Underwater local dry-method GMAW welding torch for double-layer gas structure

A local dry method and structural water technology, applied in the characteristics of welding electrodes, welding equipment, welding accessories, etc., can solve the problems of easy turbulent flow, unsatisfactory drainage effect, large gas flow, etc., and achieve the effect of improving dryness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be specifically described below in conjunction with the accompanying drawings.

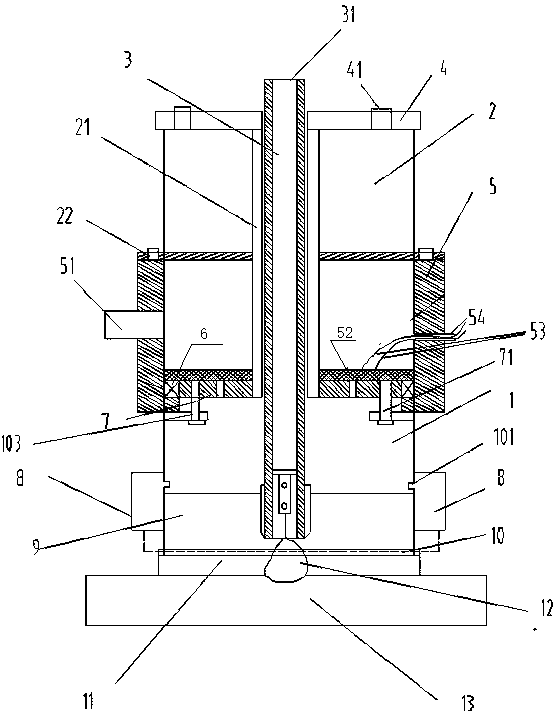

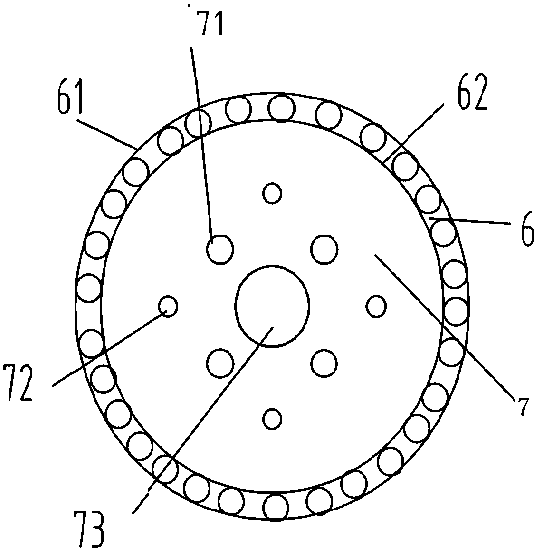

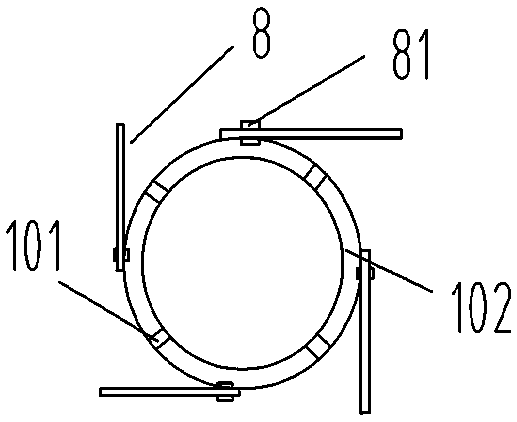

[0028] as attached figure 1 As shown, a double-layer gas structure underwater partial dry GMAW welding torch includes a drainage cover 1 that can rotate and a DC motor 2 that drives the rotation of the drainage cover. The upper end of the DC motor 2 uses top plate bolts 41 and top plate 4 Connect, and the lower end utilizes motor bolt 22 and drain static air cover 5 to connect. The drainage cover 1 is provided with four drainage gas outlet holes 101 in the circumferential direction, which are specially used to discharge the gas in the welding torch out of the welding torch through the outlet holes. The inside of the motor shaft of the DC motor 2 is processed with a large-diameter through hole to form a hollow shaft 21 for passing through the welding torch 3 of the special extended nozzle. The upper end of the welding torch of the extended nozzle is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com