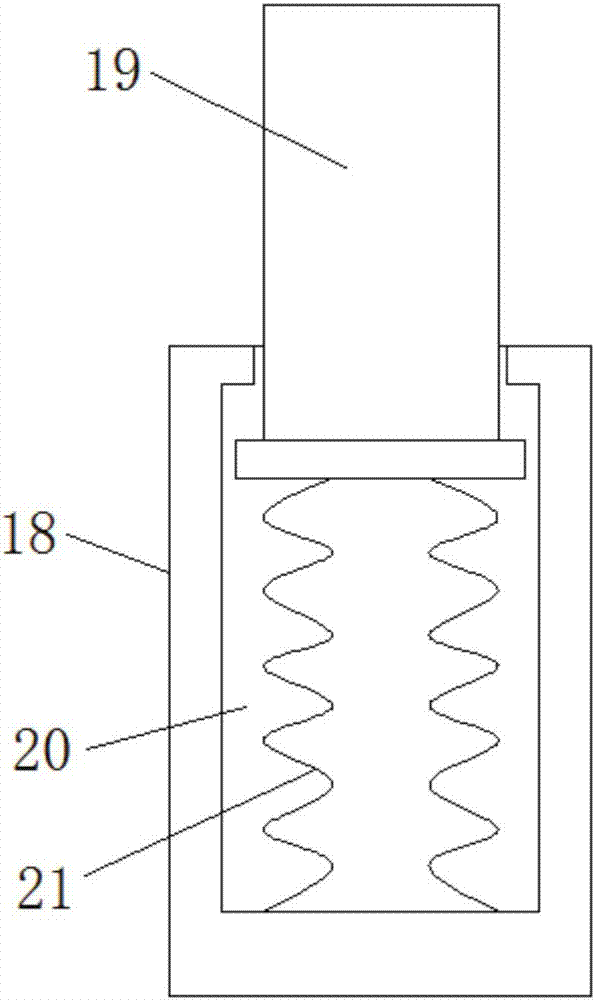

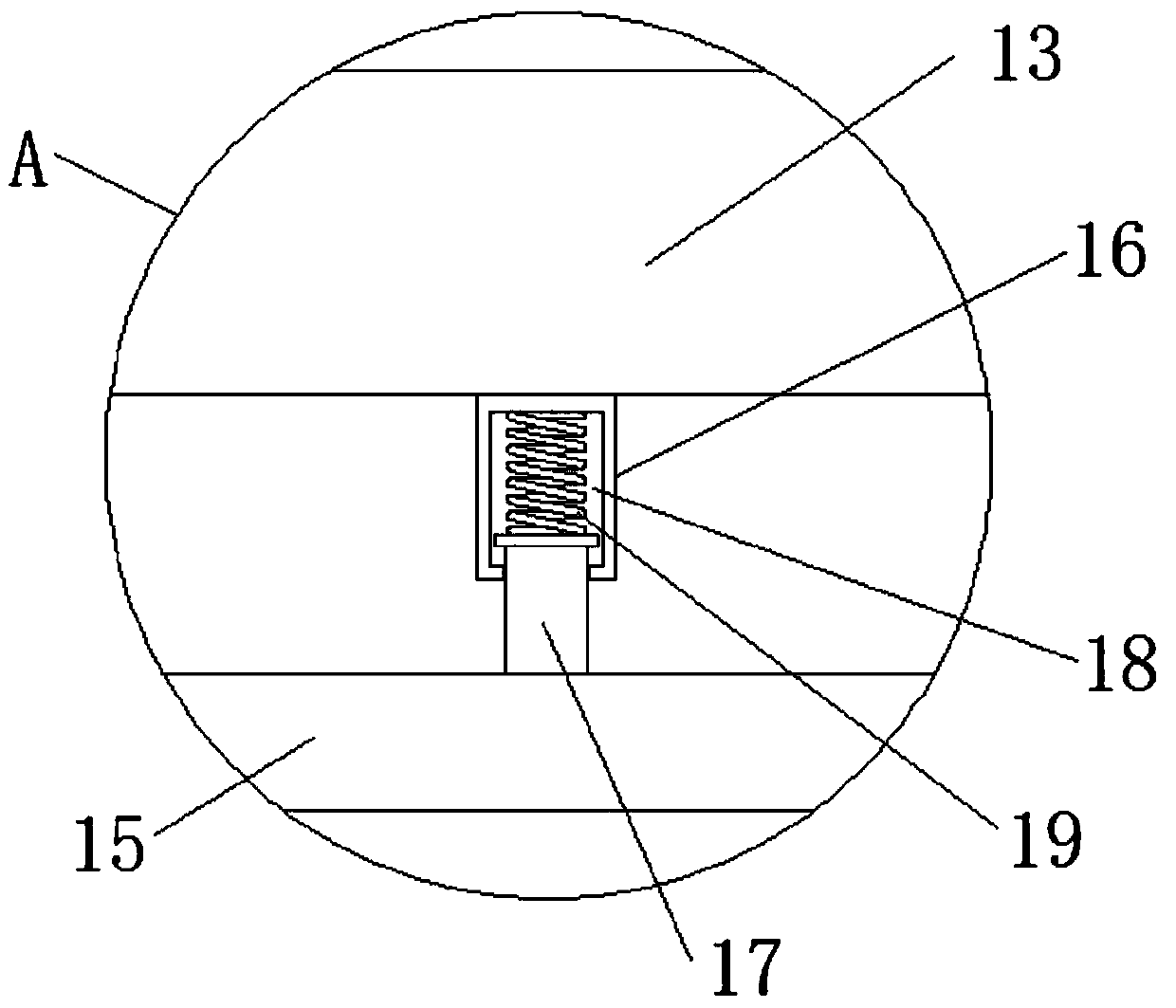

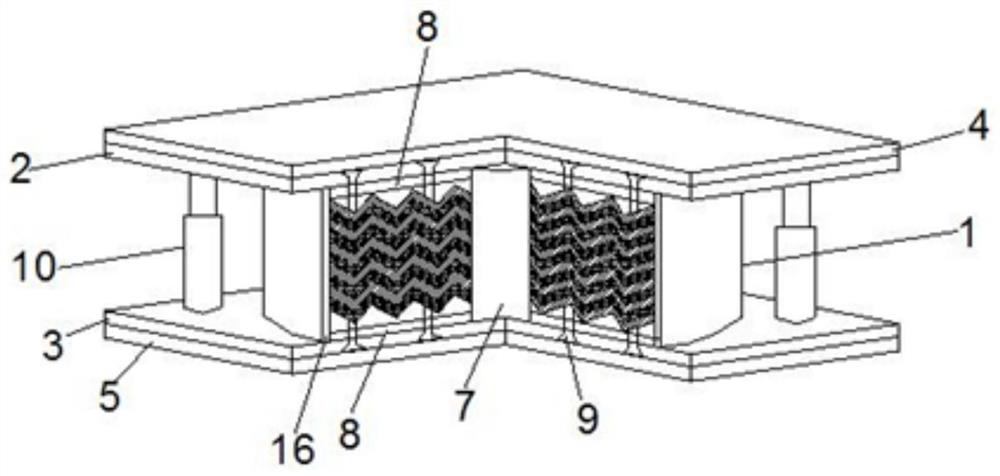

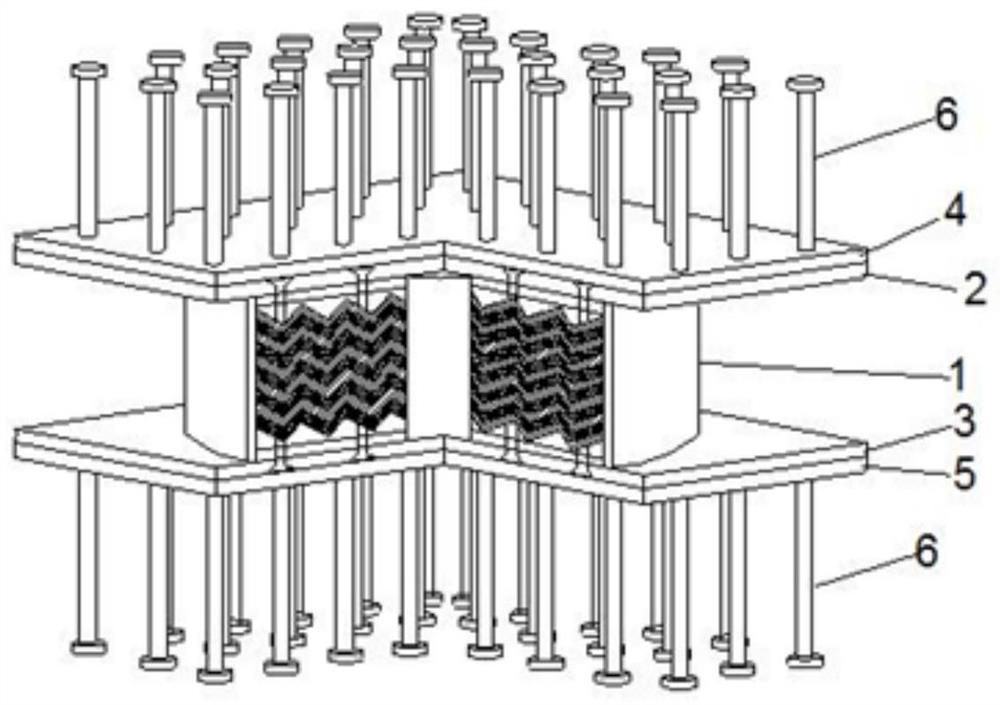

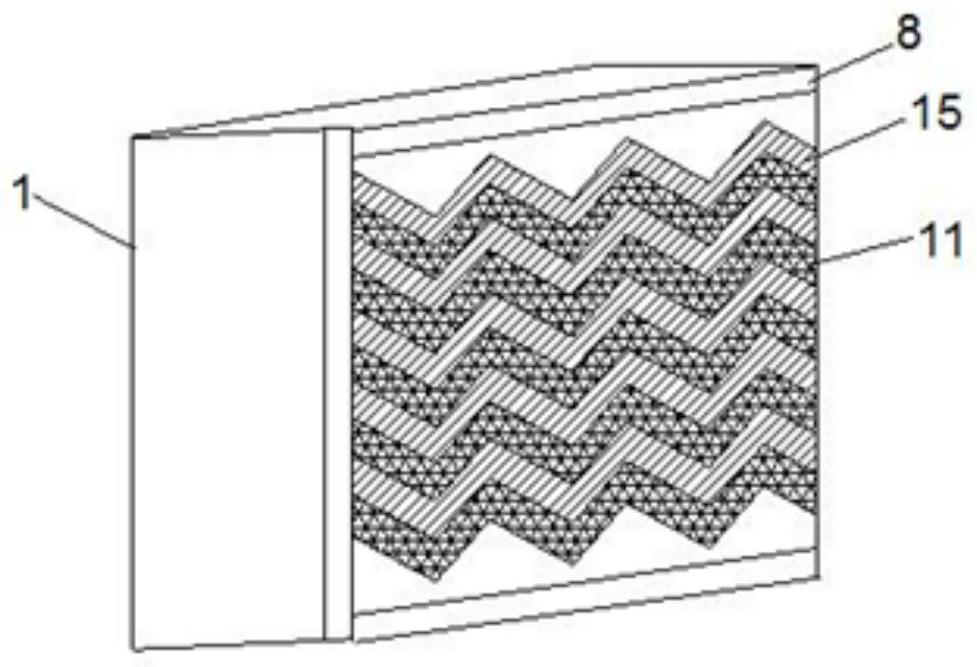

Frame structure with vibration-isolating floor system and installation method of frame structure

The invention relates to a frame structure with a vibration-isolating floor system and an installation method of the frame structure. The frame structure comprises pillars, beams and floor slabs, the pillars and beams are fixedly connected, a vibration-isolation assembly and shearing resistance buttons are arranged between the beams and the floor slabs, jointing glum is arranged between the floor slabs and the pillars, the vibration-isolation assembly is composed of embedded parts, spring bases, bolts and springs, the embedded parts are embedded into the floor slabs, and are connected with the upper spring bases, the lower spring bases are connected with the beams, the shearing resistance buttons are two T-shaped welding parts of steel plates, horizontal slabs are embedded into the floor slabs, and vertical slabs are inserted into oval-shaped holes which are formed in the upper flanges of the beams in advance. In the floor-isolating frame structure and the installation method thereof, the vibration-isolation assembly can bear vertical loads of the floor slabs, and has a function of buffering vibration loads on the floor slabs, thus a vibration-isolation effect is achieved, and the anti-shearing buttons transfer horizontal shear stress of the floor slabs to frame beams.

