Installation structure for roof rail

A structure and edge beam technology, applied in the field of installation structure of the upper edge beam, can solve the problems of difficulty in ensuring water tightness, enlargement, rainwater intrusion, etc., and achieve the effect of preventing rainwater from immersing in the car

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

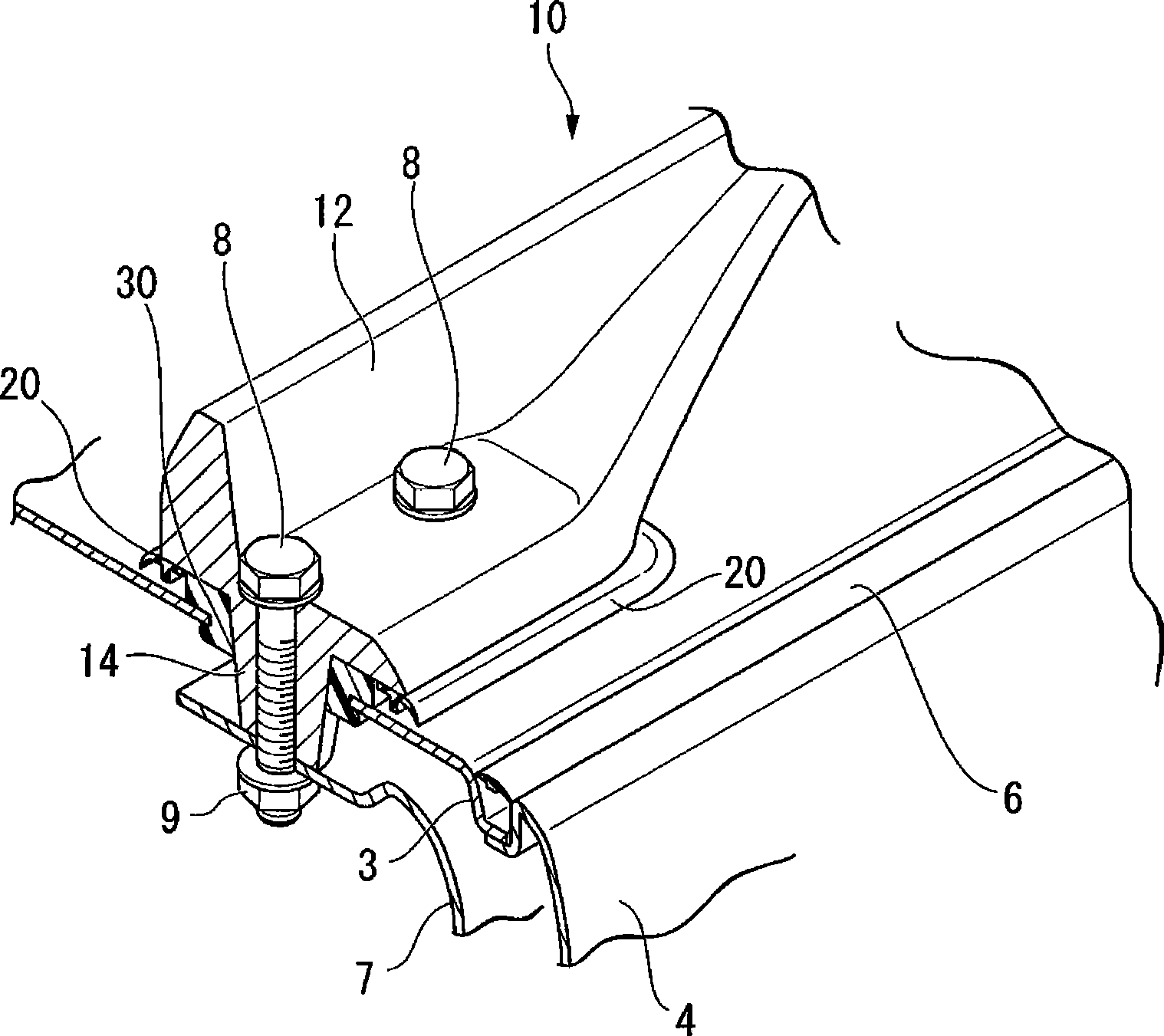

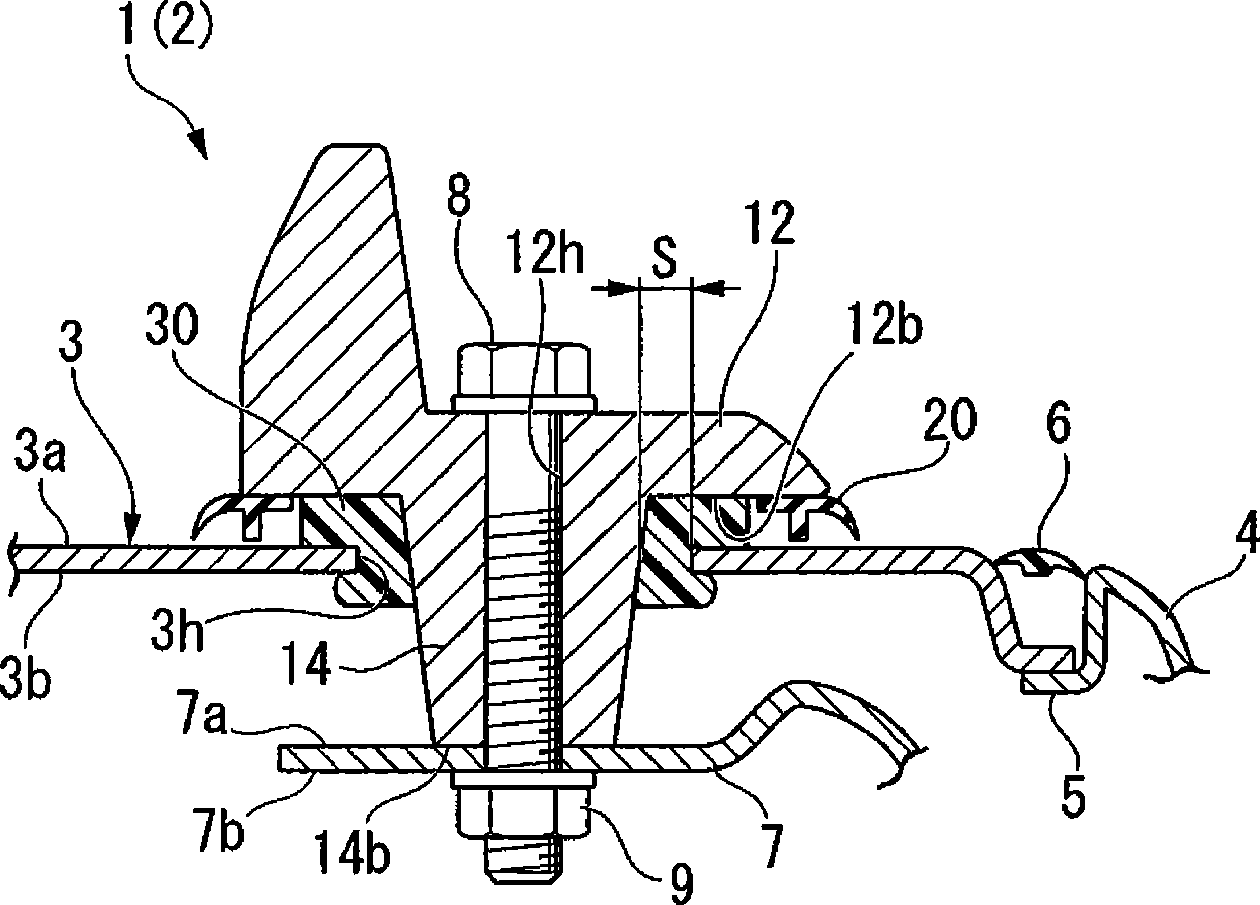

[0027] Hereinafter, embodiments of the roof rail mounting structure of the present invention will be described with reference to the drawings.

