Four-motor-driving and double-screen-fence balancing type horizontal vibrating de-watering centrifuge and parameter determining method

A technology of centrifugal dehydrator and vibrating motor, which is applied in the direction of drying solid materials, drying solid materials without heating, lighting and heating equipment, etc., which can solve the problems of low work efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0125] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

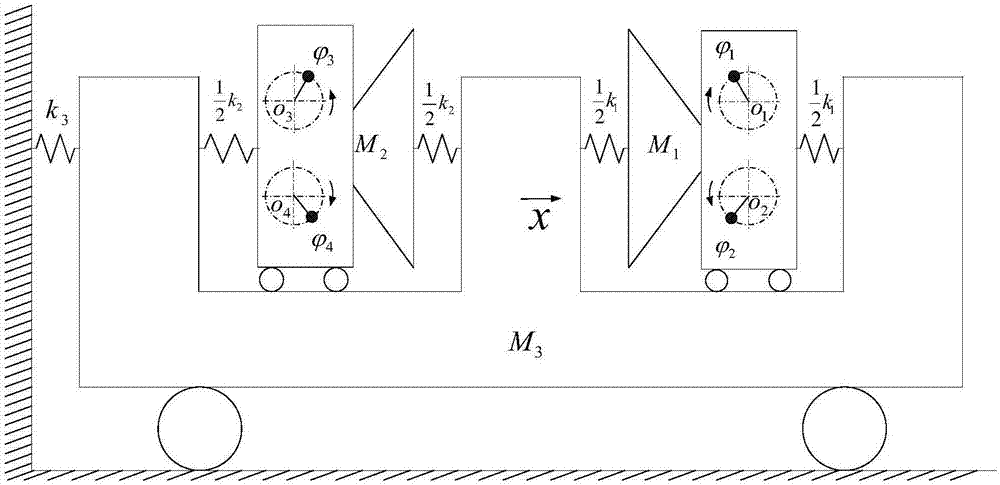

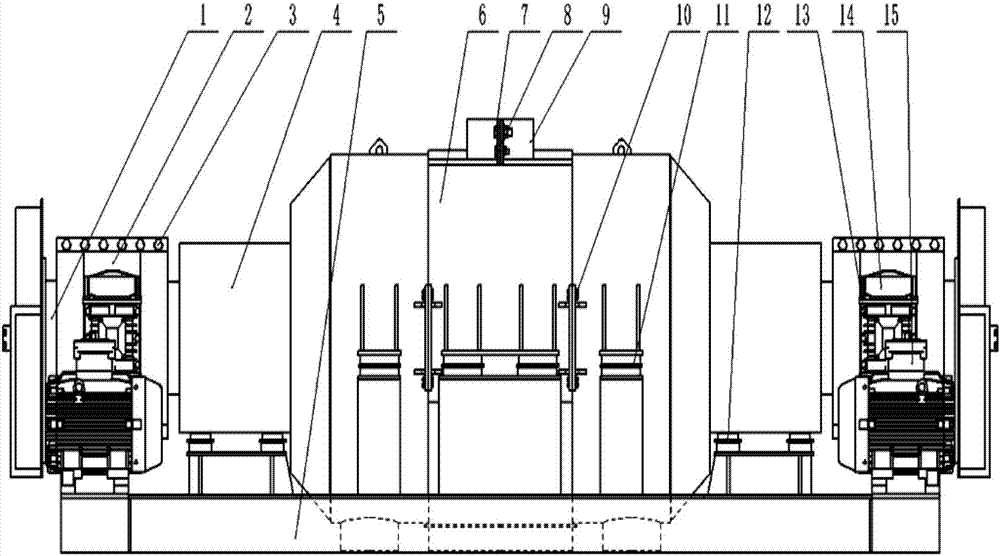

[0126] Such as figure 1 , 2 , As shown in 3, a four-machine-driven double-sieve fence balanced horizontal vibrating centrifugal dehydrator device includes a material handling mechanism, a sieve fence box mechanism, a frame, a dehydration transmission mechanism and a power mechanism, a vibration exciter and a vibration damping mechanism.

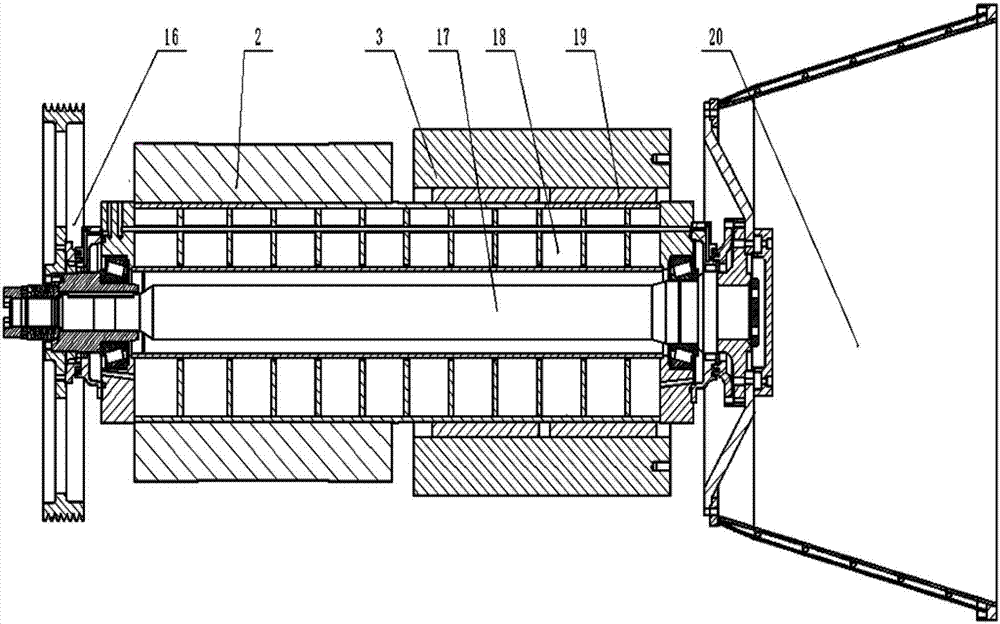

[0127] The material loading and unloading mechanism 6 is connected with the screen box body mechanism 4 through bolts in the corresponding lug plate holes. When installing the equipment, first install and fix the screen box body 4 on the left and right sides, then install the oil delivery tank 18 and the shear rubber spring corresponding to the screen box body mechanism 4, and then install the main shaft 17 and related parts to the oil delivery tank 18, And belt pulley 16 and sieve bar 20 and relev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com