Vibrating screen

A technology of vibrating screen and screen bar, applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of small raw coal processing capacity, high screen body strength requirements, high amplitude requirements, achieve low screen body strength requirements, overcome the processing The effect of small capacity and low amplitude requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

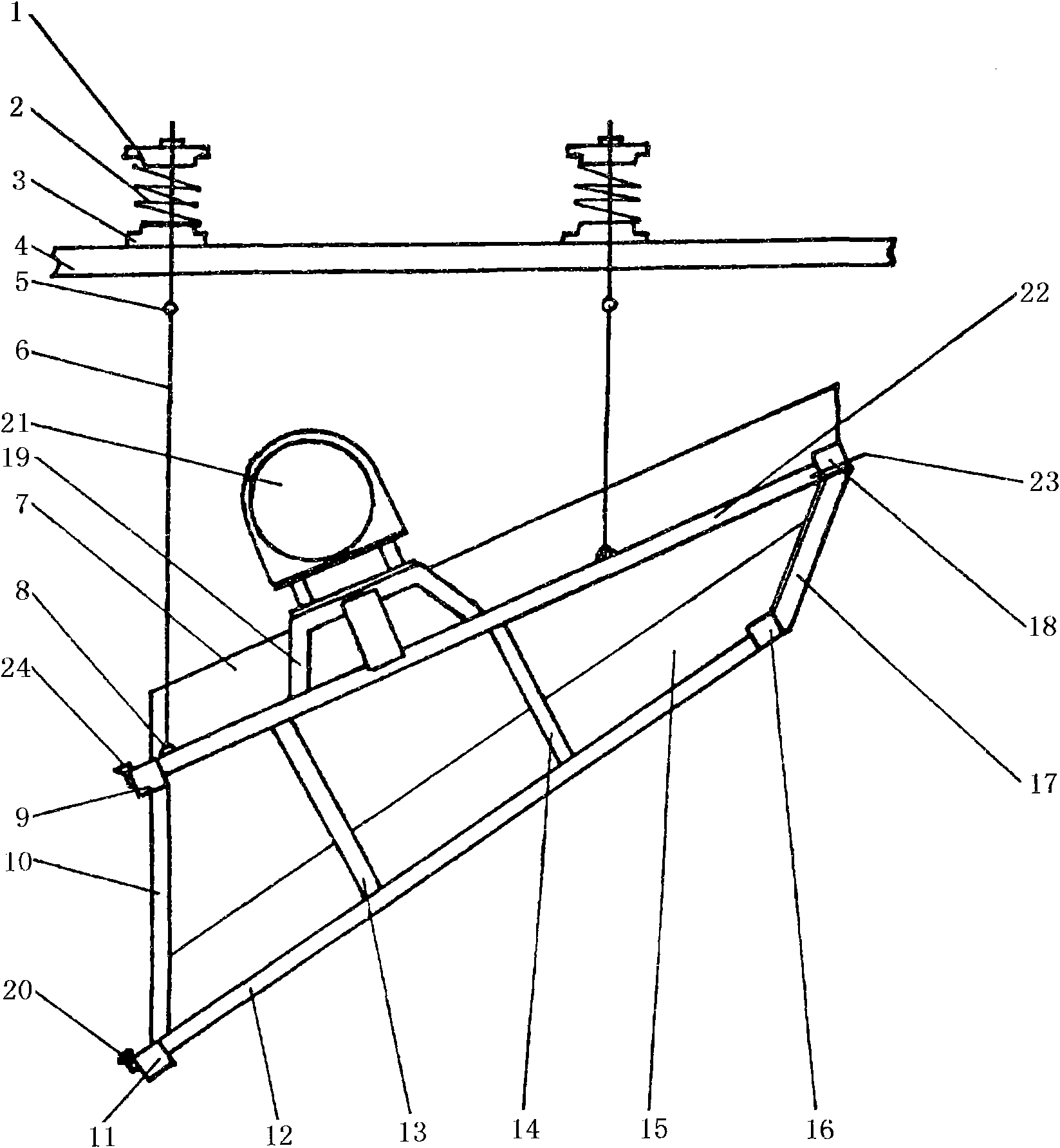

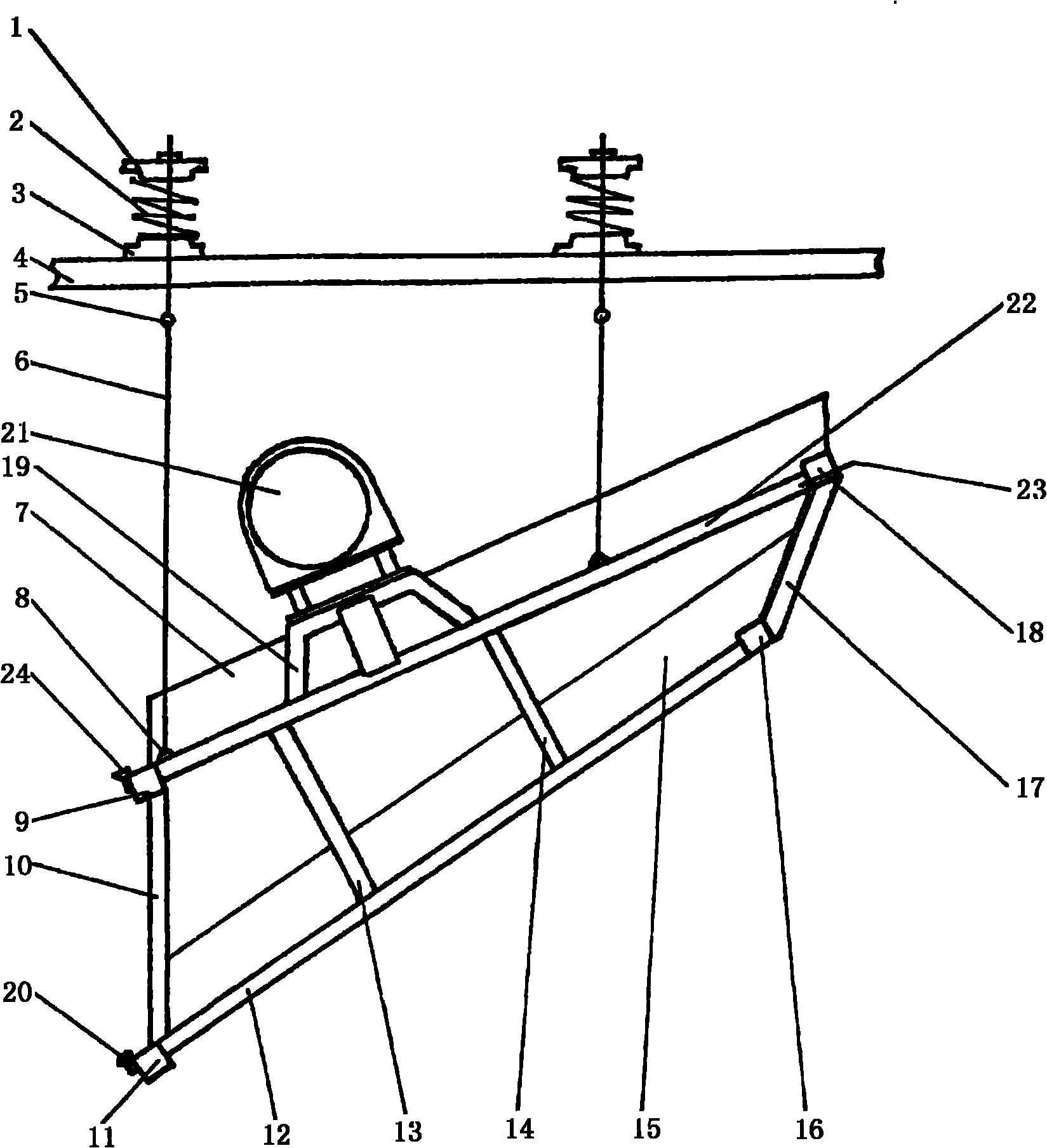

[0008] Refer to the accompanying drawings as follows: the vibrating screen includes a power part, a skeleton part of the screen body, a screen bar and a suspension part. Power part is made up of excitation motor 21 and excitation motor frame. The excitation motor frame is made of a support 19 and a beam welded by channel steel. Two supports 19 are welded respectively on the two side beams 22 of the upper screen frame, the crossbeam transverse bolts are fixed on the two supports 19, and the excitation motor 21 is bolted on the excitation motor crossbeam. The skeleton of the screen body is composed of front and rear end beams, side beams and connecting columns. The end beams 9, 11, 16, 18 are made of two channel steel buckle welds, and the side beams 12, 22 are respectively welded to the two ends of the end beams to form a rectangular screen frame. The manufacturing process of the upper and lower screen frames is the same, and four pairs of connecting columns 10, 13, 14, 17 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com