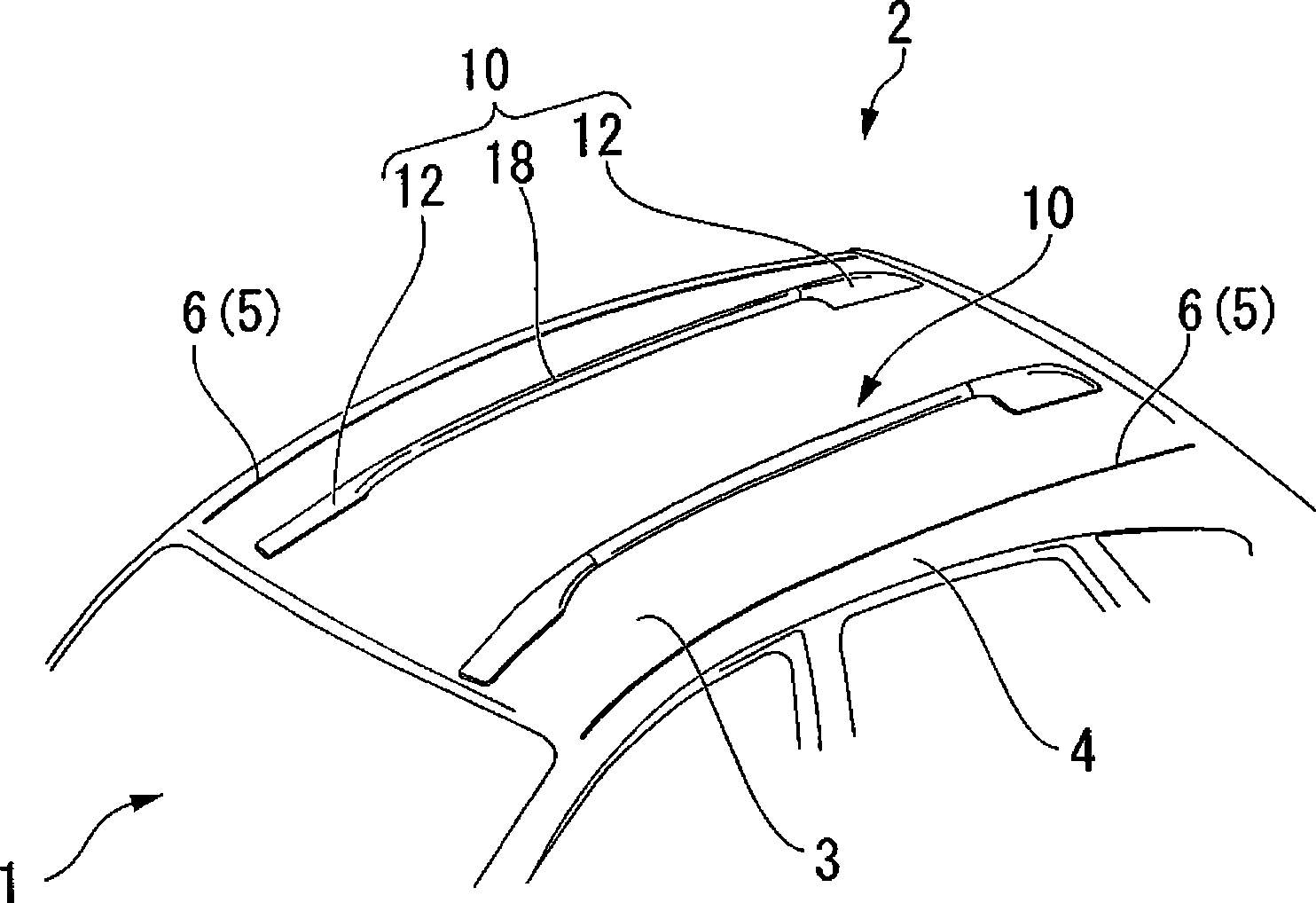

[0028] figure 1 It is an external perspective view showing the mounting structure of the roof side rail according to the embodiment of the present invention.

[0029] On the roof 2 of a vehicle 1 such as a passenger car, a pair of roof side rails 10 are provided on both end sides thereof along the front-rear direction of the vehicle 1 .

[0030] Each roof side rail 10 is constituted by a pair of leg parts 12 closely arranged on the ceiling 2 and a rail part 18 arranged between the pair of leg parts 12 .

[0031] Furthermore, each roof side rail 10 is arranged on the vehicle inner side than the pair of roof moldings 6 provided on the roof 2 . That is, the roof molding 6 is fitted into the joining portion 5 between the roof cover 3 and the vehicle body side panel 4 . Each roof side rail 10 is arranged on the inner side of the vehicl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com