Frame structure with vibration-isolating floor system and installation method of frame structure

A frame structure and vibration isolation technology, which is applied to building components, building structures, buildings, etc., can solve problems such as the impact of adjacent rooms and the surrounding environment, the forced vibration of the floor, and the lack of developers, so as to promote the industrialization of construction , Reduce forced vibration, easy to industrialize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

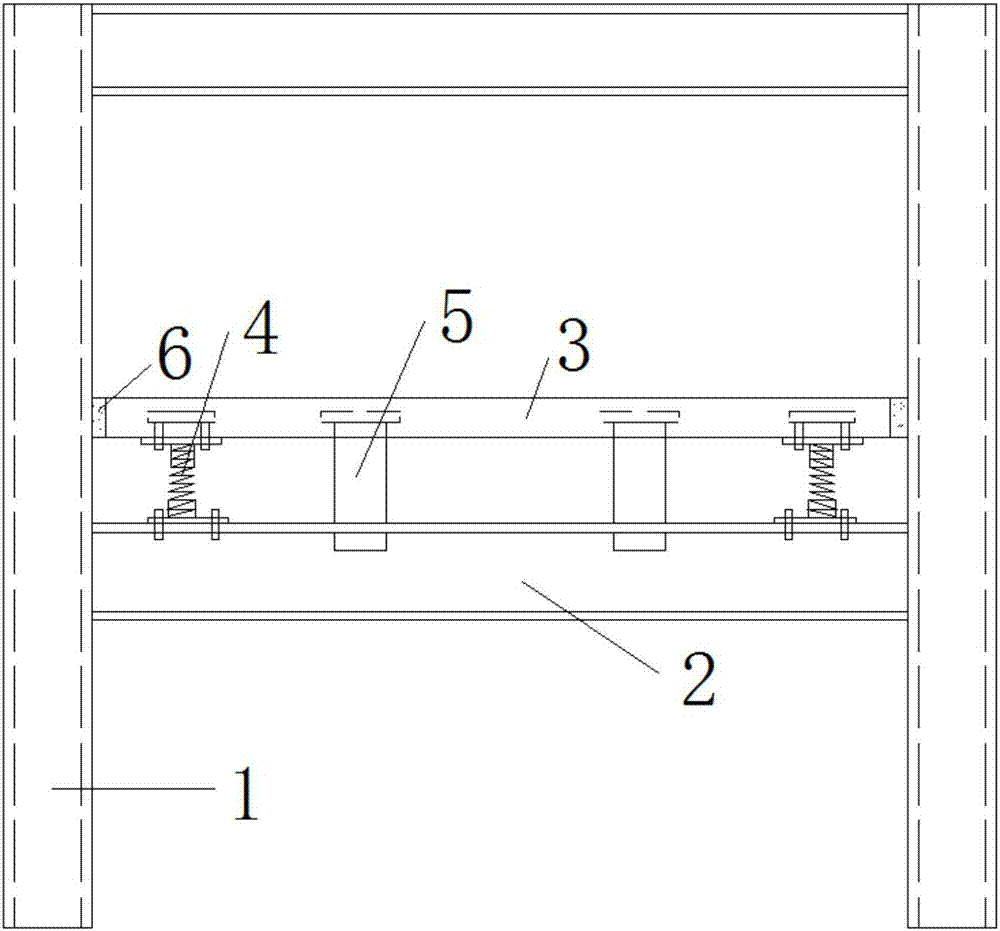

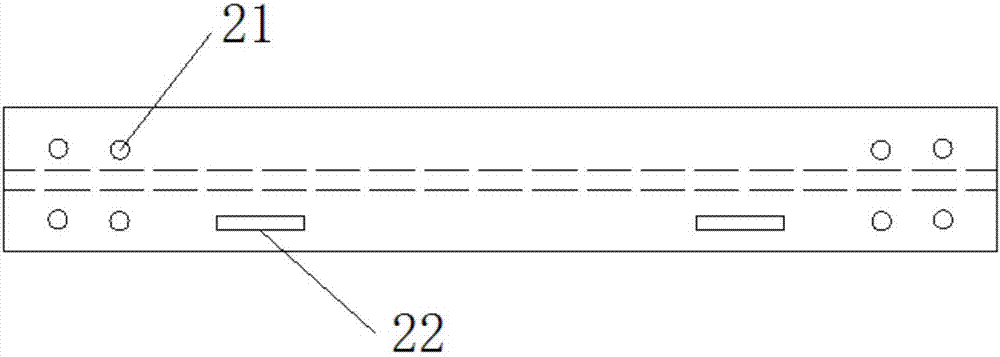

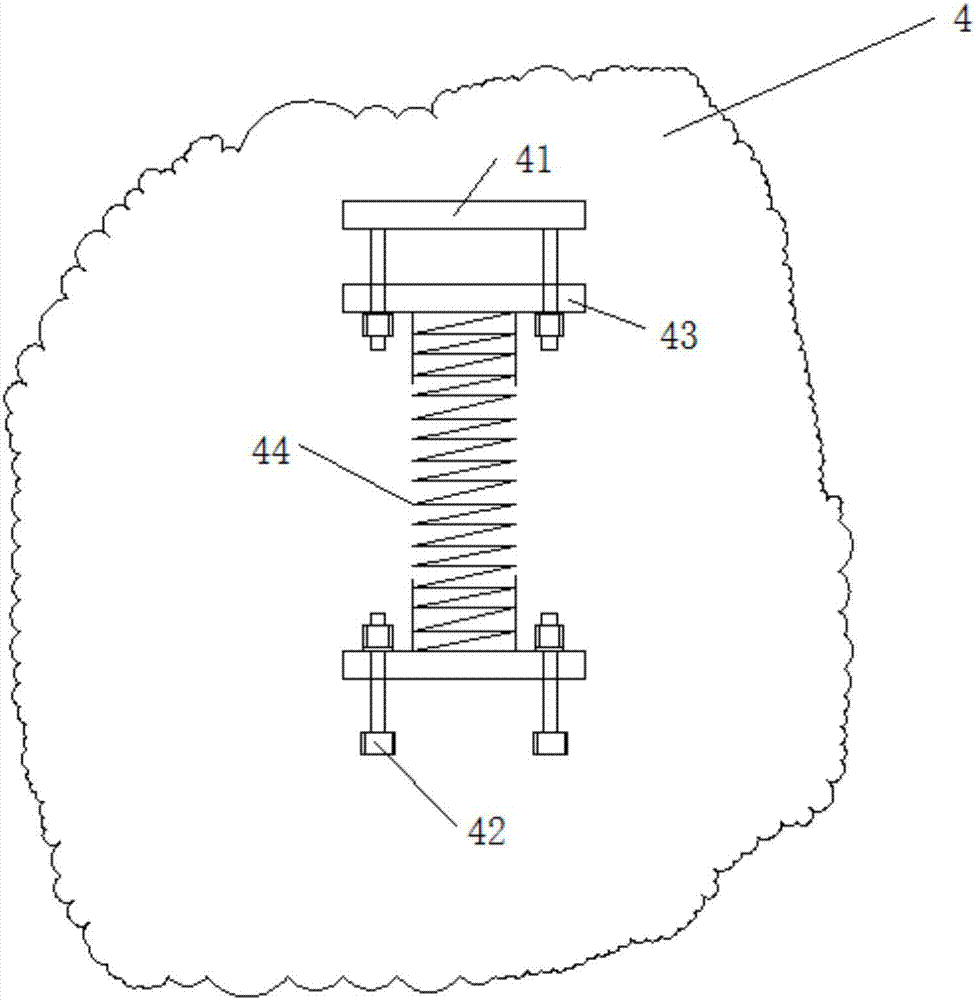

[0048] Such as Figure 1 to Figure 20 As shown, it is a frame structure for vibration isolation of a floor of the present invention, including a column 1 and a beam 2 fixedly connected, and a floor 3, and a frame structure is formed by interconnecting the column 1, the beam 2 and the floor 3, and the column 1 is Rectangular steel pipe, the beam 2 is I-shaped steel, the floor 3 is a prefabricated reinforced concrete floor, and the vibration isolation component 4 and the shear key 5 are arranged between the beam 2 and the floor 3. By setting the vibration isolation component 4 and the shear key 5, the effective The vibration of the frame mechanism is reduced, and the ...

Embodiment 2

[0067] Such as Figure 13 ~ Figure 15 As shown, compared with Example 1, the beam 2 in Example 2 adopts rectangular steel pipes, so the bolts 42 in the vibration isolation assembly 4 should pass through the bolt holes of the lower flange of the beam 2, the bolt holes of the upper flange of the beam 2, and the The bolt holes of the spring base 43 are connected by tightening the nuts; the rest are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com