Patents

Literature

154results about How to "Small preload" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

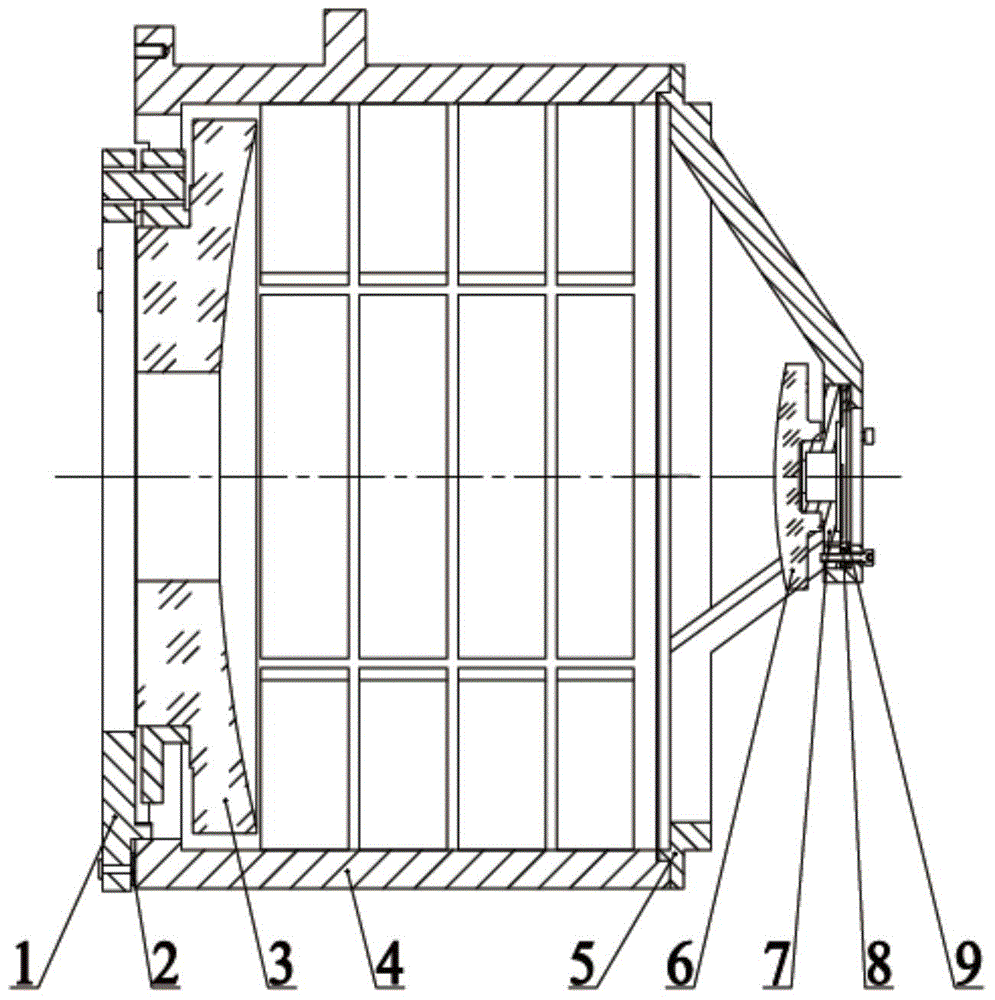

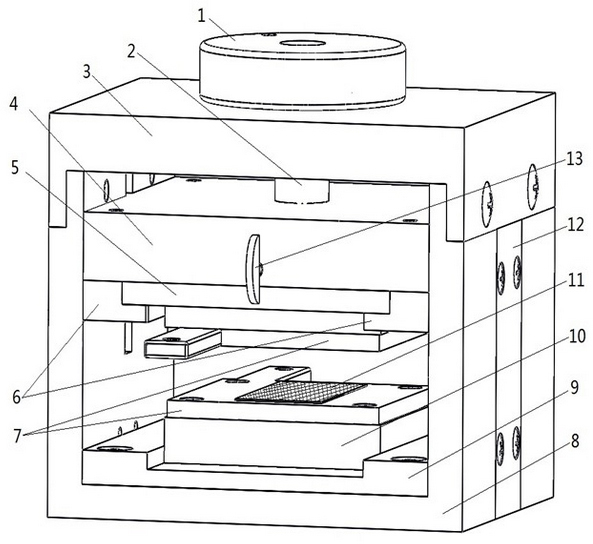

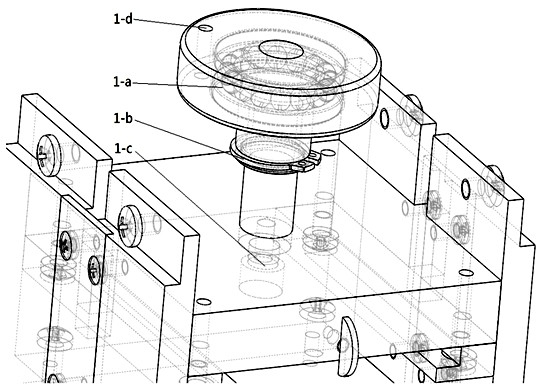

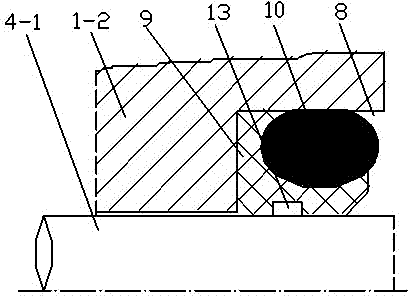

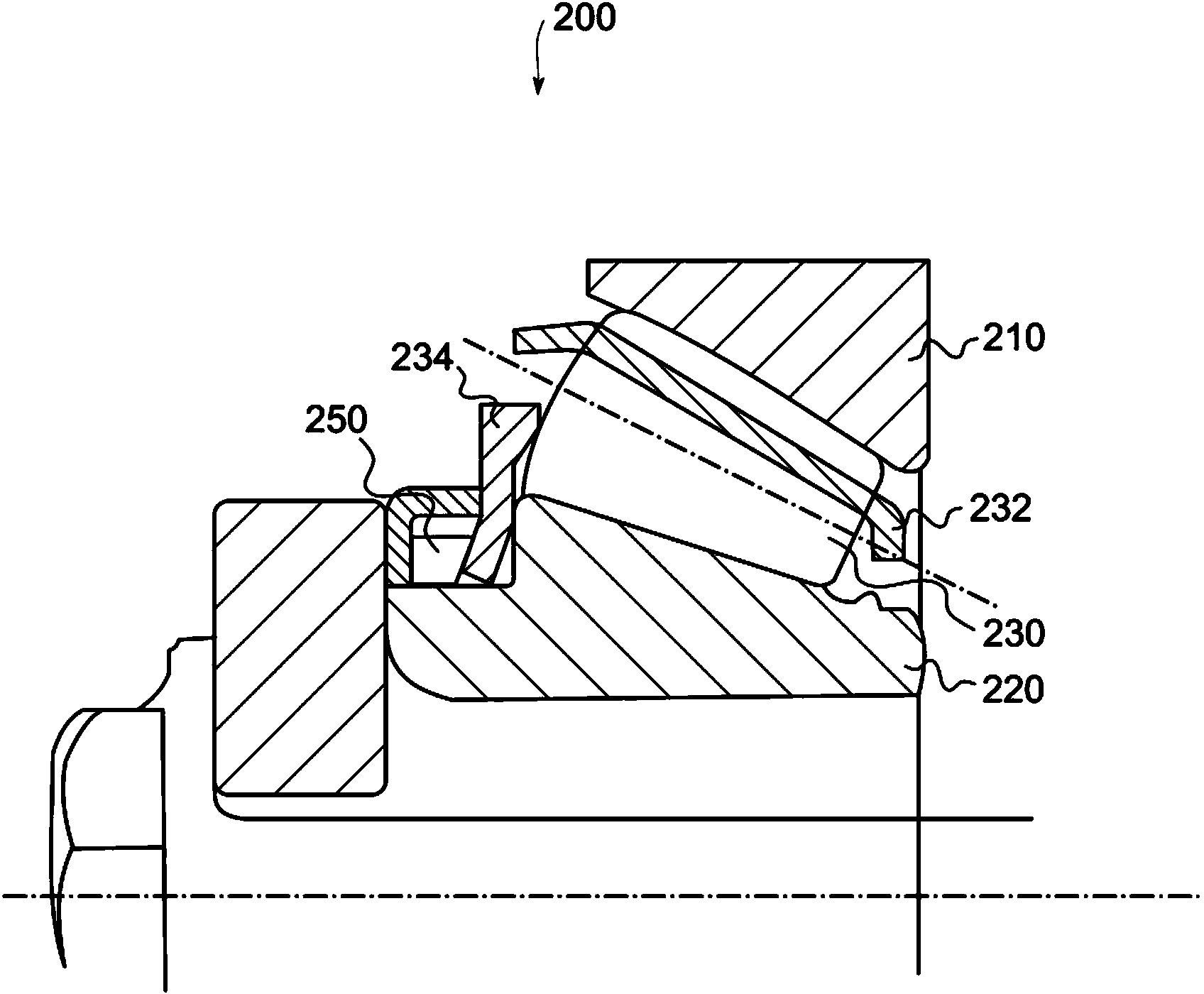

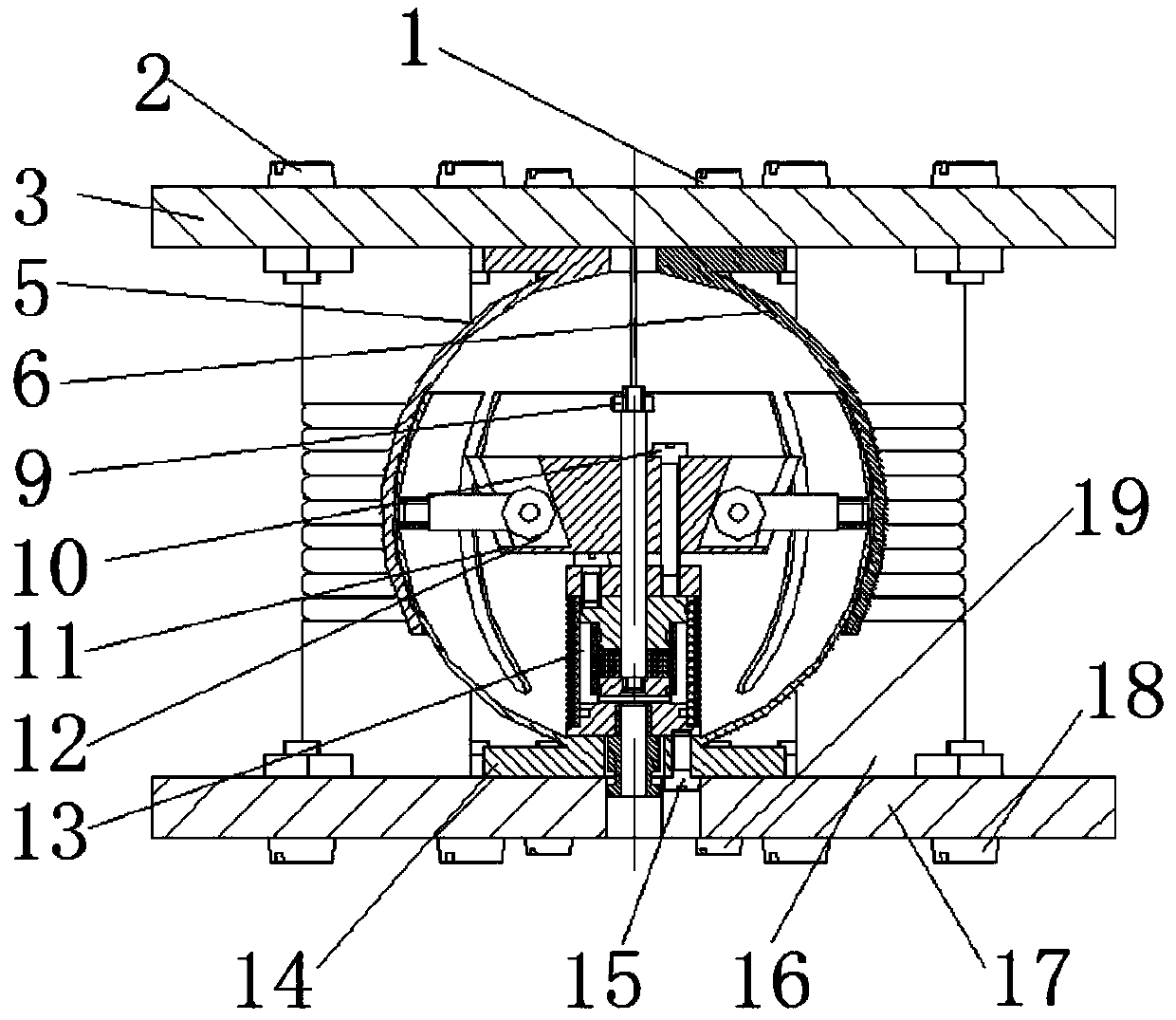

Aerial camera Cassegrain primary and secondary mirror supporting structure

The invention provides an aerial camera Cassegrain primary and secondary mirror supporting structure, belongs to the technical field of optical engineering, and aims at solving problems in the prior art that the supporting structure is complex, the processing and adjusting cycle is long and cost is high. A primary mirror base is fixedly connected with one end of a mirror cone. A primary mirror gasket is arranged between the primary mirror base and the mirror cone. A secondary mirror base is fixedly connected with a connecting frame. An axial gasket and an angular gasket are arranged between the secondary mirror base and the connecting frame. The connecting frame is fixedly connected with the other end of the mirror cone. A primary mirror and a secondary mirror are respectively fixed on the primary mirror base and the secondary mirror base. Flexible hinges are directly processed on the primary mirror base and flexible slots are processed on the secondary mirror base so that stress transmitted to the surface of a reflecting mirror in change of external environment temperature and the assembling process can be reduced and optical surface figure accuracy can be enhanced; and axial distance and relative angle of the primary mirror and the secondary mirror are adjustable so that the primary mirror and the secondary mirror are ensured to possess correct spatial position, and the assembling process is simple and short in the cycle.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