Owner:江苏城乡建设职业学院

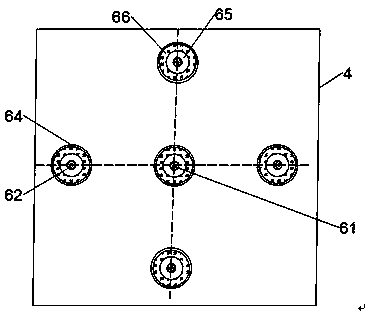

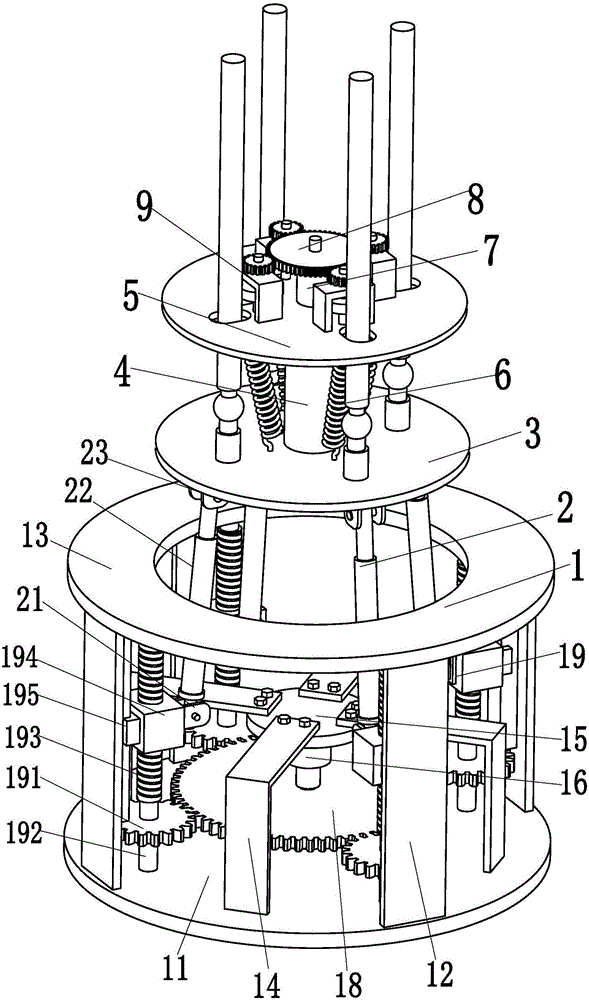

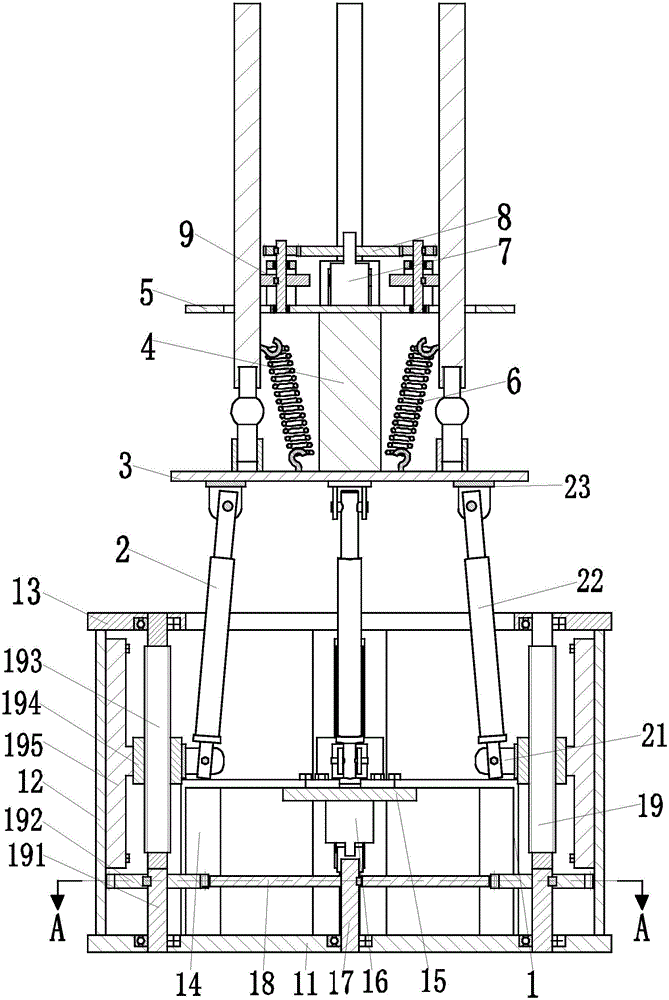

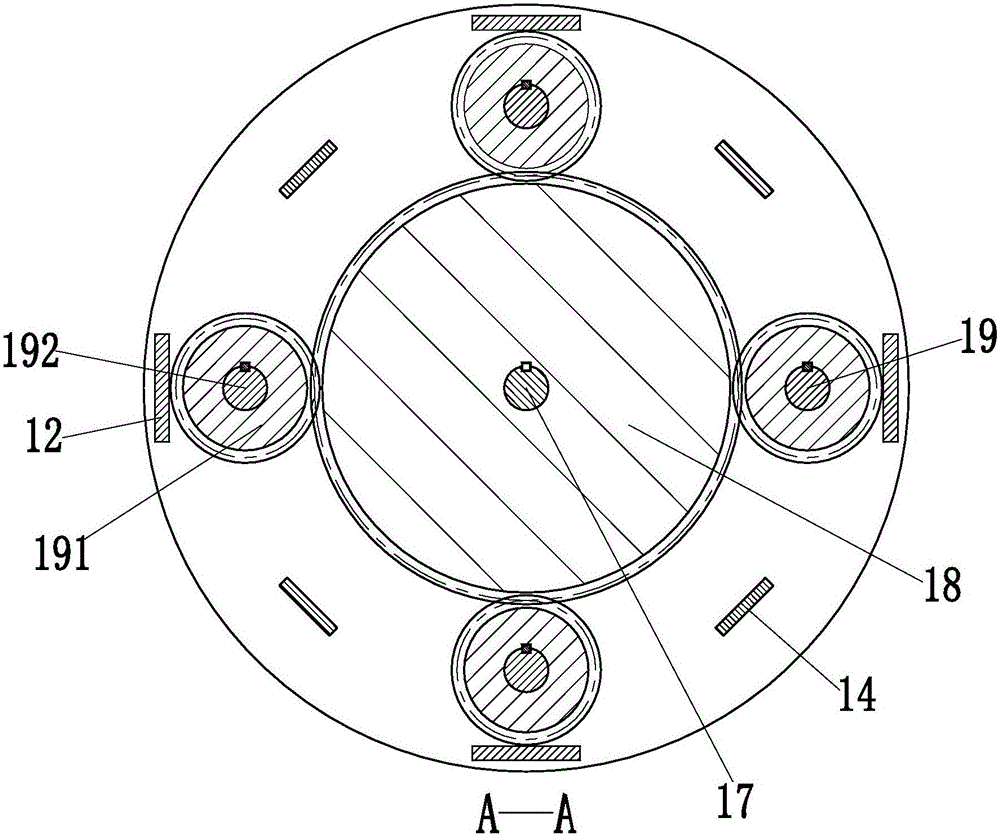

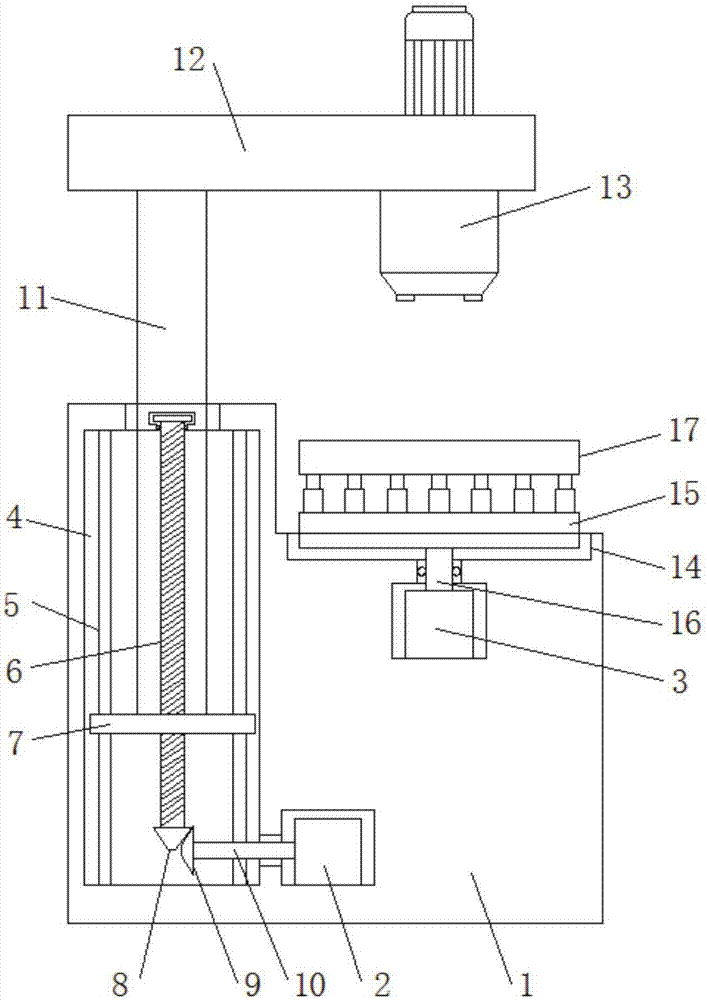

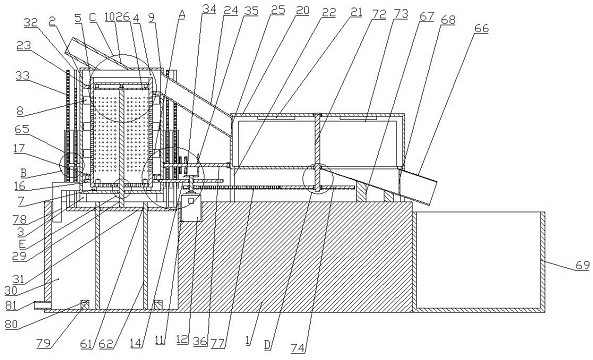

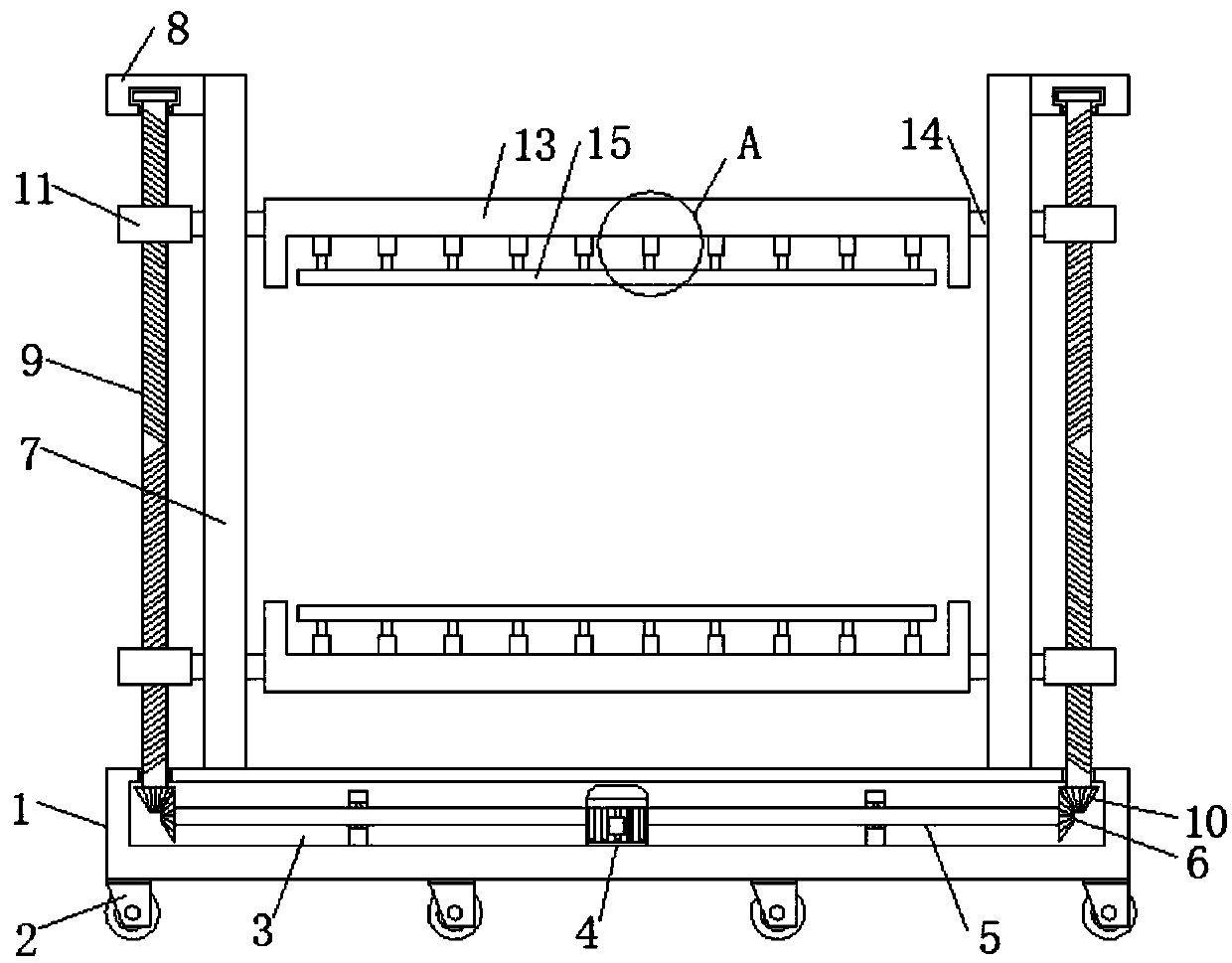

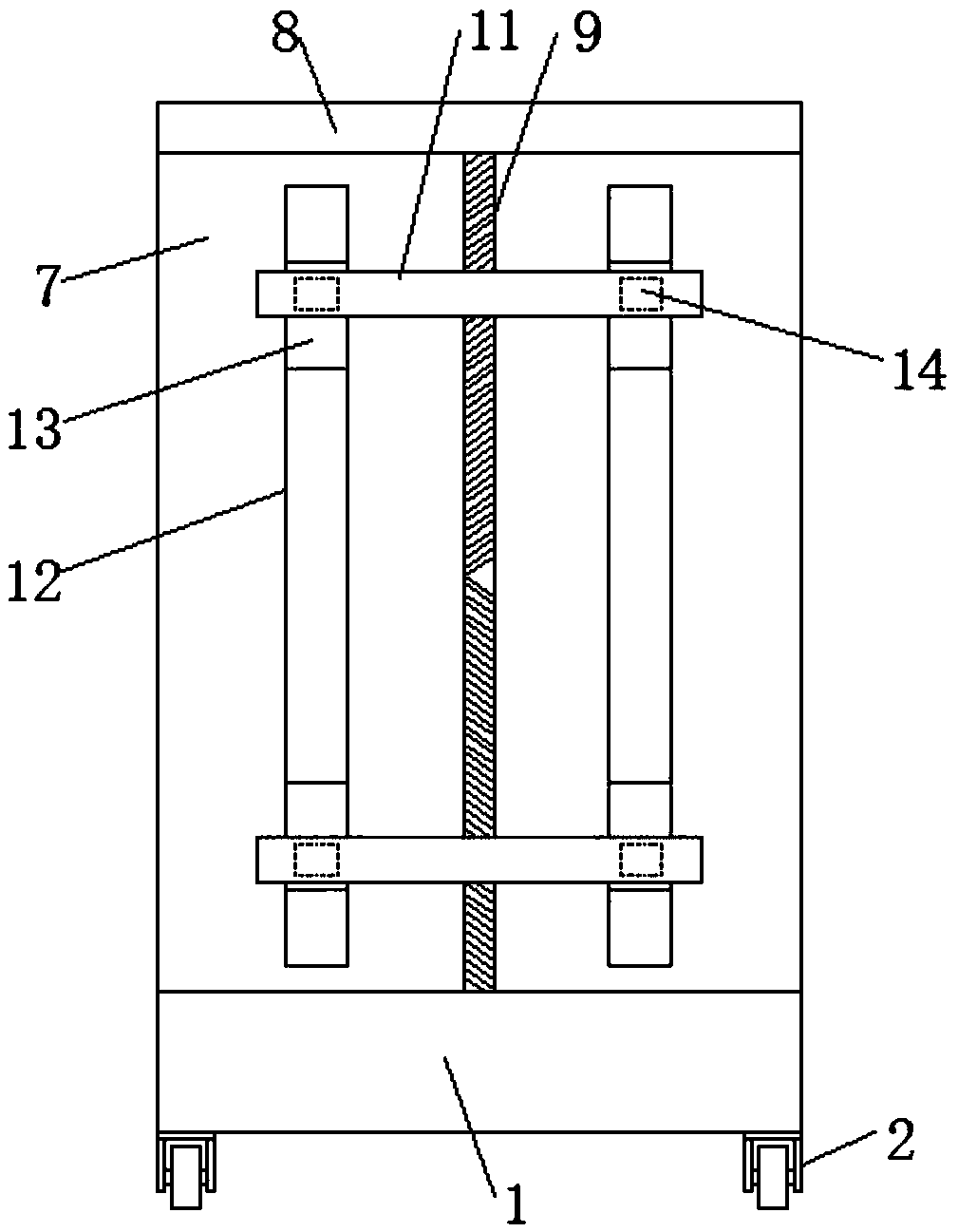

Building concrete pouring vibration robot

ActiveCN106012840ANo manual operationHigh degree of automationBridge erection/assemblyBuilding material handlingCircular discElectric machinery

The invention relates to a building concrete pouring vibration robot which comprises a fixing rack. Locating columns are arranged at the middle portion of the upper end face of an operation table. A limiting disc is welded to the upper ends of the locating columns. The locating columns achieve the effect of supporting the limiting disc. Four kidney-shaped limiting holes are evenly formed in the limiting disc in the axis direction. Four vibration branch chains are evenly installed on the operation table in the axis direction. The four vibration branch chains can conduct the high-frequency vibration movement on poured concrete at the same time, the concrete compacting speed is high, and the work efficiency is high. The middle portion of the upper end face of the limiting disc is provided with a transmission motor through a motor seat. A driving gear is fixedly installed at the output end of the transmission motor and engaged with four transmission branch chains. By the adoption of the robot, the function of compacting the poured concrete through multiple vibration bars at the same time can be achieved, the robot has the beneficial effects of being high in concrete compacting speed, good in damping performance, high in work efficiency, high in automation degree and the like, and a new way for automatically and quickly compacting the poured concrete is provided.

