Water stop structure of movable working gate and sealing device

A sealing device and water-stop technology, applied in water conservancy projects, marine engineering, coastline protection and other directions, can solve problems such as uneven gate gaps, and achieve the effects of convenient project implementation, reduced capacity, and improved adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

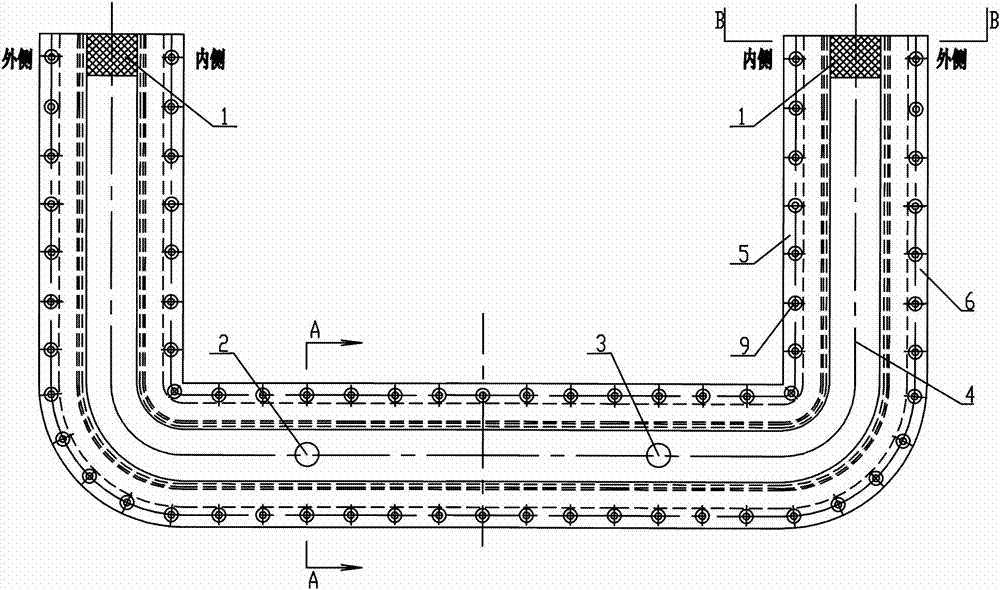

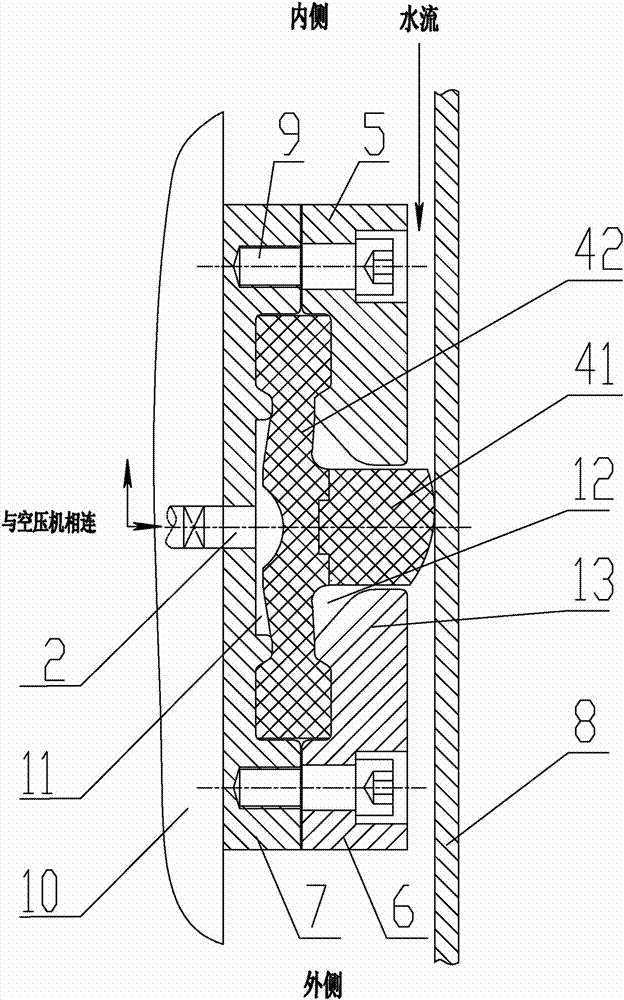

[0034] like Figure 1~3 Among them, a water-stop structure for a mobile working gate, the water-stop structure is in the shape of a "U", cavity plugs 1 are provided at both ends of the "U", the seat plate 7 is connected with the gate panel 10, and the sealing device 4 fixedly installed on the seat plate 7 through the inner pressure plate 5 and the outer pressure plate 6;

[0035] In the sealing device 4, a pressure chamber 11 is formed between the air seal member 42 and the seat plate 7, and the seat plate 7 is provided with an air inlet 2 and an air outlet 3 communicating with the pressure chamber 11. In the sealing device 4, there is also There is a water seal head 41 which is driven by the air seal 42 to contact or separate from the water-stop dual surface 8 of the door slot;

[0036] Preferably, at the position of the cavity plug 1, the bottom of the water seal head 41 is straight and in direct contact with the seat plate 7, and the two sides of the cavity plug 1 are prov...