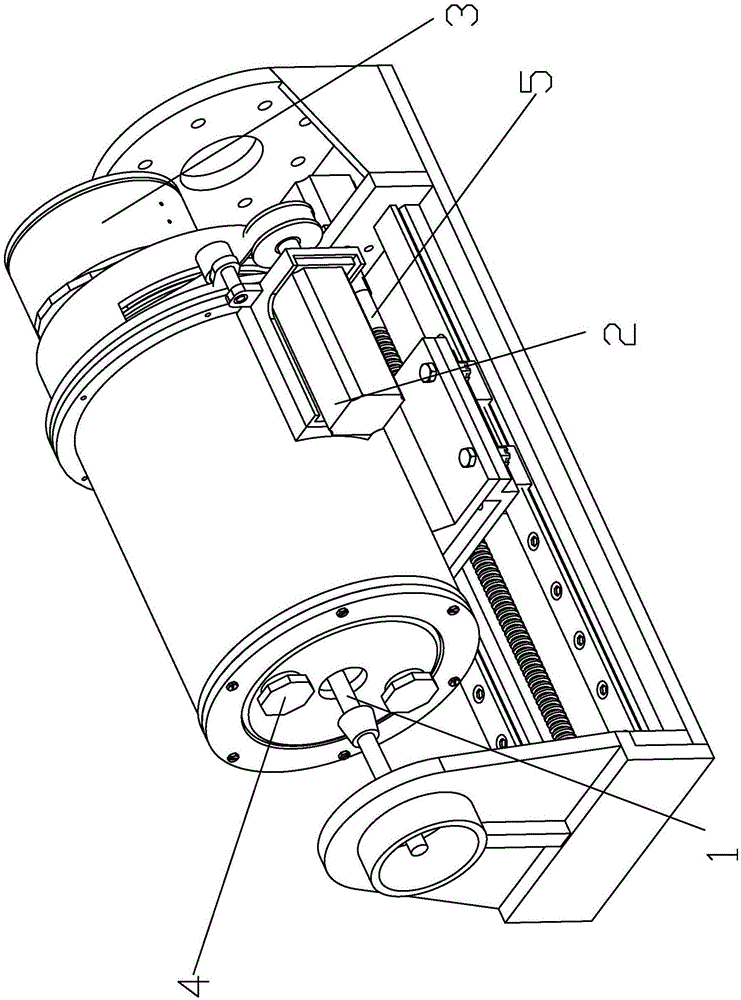

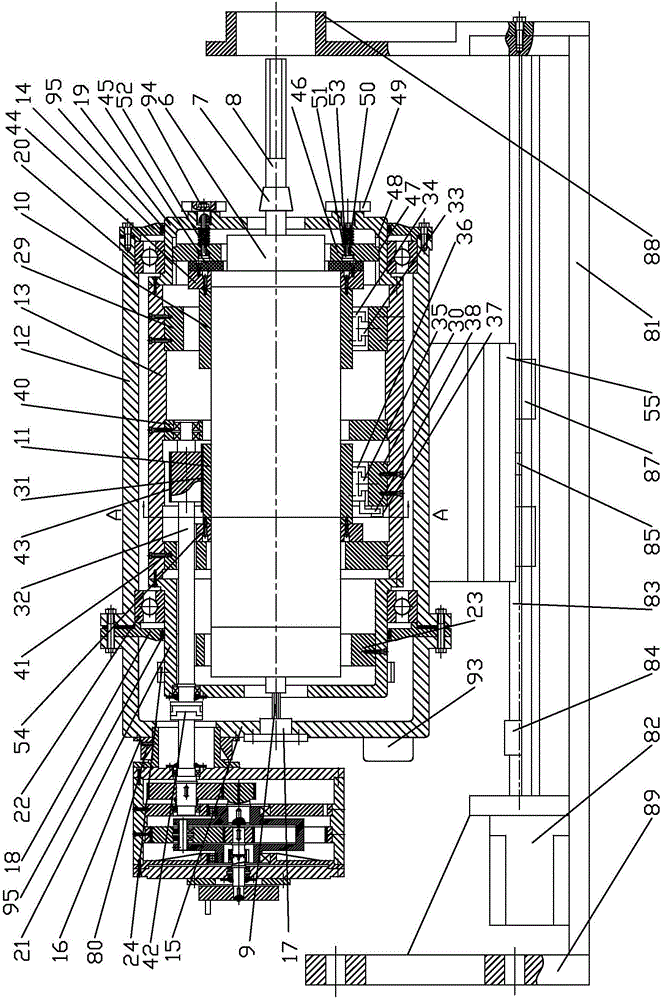

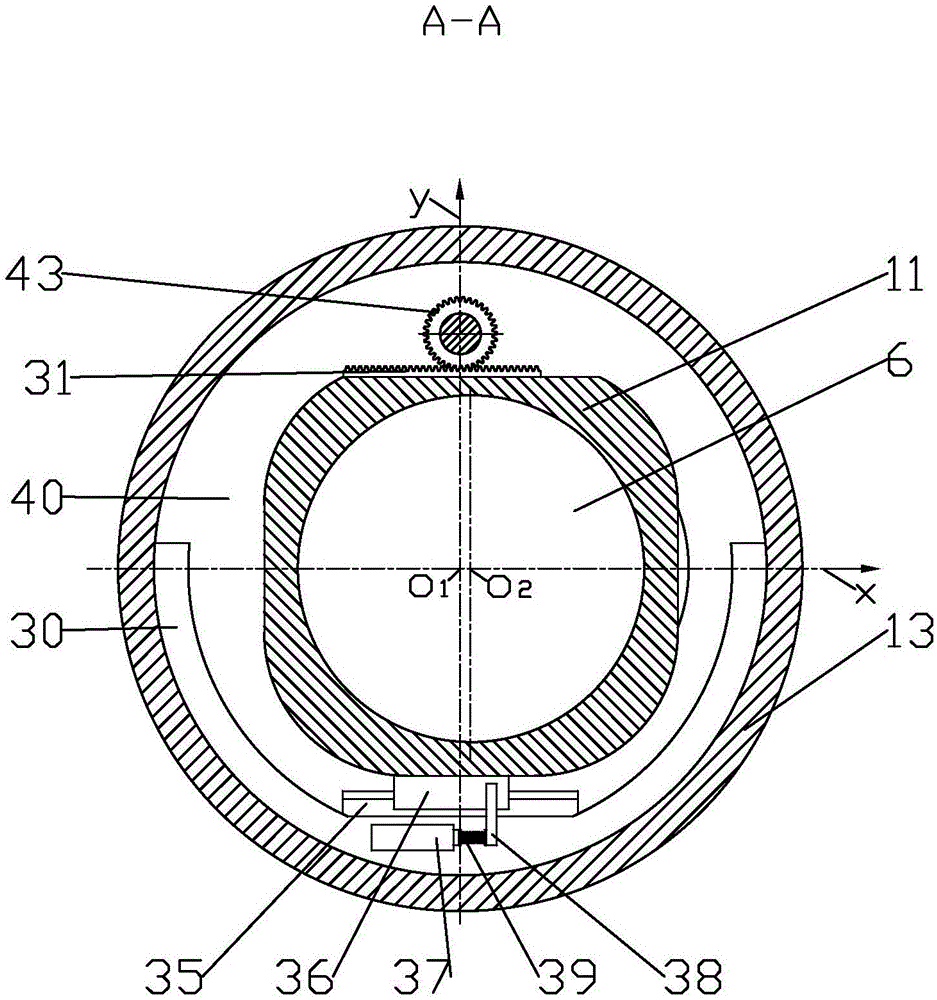

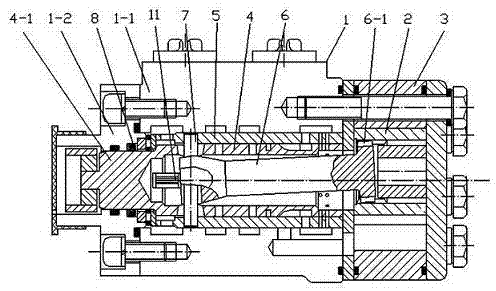

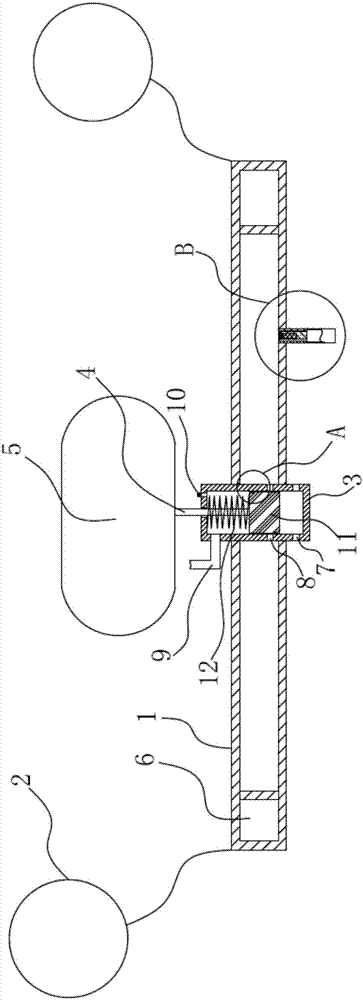

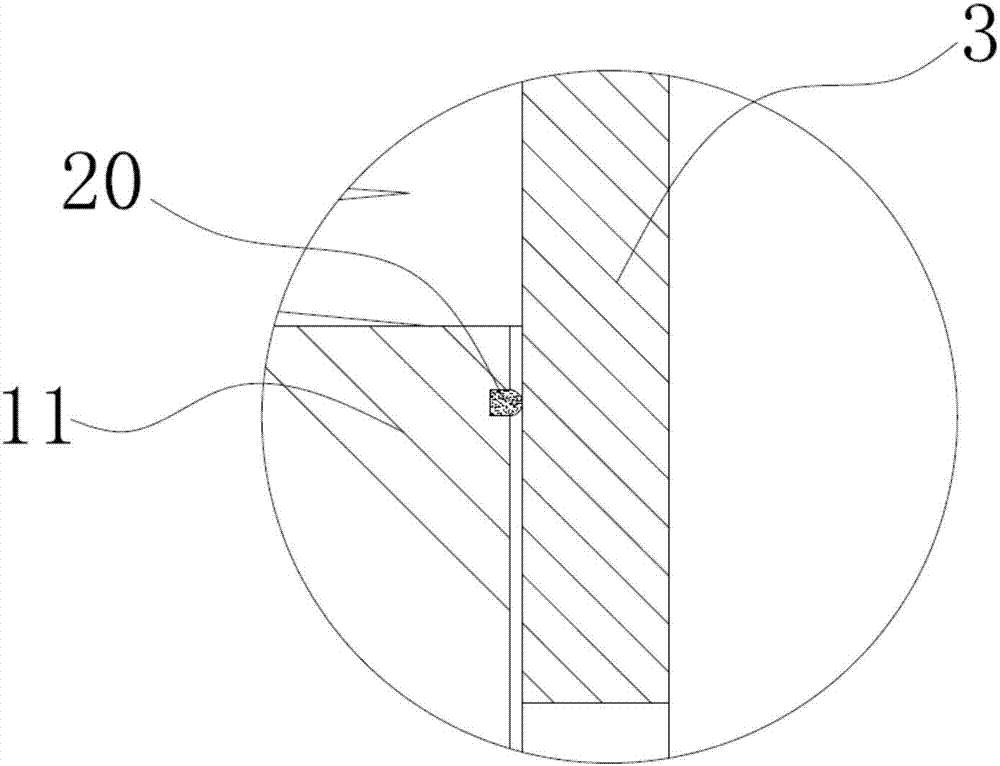

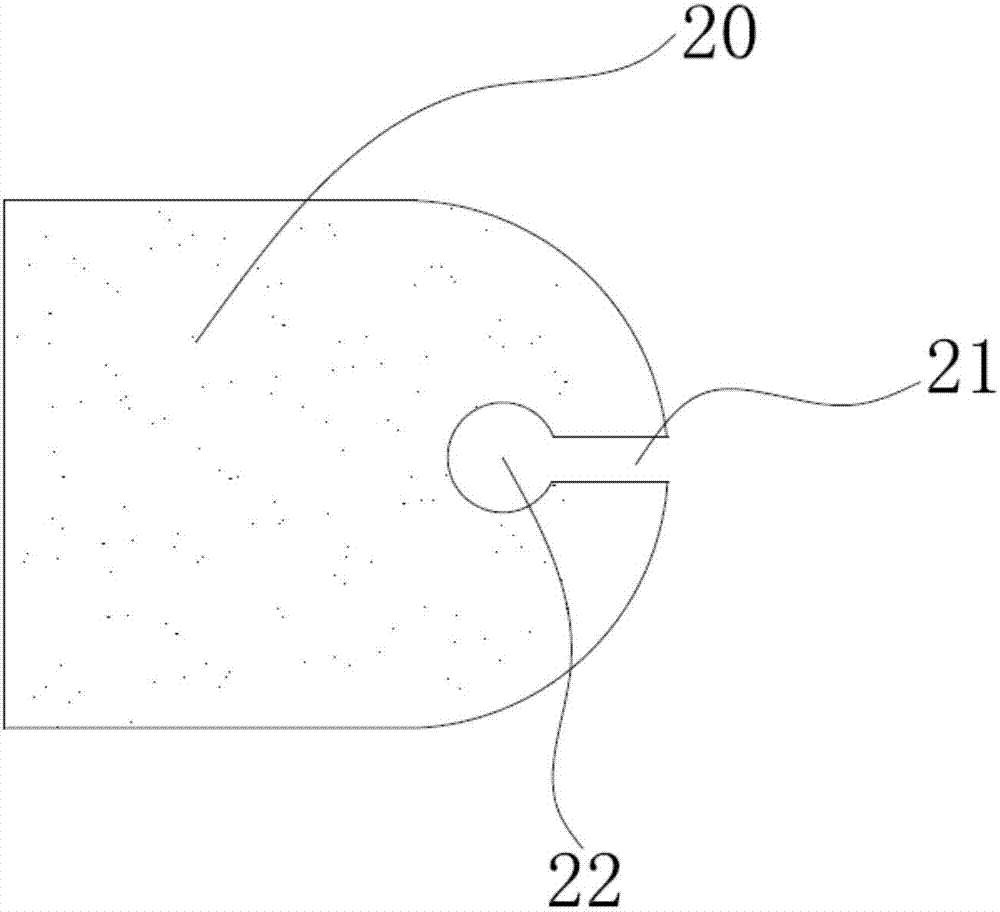

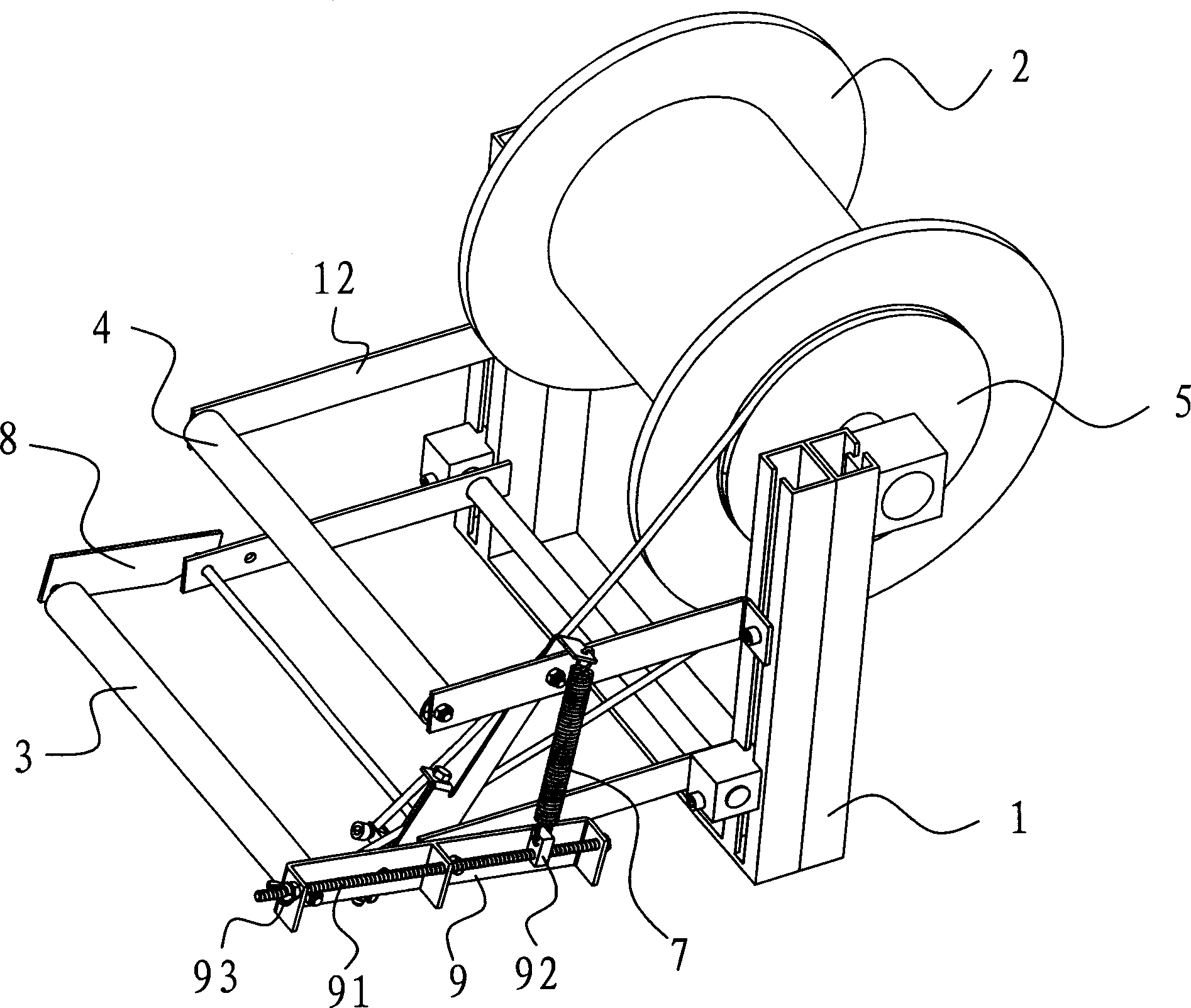

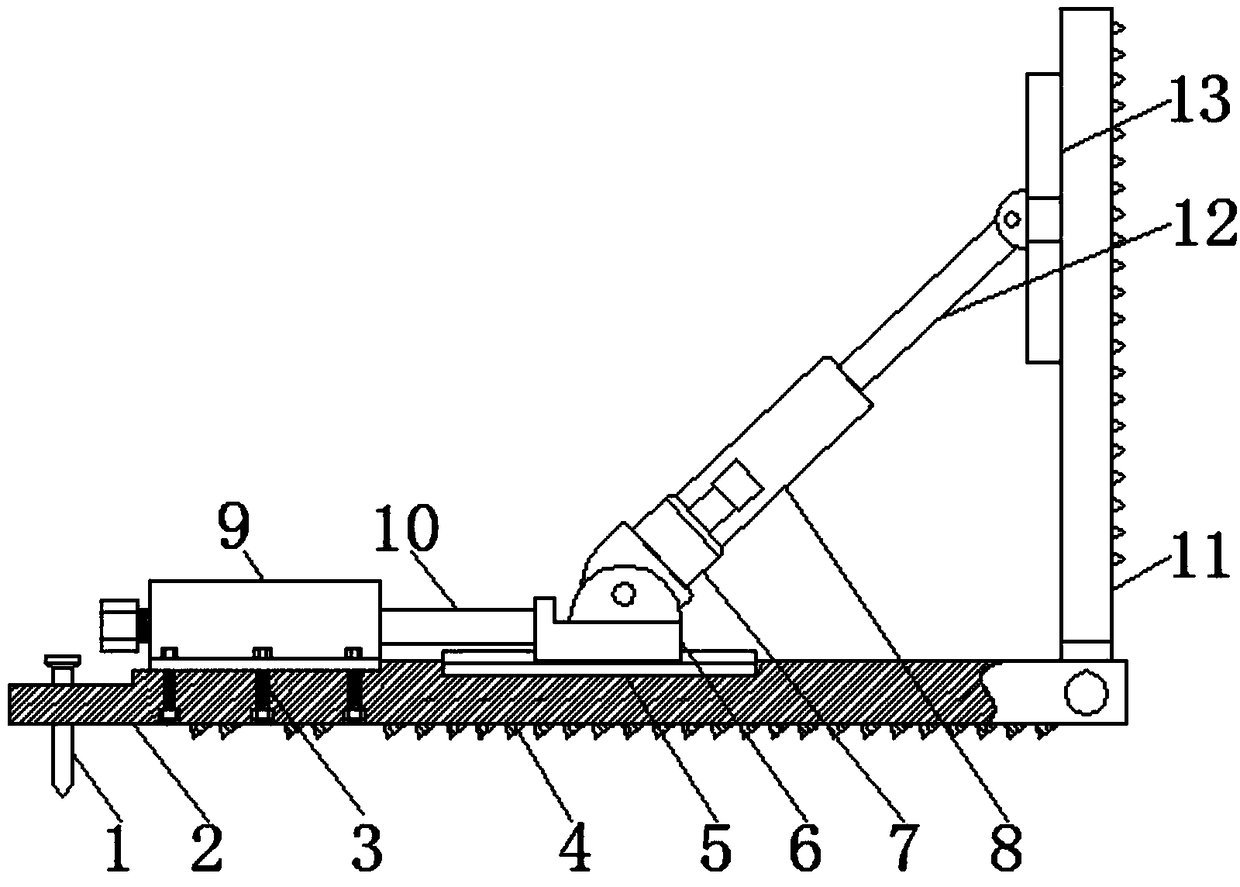

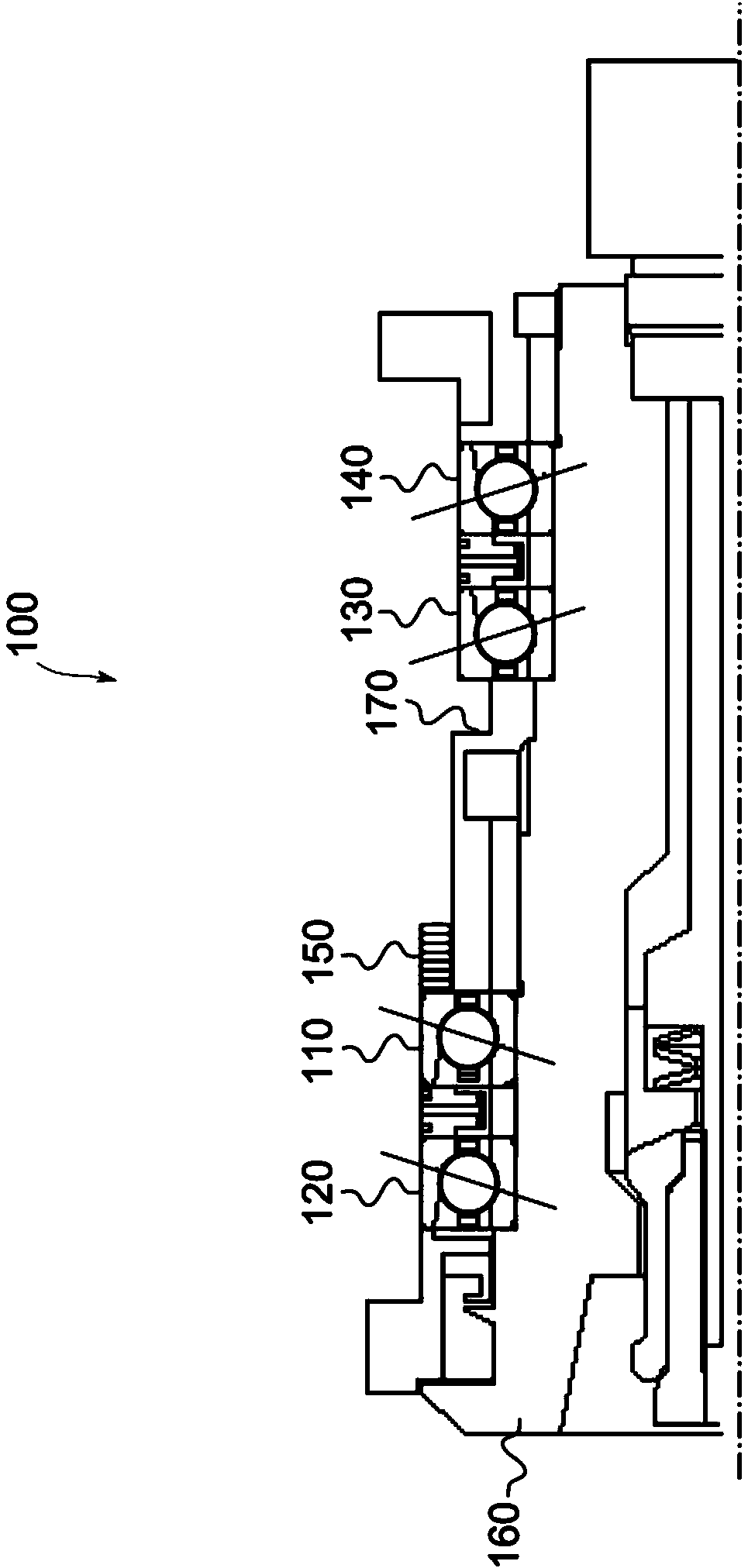

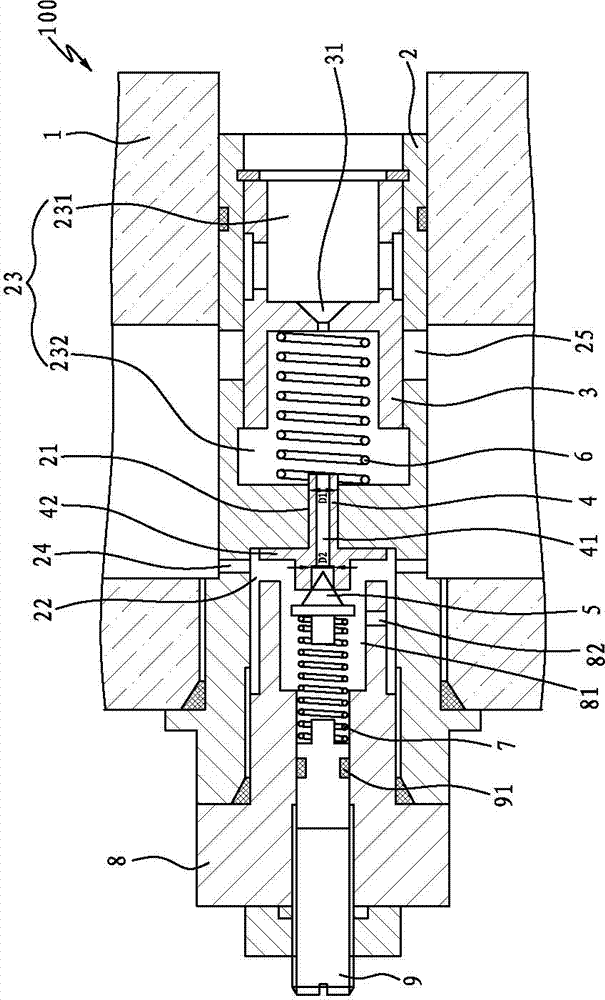

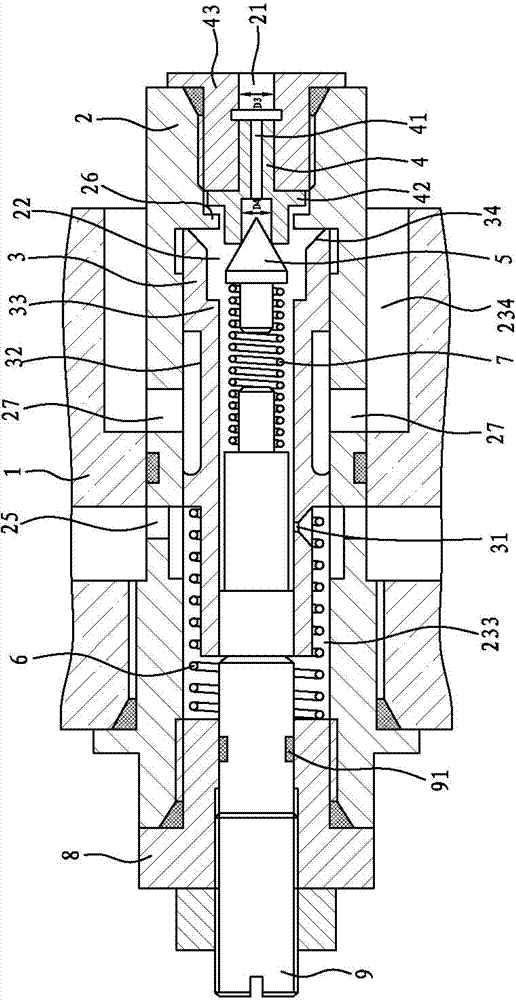

Planetary speed reduction type eccentricity-adjustable helical hole-milling device

ActiveCN106670553AReduce frictional resistanceReduce input powerFeeding apparatusLarge fixed membersSelf lockingEngineering

The invention discloses a planetary speed reduction type eccentricity-adjustable helical hole-milling device. The planetary speed reduction type eccentricity-adjustable helical hole-milling device is characterized by comprising a rotation system, a revolution system, a radial eccentricity adjusting system, a clamping braking system assembly and an axial feeding system. The radial eccentricity adjusting system can achieve precise trace linear eccentricity adjustment with high transmission ratio, and required input power is small. Compared with sliding block adjusting structures disclosed by existing patents, the radial eccentricity adjusting system can perform adjustment conveniently with less labor, and compared with a dual eccentric sleeve structure and an offset sliding block structure, the ratio of the size of the adjusting structure to the size of a rotation power source is greatly decreased, the occupied space is reduced, and the dead weight is reduced relatively in case of the identical material. Compared with an electromagnetic brake, the clamping braking system assembly can perform braking easily and conveniently; compared with a radial screw holding structure, the required pretightening force is small, and clamping is reliable; and compared with a worm and gear structure, self-locking never fails, and the working stability is high.