Owner:福建省东霖建设工程有限公司

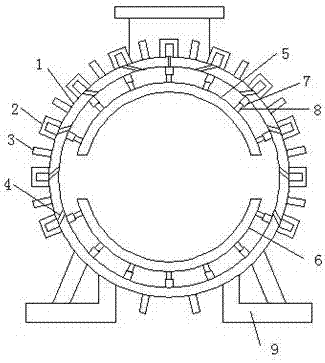

Lubrication shell of motor

InactiveCN107086714AAvoid enteringImprove work efficiencySupports/enclosures/casingsMultiple bufferingEngineering

The invention discloses a lubricating housing for a motor, which comprises a housing body, the housing body is a hollow circular structure, a plurality of protruding plates and reinforcement plates are respectively welded on the outer wall of the housing body, and protruding The plates and reinforcement plates are arranged alternately. The side of the protruding plate close to the shell body is provided with a heat dissipation groove. Both sides of the shell body are provided with a plurality of heat dissipation ports, and the heat dissipation ports are connected with the heat dissipation grooves. The shell body A first pressure plate and a second pressure plate are respectively arranged inside, and a plurality of buffer rods are welded on the side away from the first pressure plate and the second pressure plate, and a plurality of buffer rods are welded on the inner wall of the top end and the bottom end of the shell body. The support rod is provided with a placement groove on one side of the support rod close to the buffer rod, a spring is fixedly connected to the inner wall of the placement groove, and one end of the spring is connected to the buffer rod. The invention has reasonable design, remarkable heat dissipation effect, reduces noise, and effectively improves the use quality and work efficiency of the motor.

