Steel boxed cofferdam and recovery method thereof

A technology of steel casings and cofferdams, applied in caissons, sheet pile walls, buildings, etc., can solve the problems of wasting materials, achieve the effects of easy disassembly, reuse, and watertightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

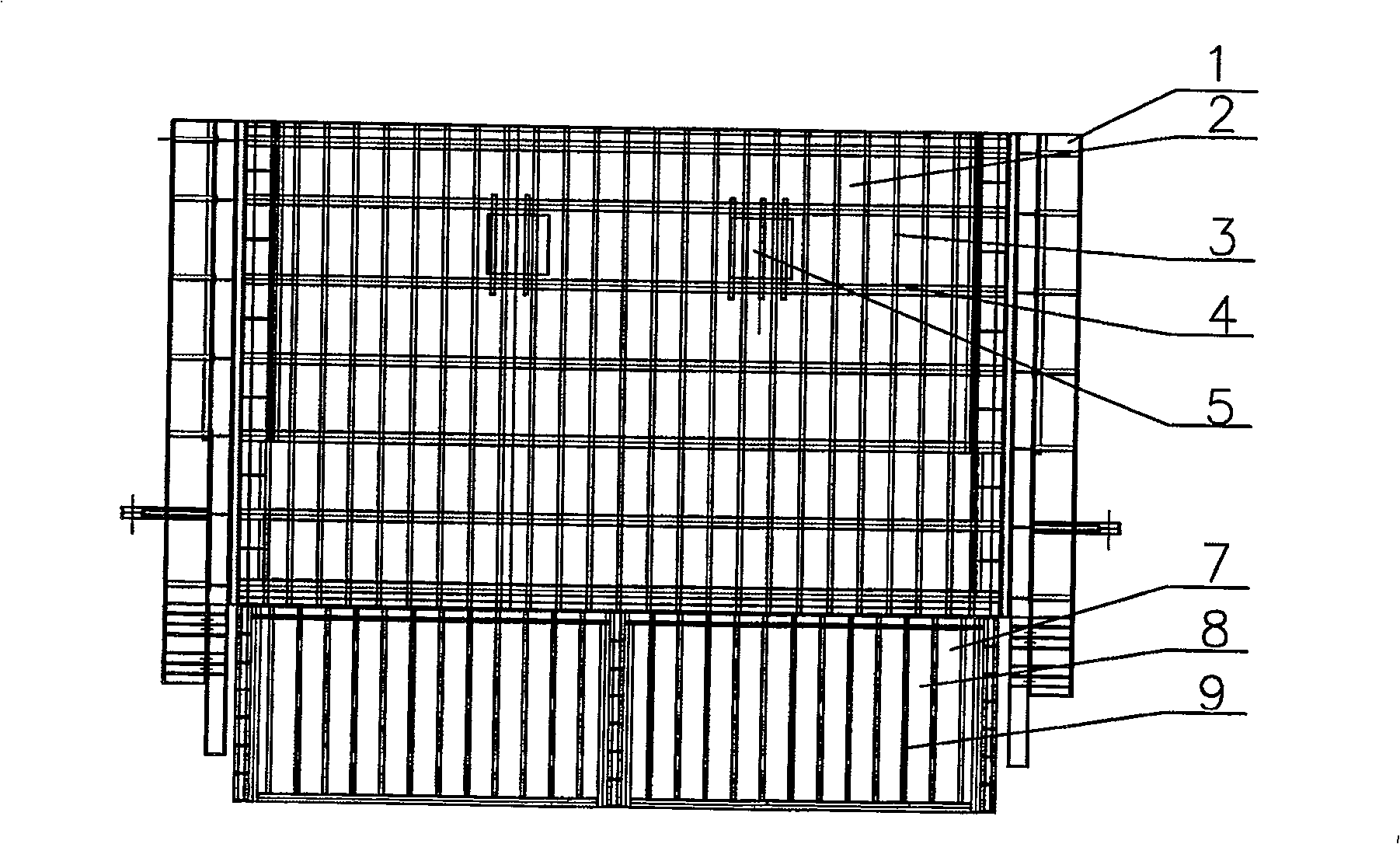

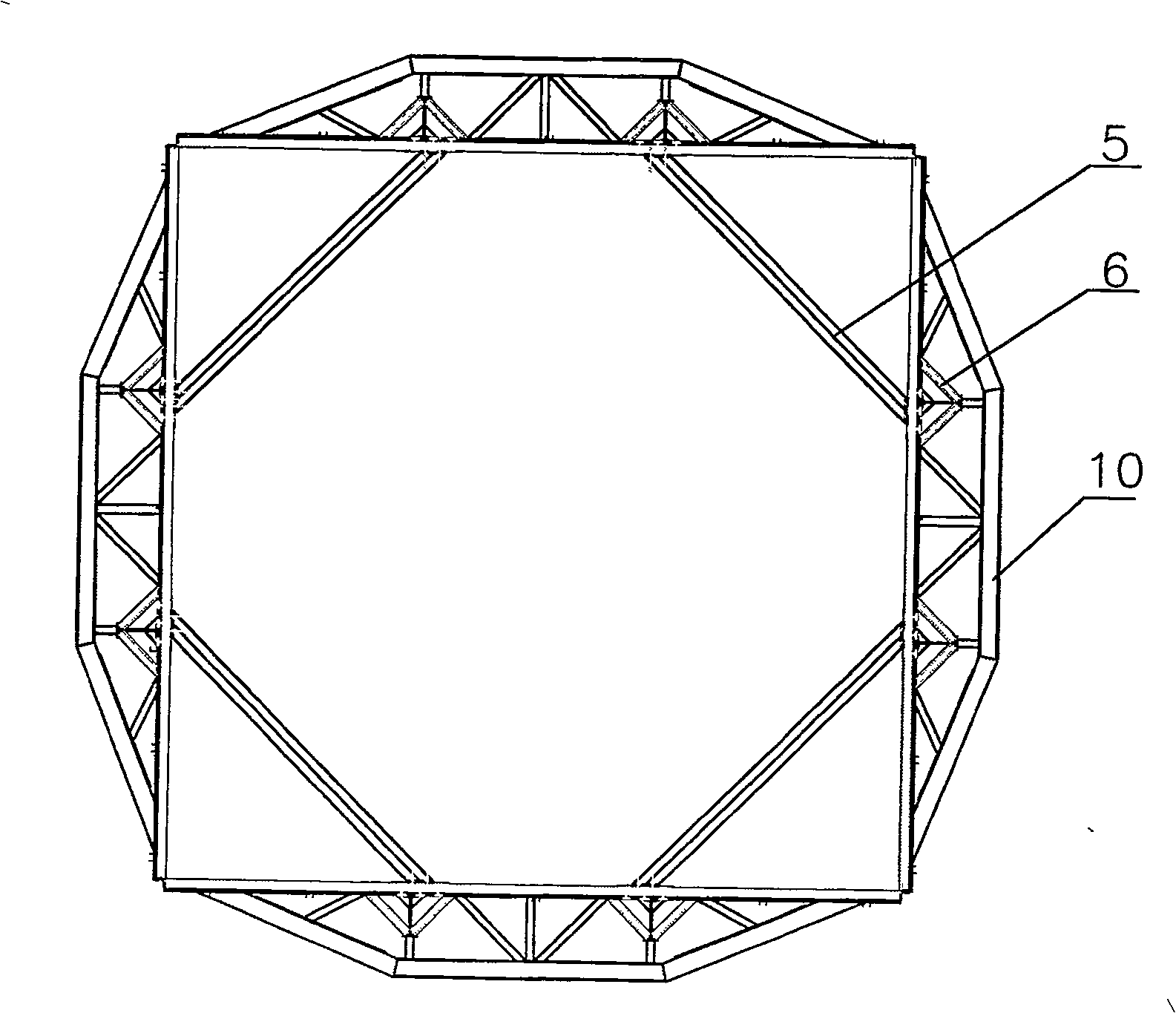

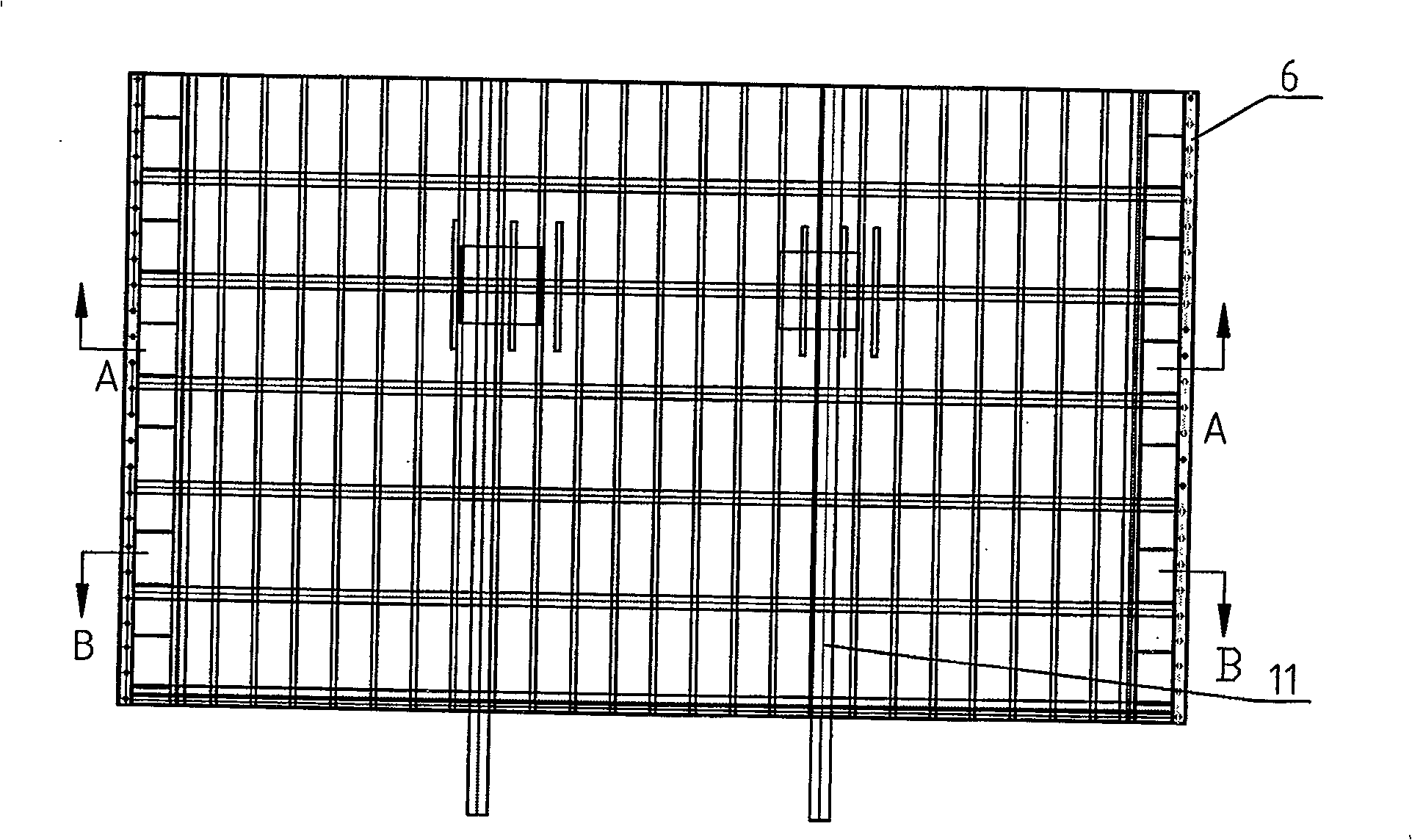

[0031] Refer to the attached Figures 1 to 10 , the steel box cofferdam of the present invention includes an upper section 1 and a bottom section 7, both of which are bolted through water-sealed angle steel flanges to ensure watertightness during construction and prevent caps and upsetting columns from contacting water prematurely , affecting its service life; the upper section includes