Owner:DALIAN JIAOTONG UNIVERSITY

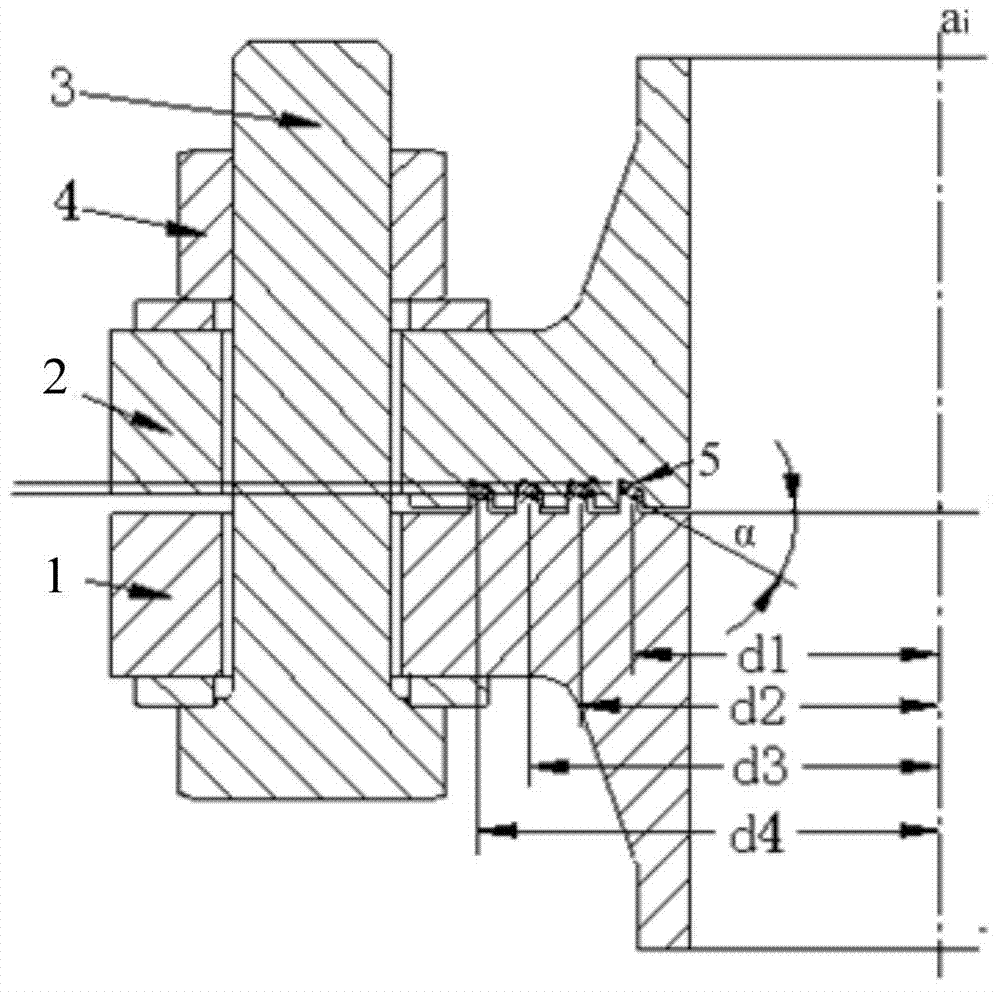

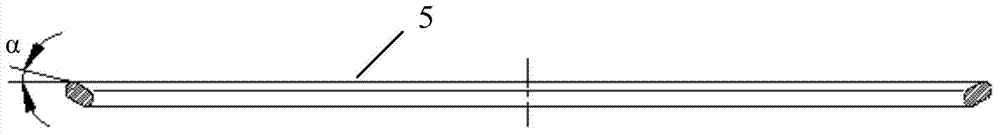

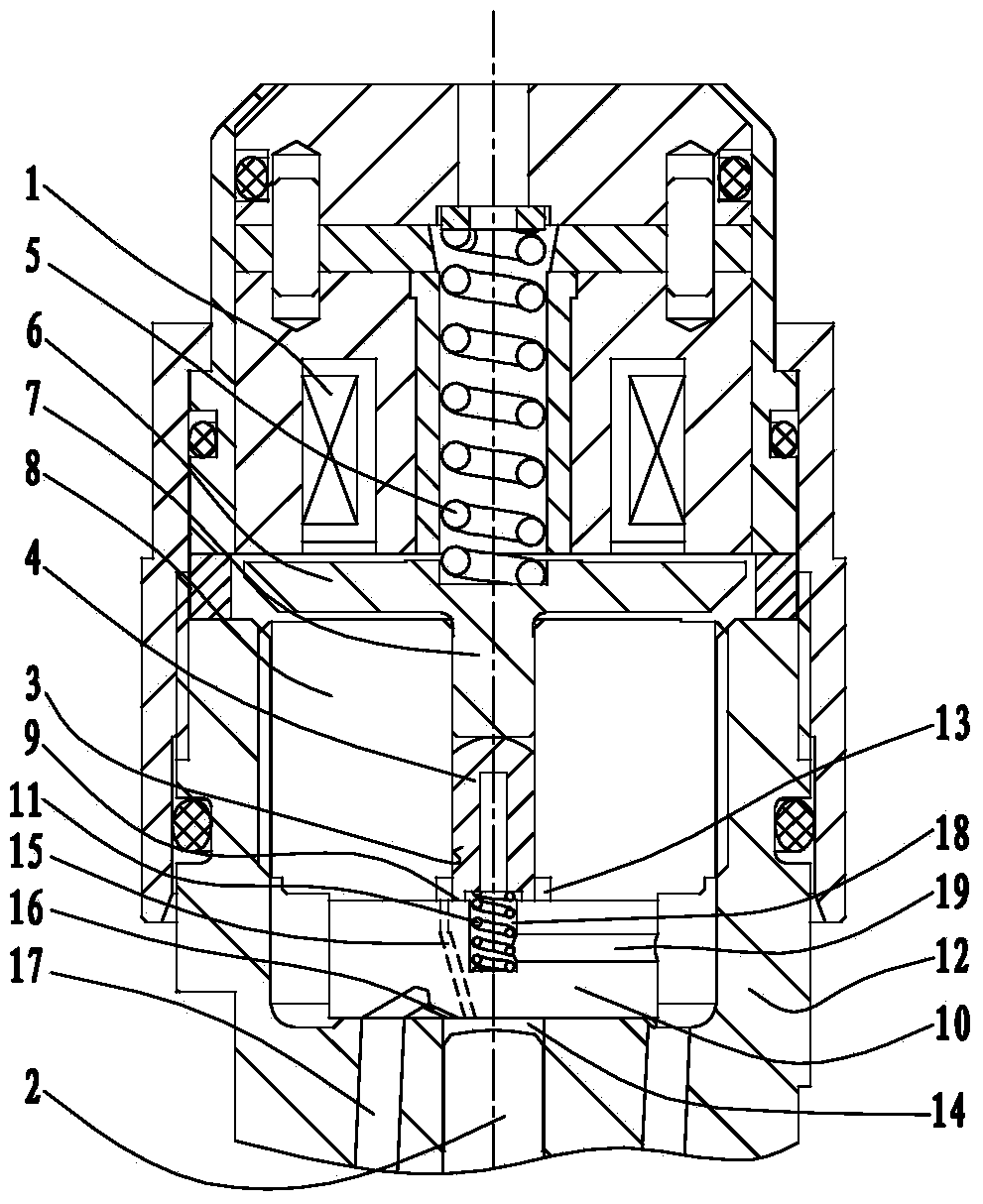

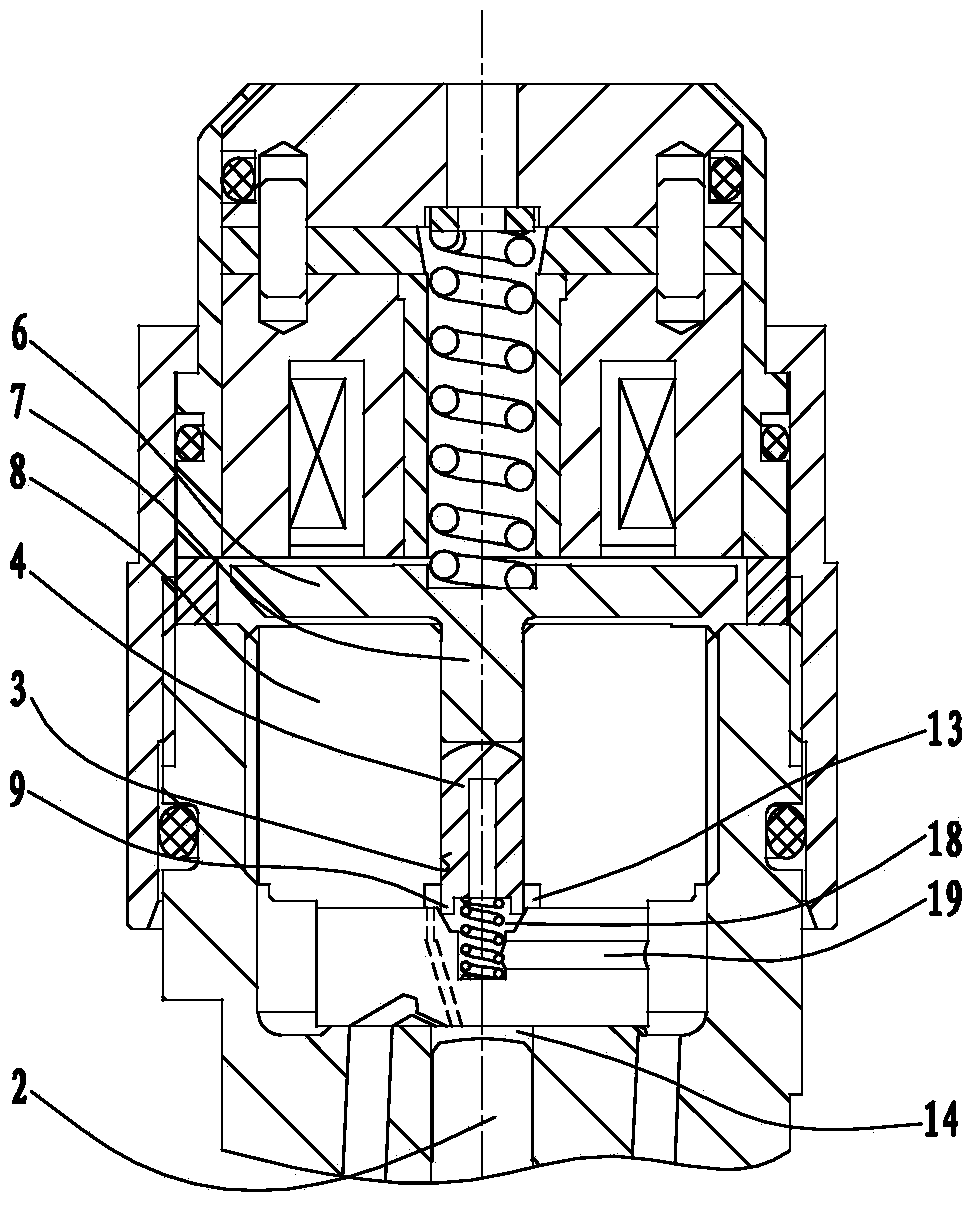

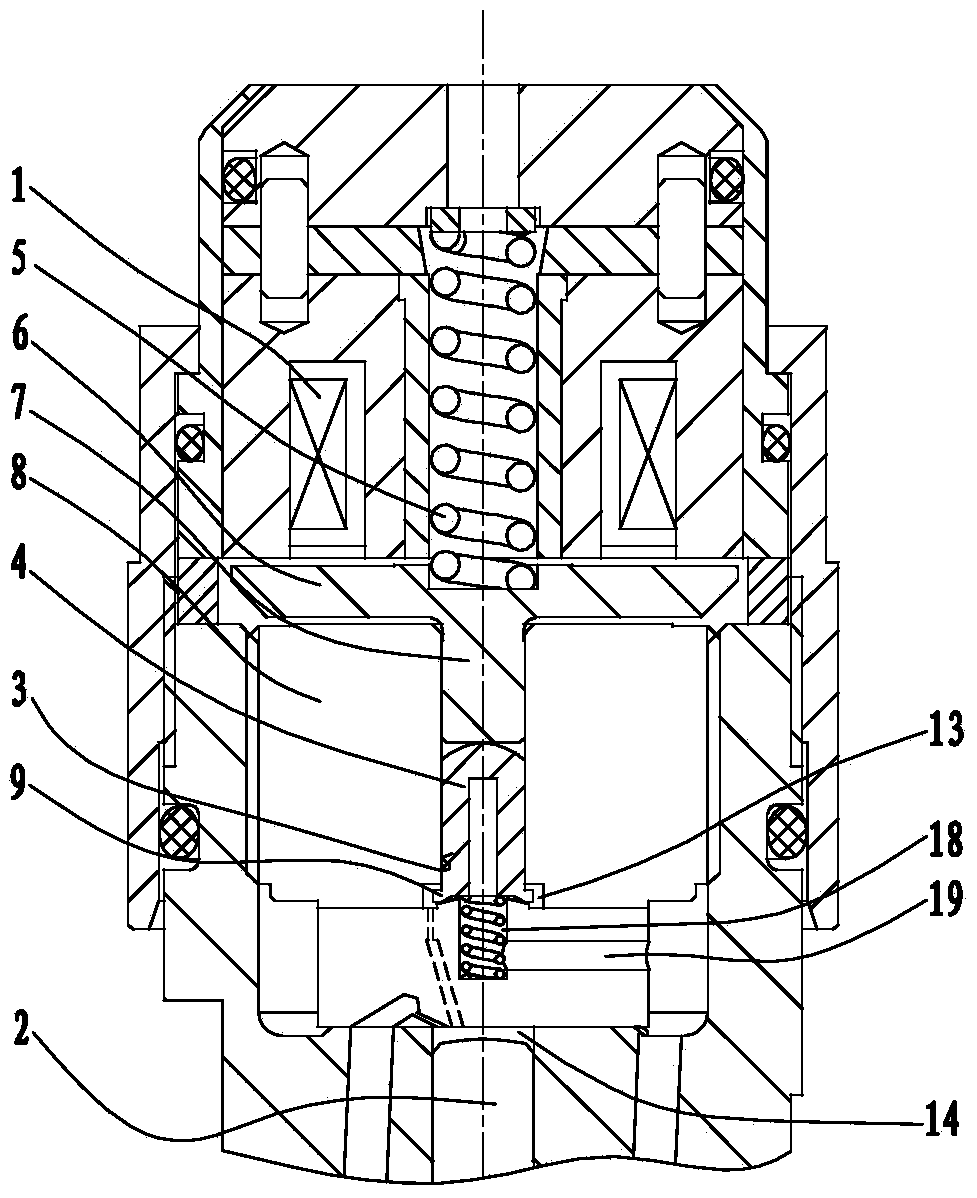

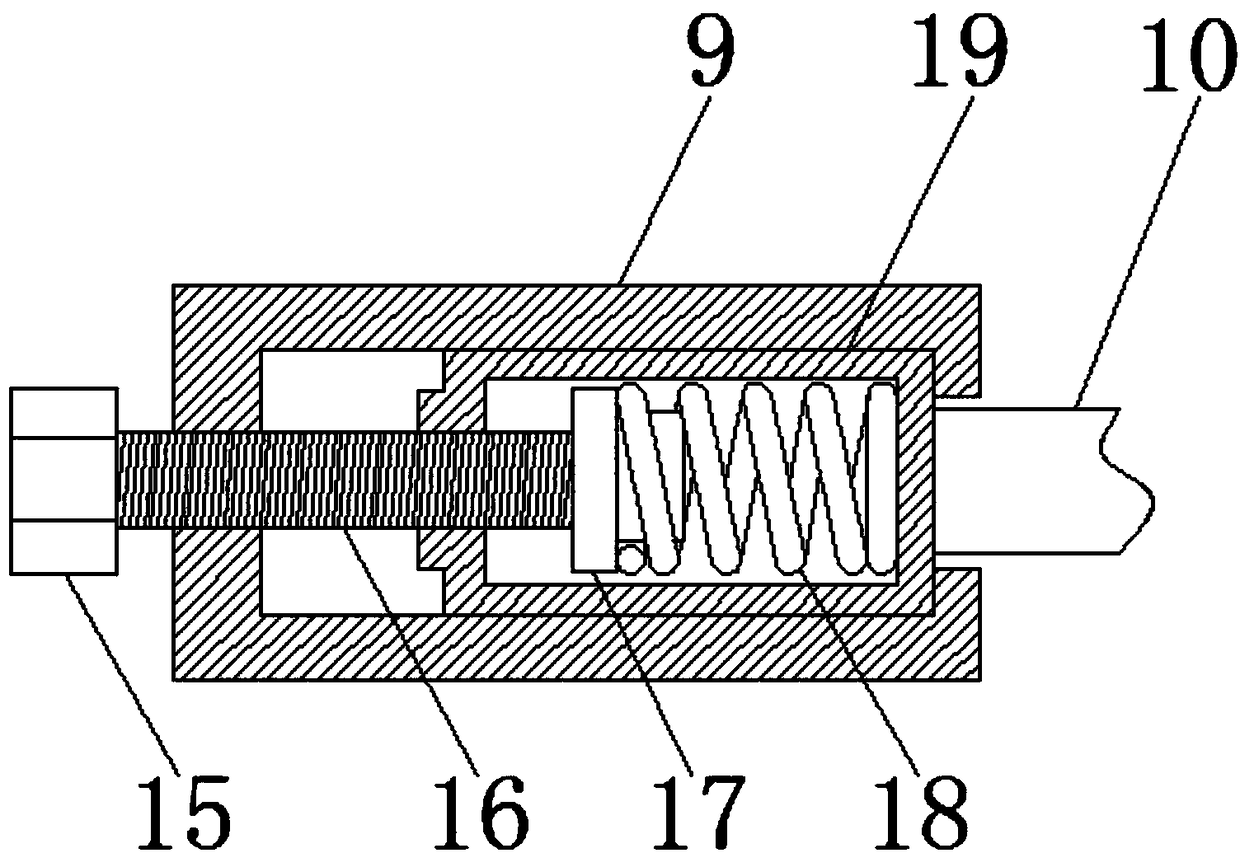

Electronic control diesel engine fuel injector with control valve

ActiveCN103104391AIngenious structureSmall preloadFuel injection apparatusMachines/enginesCommon railDieseling

The invention relates to an electronic control diesel engine fuel injector with a control valve. The electronic control diesel engine fuel injector with the control valve comprises a fuel injector body and the control valve which is arranged in an inner cavity of the fuel injector body. The electronic control diesel engine fuel injector with the control valve is characterized in that the control valve comprises an armature, a control valve base, a sealing matching member and a throttle sealing board. The throttle sealing board is placed on an installation end face of the inner cavity of the fuel injector body. The control valve base is placed on the throttle sealing board and is installed with the fuel injector body in a connected mode. The control valve base generates downward press force through installing torque to be pressed on the upper end face of the throttle sealing board, so that the lower end face of the throttle sealing board is tightly pressed on the installation end face of the inner cavity of the fuel injector body. The control valve is ingenious in structure, electronic control diesel engine fuel injector with the control valve applied is applicable to occasions with high pressure, pretightening force of a return spring of the armature of the common-rail fuel injector is greatly reduced, even though only small spring pretightening force is used, a pressure control cavity can be completely sealed, and highest pressure of a common-rail system can be improved to above 200 MPa.

Owner:CHINA FIRST AUTOMOBILE

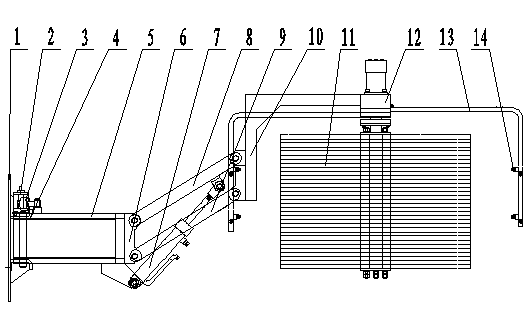

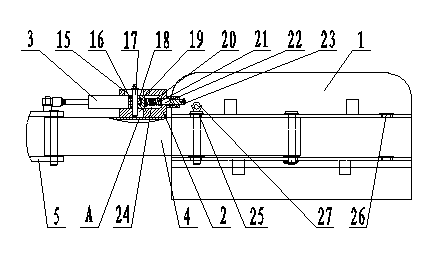

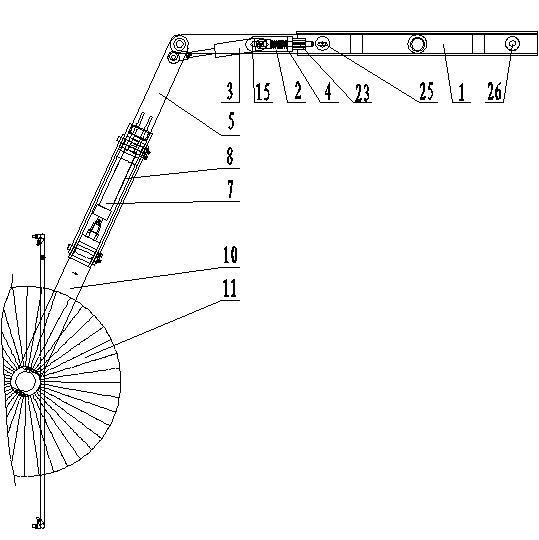

Expressway guardrail cleaning device

The invention discloses an expressway guardrail cleaning device which comprises a connecting support, a reversing arm, a steering arm, a connecting bar component, a spring, a sweeper and a sweeper support assembly, a swing cylinder, a swing cylinder seat, a lifting cylinder, and a four bar mechanism formed by the connecting bar component, the steering arm and the sweeper support assembly. The middle of the swing cylinder seat is groove-shaped and provided with a connecting block inside. The connecting block is fixed with one end of a guide shaft. The other end of the guide shaft penetrates through a guide hole in the groove-shaped bottom of the swing cylinder seat. The other end of the guide shaft is provided with a limit adjusting nut. The spring, a compression spring, is arranged on the guide shaft and arranged between the connecting block and the groove-shaped bottom of the swing cylinder seat. The swing cylinder seat is arranged on the reversing arm. A piston of the swing cylinder is hinged with the reversing arm. The expressway guardrail cleaning device is convenient to operate and capable of adjusting vertical position of the sweeper and prolonging service life of the spring.