Owner:江苏中泉科技有限公司

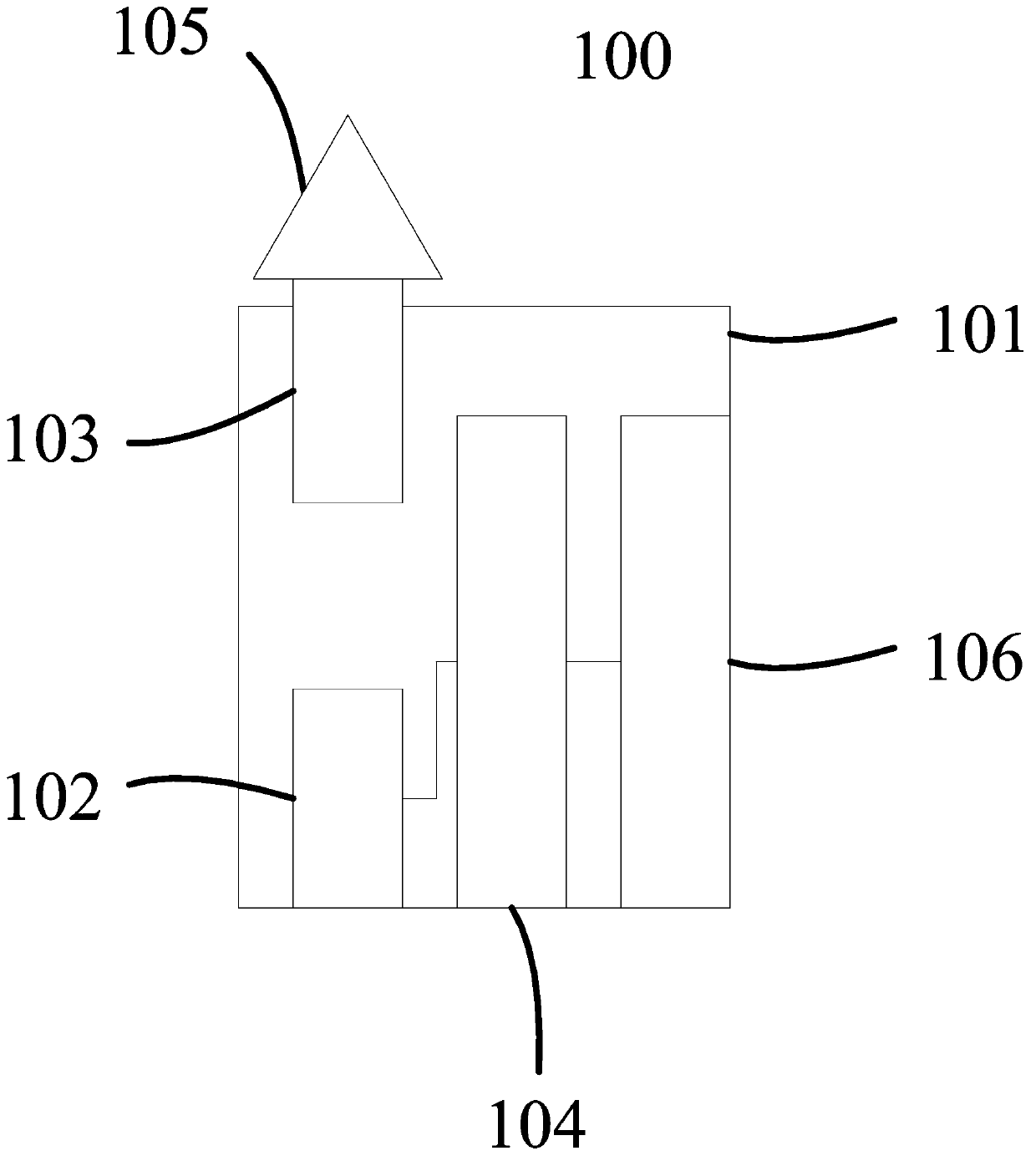

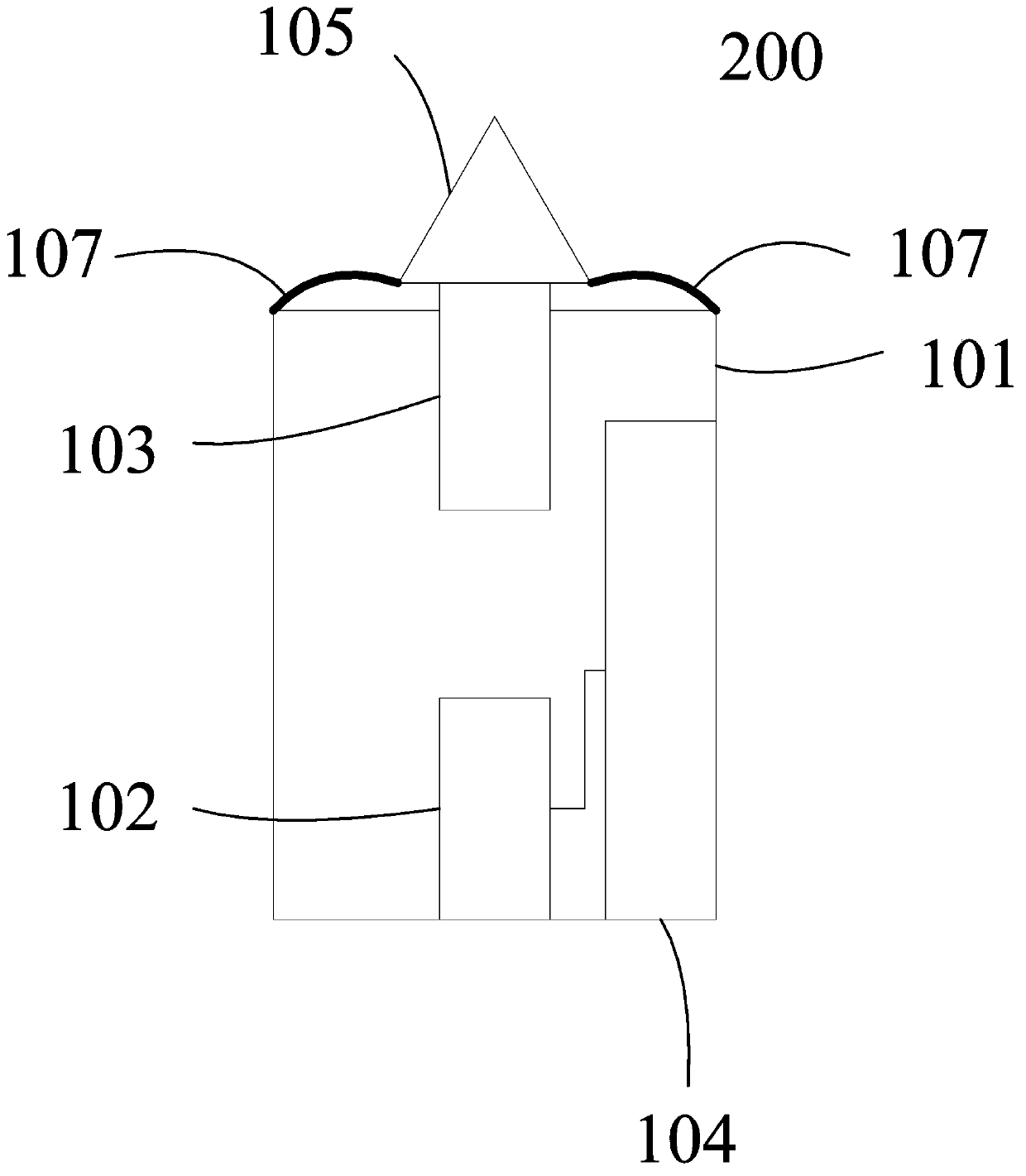

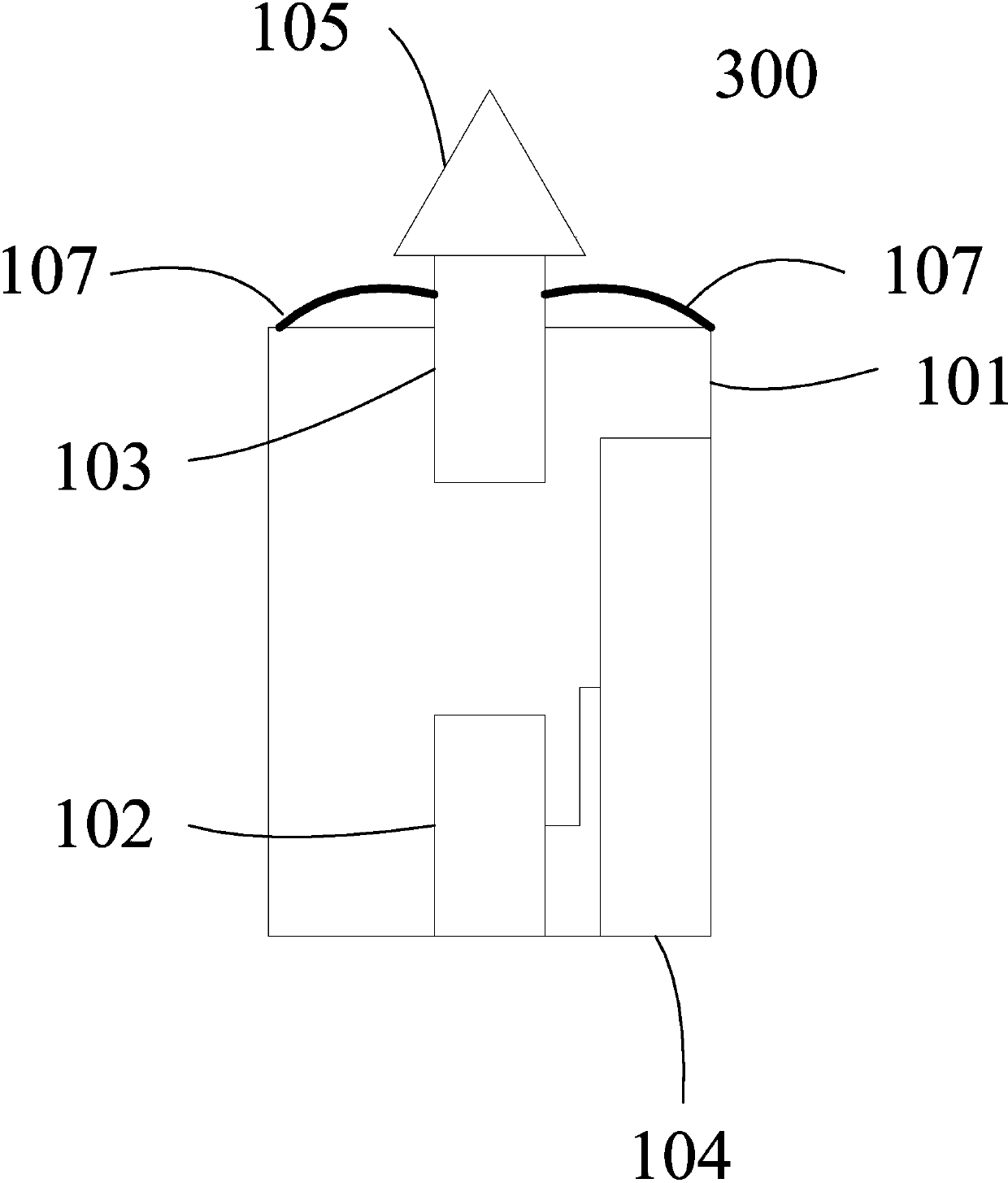

Quakeproof container

Owner:WUXI AOYUTE NEW TECH DEV

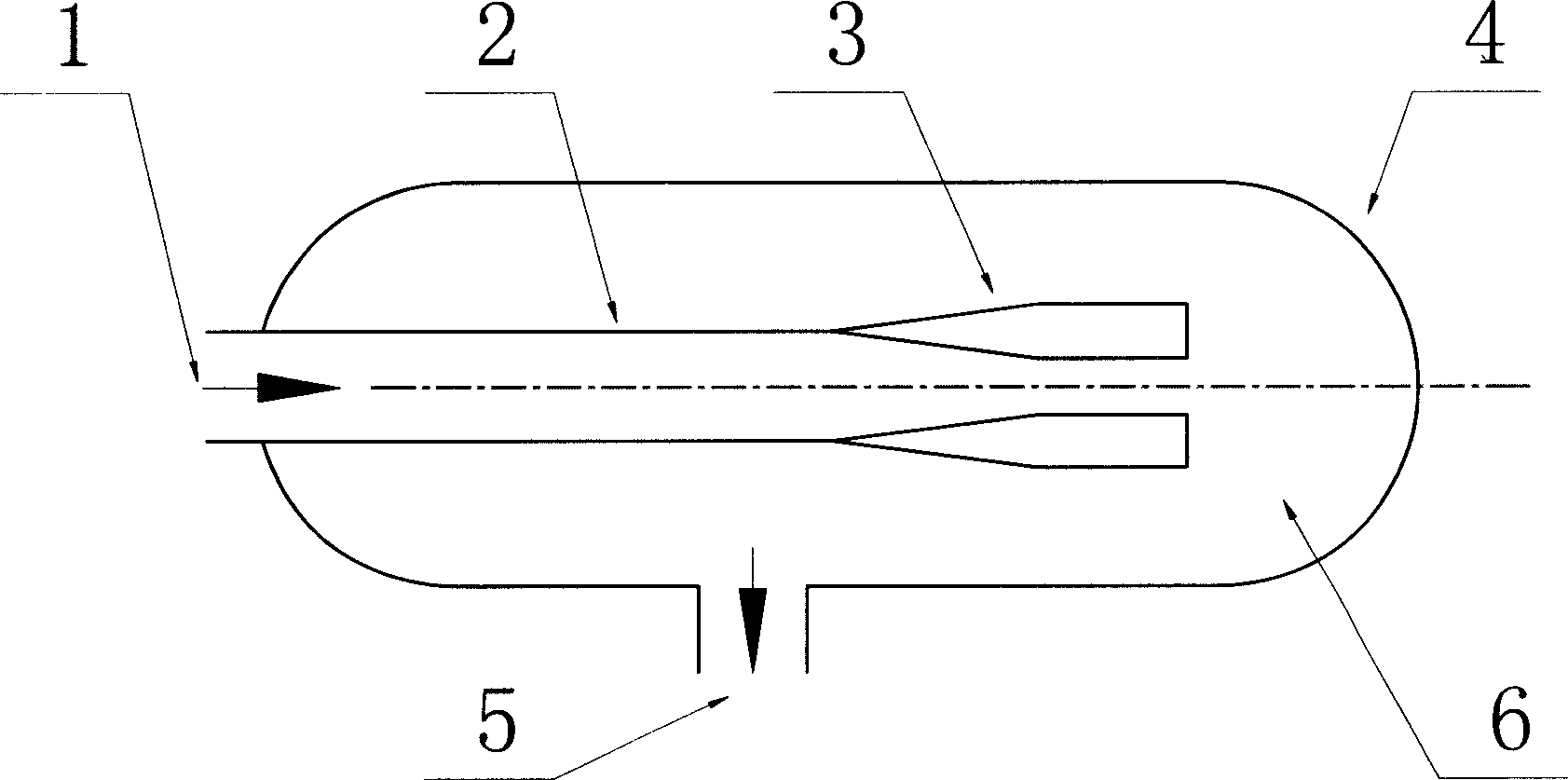

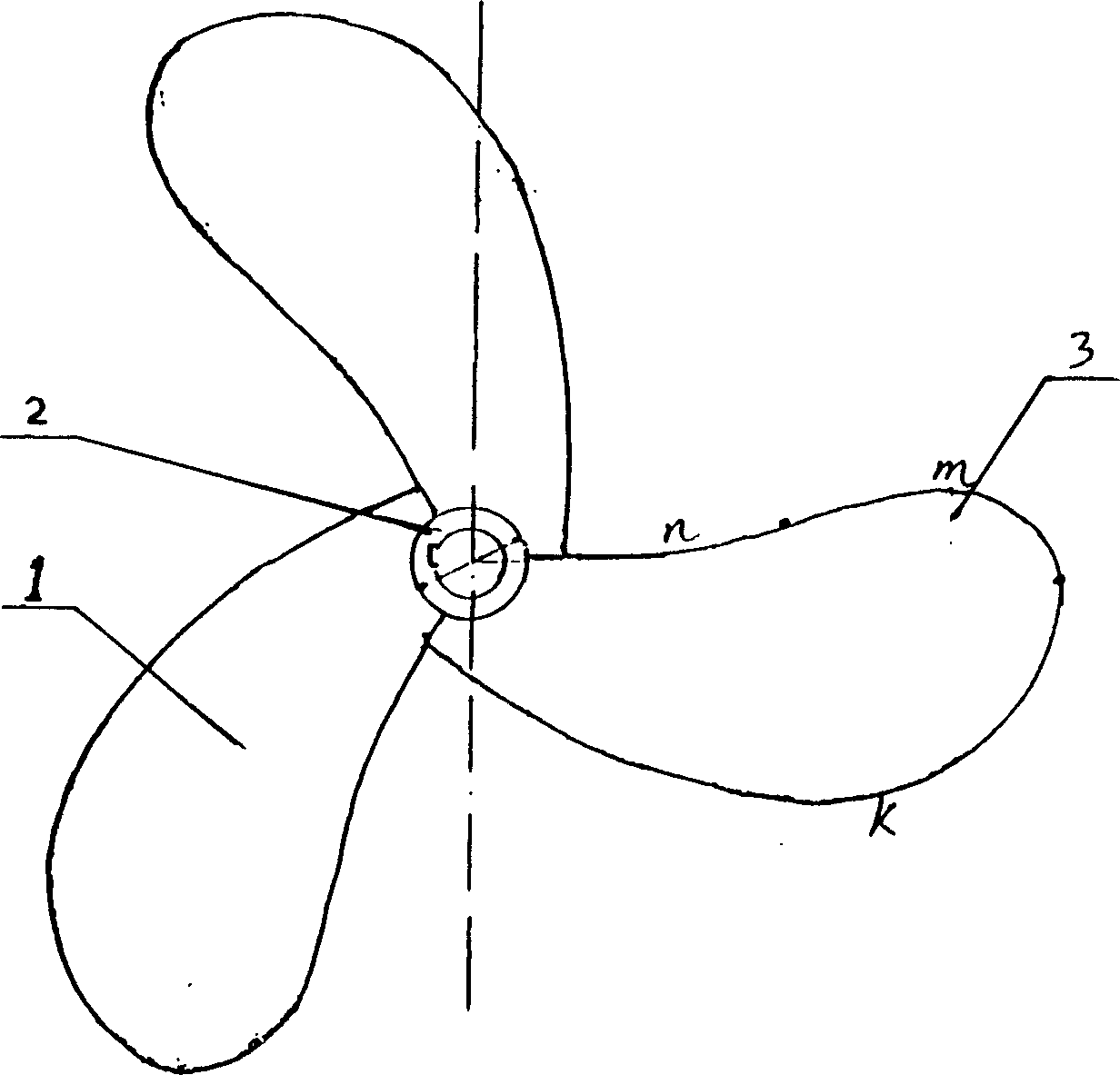

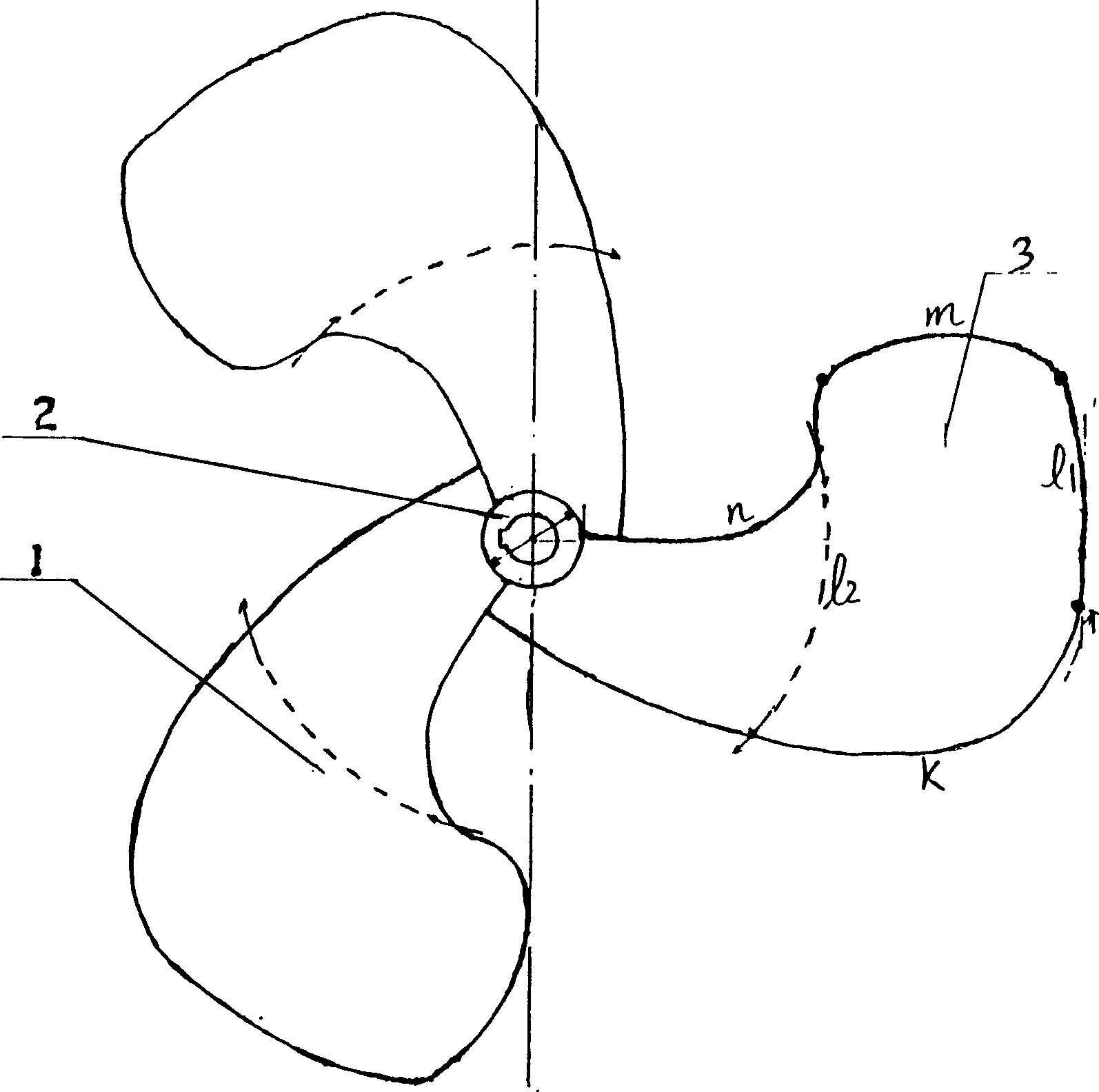

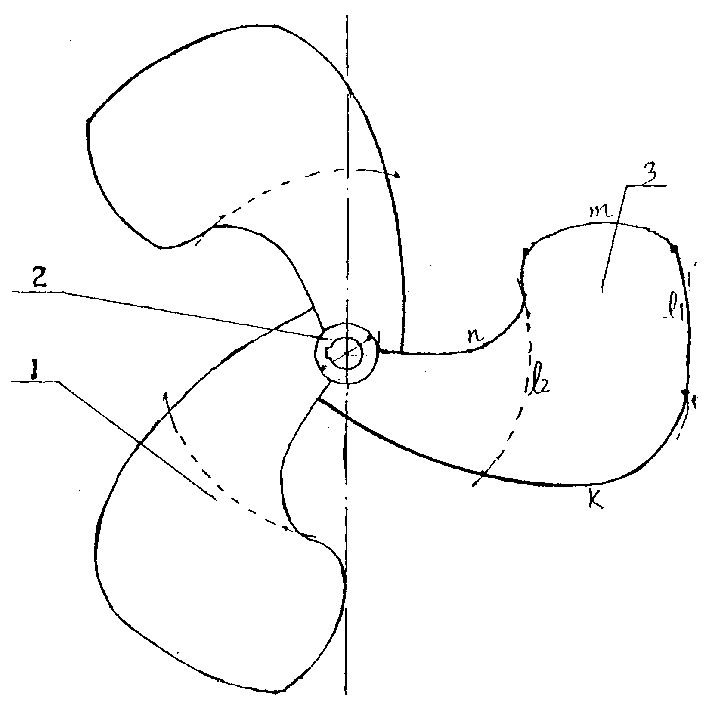

Propeller

A novel propeller is composed of an axle and multiple blades, and features that the axial length of blade tail is elongated by 2-4 times and the edge of blade consists of anti-resistance curve, external edge curve which is an arc line, a transition curve and a water curve which is an arc line, a transition curve and a water yielding curve. The partial blade between said external edge curve and a particular arc has a concave surface. Its advantages are high shap speed increased by 30%, low vibration, and simple structure.

Owner:李日华

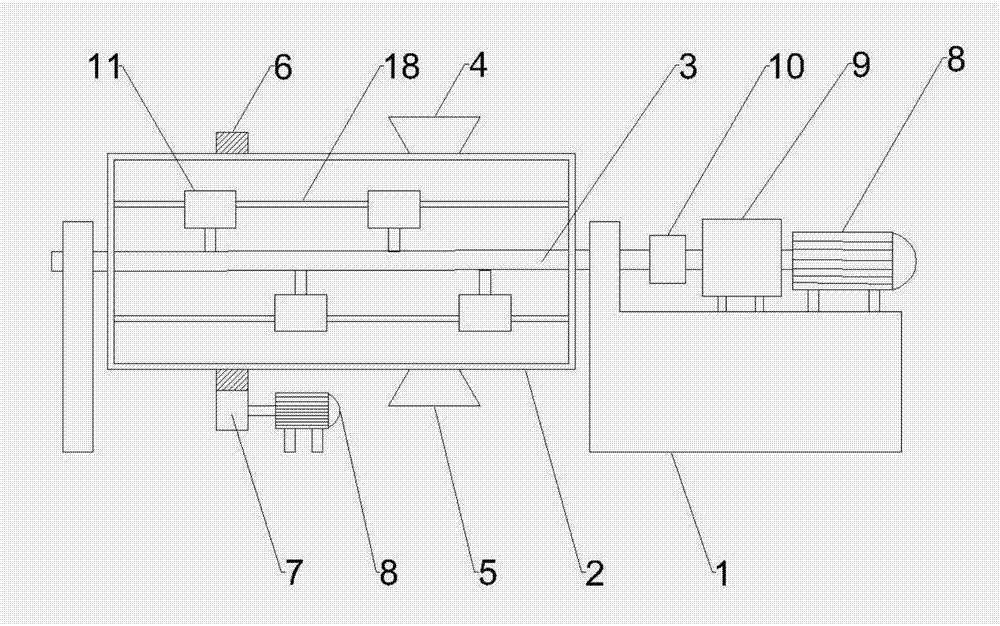

Material mixing machine for manufacturing food packaging bags

The invention discloses a material mixing machine for manufacturing food packaging bags, and belongs to the field of mechanical equipment. The material mixing machine comprises a rack, a horizontally-placed material mixing barrel is arranged on the rack, a rotating shaft is arranged at the axis position in the material mixing barrel, is rotationally connected with the rack, and is rotationally connected with the material mixing barrel, a driven gear is annularly arranged outside the material mixing barrel, a driving gear is arranged below the material mixing barrel, and the driving gear is meshed with the driven gear; the rotating shaft and the driving gear are driven by a motor to rotate, the rotating directions of the rotating shaft and the material mixing barrel are opposite, a vibrating blade is arranged on the rotating shaft and comprises blades and stirring arms, the two ends of each stirring arm are connected with the rotating shaft and the corresponding blade correspondingly, an eccentric gear and an electromotor are arranged in each blade, and each eccentric gear is connected with the