the upper section panel 2 made of steel plate, which is used as the main water retaining part, and the vertical ribs 3 of the upper section panel are evenly distributed in the horizontal direction, and the horizontal ribs 4 are evenly distributed vertically. The ribs mainly strengthen the structural strength of the caisson to resist the influence of water pressure and tidal force on the caisson. The panels of the upper section are bolted through water-tight angle steel flanges 11 to ensure water seepage prevention. The ability of the angle steel flanges to resist fatigue stress is higher than t...

Embodiment 2

[0035] Refer to the attached Figures 1 to 10 , The structure of the steel casing cofferdam of the present invention is the same as that of Embodiment 1, and the water seal between its components is sealed with an expansion belt, which is convenient for installation and use.

[0036] If the steel plate column cofferdam is used, the size of the cap is 6.45m×6.45m. In order to meet the construction requirements of concrete anticorrosion and cap formwork support, a 1m operating space is reserved between the cap and the steel plate column. Considering that the height of the steel plate column is 15.5cm , the number of sunken steel sheet piles is odd, and the value is 9.2m. At the same time, an inner fence is installed, so that the total engineering quantity and steel consumption of each steel sheet column cofferdam is 112.64t. And if the steel box cofferdam of the present invention is adopted, the steel box cofferdam adopts 8.05m×8.05m, and the height is 7 meters, which can meet t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com