Owner:JINGSU YUEDA SPECIAL VEHICLE CO LTD

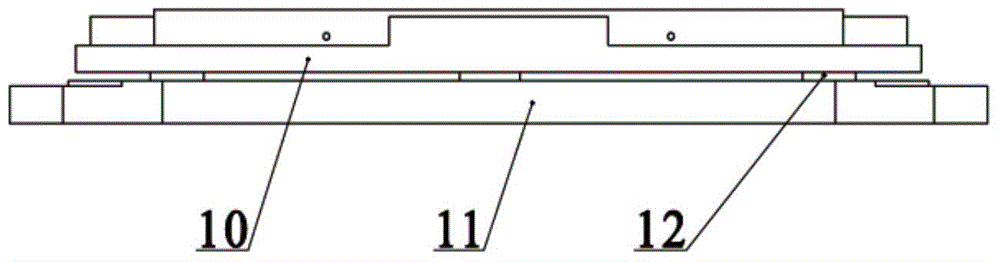

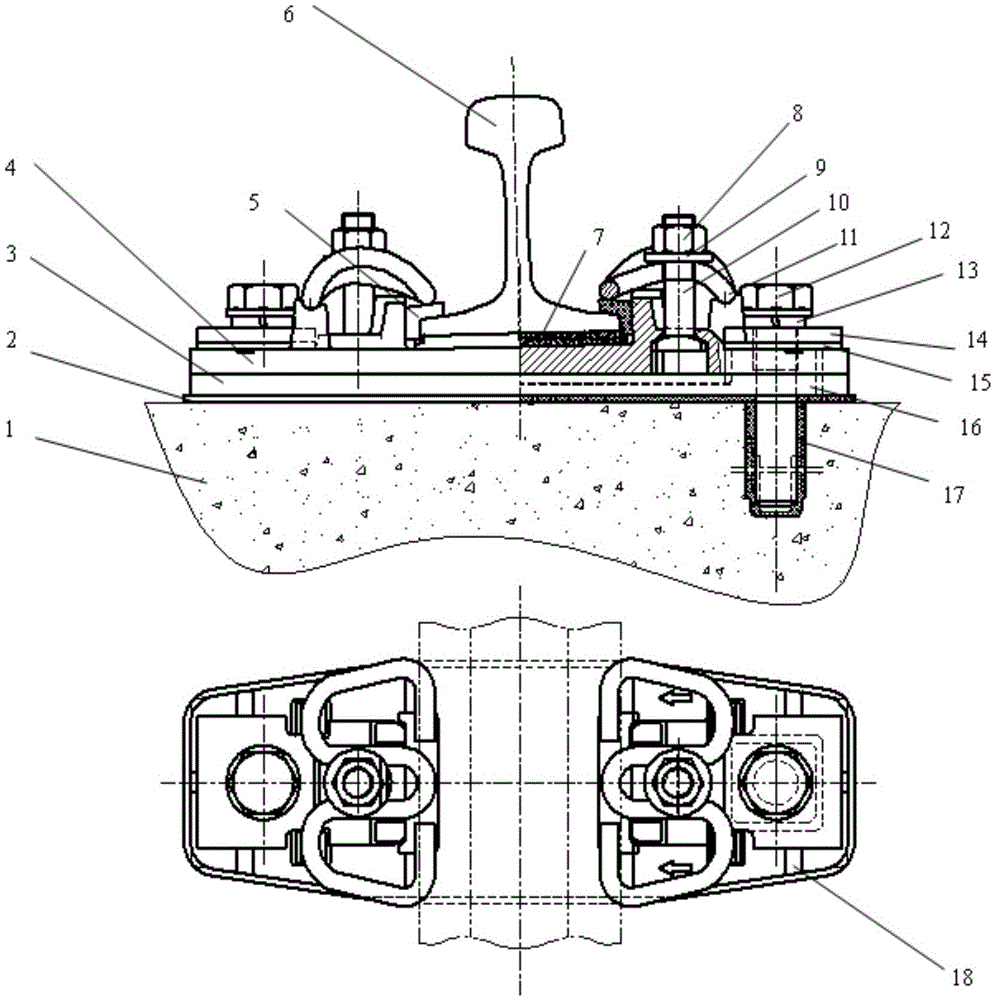

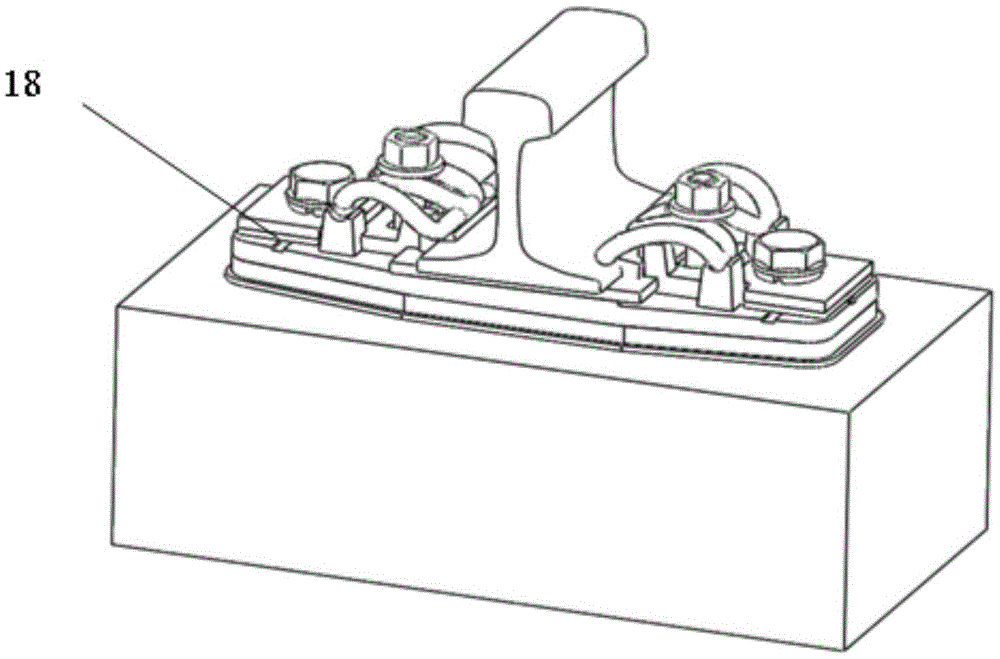

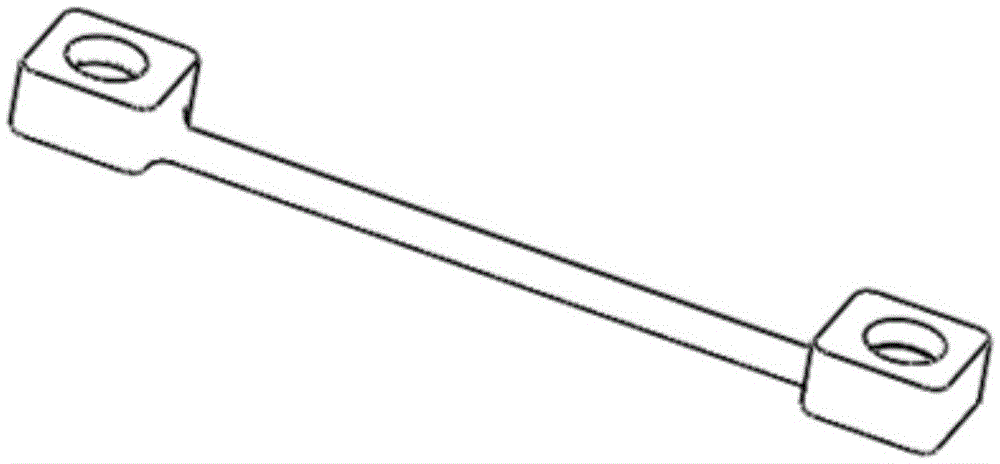

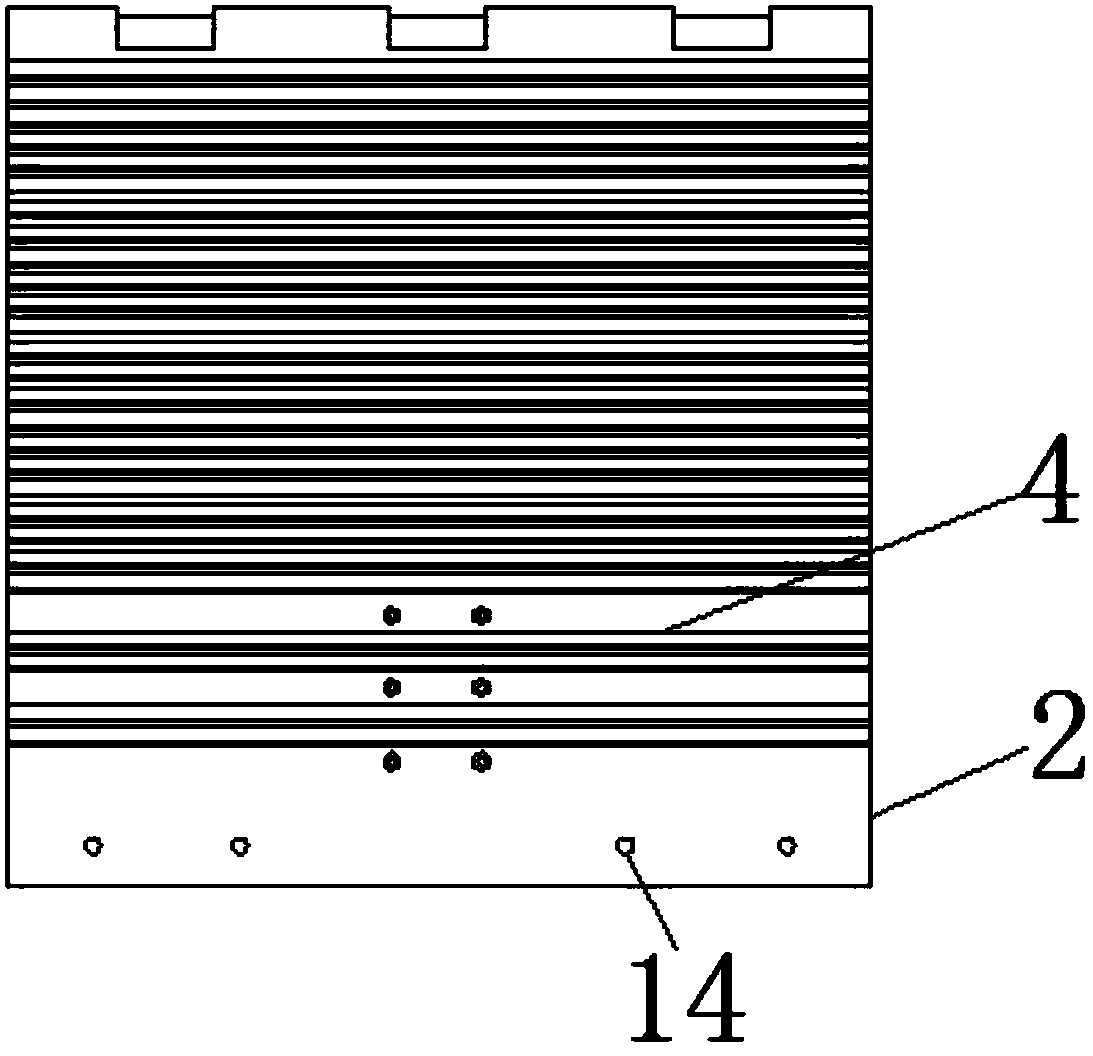

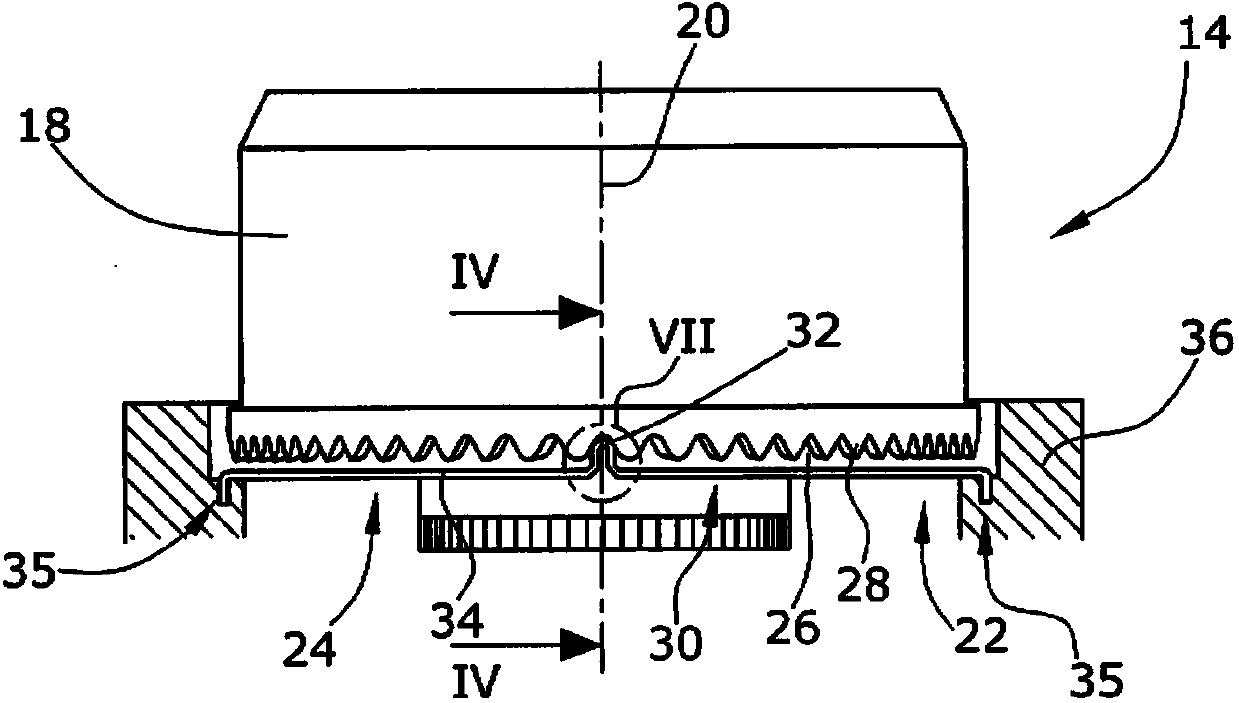

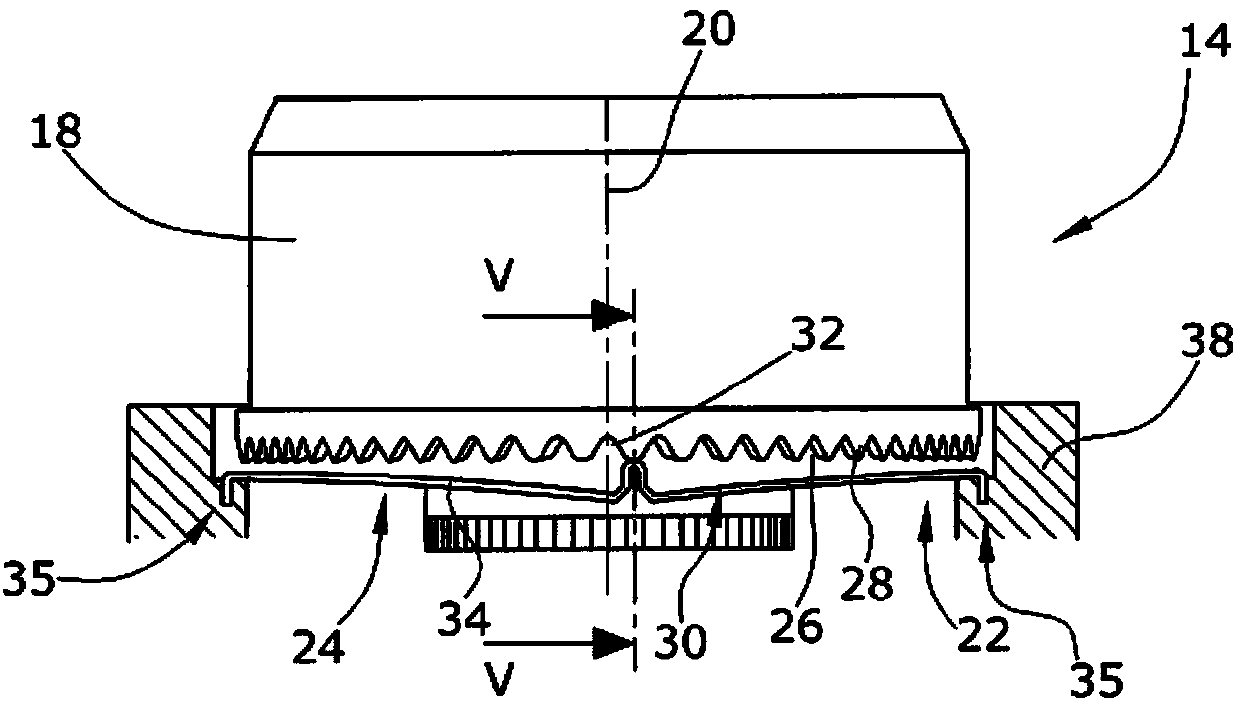

Dual-layer vibration-damping fastener for city railway

The invention discloses a dual-layer vibration-damping fastener for a city railway. The dual-layer vibration-damping fastener comprises a base, an insulation buffer cushion plate, an elastic cushion layer, an upper-layer iron cushion plate, an insulation gauge block, a steel rail, an under-rail rubber cushion plate, a nut, a flat washer, T-shaped bolts, an elastic strip, anchor bolts, heavy spring washers, pressing plates, an insulation press cover, an iron connecting rod, and a nylon sleeve pipe. The dual-layer vibration-damping fastener disclosed by the invention has the beneficial effects that a creative designed structure without a lower-layer iron cushion plate is adopted, a special tool is not needed, and the dual-layer vibration-damping fastener can be manually disassembled; the elastic cushion layer is simple to repair and replace, and the conservation and the repair are facilitated; the iron connecting rod is used, so that the two anchor bolts are stressed at the same time, the operating state of the anchor bolts is optimized, the safety of the fasteners is improved, besides, the structure is simple, and the cost is low.

Owner:ANHUI CHAOHU CASTING FACTORY +1

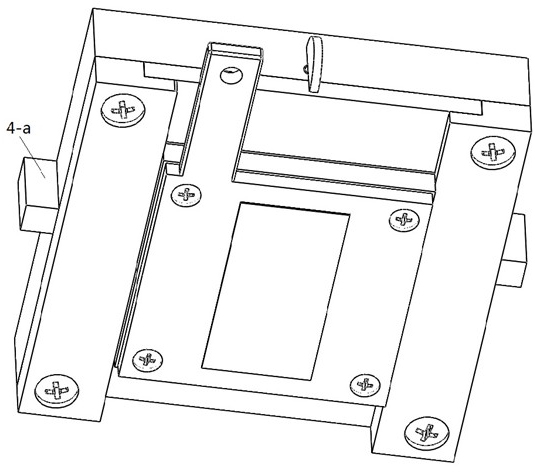

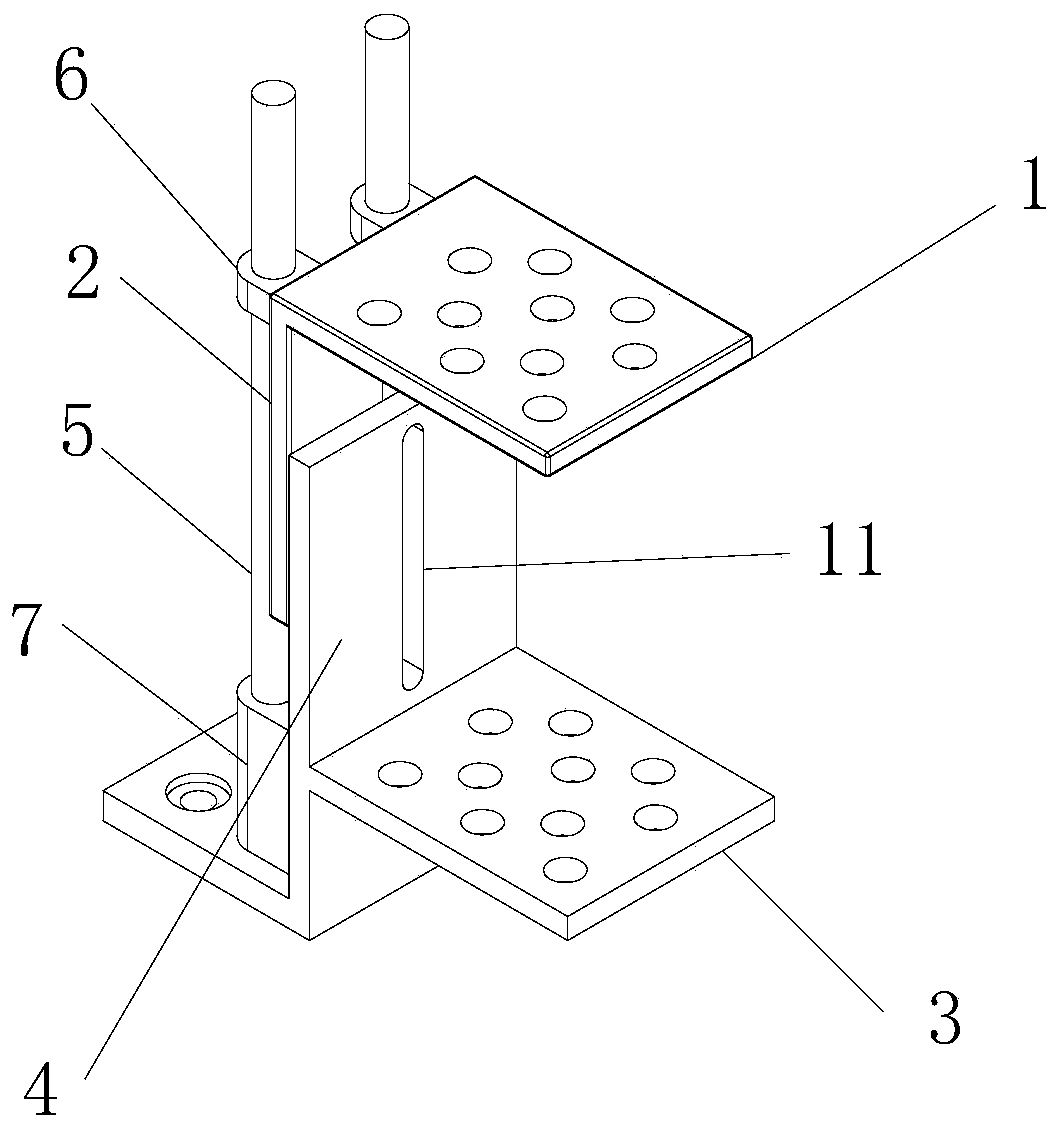

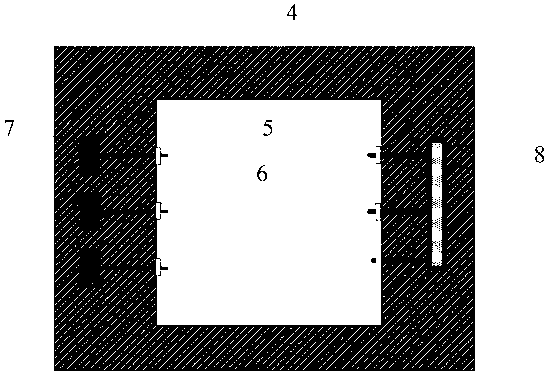

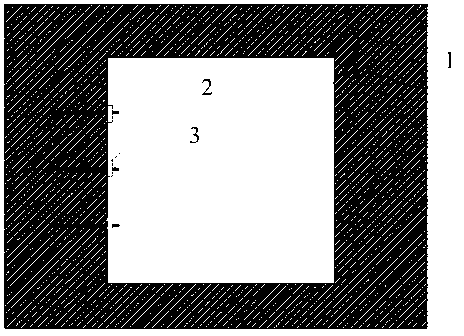

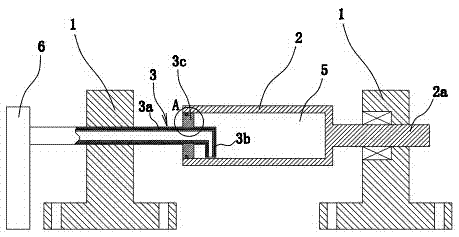

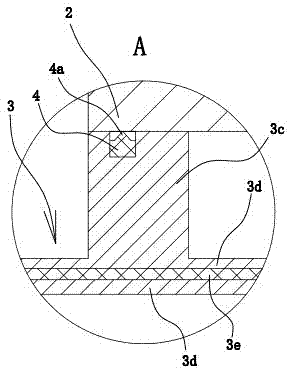

Fixture for conductivity test and assembling method thereof

ActiveCN102323453AImprove versatilitySmall preloadManufacture of electrical instrumentsMeasurement instrument housingSolid state electrolytePorous carbon

The invention discloses a fixture for a conductivity test and an assembling method thereof. The fixture comprises a precise pretightening sliding mechanism, a fixing border, and a clamping module assembly for fixing electrolyte, wherein the precise pretightening sliding mechanism comprises a pressing head and a positioning head matched with the pressing head; a screw is fixed on the pressing head; sliding chute fixing side plates are arranged on two sides of the fixing border; the clamping module assembly has two types which can be used for a solid electrolyte test and a liquid electrolyte test; the clamping module assembly for the liquid electrolyte test comprises an upper electrode plate, a lower electrode plate, an upper insulating plate and a lower insulating plate; the clamping module assembly for the solid electrolyte test comprises a porous carbon material; and different clamping module assemblies are selected according to different test objects. By adopting the design scheme that a modularized assembly is used, the fixture and the method respectively become a general fixture and a general method for testing the conductivity of the electrolyte.

