Elliptic or circular motion antiresonance vibrating screen

A circular motion, anti-resonance technology, applied in the direction of filter screen, solid separation, grid, etc., to achieve the effect of motor power reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

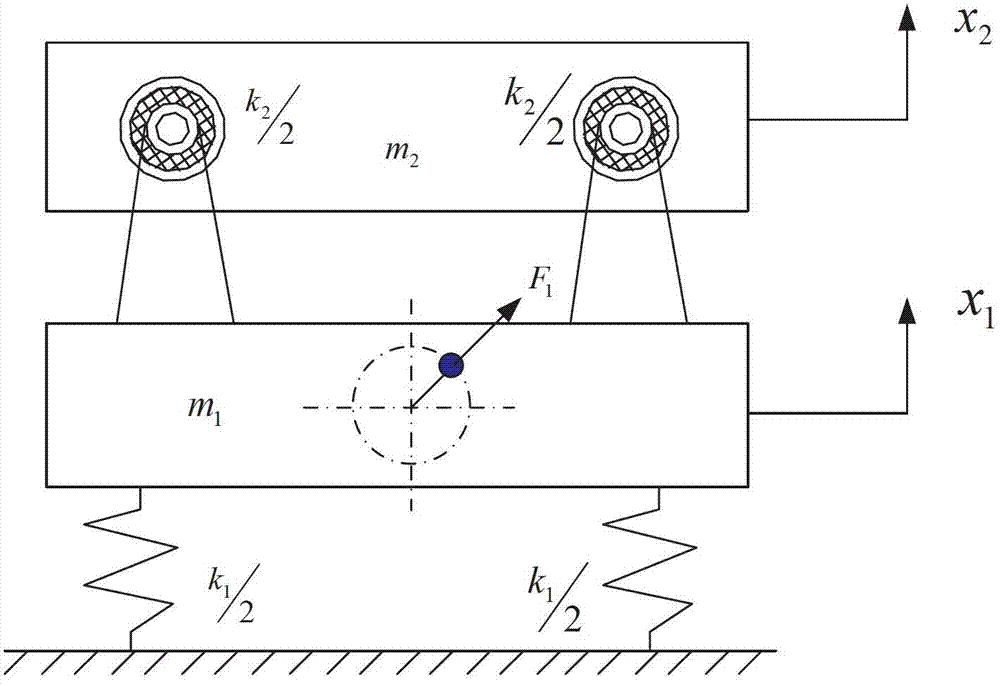

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

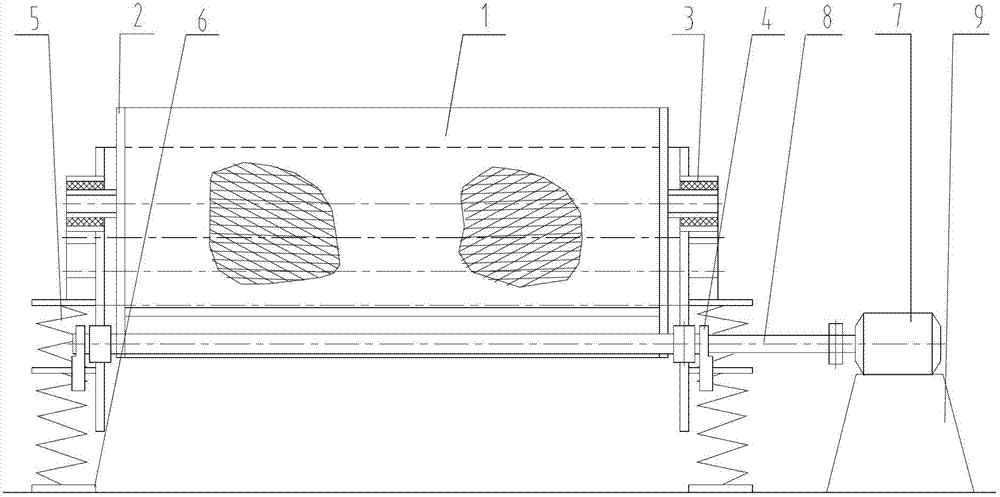

[0060] The present invention is applied to a thick sieve such as a large double-axis elliptical or circular motion anti-resonance, and the structure is as follows Figure 8 with Figure 9 As shown, the screen box 1, the upper plastid, is the working part of the anti-resonance vibrating screen, and the exciter 2, the lower plastid, is the driving part of the anti-resonance vibrating screen. The box 1 and the excitation body 2 are connected by the main vibration spring 3, the excitation body 2 is seated on the foundation 6 through the vibration isolation spring 5, the motor 7 is installed on the motor bracket 9, and is connected to the vibration exciter 4 through the transmission shaft 8 connected. In this embodiment, multiple sets of main vibrating springs 3 are installed on both sides of the screen box 1. The main vibrating springs 3 are circular rubber springs with equal rigidity in all directions, and the biaxial vibrator rotates in the same direction of rotation.

Embodiment 2

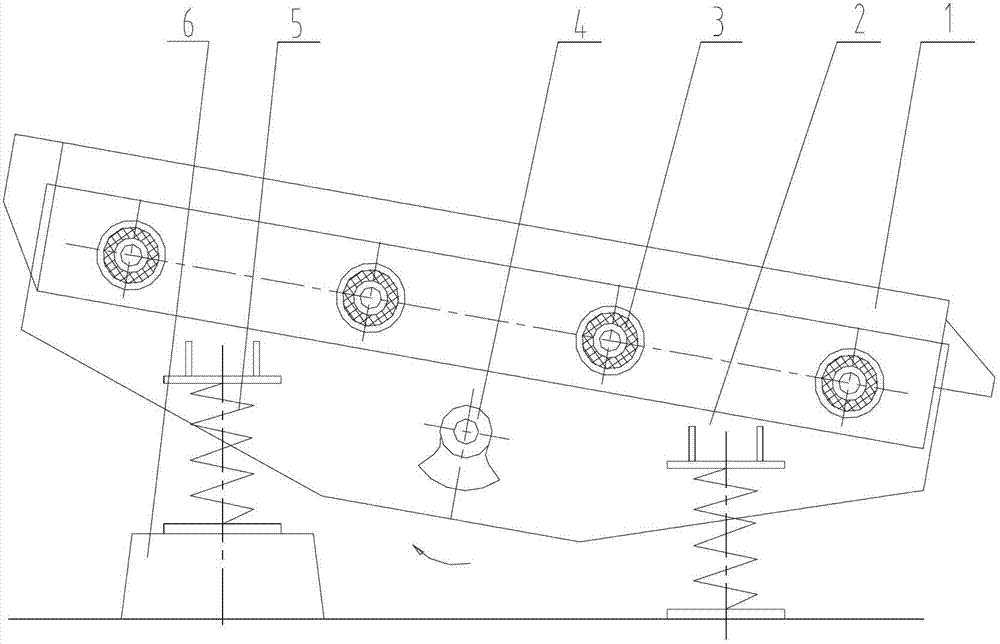

[0062] The present invention is applied to a large three-axis elliptical motion anti-resonance equal-thickness screen, and the structure is as follows Figure 10 with Figure 12 As shown, different from the large dual-axis elliptical or circular motion anti-resonance equal-thickness screen, the large-scale three-axis elliptical motion anti-resonance equal-thickness screen has three exciter shafts, and the exciter shaft adopts a forced synchronous structure, which can realize two of them. The shafts of the vibrator rotate in the same direction of rotation, and the shaft of the other exciter rotates in the opposite direction to that of the other two shafts of the vibrator. At this time, the trajectory of the anti-resonance vibrating screen is elliptical. Figure 10 Shown is a large three-axis elliptical motion anti-resonance equal-thickness sieve main vibration spring 3 adopts the following Image 6 (a) shows the structure of the circular rubber spring 12 with equal stiffness i...

Embodiment 3

[0064] Figure 11 with Figure 12 Shown is a schematic structural view of the present invention applied to another large-scale three-axis elliptical motion anti-resonance equal-thickness screen 2, and Figure 10 The difference between the vibrating screen is that the anti-resonance vibrating screen uses such as Image 6 (b) shows the square rubber spring 12 with equal stiffness in all directions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com