Vortex elimination fin structure with detachable fins

A fin blade and vortex elimination technology, applied in the field of vortex elimination fin structure, can solve the problems of no fin blade, no energy saving effect and high maintenance cost in the diversion cap structure, so as to improve maintainability, improve propulsion performance, The effect of easy processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

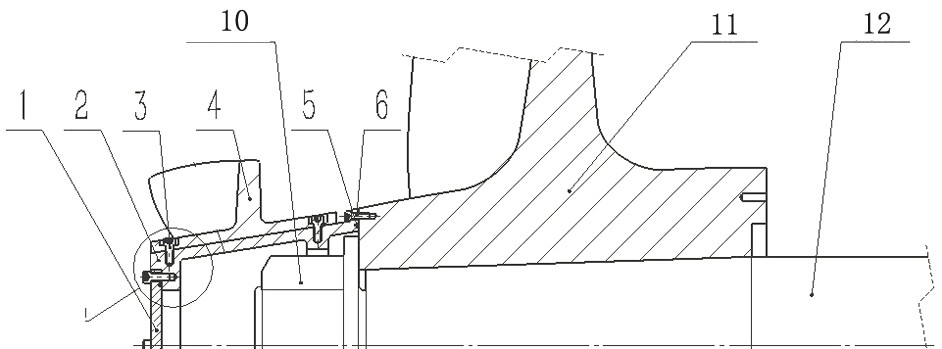

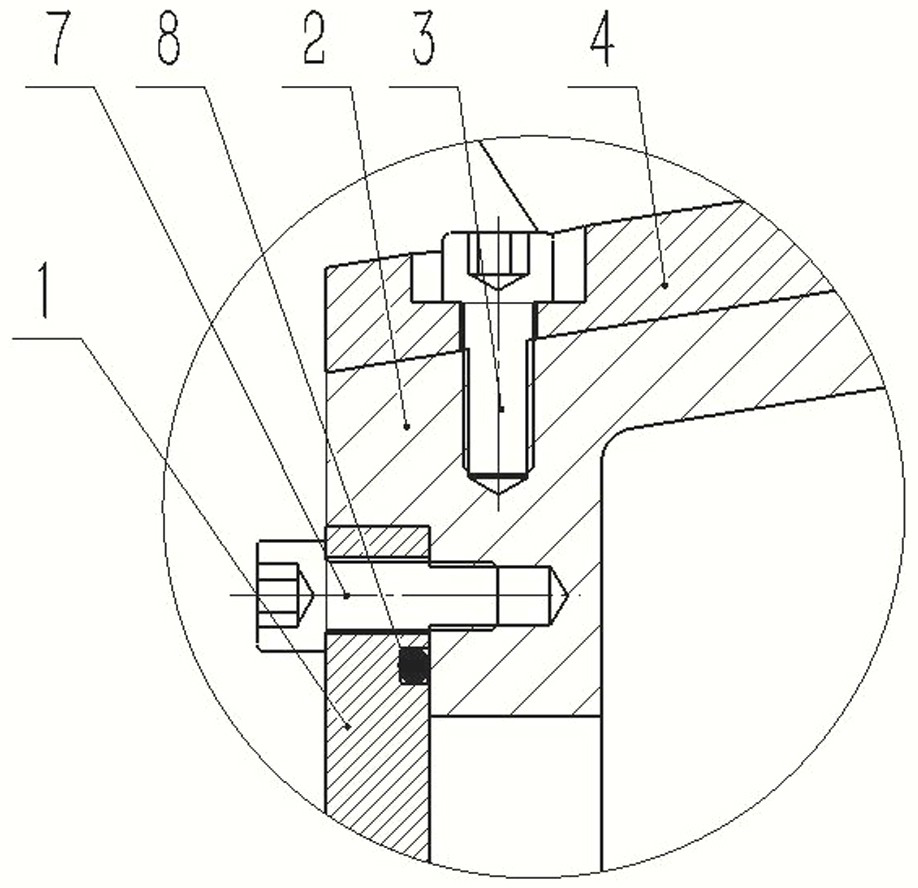

[0019] Example: figure 1 , 4 As shown in , the vortex-eliminating fin structure with detachable fins has a flush rear structure, which is different from the traditional vortex-eliminating fin structure in which the radial dimension gradually decreases to zero. Implementing the structure shortens the length of the vortex-eliminating fin and reduces the manufacturing cost. In addition, the water flows along the linear shape of the propeller hub and the vortex-eliminating fin, and automatically shrinks after detaching from the vortex-eliminating fin, which increases the imaginary length of the vortex-eliminating fin and reduces the frictional resistance between the water flow and the vortex-eliminating fin.

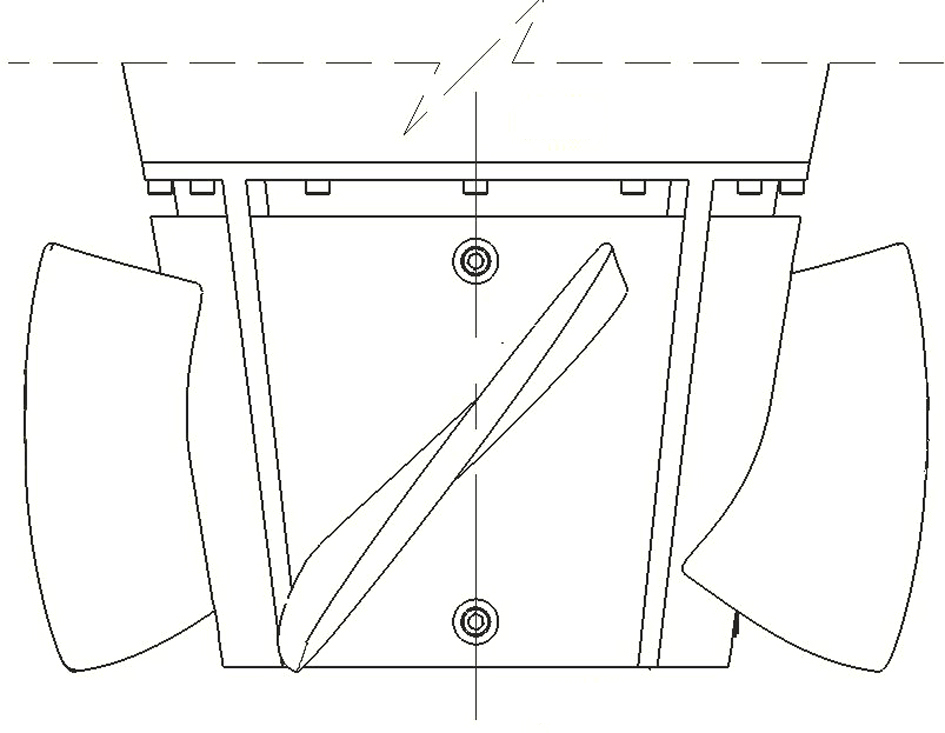

[0020] Example: image 3 As shown: the vortex-eliminating fin structure with detachable fins, the fins are installed in the outer groove of the guide body; the width of the guide body groove gradually decreases from the front side to the rear side, A tapered groove is for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com