Embodiment 2

[0044] Such as Figure 2~4 Among them, a sealing device, the sealing device is fixedly installed on the seat plate 7 through the inner pressure plate 5 and the outer pressure plate 6, the two ends of the sealing device are provided with cavity plugs 1, and the air seal 42 in the sealing device 4 is connected to the seat plate A pressure chamber 11 is formed between the 7, and the seat plate 7 is provided with an air inlet 2 and an air outlet 3 communicating with the pressure chamber 11, and the sealing device 4 is also provided with a dual surface driven by the air seal 42 and the water-proof surface of the door groove. 8 contact or separate water seal head 41;

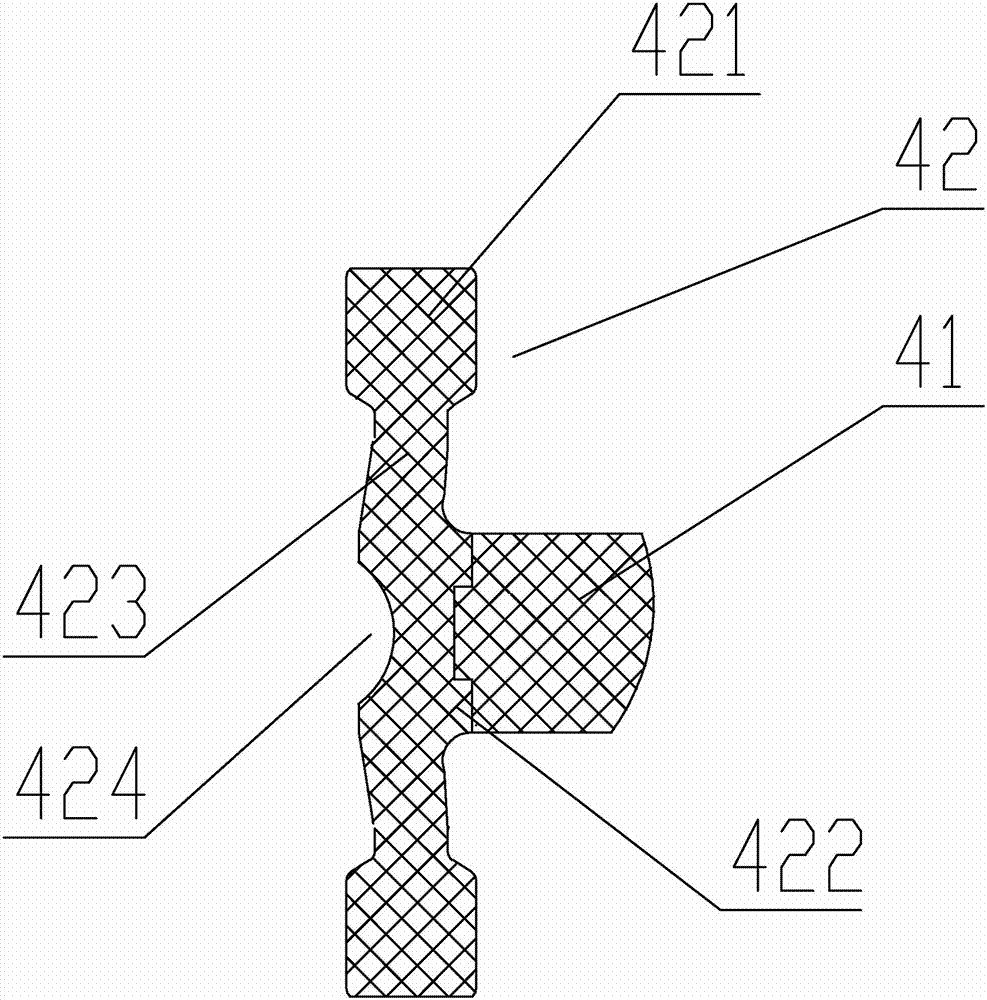

[0045] The air seal 42 is movably engaged with the water seal 41 , wherein the hardness of the air seal 42 is lower than that of the water seal 41 .

[0046] The air seal 42 is provided with a connection portion 422 for connecting with the water seal head 41, and both sides of the air seal 42 are connected to the win...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com