Socket structure

A socket and contact spring technology, applied in the field of socket structure, can solve the problems of not being able to fully meet miniaturization, low profile, etc., and achieve the effect of combining high water tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, modes for implementing the invention will be described in detail based on examples and with reference to the drawings.

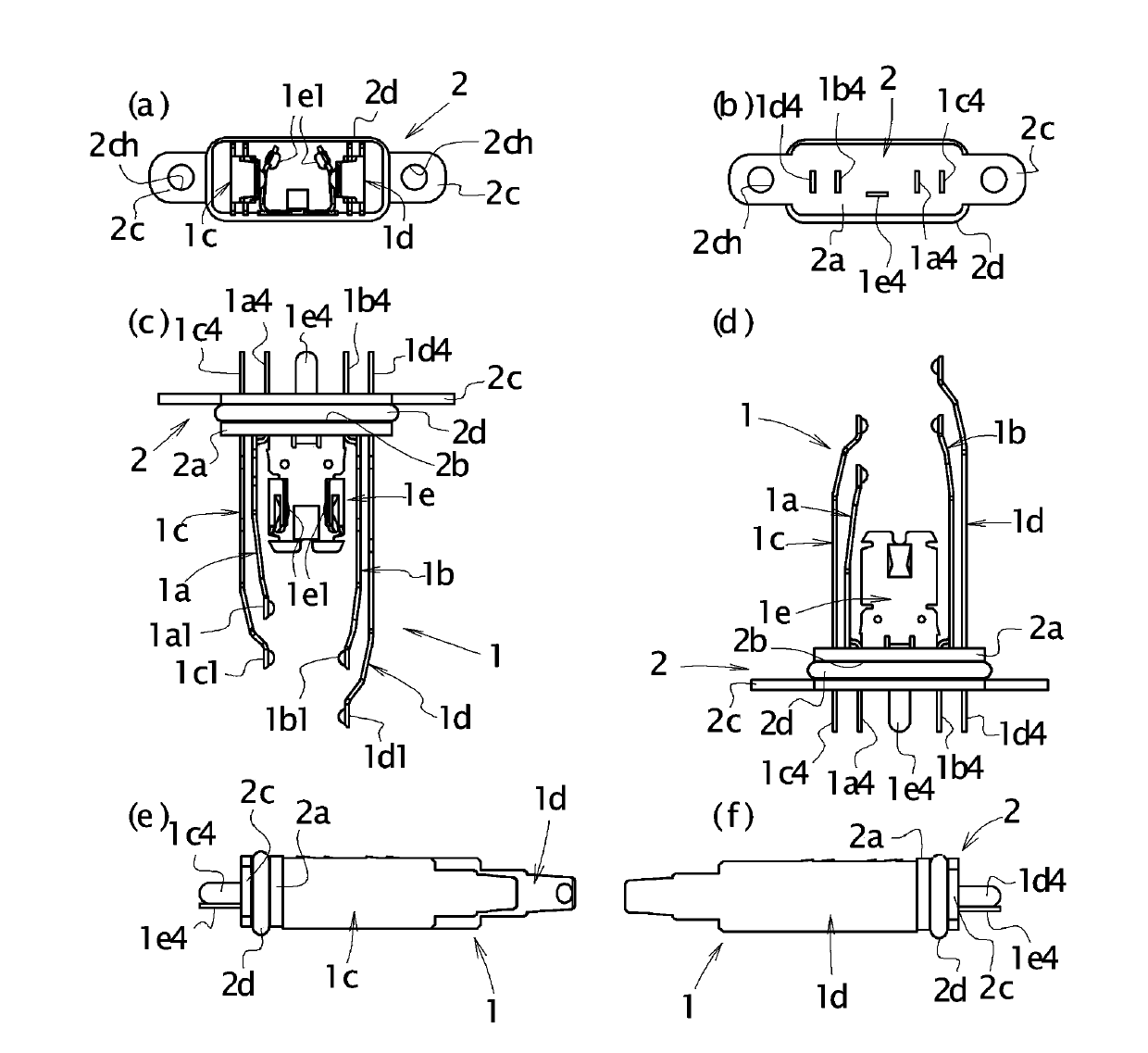

[0036] Such as figure 1 As shown in (a) to (f), the socket of the socket structure of the embodiment basically consists of a contact spring assembly 1 and a cover member 2 integrally mounted with the contact spring assembly 1 .

