Rotor Support Mechanism of Rolling Bearing Turbocharger

A technology for turbochargers and rolling bearings, applied to rolling contact bearings, rigid supports for bearing components, bearings for rotational motion, etc., can solve problems such as poor sensitivity of floating bearings, improve reliability, solve lubrication problems, and improve support The effect of stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

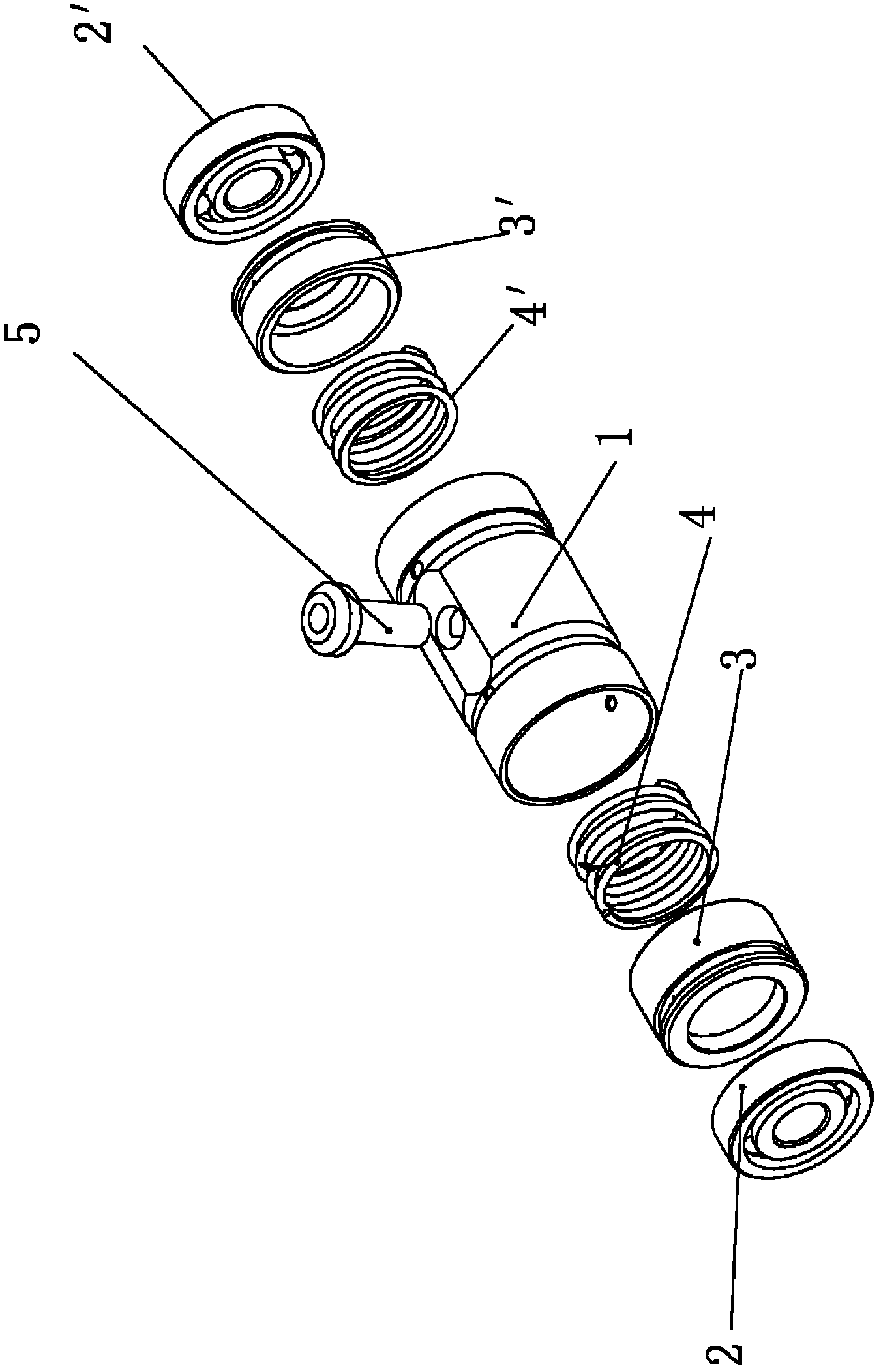

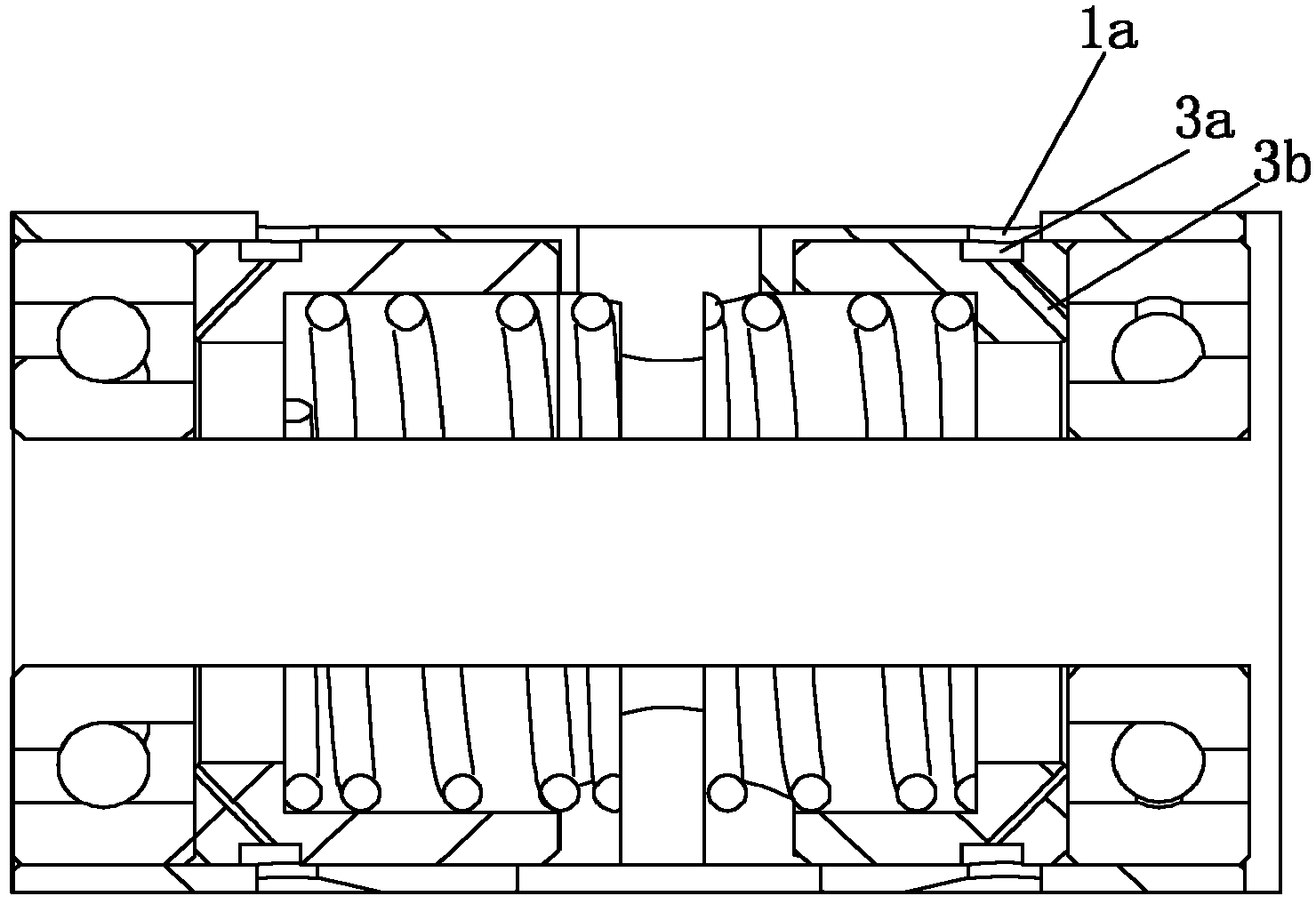

