Vibration-type wolfberry fruit picking mechanism

A vibrating, wolfberry technology, applied in picking machines, harvesters, agricultural machinery and implements, etc., can solve the problems of unsatisfactory picking effect, low stiffness, affecting the growth of wolfberry, etc., to improve picking efficiency and picking rate, reduce damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

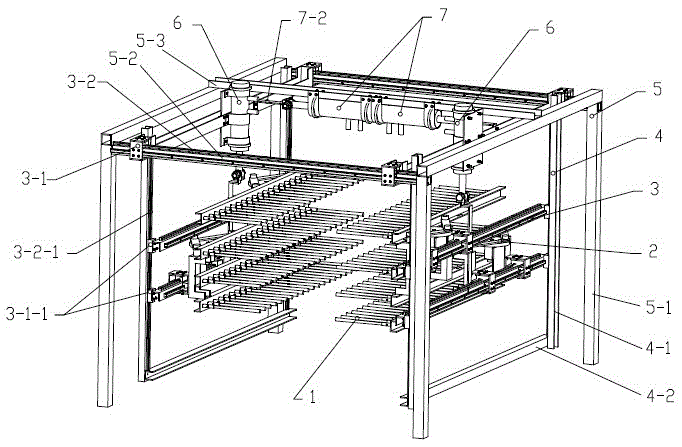

[0023] The vibrating type wolfberry picking mechanism of the present embodiment is as figure 1 As shown, the fixed frame 5 is composed of the door-shaped brackets 5-1 on the left and right sides and the front and rear slideways 5-2 and the middle connecting beam 5-3 across the top of the door-shaped brackets on both sides.

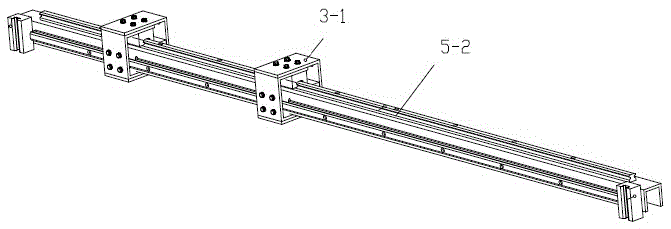

[0024] Both sides of the front and rear slideways 5-2 respectively form a left and right horizontal movement pair with the left and right lifting opening and closing frames 4. -1, the opening and closing slider 3-1 such as image 3 shown (see Figure 5 ), the top, left, and right of the mouth-shaped frame are fixedly connected with dovetail slot inserts, and the top, left, and right sections of the slideway 5-2 have convex ribs matching the dovetail slot, so after assembly, a stable and reliable structure is formed. mobile sub.

[0025] Two opening and closing cylinders 7 are installed in the middle part of the connecting beam 5-3 in the middle, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com