corresponding electromotor; and connected wires are arranged in the rotating shaft and the stirring arms, and the wires are connected with the electromotors. A material throwing plate is further arranged on the inner wall of the material mixing barrel. When the material mixing machine is used for mixing materials, the materials can be mixed more evenly.

Owner:广德美好包装科技有限公司

Vertical type liftable and rotary milling machine

PendingCN107442821AEasy to handleReduce vibration forceMilling machinesFeeding apparatusMachine partsMilling cutter

The invention discloses a vertical liftable rotary milling machine, which comprises a milling machine body. The inside of the milling machine body is respectively provided with a first motor and a second motor arranged up and down. One side of the milling machine body is provided with an adjustment chamber. A positioning rod and a screw rod are respectively arranged in the adjustment chamber, a lifting plate is slidably connected between the two positioning rods, and the lifting plate is threadedly connected with the screw rod, a first gear is installed on one end of the screw rod, and a bottom side of the adjustment chamber There is a rotating rod, one end of the rotating rod is equipped with a second gear meshing with the first gear, the other end of the rotating rod is connected with the output shaft of the first motor, and the top side of the milling machine body is provided with a lifting rod, and The lifting rod is fixedly connected with the lifting plate, and the top side of the lifting rod is welded with a top plate. The invention has reasonable design, conveniently adjusts the lifting height of the milling cutter, can process workpieces at different angles, alleviates the vibration force generated during the milling machine processing, and improves the processing accuracy.

Owner:JINGYIHENGZHUN TIANJIN CNC EQUIP CO LTD

Drying device for bolt machining

ActiveCN113108559AReduce vibration forceExtended service lifeDrying solid materials without heatDrying gas arrangementsMachiningWorkbench

