T-shaped staggered-type labyrinth seal capable of eliminating rotor exciting force

A technology of labyrinth sealing and exciting force, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of damaging the rotor, reducing the sealing performance, and increasing the original gap of the seal, so as to improve the sealing performance and reduce leakage , Reduce the effect of sealing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in more detail below in conjunction with accompanying drawing example:

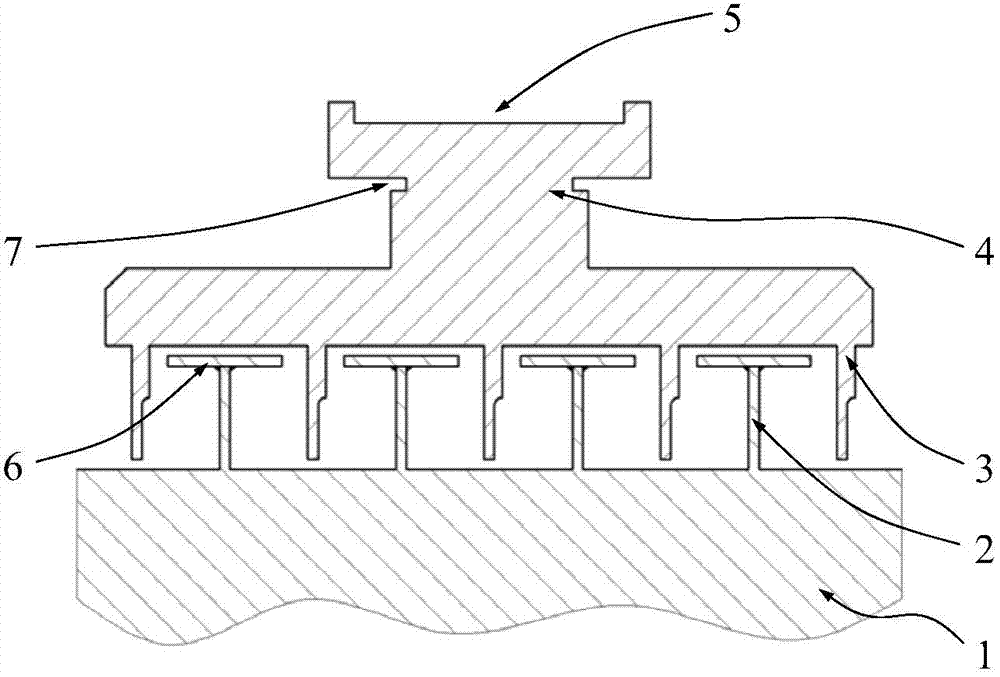

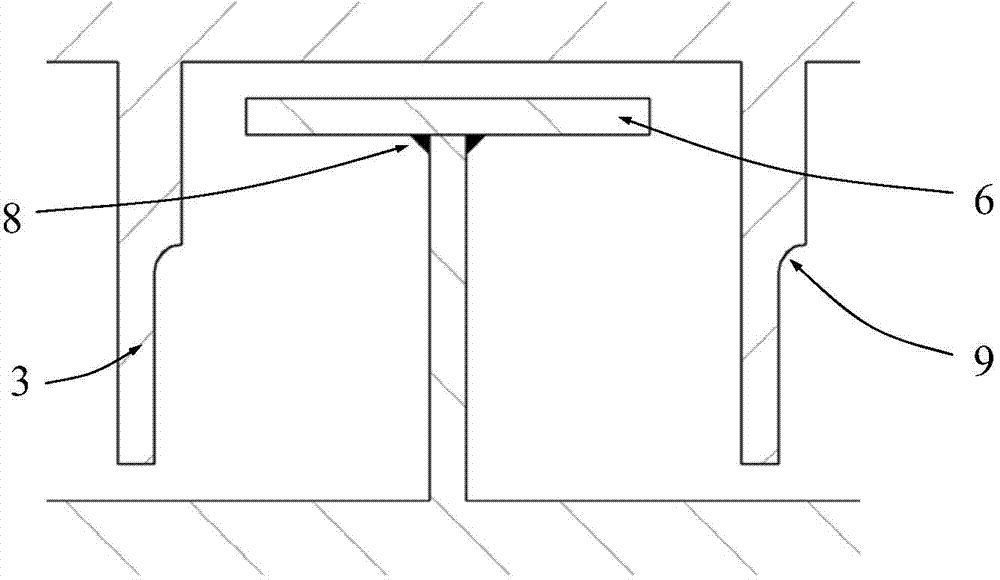

[0017] In combination with Figures 1 to 3, the technical solution adopted by the present invention is: by designing the T-shaped structure of the low teeth in the staggered teeth, the force