Impeller modified structure of chemical process pump

A technology for process pumps and impellers, which is applied to parts, pumps, and pump components of pumping devices for elastic fluids, and can solve problems such as loss, reduced pump efficiency, and reduced pump efficiency, achieving less friction loss and reduced Efficiency loss, effect of reducing friction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] specific implementation

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described;

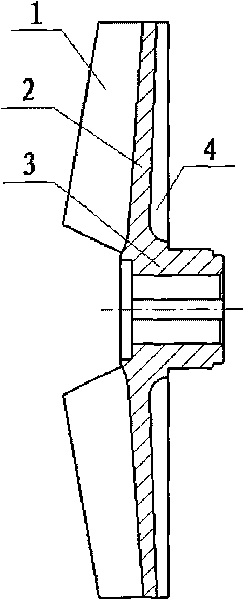

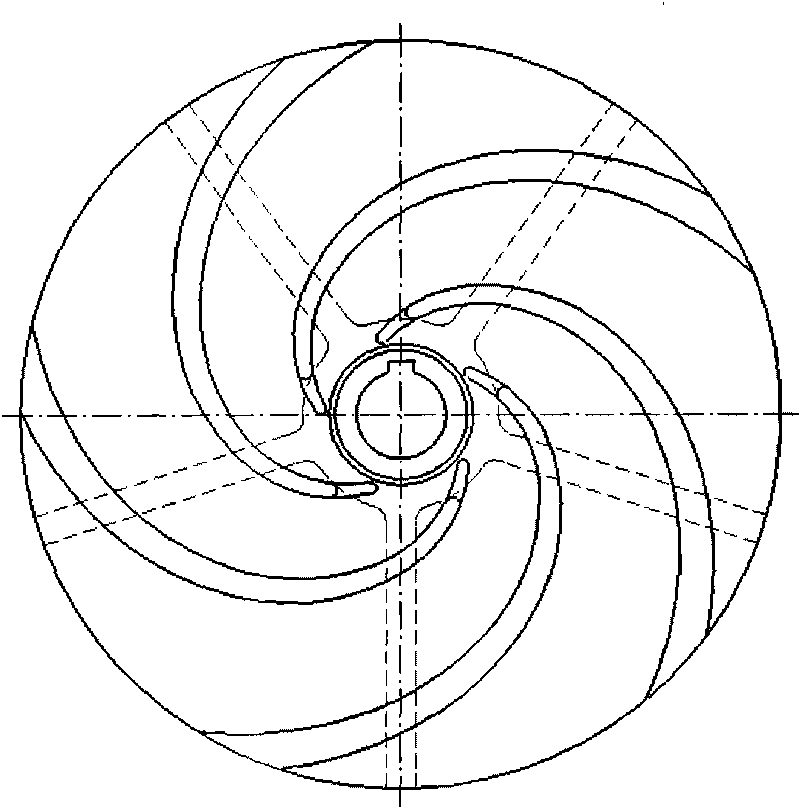

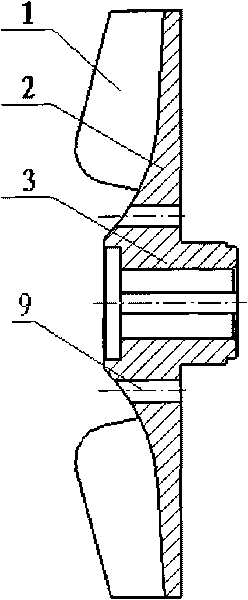

[0021] Such as image 3 , Figure 4 As shown, a modified impeller structure of a chemical process pump according to the present invention includes blade 1 , cover plate 2 , hub 3 ; peripheral equipment includes pump cover 6 , mechanical seal 7 , pump shaft 8 , and impeller nut 10 . Among them: blade 1 adopts equivariant angle logarithmic spiral to draw the profile line, the thickness of the blade gradually increases along the profile line from the inlet end to the outlet end, the inlet end is 6 mm, and the outlet end is 9 mm; at the blade outlet, the end point of the profile line is the cut Make a circular arc uniform hollow cover with a radius of 20mm, retain part of the cover, and evenly distribute six Φ6mm balance holes 9 with a center diameter of Φ50mm on the cover; the hub is a ring-shaped body, and the connection with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com