The invention discloses a drying device for bolt machining. The drying device comprises a workbench, wherein a drainage mechanism is arranged on one side of the workbench, a feeding and water throwing mechanism is arranged on the workbench, a discharging and drying mechanism is arranged on one side of the feeding and water throwing mechanism, and a collecting mechanism is arranged on one side of the discharging and drying mechanism. The drying device for bolt machining has the beneficial effects that bolts can be automatically received and dried in a spin-dry mode, then the bolts are transferred into a drying box to be dried and are collected, manual participation is not needed, the manual labor amount is reduced, the working efficiency is improved, and use is convenient.

Owner:河北中通铁路配件有限公司

Part transportation device for construction

InactiveCN109928022AReduce vibration forceSo as not to damageContainers to prevent mechanical damageInternal fittingsArchitectural engineeringBevel gear

Owner:吴迪

Rubber shock absorption and isolation system for high-rise building

ActiveCN112411762AIncrease the effect of longitudinal vibration isolationPlay a shock absorbing roleProtective buildings/sheltersShock proofingArchitectural engineeringControl cell

The invention discloses a rubber shock absorption and isolation system for a high-rise building. The rubber shock absorption and isolation system comprises a main shock absorption body, an upper connecting plate and a lower connecting plate, wherein a rubber layer and a steel plate layer are arranged in the main shock absorption body and are mutually sequentially overlapped; a lead core is arranged in the middle of the rubber layer and the middle of the steel plate layer in a penetrating manner; the top and the bottom of the main shock absorption body are connected with sealing plates; the topand the bottom of the lead core are connected with the sealing plates; and a plurality of auxiliary shock absorption bodies are evenly arranged on the peripheral side of the shock absorption body. Byarranging the main shock absorption body and arranging the rubber layer and the steel plate layer which are bent and overlapped, when the rubber