Owner:安徽元隽氢能科技股份有限公司

Universal curved-surface clamp

ActiveCN110026793AModerate stiffnessSmall preloadPositioning apparatusMetal-working holdersElastic componentIndustrial engineering

Owner:CATARC TIANJIN AUTOMOTIVE ENG RES INST CO LTD +1

Support method and support structure for soft coal/ rock stratum alley

The invention discloses a support method and a support structure for a soft coal / rock stratum alley and relates to the technical field of coal stratum alley support. The support method and the support structure for the soft coal / rock stratum alley aim at solving the problem that the soft coal / rock stratum alley is easy to deform. The support method for the soft coal / rock stratum alley comprises the steps: holes are drilled in edges of the soft coal / rock stratum alley; grout is directionally controlled at the bottom of each drilled hole so that grout reinforcing groups are formed; and an anchor cable is arranged in each drilled hole and a cable body end portion of each anchor cable is anchored on each grout reinforcing group. According to the support structure for the soft coal / rock stratum alley, the cable body end portion of each anchor cable is anchored on each grout reinforcing group. The support method and the support structure are suitable for alley support and particularly suitable for the alley support of soft coal / rock strata.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

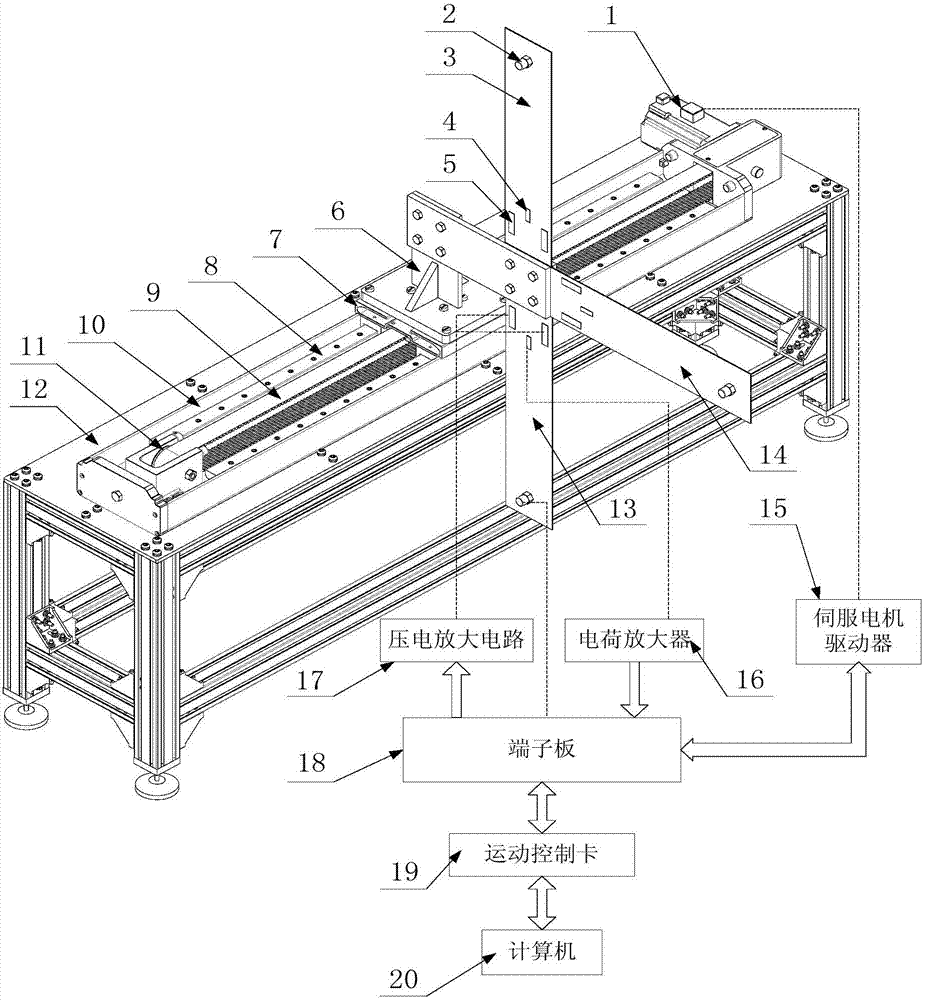

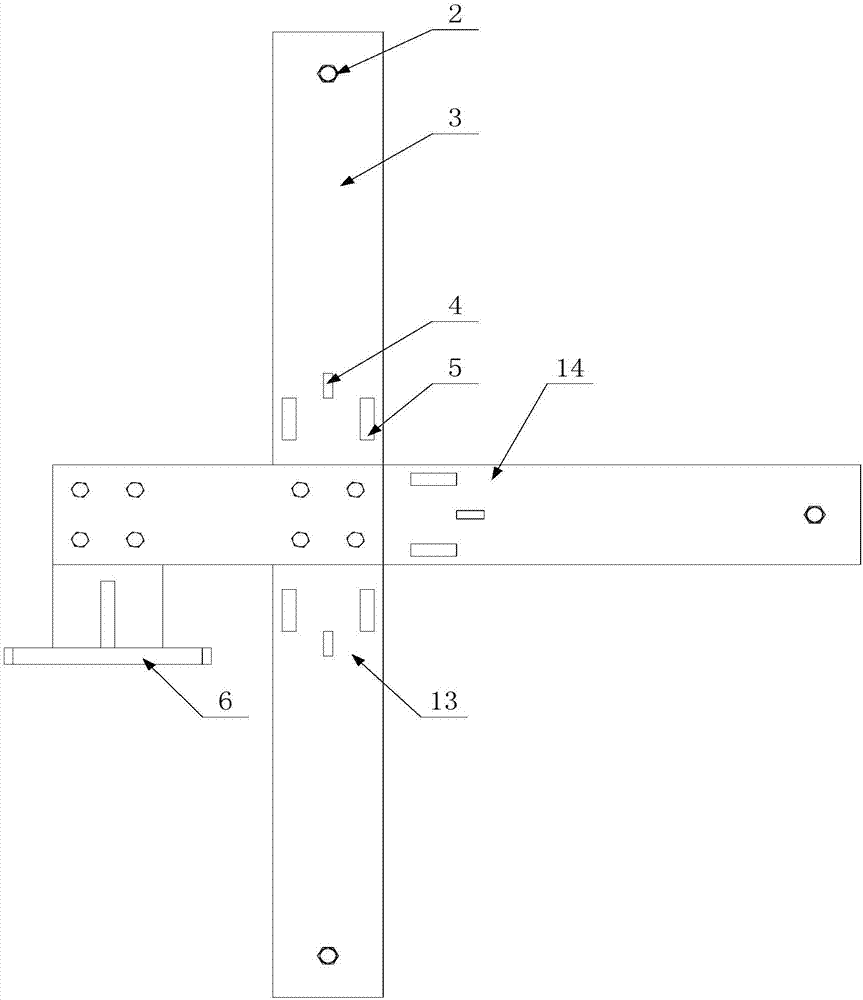

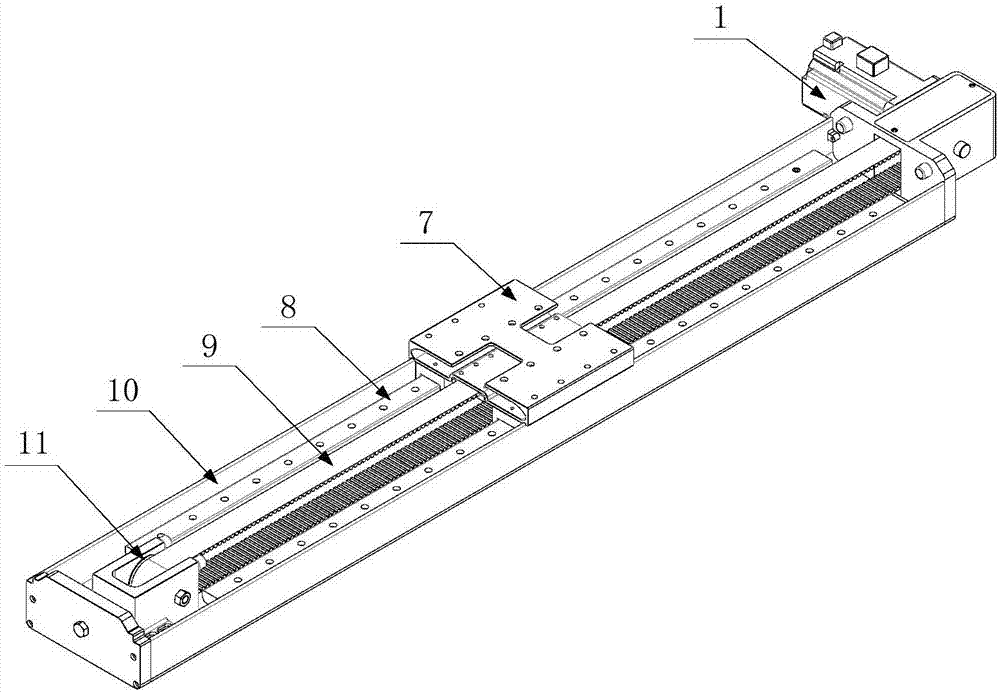

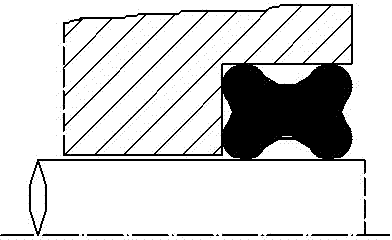

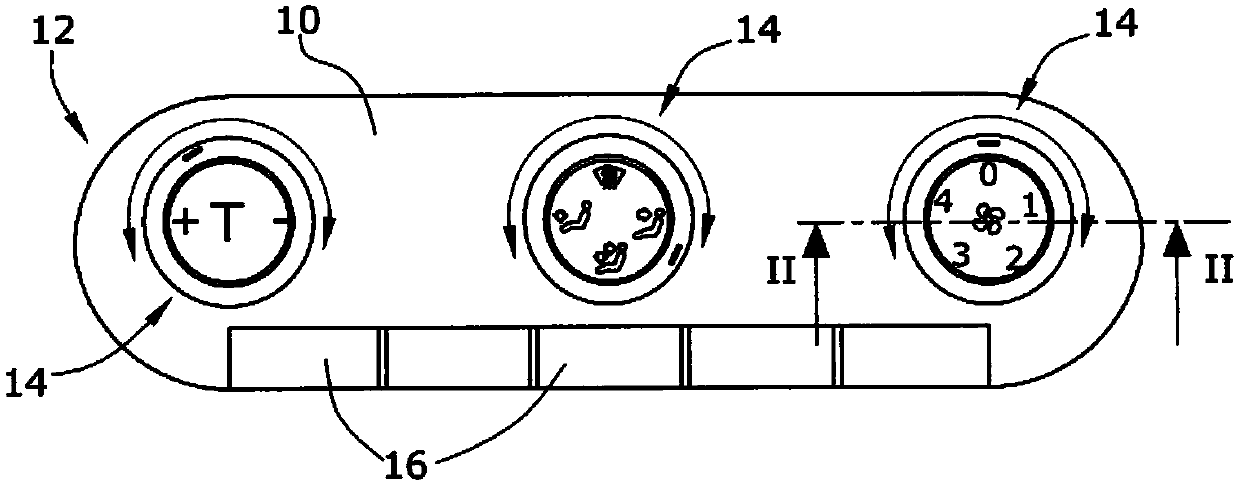

Multi-flexible beam vibration control device and method based on synchronous belt drive

InactiveCN106933266AEliminates the effects of vibration control effectsStable positioningMechanical oscillations controlVibration controlControl system

The invention discloses a multi-flexible beam vibration control device and method based on synchronous belt drive. The device comprises a flexible beam body, a detection part and a control part. The flexible beam body comprises three flexible beams of the same size. The detection part comprises a piezoelectric sensor and an acceleration sensor, wherein the piezoelectric sensor and the acceleration sensor are respectively arranged on the flexible beams. The control part comprises a synchronous belt drive control system and a piezoelectric drive control system. The vibration signal of the flexible beam structure is detected by the piezoelectric sensor and the acceleration sensor. A synchronous belt driven by a servo motor and a piezoelectric drive are used as an actuator for suppressing vibration. The device can be used to study the influence and vibration control of gravity, synchronous belt gap characteristics, synchronous belt elasticity and other factors on the vibration of the flexible beam structure.

Owner:SOUTH CHINA UNIV OF TECH

Hydraulic steering gear

InactiveCN102328685AFit tightlyReduce frictional resistanceEngine sealsHydraulic steering gearsWear resistantEngineering

The invention relates to a hydraulic steering gear, belonging to the technical field of hydraulic transmission and control. One end of the valve body of the steering gear is fixedly connected with a stator with a cycloidal pin wheel rotor. A spool which stretches out of a front shaft and a valve pocket which can form a runner switching valve together with the spool are arranged in the valve body. A linkage shaft penetrates through the inner hole of the spool. One end of the linkage shaft is provided with outer teeth which are engaged with a spline in the rotor, and the other end of the linkage shaft is connected with the spool through a radial shifting pin. An annular sealing groove is arranged on the surface of the inner hole of the valve body which is matched with the front shaft. An annular sealing skeleton made of a lubricating wear-resistant material is installed in the sealing groove. One surface of the sealing skeleton is in fit with one sealing surface, and the other surface of the sealing skeleton is provided with a groove which can hold a sealing ring. An elastic sealing ring which is in fit with the other sealing surface is arranged in the groove. On the premise that a good sealing effect is guaranteed, the input torque for power steering is effectively reduced.

