Discharge valve assembly, compressor and air conditioner

An exhaust valve and component technology, applied in the field of compressors, can solve the problems of complex exhaust valve structure, difficult processing and production of exhaust valve, long response path, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

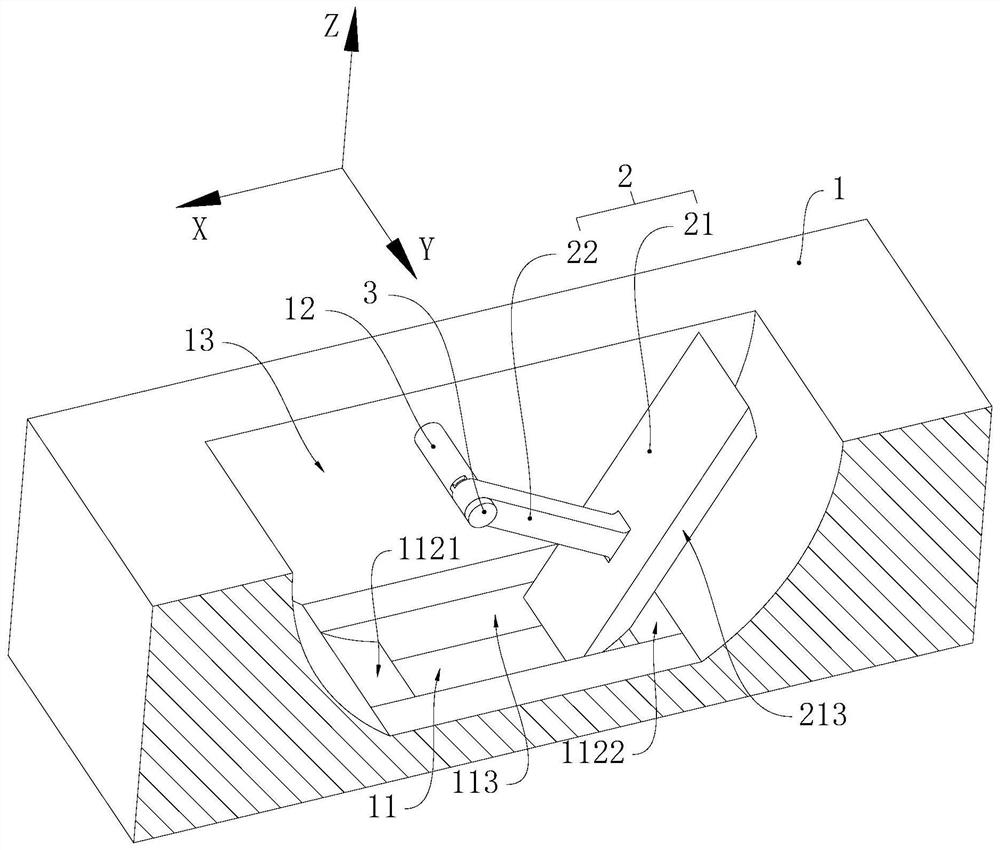

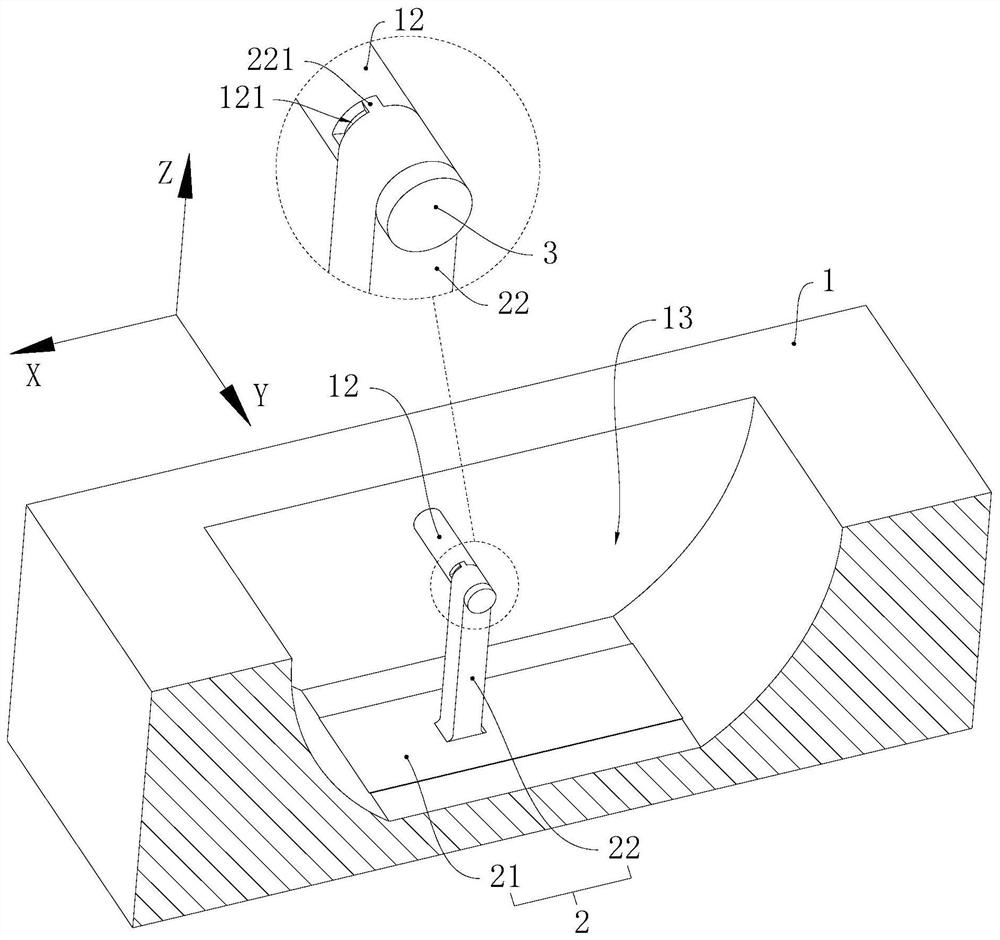

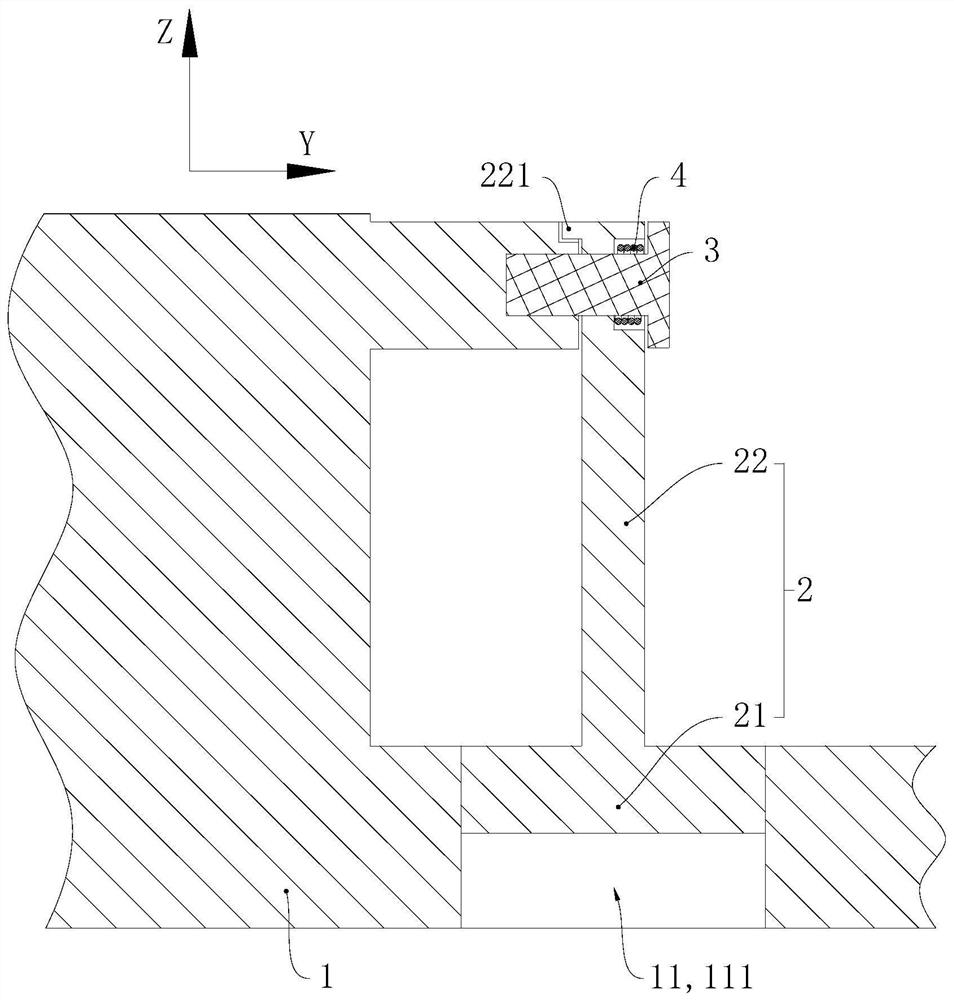

[0032] Examples of exhaust valve assemblies, compressors and air conditioners:

[0033] of this embodiment Figure 1 to Figure 5 A unified spatial rectangular coordinate system (right-handed system) is used to represent the azimuth relationship between the components, wherein the Z-axis direction in this embodiment is the first direction, and the Z-axis direction is the vertical direction. The Y-axis direction is the second direction, and the X-axis direction in this embodiment is the third direction.

[0034] The air conditioner of this embodiment includes the compressor of this embodiment, and the compressor of this embodiment includes the exhaust valve assembly of this embodiment.

[0035] Please refer to figure 1 , the compressor assembly includes a base body 1, a movable body 2, a pin 3 and a torsion spring 4 (see image 3 ), the base body 1 is the flange of the compressor, and the base body 1 is provided with an exhaust hole 11 penetrating along the Z-axis direction, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com