Rapid predication method for variable-helix milling cutter

A prediction method and technology of stability, applied in the field of parts processing and manufacturing, can solve problems such as poor engineering applicability, and achieve the effects of improving processing efficiency, reducing stability area prediction, and reducing selection time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

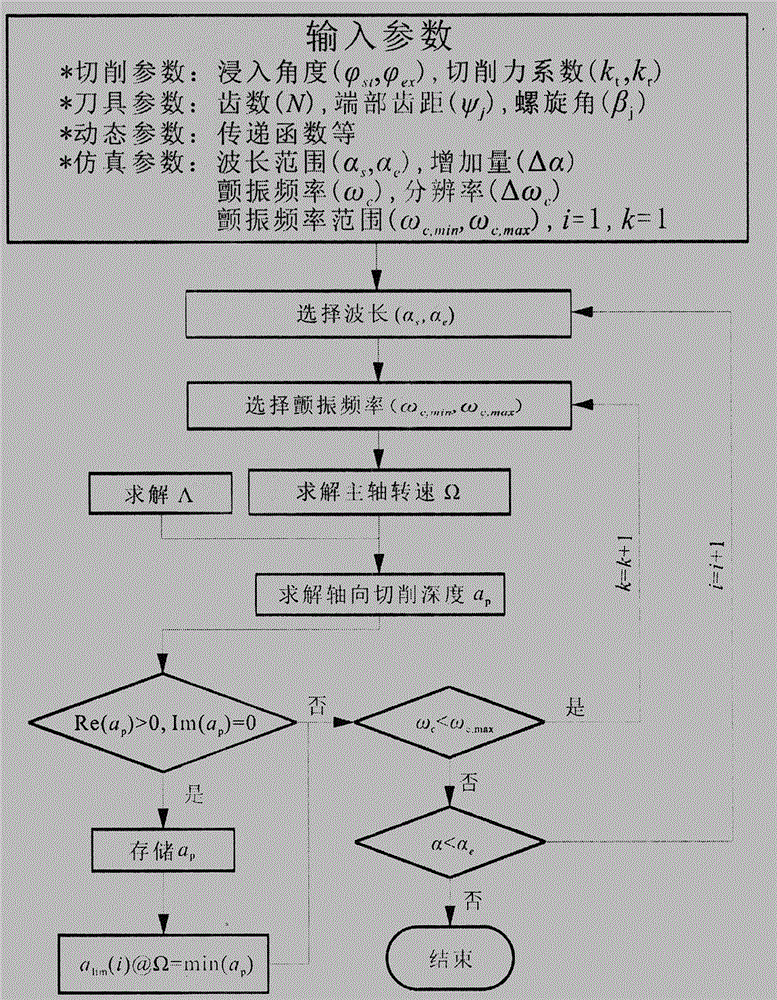

[0022] Step 1: In the range of 10-3600 degrees, with limited wavelength α l , j = 5 degrees as an increment, scan the flutter wavelength α l , j ;

[0023] Step 2: Select the dither frequency ω near the dominant mode c ;

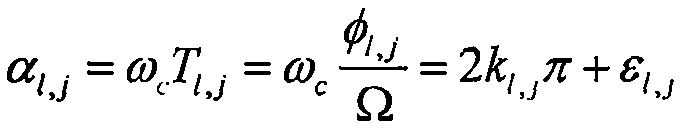

[0024] Considering the flutter wavelength α l , j Calculation formula

[0025]

[0026] Among them, k l , j is the number of lobes, ε l , j is the phase shift of the cutting surface. When only the first tooth is considered, substitute the obtained wavelength and chatter frequency into the following formula to obtain the spindle speed

[0027]

[0028] Step 3: Substitute the obtained rotational speed and other variables into the formula to obtain the limit cutting depth.

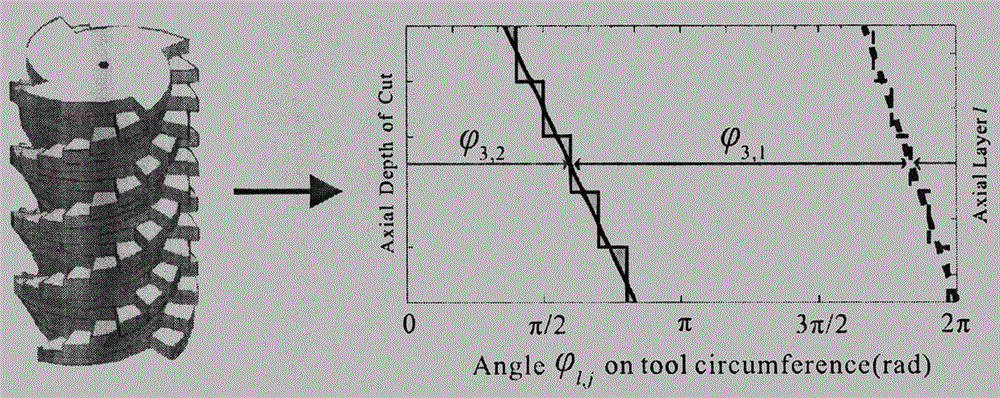

[0029] (1) Due to the variable helical characteristics of the teeth, the tooth body is sliced along the length direction, and the corresponding inter-tooth angle of each slice can be expressed as:

[0030]

[0031] Among them, M is the axial discrete fraction, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com