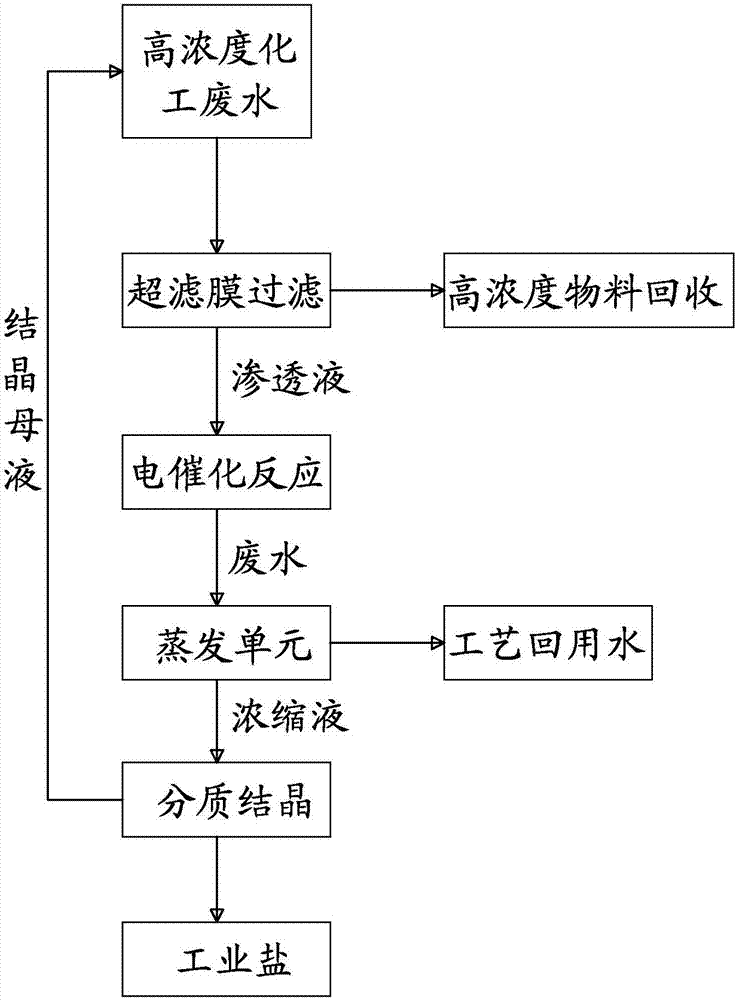

High-concentration chemical wastewater resourceful integrated treatment technology

A chemical wastewater, high-concentration technology, applied in electrochemical water/sewage treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as increasing treatment difficulty, secondary water pollution, and waste of water resources , to achieve the effect of improving resource reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]The COD of production wastewater in a coal chemical plant workshop is 10g / L, and the TDS is 6g / L. A tubular ceramic membrane with a pore size of 4nm is used to filter under the conditions of a transmembrane pressure difference of 0.8MPa and an operating temperature of 80°C. The COD of the produced water is 5g / L; the permeate after membrane filtration is transported to the electrocatalytic oxidation system with a high-pressure pump, the catalyst is alumina particles loaded with manganese oxide, the catalyst dosage is 10wt.% of the system weight percentage, and the reaction current density is 20mA / cm 2 , the pH is controlled at 10, the reaction residence time is 2.5h, and the COD of the wastewater after electrocatalytic oxidation is 20mg / L; the wastewater after electrocatalytic oxidation enters the evaporation unit, and the evaporation process uses a three-effect evaporator with an operating temperature of 50°C. The operating pressure is 0.1kPa, the COD of the water vapor c...

Embodiment 2

[0037] The COD of wastewater produced by a chemical factory is 300g / L, and the TDS is 250g / L. A tubular ceramic membrane with a pore size of 500nm is used to filter under the conditions of a transmembrane pressure difference of 0.1MPa and an operating temperature of 50°C. The COD of the produced water is 100g / L. L; The permeate after membrane filtration is transported to the electrocatalytic oxidation system with a high-pressure pump, and the catalyst is used to support tin oxide on ceramic particles. The catalyst dosage is 30wt.% of the system weight percentage, and the reaction current density is 100mA / cm 2 , the pH is controlled at 5, the reaction residence time is 5h, the COD of the wastewater after electrocatalytic oxidation is 60mg / L; the wastewater after electrocatalytic oxidation enters the evaporation unit, and the evaporation process adopts a mechanical vapor compressor (MVR) evaporator. The temperature is 180°C, the operating pressure is 200kPa, the COD of the water ...

Embodiment 3

[0039] The COD of production wastewater in a fine chemical factory workshop is 130g / L, and the TDS is 110g / L. An organic hollow fiber membrane with a pore size of 100nm is used to filter under the conditions of a transmembrane pressure difference of 0.2MPa and an operating temperature of 10°C. The COD of the produced water is 10g / L; the permeate after membrane filtration is transported to the electrocatalytic oxidation system with a high-pressure pump, and the catalyst is used to support vanadium pentoxide on alumina particles. The catalyst dosage is 20wt.% of the system weight percentage, and the reaction current density is 50mA / cm 2 , the pH is controlled at 7, the reaction residence time is 2.5h, and the COD of the wastewater after electrocatalytic oxidation is 50mg / L; the wastewater after electrocatalytic oxidation enters the evaporation unit, and the evaporation process uses a mechanical vapor compressor (MVR) evaporator. The operating temperature is 130°C, the operating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com