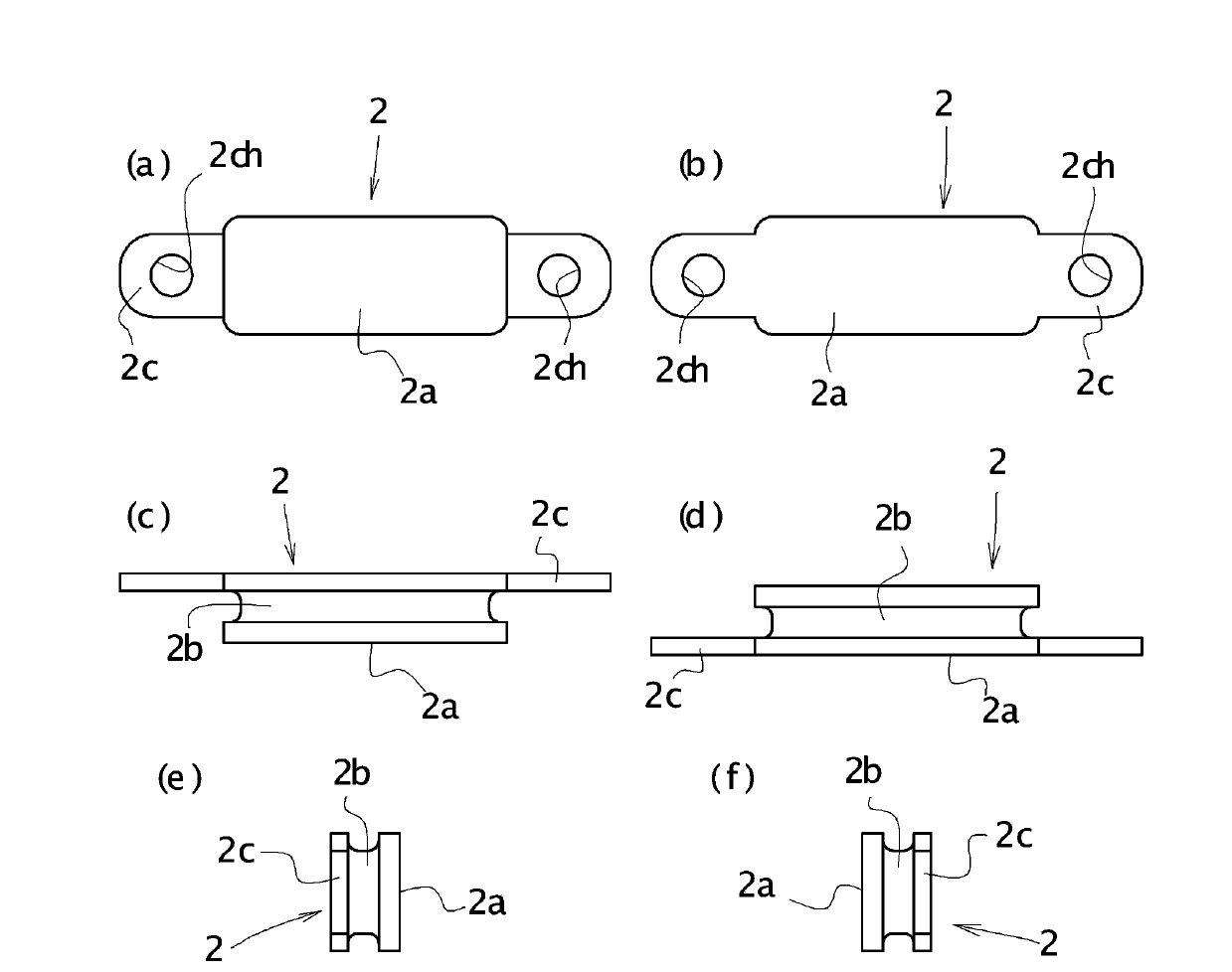

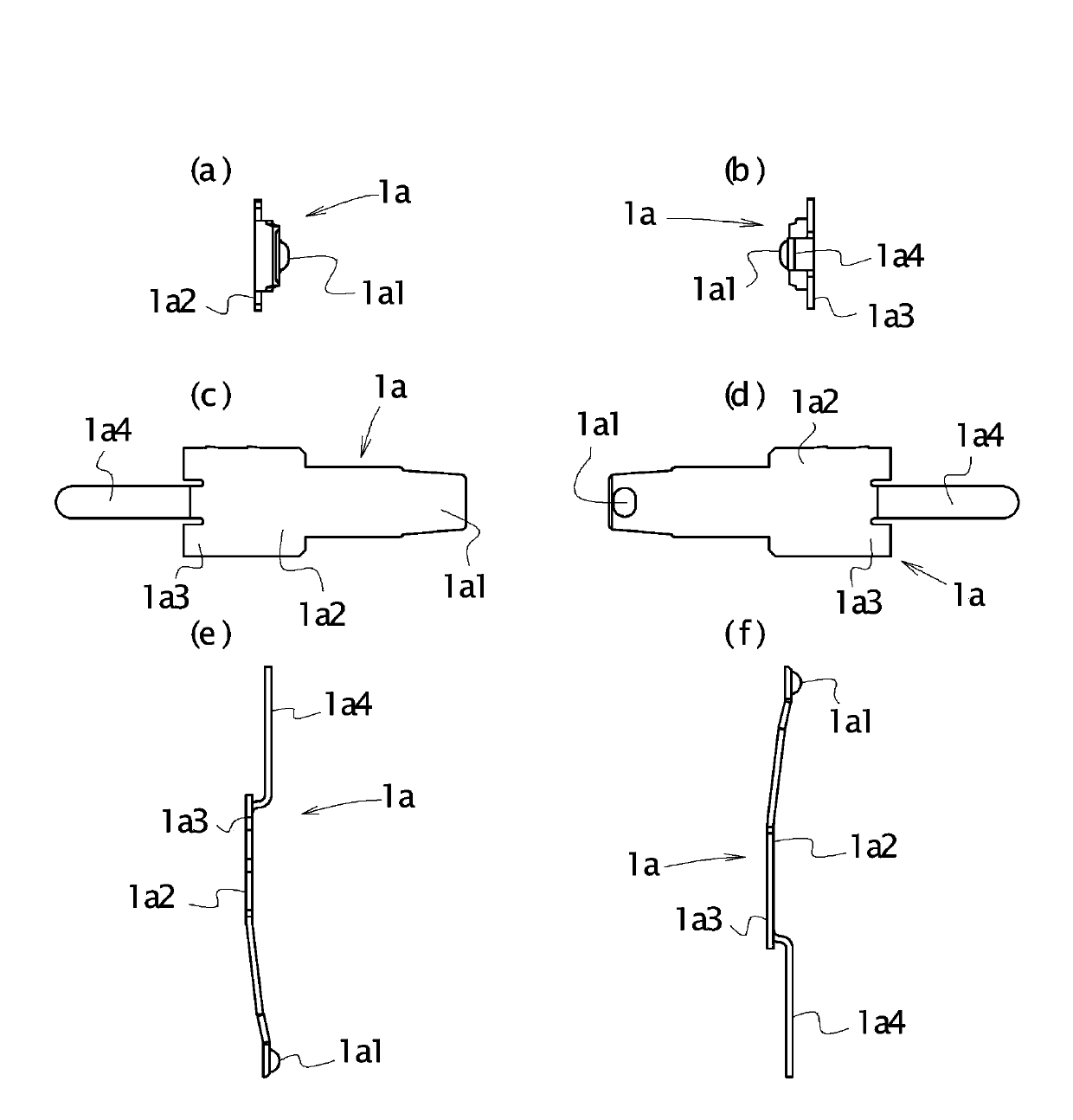

[0037] Such as figure 1 (a)~(f), image 3 (a)~(f), Figure 7 (a)~(f), Figure 8 (a), (b) and Figure 10As shown in (a) and (b), the above-mentioned contact spring assembly 1 is an assembly of the ring spring 1a, the second sleeve spring 1b, 1c, the first sleeve spring 1d and the leaf spring 1e. In this embodiment, the The above five contact springs are integrally mounted on the above-mentioned cover member 2 in the following positional relationship: in the state where the respective contact points 1a1, 1b1, 1c1, 1d1, and 1e1 are assembled on the frame of the installation target device 11, they can be connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com