shock absorption and isolation system is transverselyor longitudinally deformed, rubber sheets deform and are sheared, and certain damping and rigidity are provided; by arranging the auxiliary shock absorption bodies, pressure signals are received through pressure sensors and transmitted to a control unit to change the strength of a magnetic field, and damping of electromagnetic liquid changes along with changes of the strength of the magnetic field; and a better shock absorption function is achieved.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

Charging pile facilitating positioning

InactiveCN107672482AImprove the quality and life of useReasonable designCharging stationsMobile unit charging stationsEngineering

The invention discloses a charging pile facilitating positioning. The charging pile includes a charging pile body and a protection plate which is horizontally arranged below the charging pile body, two through holes are formed in each of the two sides of the protection plate, two guide rods are welded to each of the two sides of the bottom of the charging pile body, the outer sides of the guide rods are sleeved with first springs, one end of each first spring extends into the corresponding through hole, positioning plates are arranged at the two sides of the lower portion of the protection plate, support rods are welded to the tops of the positioning plates, one end of each support extends into the corresponding through hole, each support rod is fixedly connected with one end of the corresponding first spring, a plurality of positioning holes are formed in the sides, away from each other, of the two positioning plates, and a limit block is arranged in the middle of the bottom of the charging pile body. The charging pile facilitating positioning is reasonable in design, it is convenient to carry out positioning installation according to requirements of an installation site, at the same time, elements inside the charging pile are protected from damage, the usage quality of the charging pile is effectively improved, and the service life of the charging pile is effectively prolonged.

