Rotary excavating pile foundation double-steel-casing construction method

A construction method and technology of steel casings, which can be applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of low construction efficiency of rotary excavation piles and complicated treatment of mud and quicksand, and achieve good mobility and convenience, shorten The effect of small construction period and exciting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below by means of specific embodiments:

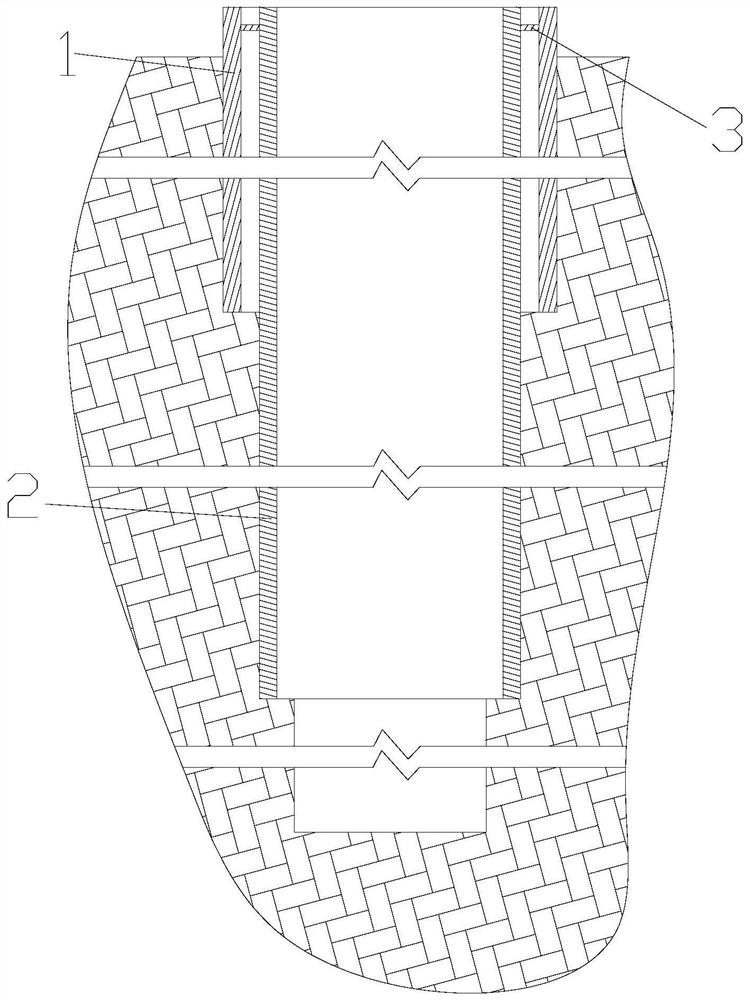

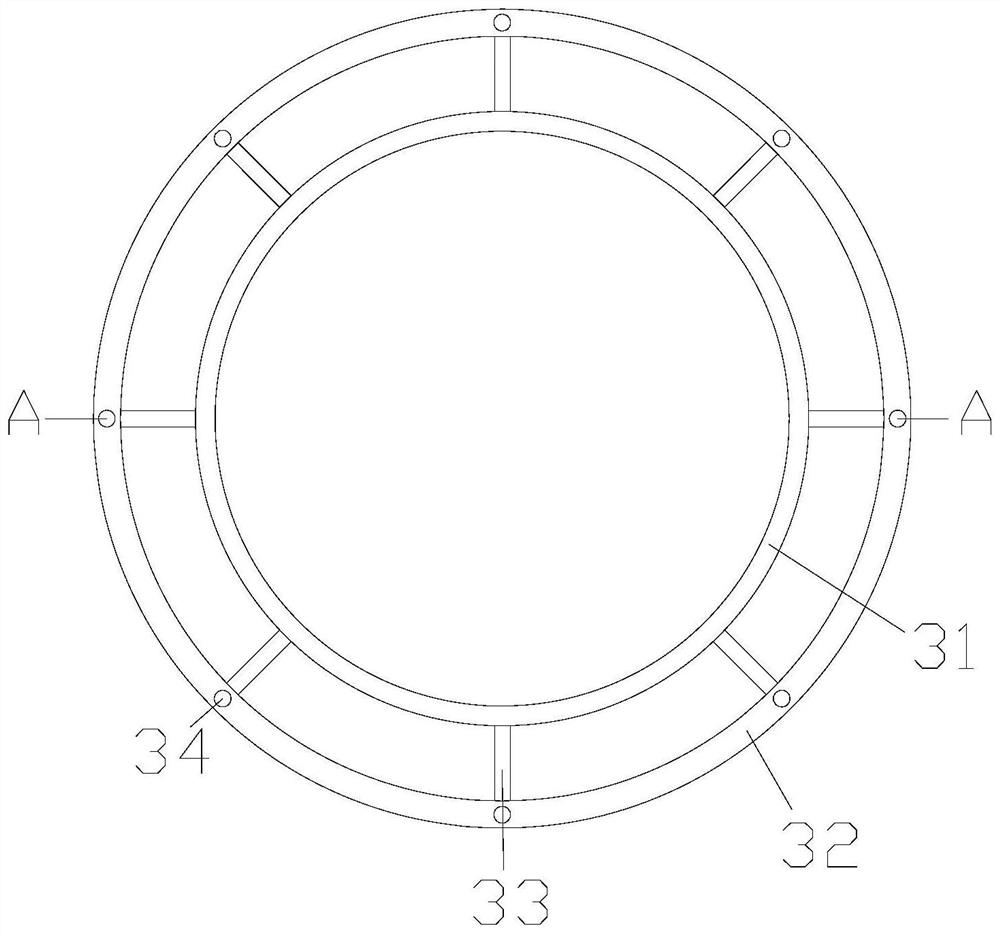

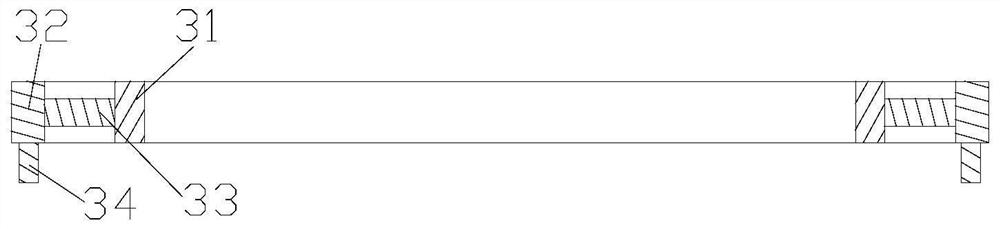

[0026] The reference signs in the drawings of the description include: outer steel casing 1, inner steel casing 2, positioning hoop 3, inner ring reinforcement 31, outer ring reinforcement 32, connection reinforcement 33, positioning reinforcement 34.

[0027] The embodiment of the present invention proposes a double-steel casing construction method for a rotary excavation pile foundation, comprising the following steps:

[0028] 1. Construction preparation

[0029] Familiar with the requirements of the construction design drawings and specifications, and at the same time, according to the geological survey report and other materials, understand the soil quality of the land where the pile foundation is located, whether there are underground pipelines, the depth of groundwater, the estimated buried depth of the foundation, etc., and prepare a targeted construction plan. R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com