Suspended parallel hybrid power-driven system with double clutches and double motors

A hybrid and dual-clutch technology, which is applied in the system field of the automotive technology field, can solve the problems of difficult optimization of fuel saving and emission reduction of the whole vehicle, and difficulty in realizing the main functions of hybrid power, so as to avoid dragging the engine backwards and improve pure electric drive. Efficiency and regenerative braking energy feedback efficiency, effect of eliminating influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

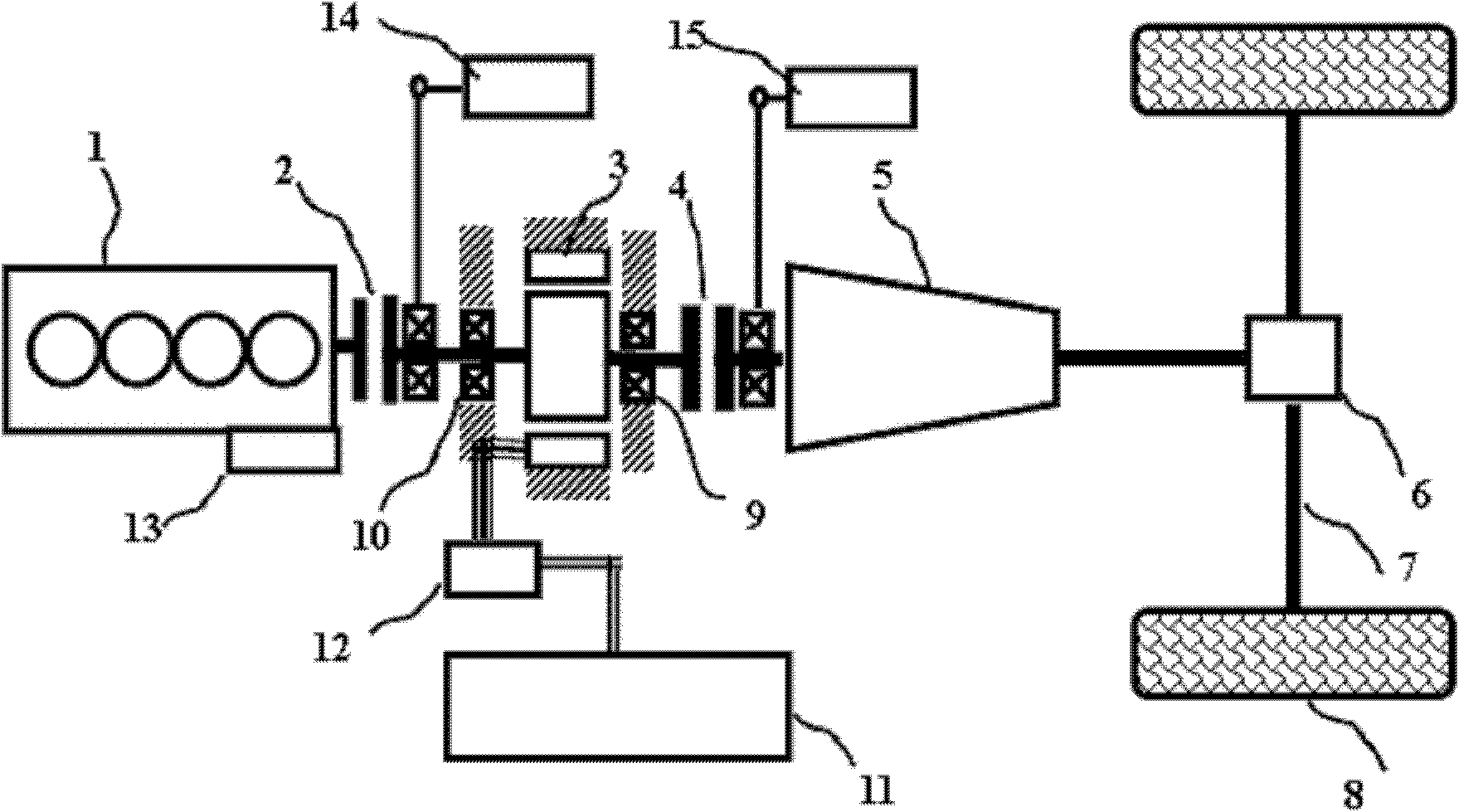

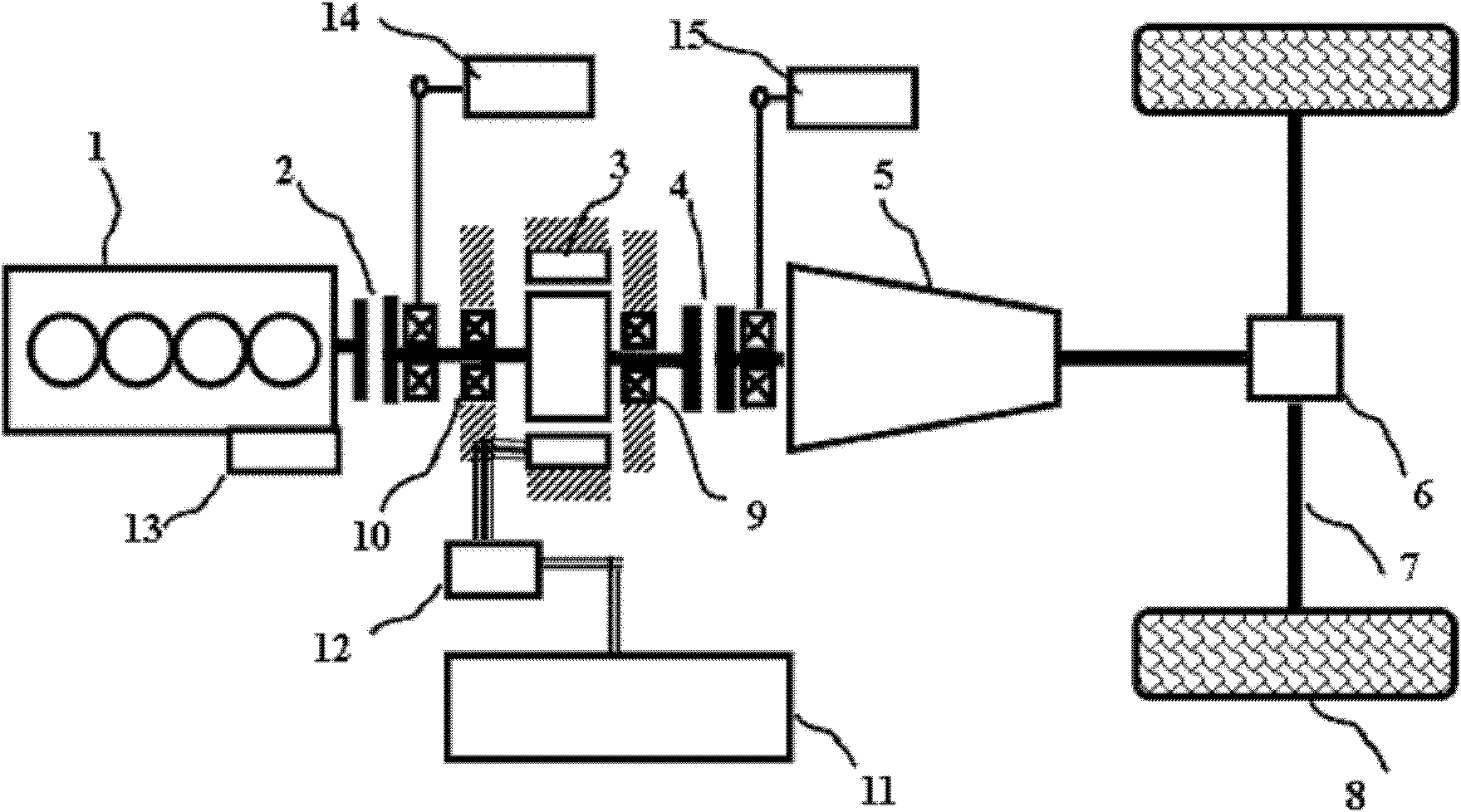

[0038] Such as figure 1 As shown, the present embodiment includes: engine 1, first clutch 2, motor 3, second clutch 4, gearbox 5, reduction differential 6, drive half shaft 7, wheel 8, second bearing 9, first bearing 10. Energy storage device 11, motor control device 12, starter motor 13, transmission shaft, first clutch electric control actuator 14, second clutch electric control actuator 15, first bearing seat, second bearing seat and speed sensor, Wherein: the output end of the crankshaft of the engine 1 is connected with the flywheel of the driving side of the first clutch 2, the driven side of the first clutch 2 is connected with one end of the transmission shaft, and the other end of the transmission shaft is connected with the rotor of the motor 3, The rotor of the motor 3 is connected with the first bearing 10 and the second bearing 9 respectively, the first bearing 10 is arranged on the first bearing seat, the second bearing 9 is arranged on the second bearing seat, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com