Propeller

A new type of propeller technology, applied in the direction of rotating propellers, rotating propellers, etc., can solve the problems of insufficient economy, power loss, increased energy consumption, etc., and achieve the effect of simple structure, small vibration force and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in detail below in conjunction with the accompanying drawings.

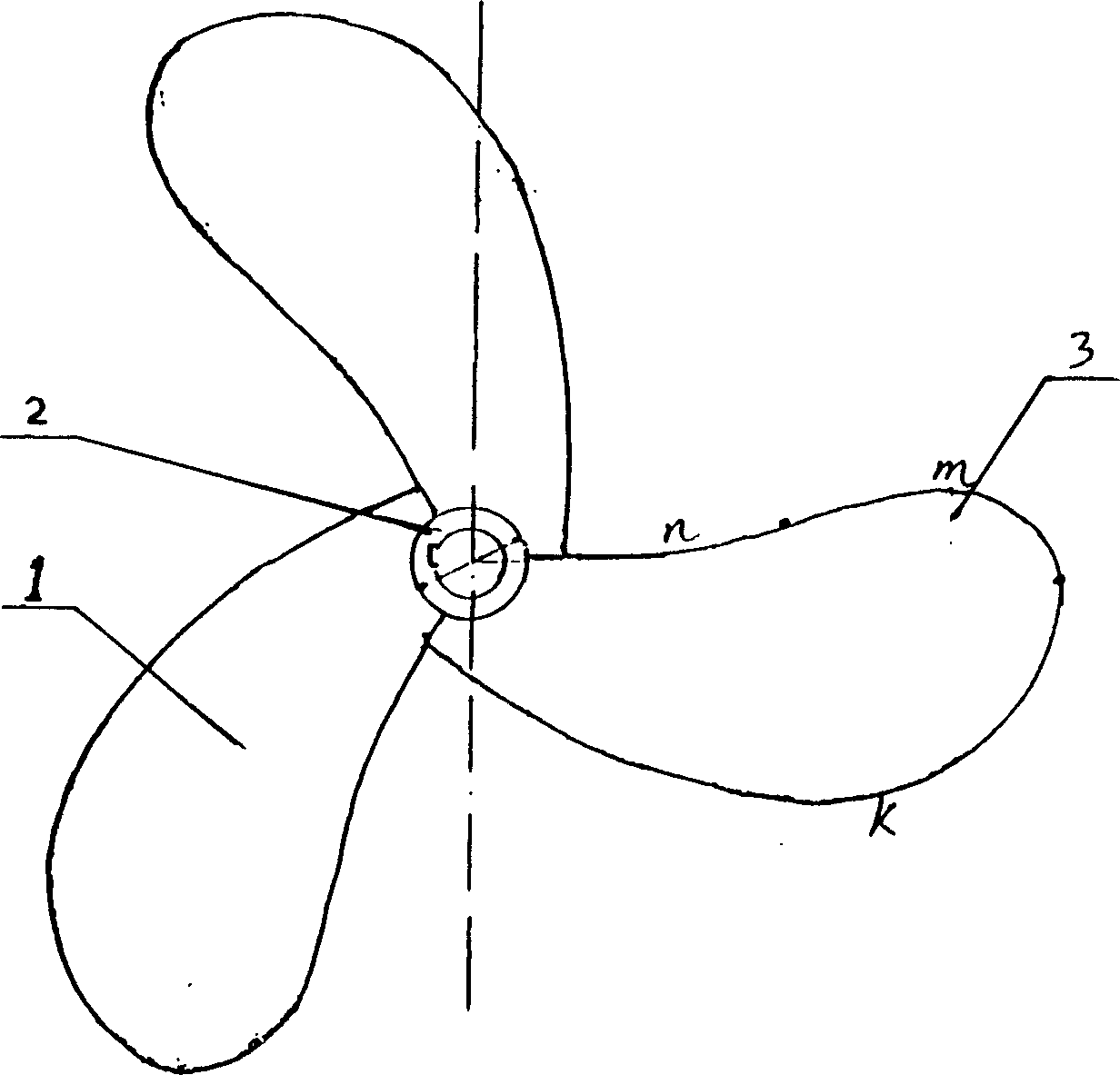

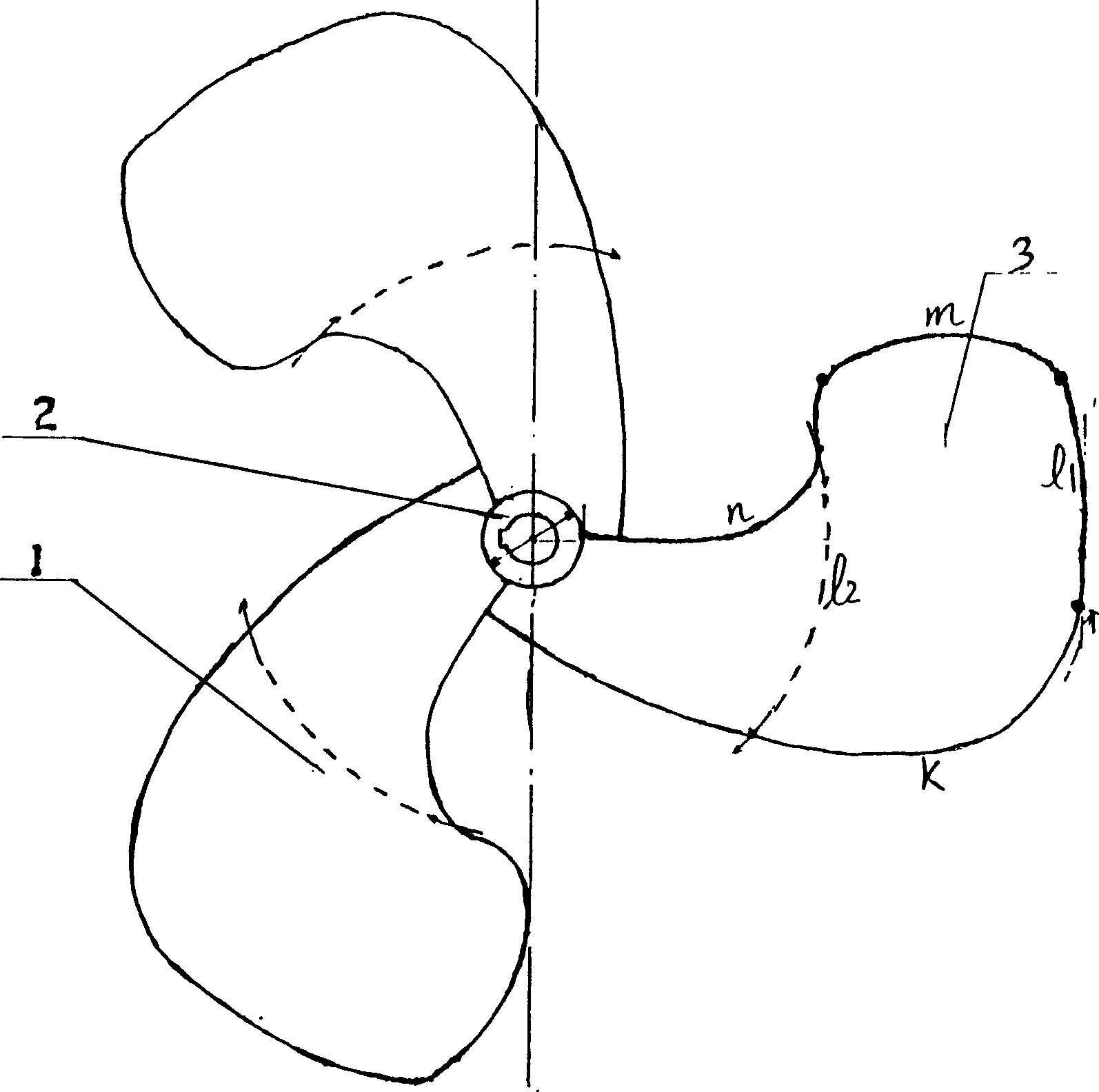

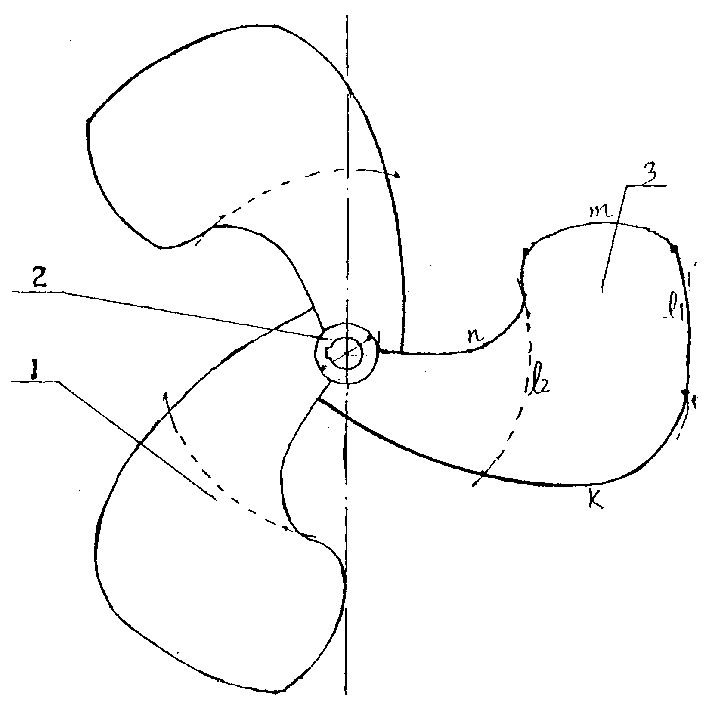

[0010] The invention as figure 2 As shown, it is composed of a wheel shaft 2 and a plurality of blades 1, and the edge of the blade 1 is composed of four curves connected in sequence: the anti-drag line k, the outer rotation line l1, the connecting line m, and the waterline n. Assume that the length of the propeller tail in the traditional technology is D, then the length 3 of the propeller tail part of the present invention is 2D-4D, and the outer rotation line l1 is an arc line with the axle center as the center, and half of the radius of this circle is a radius to draw a circle to form the arc line l2, within the outer rotation line l1 The part of the blade 1 other than the arc line l2 is concave along the direction perpendicular to the radial direction, and forms an angle of 13-23 degrees with the shaft section.

[0011] The following examples illustrate:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com