Drum-type micro-electrolysis reaction device and water treatment method thereof

An electrolytic reaction and drum-type technology, which is applied in the field of water treatment, can solve the problems of reduced treatment efficiency, compaction and blockage, and affect the treatment effect, and achieve the effects of high oxidation potential, high oxidation capacity, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

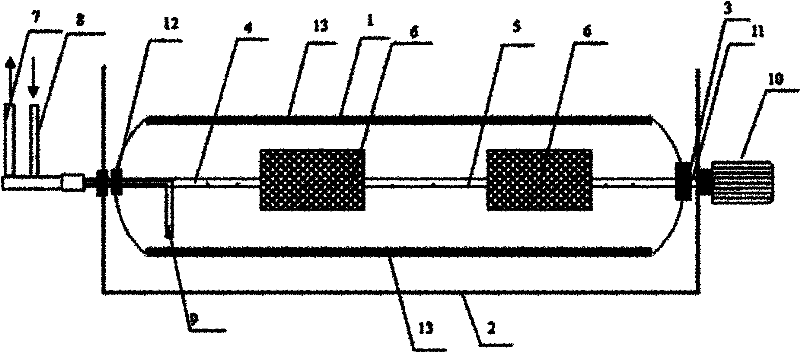

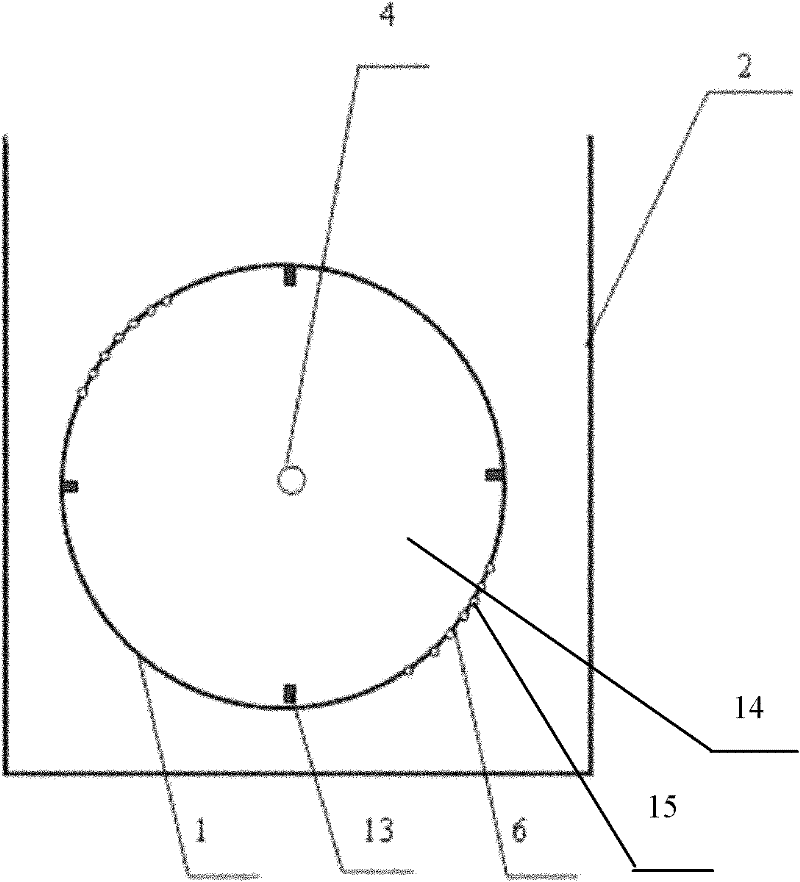

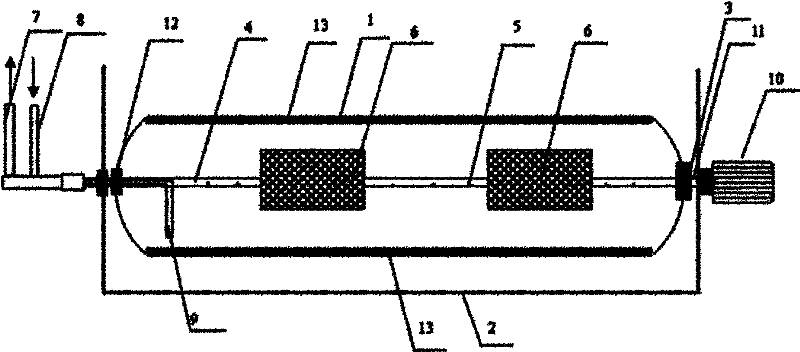

[0021] Such as figure 1 and figure 2 As shown, this embodiment includes: a drum reactor 1, a driving motor 10, a water tank 2, a drain conduit 9 and an aeration pipe 4, wherein: the drum reactor 1 is installed in the water tank 2, and the driving motor 10 is fixed at one end of the water tank 2 The outer side is connected with the drum reactor 1 in the water tank 2 to realize the rolling of the drum reactor 1. One side of the drum reactor 1 is provided with a sealed rotary interface 12 and is connected with the other end of the water tank 2. The drainage conduit 9 and aeration The tubes 4 are all arranged inside the drum reactor 1 and connected with the sealed rotary interface 12 .

[0022] The drum reactor 1 is made of plexiglass;

[0023] The iron-carbon reaction zone 14 in the described roller reactor 1 is used to hold the iron-carbon mixture, and the rolling of the roller reactor 1 driven by the drive motor 10 forms a dynamic iron-carbon bed, and the roller reactor is p...

Embodiment 2

[0028] The roller reactor 1 that adopts plexiglass to be made by embodiment 1, the effective volume of roller reactor 1 is 5 liters, and the effective volume of tank 2 is 10 liters, iron filings and gac are packed into roller reactor 1, the opening of roller reactor 1 The diameter of the bore hole 15 of the sealing cover 6 is controlled at 1.0mm, and the COD6000mg / amantadine hydrochloride distribution water with pH 1.0 is lifted into the water tank 2 by the pump until the drum reactor 1 is submerged in the waste water, and the reactor 1 is rotated and aerated to carry out For wastewater treatment, the residence time is controlled at 0.5 hours, and the COD removal rate is 45%.

Embodiment 3

[0030] The roller reactor 1 that adopts plexiglass to be made by embodiment 1, the effective volume of roller reactor 1 is 5 liters, and the effective volume of tank 2 is 10 liters, iron filings and gac are packed into roller reactor 1, the opening of roller reactor 1 The hole diameter of the hole 15 of the sealing cover 6 is controlled at 1.5mm, and the pH 5.0 COD6000mg / amantadine hydrochloride distribution water is lifted by the pump to the water tank 2, and the drum reactor 1 is submerged in the wastewater, and the reactor 1 is rotated and aerated to carry out the wastewater treatment. Treatment, the residence time is controlled at 6 hours, and the COD removal rate is 40%. The water treated by the drum-type iron-carbon micro-electrolysis reaction device is added with H 2 o 2 3ml / L, Fenton oxidation for 20min, the COD removal rate increased by 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com