Owner:ZHENJIANG HYDRAULICS

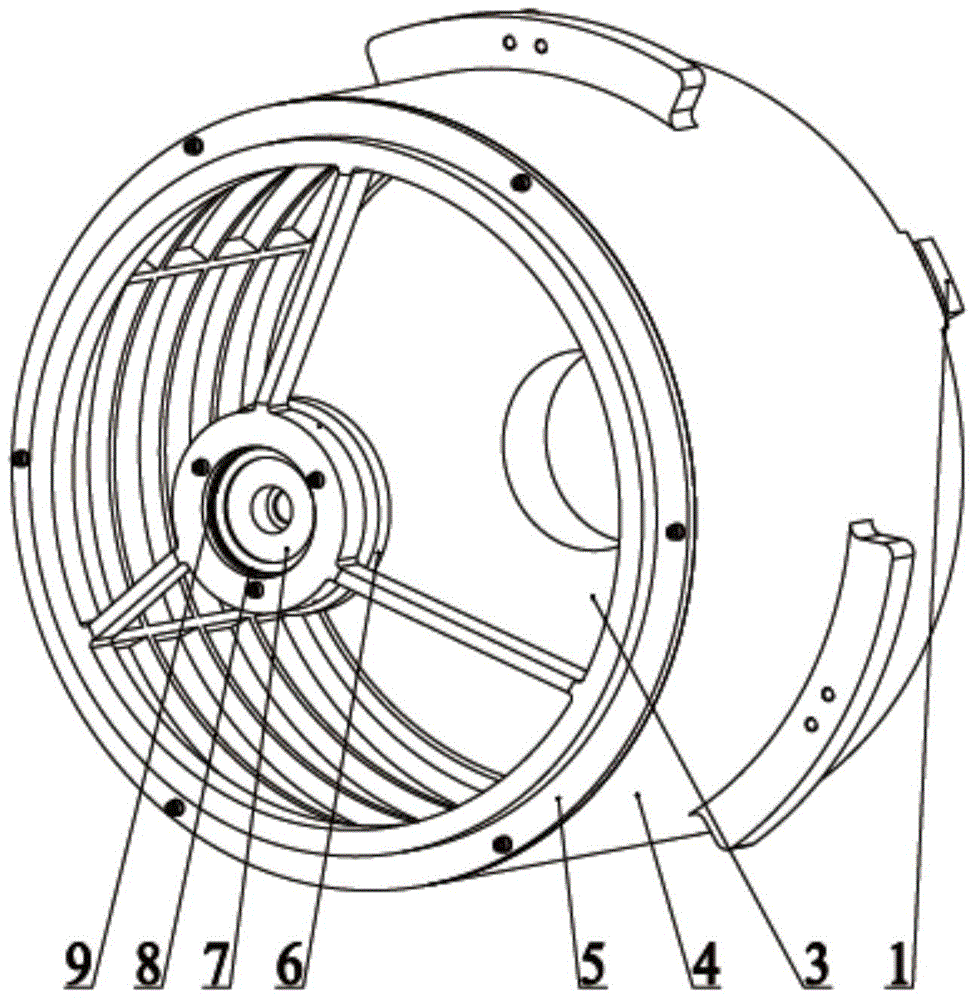

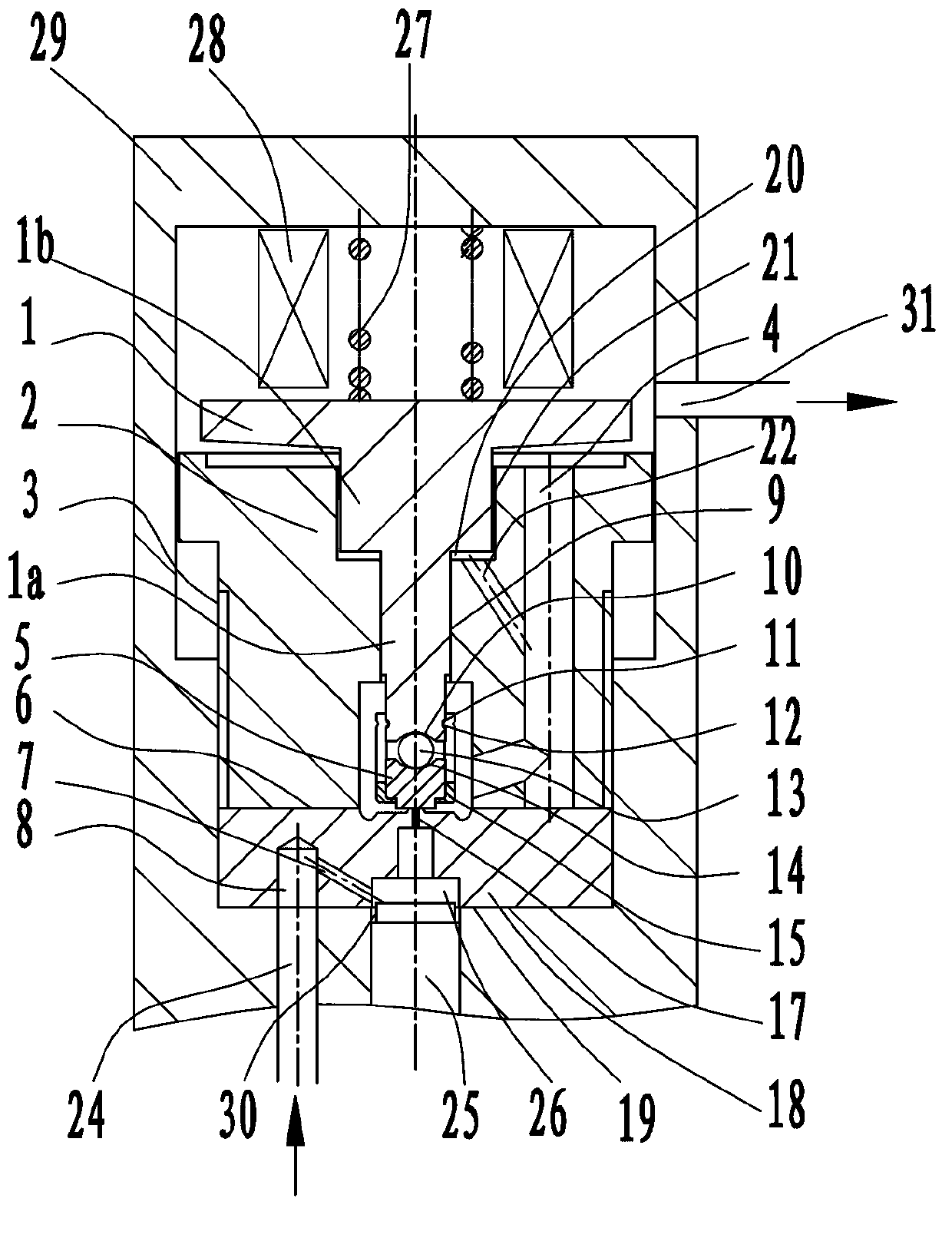

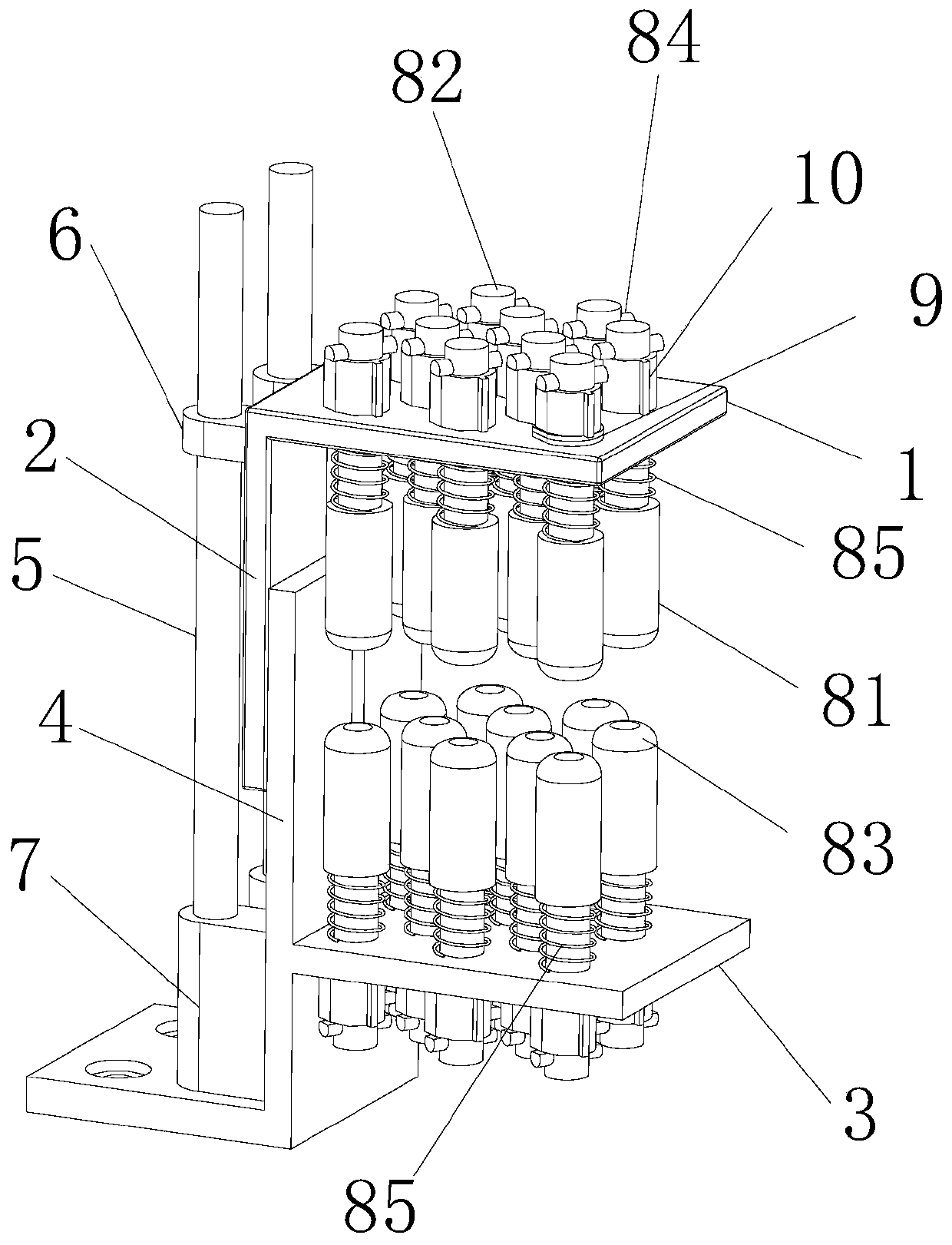

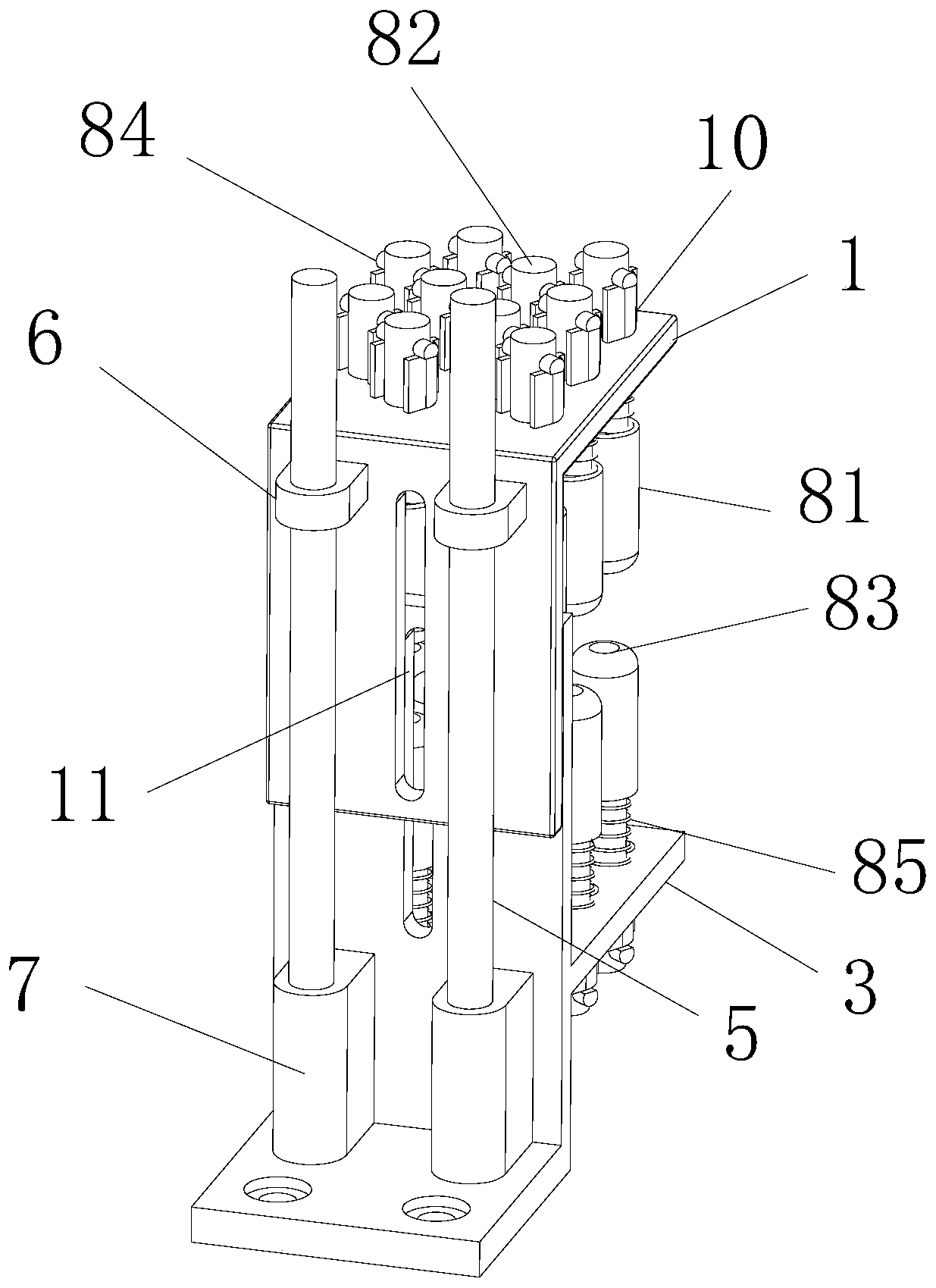

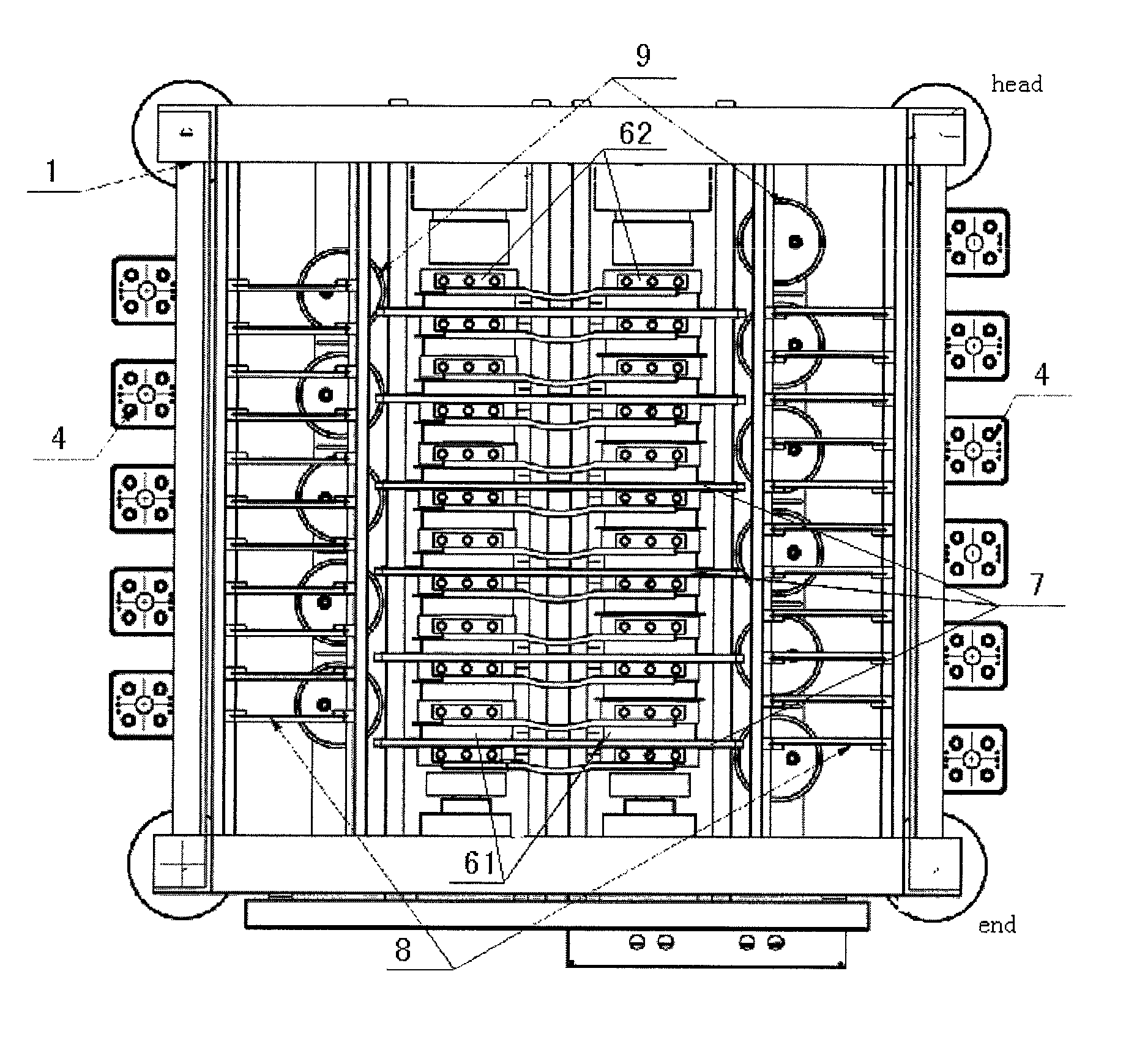

Self-cooled thyristor valve

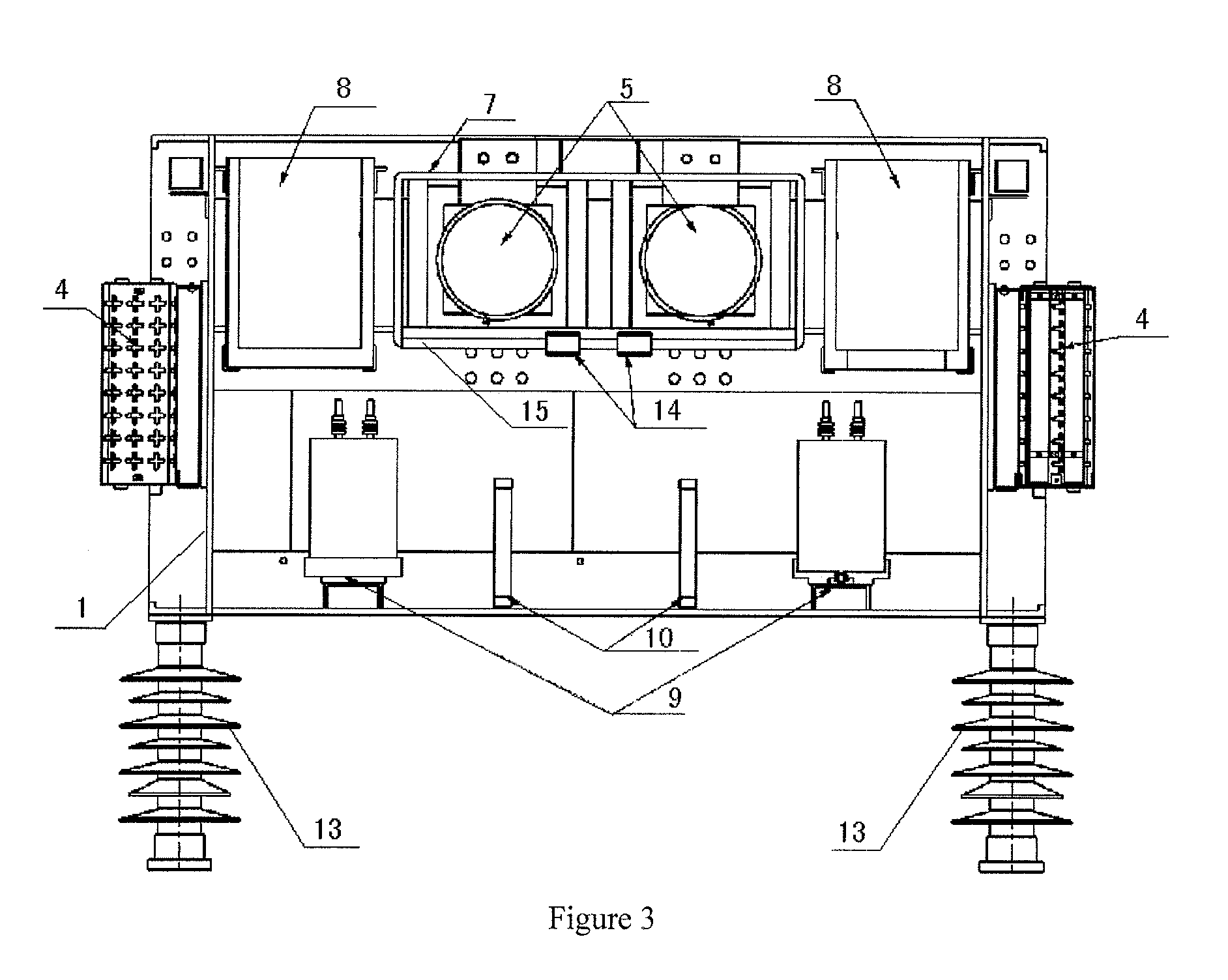

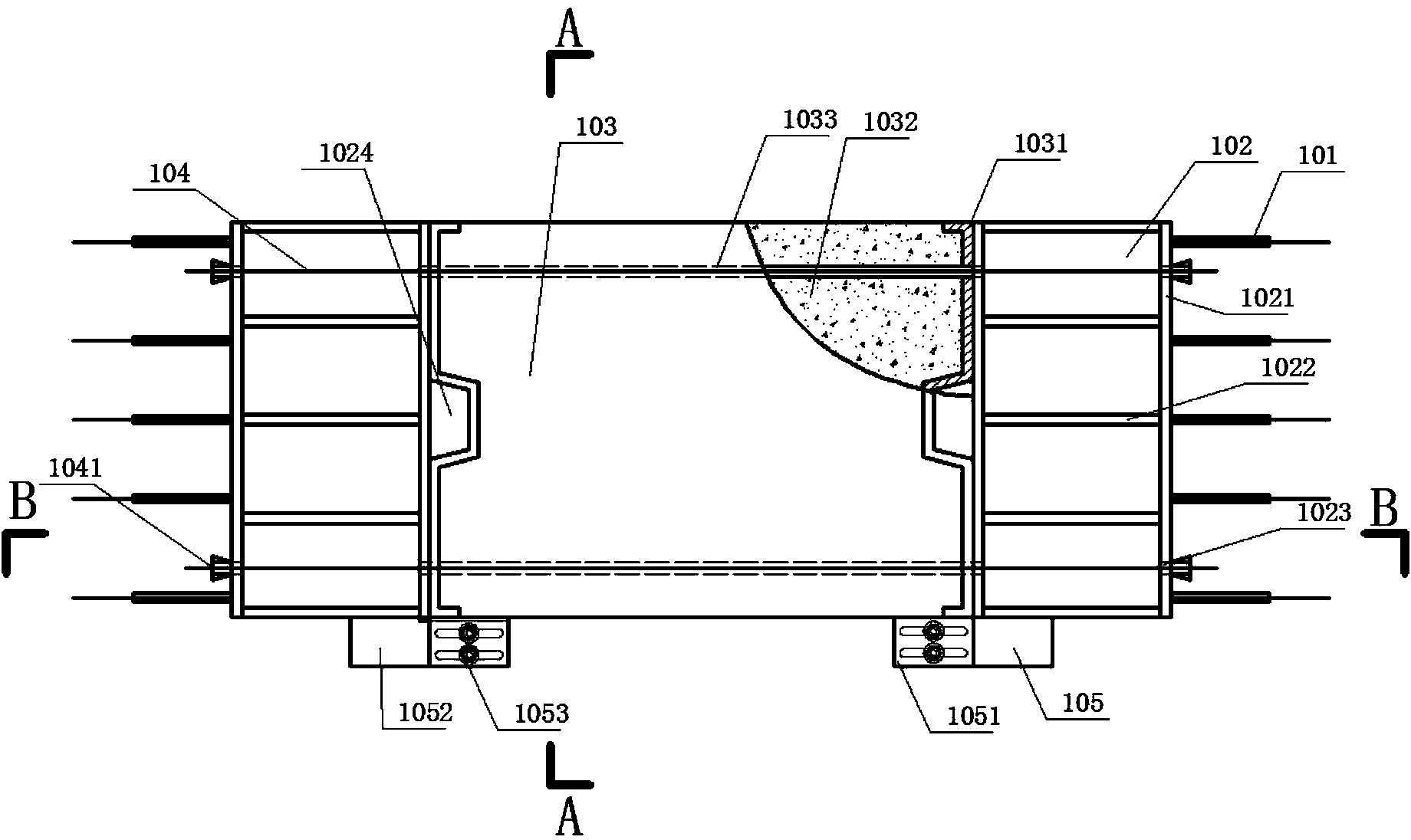

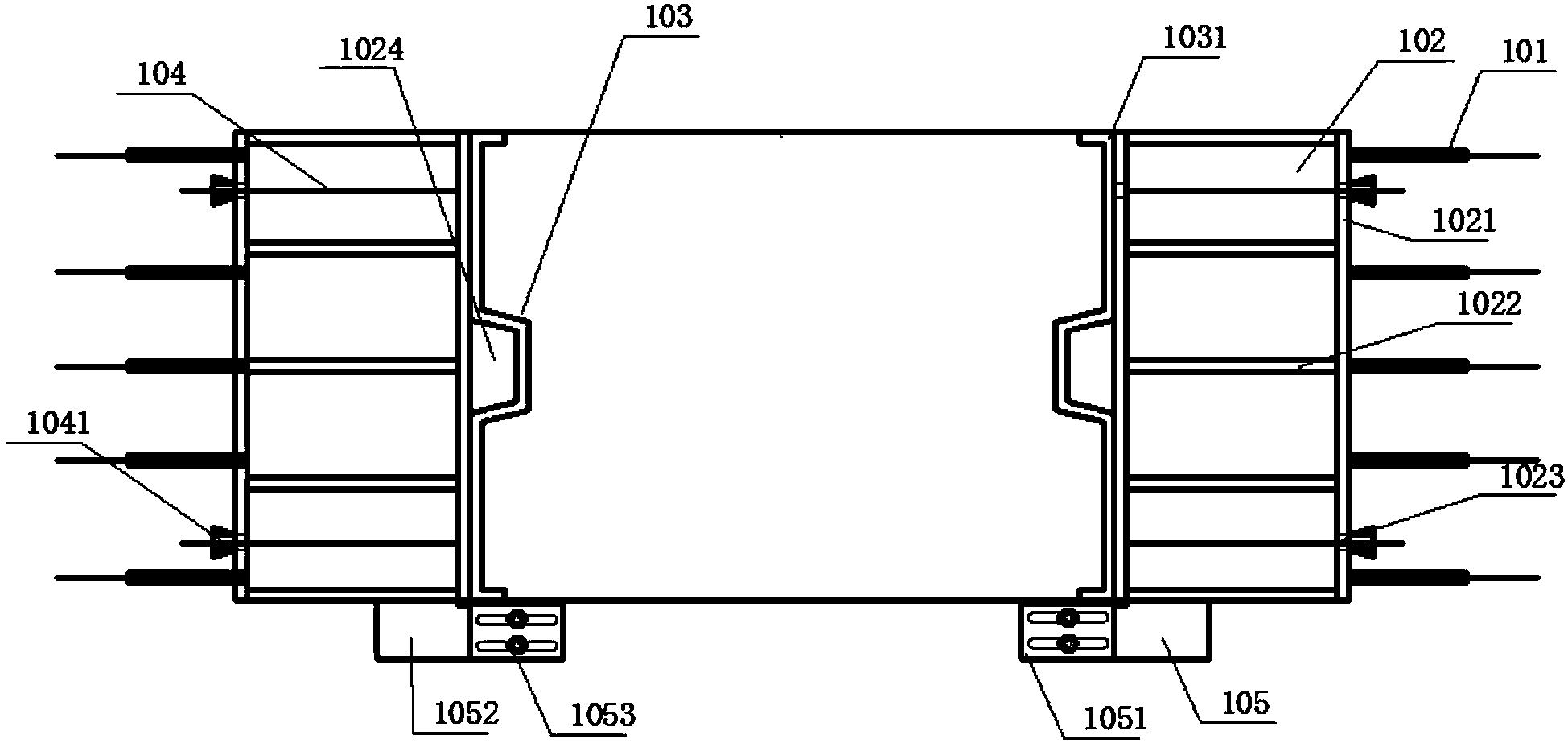

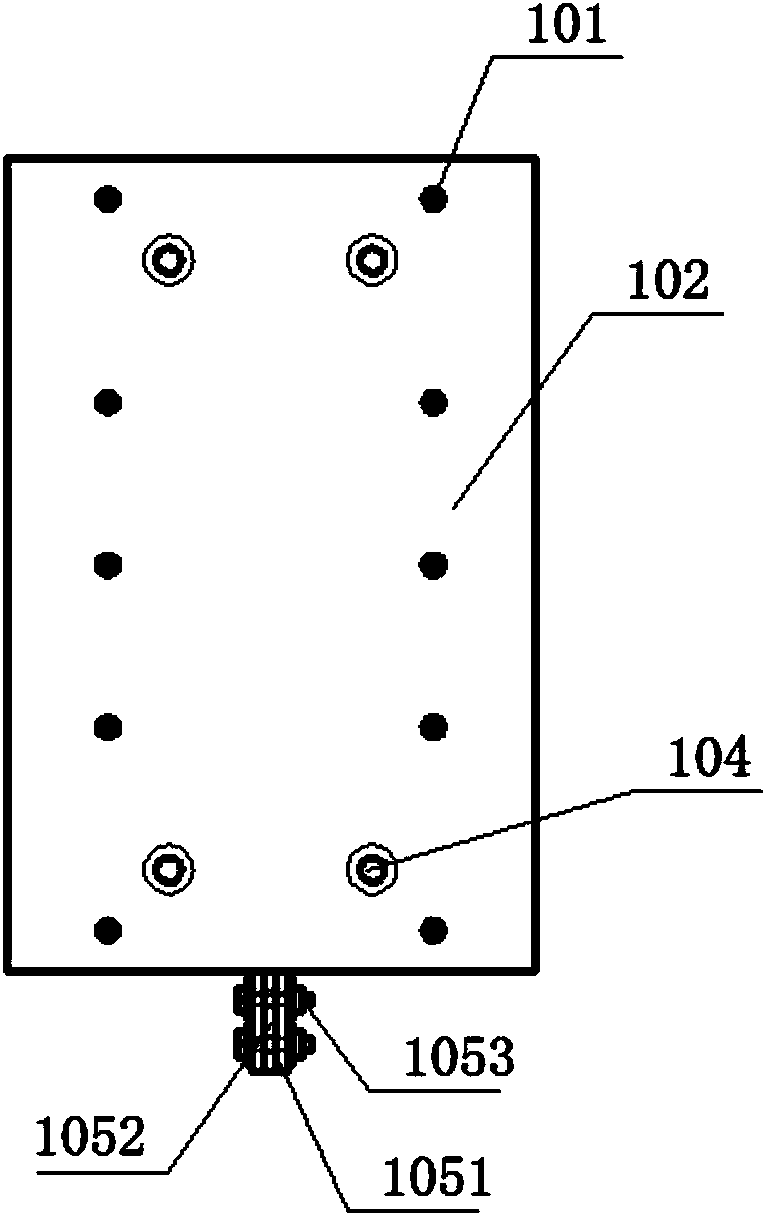

InactiveUS8149577B2Lower impedanceLower resistanceSubstation/switching arrangement detailsSemiconductor/solid-state device detailsUltra high voltageThyratron

The present invention relates to a self-cooled thyistor device for ultra-high voltage fault current limiter. a self-cooled thyristor valve, it adopts horizontal structure consisted by frames, frames is divided into upper and below two spaces by crossbeams, the bottom of frames is supported by insulators. There is a cross plate between two vertical said frames, the cross plate mounts resistors connect with a high potential plate and capacitor through two wires. There is a thyistor string in said frame upper space, which is constituted of thyistors and cooler series. The thyistor string is compressed tightly by press-fit mechanism, thyistor string crosses current transformers. There are high potential plates on both sides of the thyistor, the number of the potential plates is equal to that of thyistor. One side of the high potential plates links frames, said current transformers connects with high potential plates. There are capacitors and resistors connected with the bottom plate of said frames in the below space. The small and well-structured invention meets the requirement of the energy on continuous trigger condition, improves the global reliability of thyristor valve.

Owner:CHINA ELECTRIC POWER RES INST

Novel self-reset friction damper

ActiveCN104032848AOvercome existing shortcomingsAvoid disadvantagesShock proofingPull forceReinforced concrete

The invention discloses a novel self-reset friction damper, and belongs to the technical field of energy dissipation and shock absorption of civil engineering structures. The structure of the damper is that the two sides of an outer covering steel plate concrete connecting section are respectively provided with a profile steel connecting section; anchoring steel bars are welded to the outer sides of the profile steel connecting sections, and are poured in a reinforced concrete main structure simultaneously; the bottom ends of the outer covering steel plate concrete connecting sections and the bottom ends of the profile steel connecting sections are connected through friction energy dissipation plates; the outer covering steel plate concrete connecting sections are connected with the profile steel connecting section on one side or the profile steel connecting sections on the two sides through a plurality of