Owner:南陵县铭泽玉竹种植专业合作社

Vibrating screen

InactiveCN102029257AReduced strength requirementsReduce vibration forceSievingScreeningLow noiseEngineering

The invention relates to a vibrating screen and belongs to raw coal screening equipment. The vibrating screen consists of a power part, a screen body framework part, screening bars and a suspension part, and is characterized in that: a bracket is fixedly welded on two side beams of an upper screen frame; a transverse bolt of a crossbeam is fixed on the bracket; a vibration motor is fixed on the crossbeam; the side beams are respectively welded at two ends of an end beam to be respectively welded among a front end beam, the side beams and a rear end beam on upper and lower screen frames through four pairs of connecting posts; and the long annular screening bars are suspended on screening bar posts and screening bar hooks of the upper and lower screen frames. The vibrating screen has low amplitude and low noise, the requirement on screen intensity is low, transverse screening bars are absent, and the screen surface is not blocked.

Owner:薛熠 +1

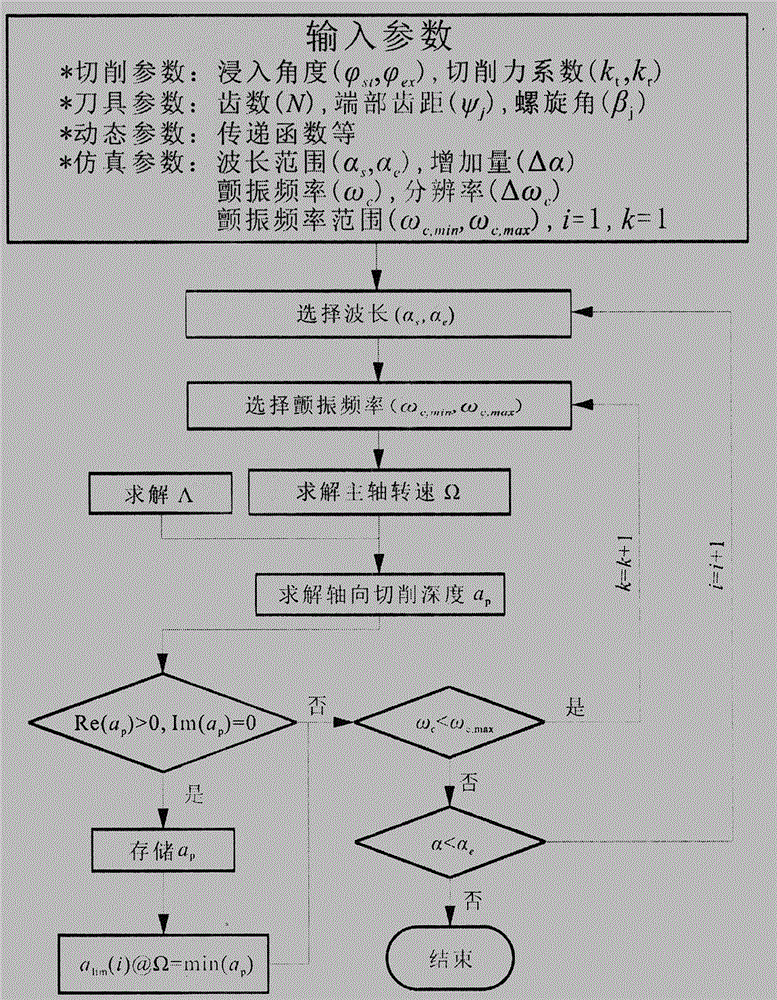

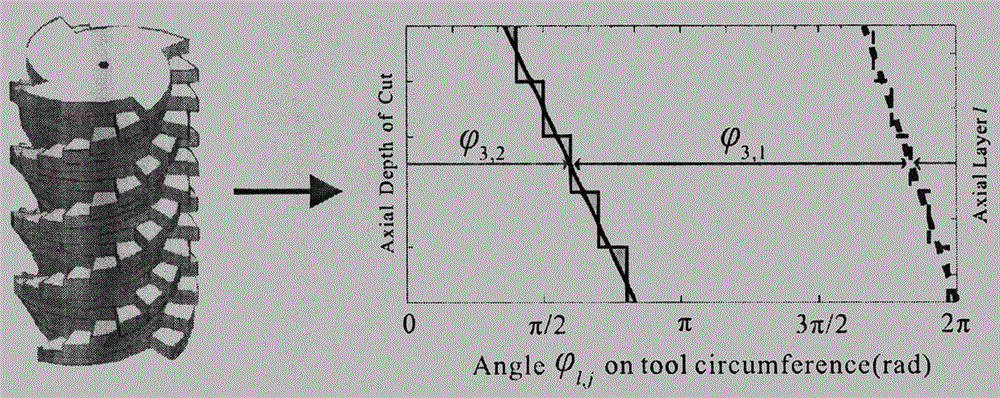

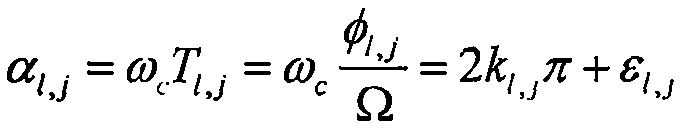

Rapid predication method for variable-helix milling cutter

InactiveCN106541301AReduced Stability Region PredictionReduce selection timeMeasurement/indication equipmentsNull pointData point

The invention brings forward a rapid predication method for a variable-helix milling cutter. The method comprises following steps: selecting limited wavelength and wavelength as the increment and scanning flutter wavelength within the rotating circular period of the cutter; selecting flutter frequency nearby a master mode on the basis of obtaining the mode feature of a spindle system and obtaining spindle rotation speed by calculating flutter wavelength based on flutter frequency; obtaining extreme cutting depth based on variables including spindle rotation speed; keeping cutting depth value and spindle rotation speed if the real part of the cutting depth is the positive number and the imaginary part is zero and circularly scanning flutter wavelength; continuing to scan flutter frequency if the real part of the cutting depth is the negative number and discarded; and finally obtaining data points including spindle rotation speed and extreme cutting depth after finishing scanning and drawing a stability lobe diagram. The rapid predication method for the variable-helix milling cutter has following beneficial effects: the problem of the conventional time-domain method such as a large number of null points is solved so that calculation efficiency is not low; and at the same time, a stability region for a cutting process of the variable-helix milling cutter can be rapidly obtained.

Owner:TIANJIN AEROSPACE CHANGZHENG ROCKET MFGCO +2

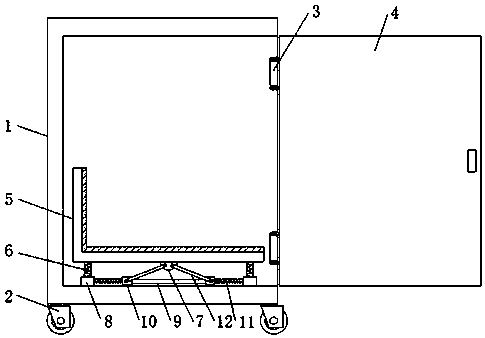

Transportation apparatus for charging pile

InactiveCN107697118AReduce vibration forceExtended service lifeHand carts with multiple axesHand cart accessoriesEngineeringMechanical engineering

The invention discloses a transportation apparatus for a charging pile. The transportation apparatus comprises an apparatus body. The apparatus body is in a cavity structure; movable wheels are both arranged on two ends of the bottom end of the apparatus body; one side of the apparatus body is provided with a cabinet door via a hinge chain; a carrying rack is disposed in the apparatus body; two sides of the bottom end of the carrying rack are respectivelyfixedly connected with one ends of two first springs; two spacing blocks are welded on the middle of the bottom end of the apparatus body; one spacing block is corresponding to the two first springs; two fixing blocks are welded on the inner wall of each bottom end of the two sides of the apparatus body; the top end of each fixing block isfixedly connected with the other end of each first spring; and slide rods horizontally arranged are connected between each two fixing blocks. The transportation apparatus is rationally designed; vibration force in transverse and longitudinal directions can be relived during the transportation of the charging piles; damages to element devices inside the charging piles can be avoided; and service life and use quality of the charging piles can be enhanced.

Owner:ANHUI MINGRUI INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com