Radial ring seal

A technology of ring seals and seal sleeves, which is applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve problems such as the impossibility of fundamentally solving the airflow excitation and vibration, and achieve obvious effects of turbulent flow resistance increase, convenient adjustment of sealing gaps, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

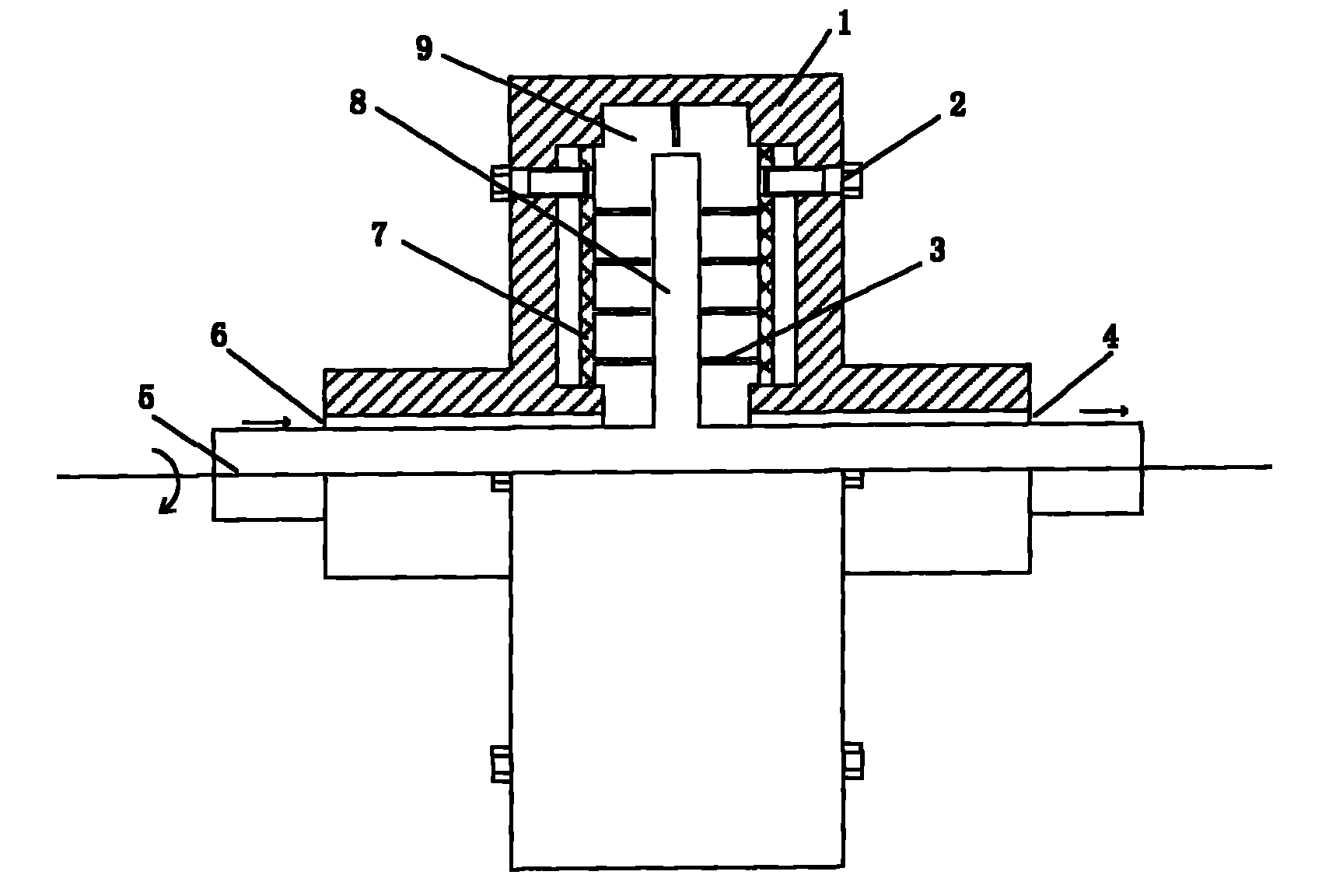

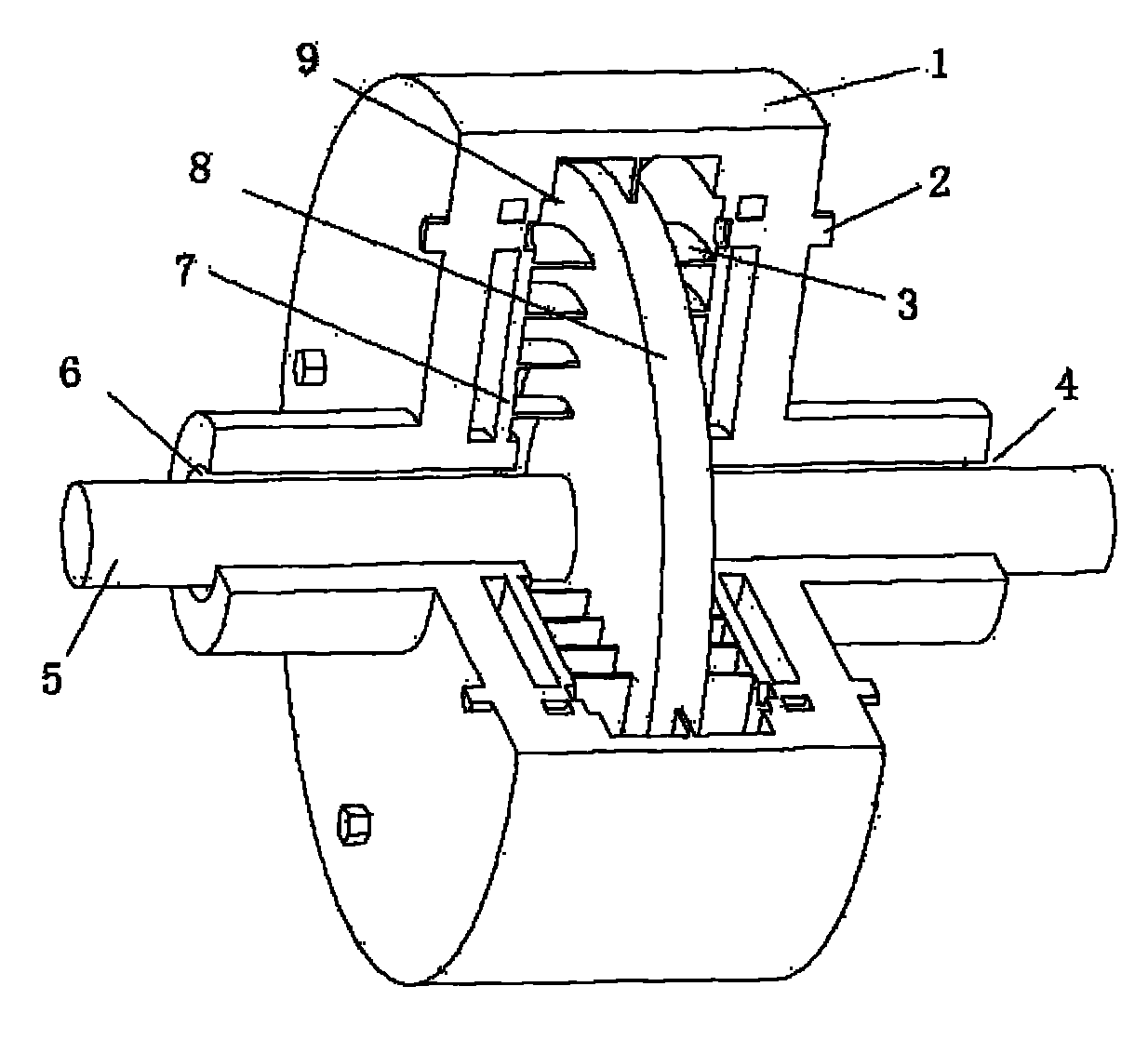

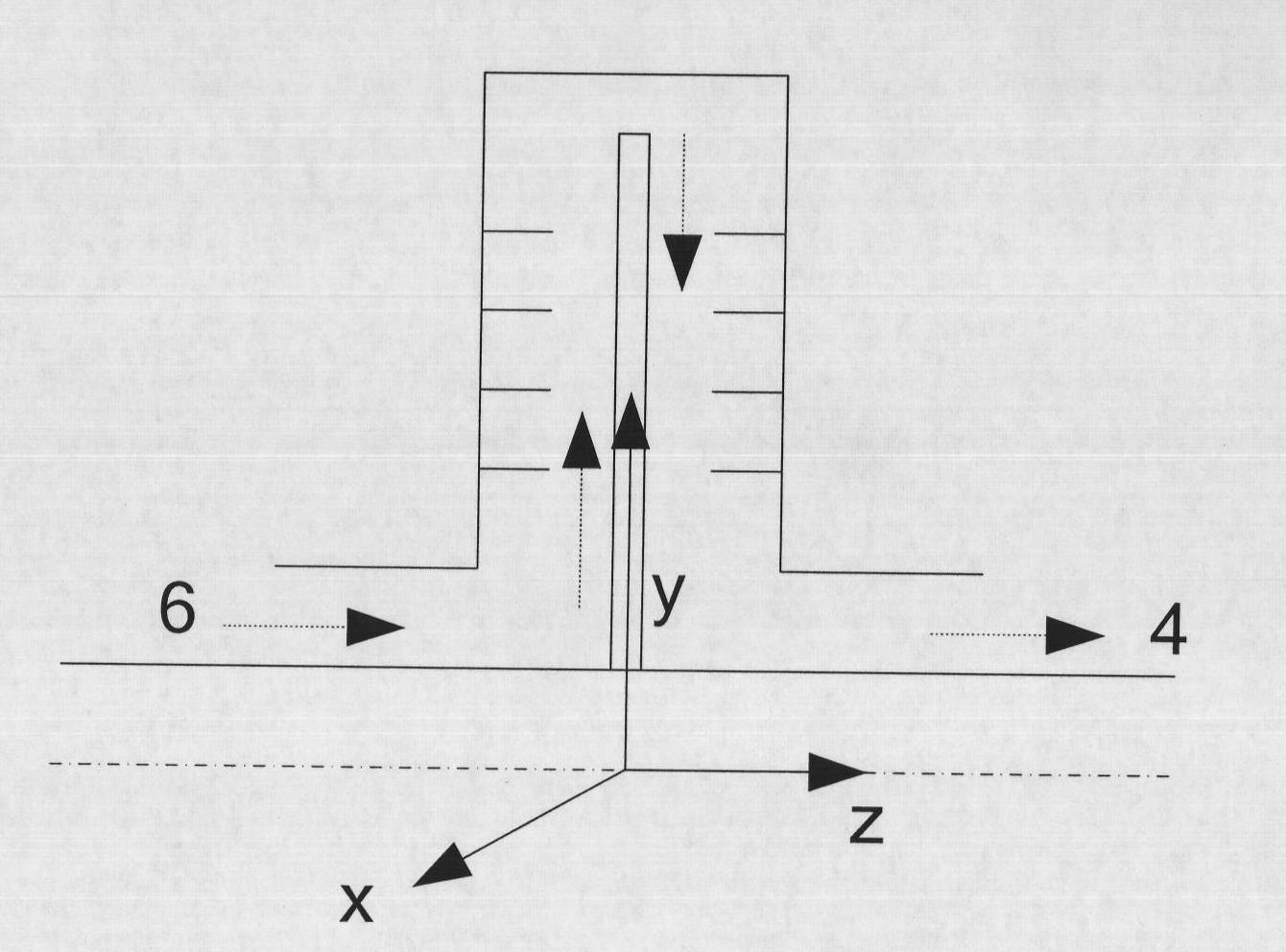

[0021] A radial annular seal, comprising: a rotor 5 and a sealing sleeve 1 sleeved on the rotor 5, a sealing cavity 9 is provided in the sealing sleeve 1, an adjusting plate 7 is slidably connected to the sealing cavity 9, and an adjusting plate 7 is slidably connected to the sealing cavity 9. An adjusting screw 2 is provided on the top, one end of the adjusting screw 2 is used as an adjusting end and is located outside the sealing sleeve 1, and the other end of the adjusting screw 2 is rotatably connected with the adjusting plate 7, and a sealing disc 8 is arranged on the rotor 5. An annular sealing tooth 3 is provided on the adjusting plate 7 and the annular sealing tooth 3 is located between the sealing disc 8 and the adjusting plate 7 .

[0022] figure 1 As shown, a sealing disc is designed on the rotating shaft, and there is an adjusting plate on both sides of the sealing disc, and a group of annular seals with different diameters are installed on the adjusting plate. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com