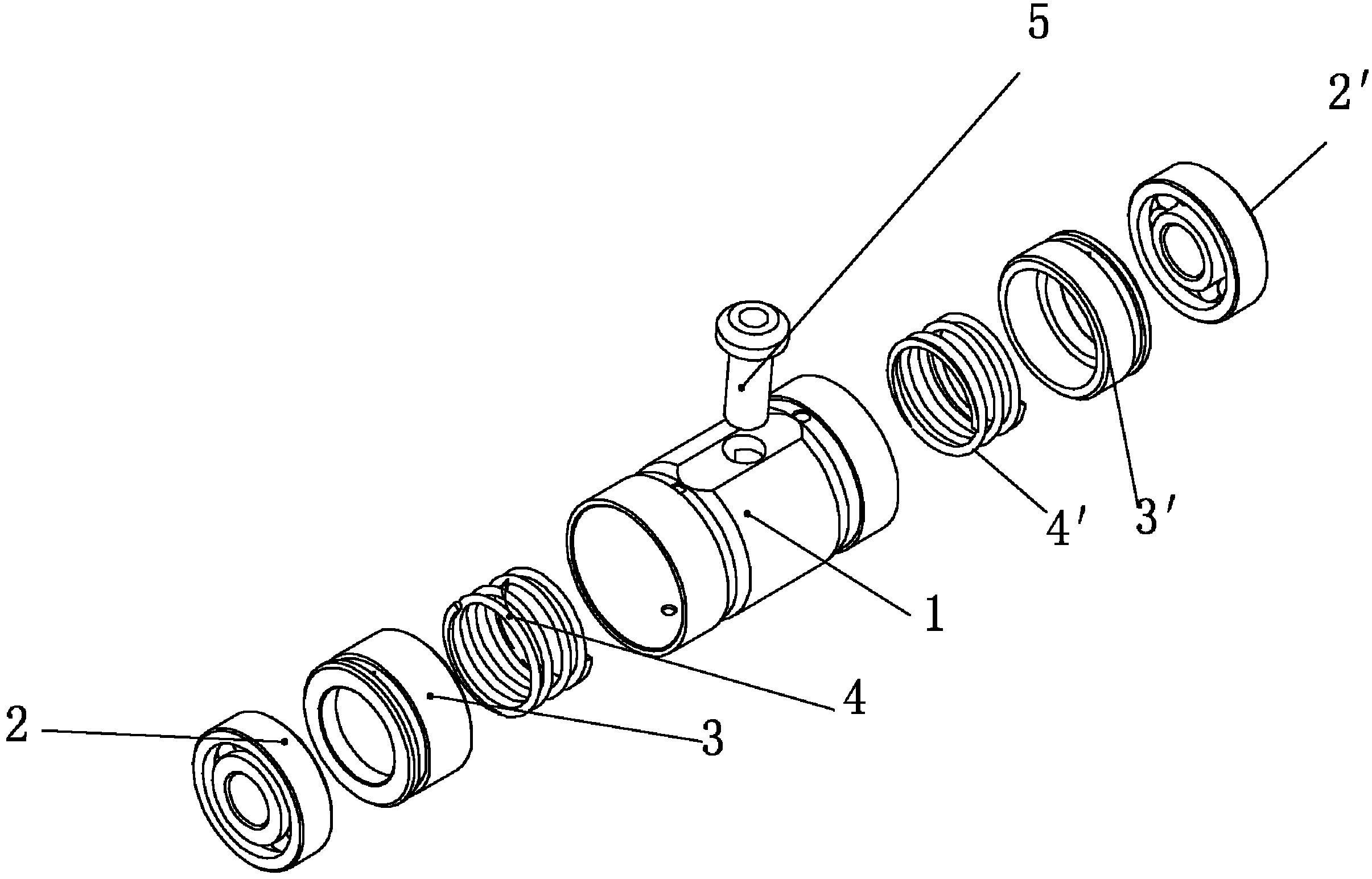

[0017] Such as figure 1 , figure 2 As shown, the rotor supporting mechanism of the rolling bearing turbocharger includes a bearing sleeve and two springs, two thrust sleeves and two bearings arranged in the bearing sleeve 1, and the two springs are respectively spring 4 and spring 4′ , the two thrust sleeves are respectively thrust sleeve 3 and thrust sleeve 3', the two bearings are angular contact rolling bearing 2 and rolling bearing 2', the spring 4 and spring 4' are symmetrically arranged in the bearing sleeve 1 and connected to each other, the two The two thrust sleeves respectively insert the springs into the thrust sleeve 1 from the ends of the two springs and apply pretightening force. The thrust sleeve 3 is arranged on the left side of the spring 4, and the spring 4 is inserted into the thrust sleeve 3, and the thrust sleeve 3 is inserted into the thrust sleeve 3. The sleeve 3' is set on the right side of the spring 4', the spring 4' is inserted into the thrust slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com