Overflow valve

A relief valve and spool technology, which is applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problems of poor reliability and short service life of relief valves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

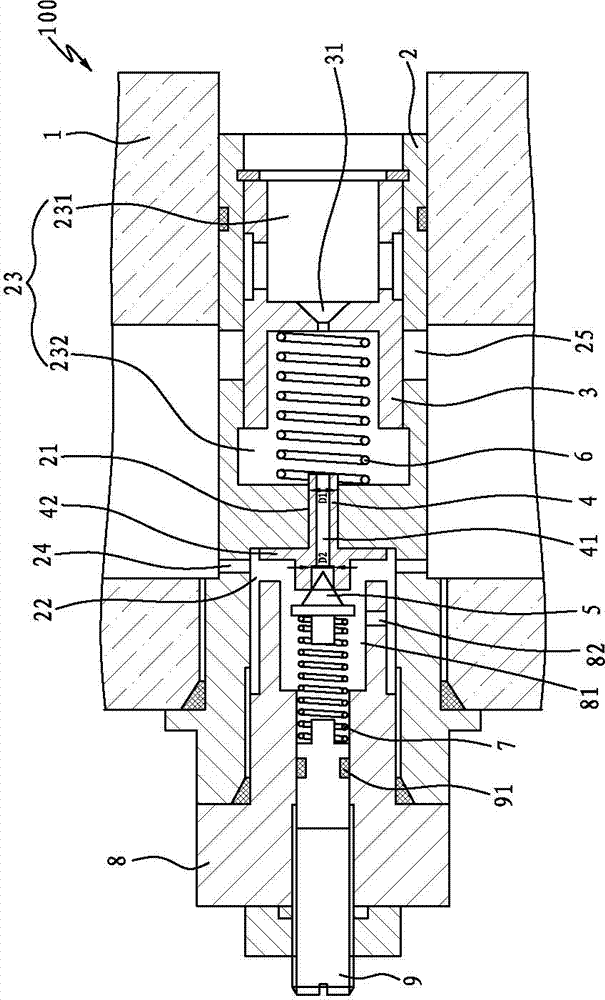

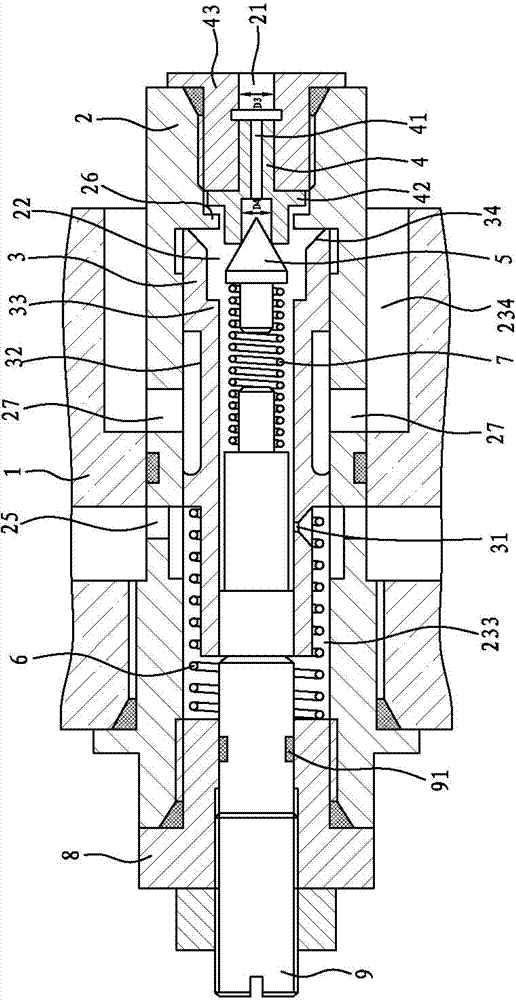

[0040] like figure 1 As shown, it is the first embodiment of a relief valve 100 according to the present invention. The relief valve 100 includes a valve body 1, a main valve seat 2, a main valve core 3, a pilot valve seat 4, a pilot valve core 5, The main valve spring 6, the pilot valve spring 7 and the gland 8, the main valve seat 2 is fixedly sleeved in the valve body 1, the above structure is basically the same as the structure principle of the traditional pilot relief valve, so no detailed description will be given.

[0041] The key improvement of the present invention is: the relief valve 100 also includes a pilot valve seat installation hole 21 and a pilot valve seat limit portion, the pilot valve seat 4 is movably sleeved in the pilot valve seat installation hole 21, the pilot valve seat 4 A pilot valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com