of the gas in the flow field in the sealed cavity can be reversed in addition to acting on the rotor. The direction acts on the T-ring that is connected to the rotor. In this way, most of the gas force can be canceled in the radial direction.

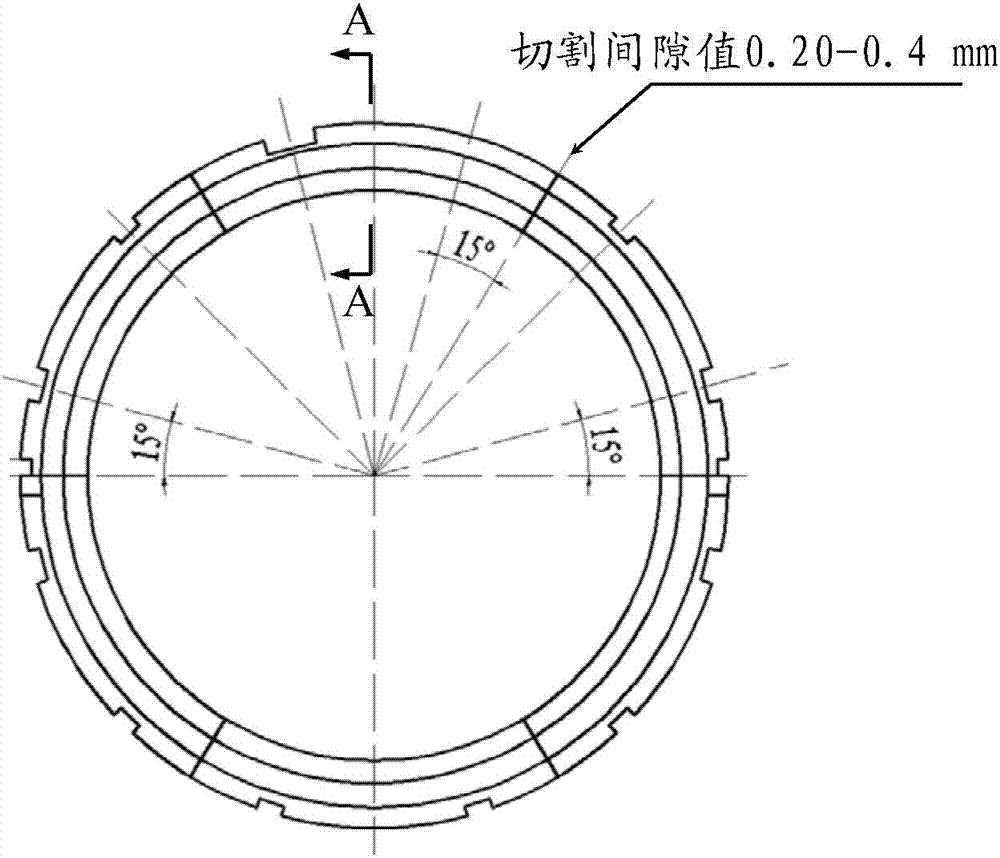

[0018] In Figure 1, the entire sealing ring is assembled from 6 independent sector rings. The sector angles of the six sector rings are all 60°, which can ensure the clamping and positioning of the sealing ring and the casing, and at the same time have the characteristics of convenient installation and disassembly and prevention of excessive deformation.

[0019] The sealed low teeth 2 are installed on the rotor 1, and 3 is the high te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com