prestressed cables. When the main structure deforms under seismic excitation, the prestressed cables anchored on the outer sides of profile steel are extended, and self-reset tension force is provided; meanwhile, the friction energy dissipation plates connected between the profile steel and the concrete connecting sections deform relatively, seismic energy is dissipated, and energy dissipation and shock absorption are achieved.

Owner:TSINGHUA UNIV

Macro-algae breeding floating frame for adsorbing arsenic in seawater

ActiveCN107535348AAchieve protectionConducive to stable growth and reproductionClimate change adaptationCultivating equipmentsEngineeringHigh pressure

The present invention discloses a macro-algae breeding floating frame for adsorbing arsenic in seawater, which comprises a floating frame, a floating ball connected with the floating frame, a connecting standpipe with two closed ends, a piston rod, and a floating airbag. A buoyancy adjusting cavity is arranged in the floating frame. A unidirectional drain pipe is arranged on the bottom surface ofthe floating frame. The connecting standpipe passes through the floating frame, and both ends of the connecting standpipe protrude out of the floating frame. Water inlet holes are formed in the outerside wall of the connecting standpipe, below the floating frame; air inlet holes are formed in the outer side wall of the connecting standpipe, inside the floating frame; a high pressure gas pipe is connected with the outer side wall of the connecting standpipe, above the floating frame; the top end of the connecting standpipe is provided with an air outlet check valve. A first piston is arrangedin the connecting standpipe. One end of a piston rod is fixedly connected with the first piston, and the other end of the piston rod is fixedly connected with the floating airbag. The piston rod is sleeved with a first spring, between the first piston and the upper wall of the connecting standpipe. The macro-algae breeding floating frame for adsorbing arsenic in seawater has ingenious structure, can adjust ups and downs, has strong anti-wind-wave ability and great practical value, and is conducive to the stable growth and reproduction of macro-algae.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

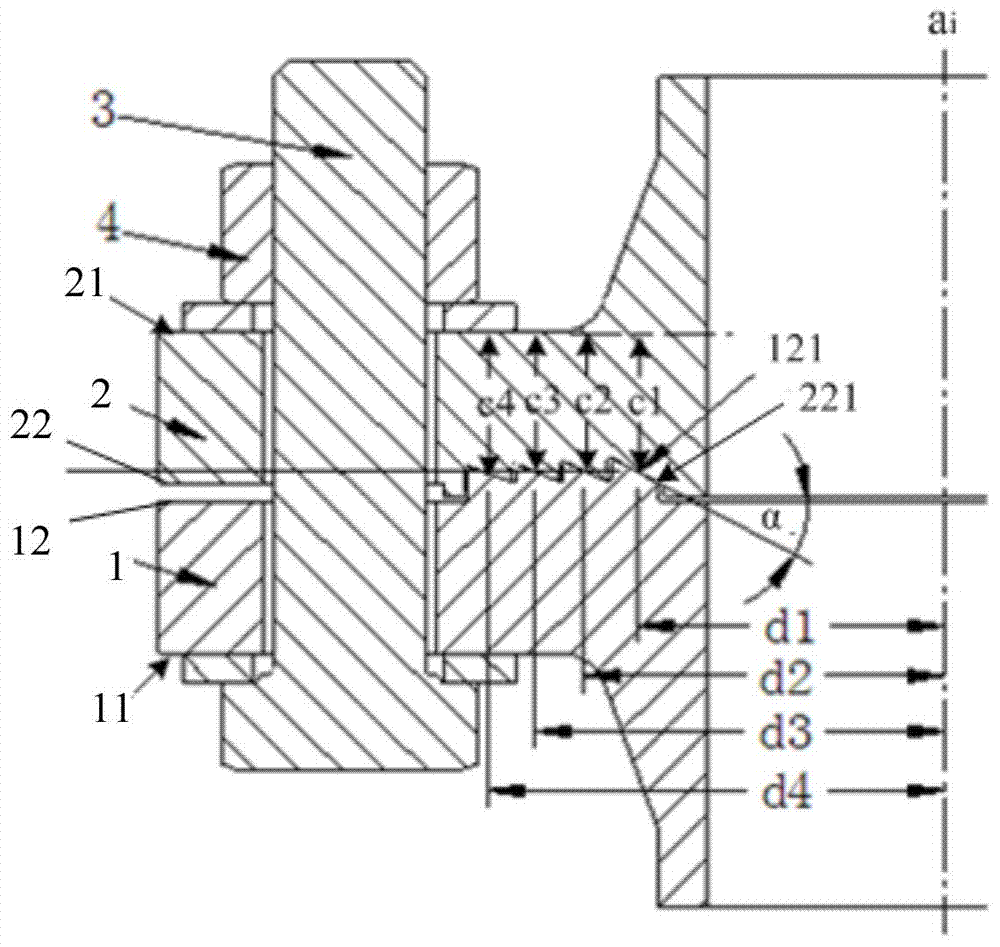

Flanged connection component

The invention provides a flanged connection component which comprises a first annular flange plate, a second annular flange plate. The first flange plate and the second flange plate are connected through a fastening piece, are aligned relative to a central shaft, and are respectively provided with base planes which are far from each other and butt joint faces which are matched with each other. Each butt joint face comprises at least one oblique plane, and a certain angle is formed between the oblique planes and the base planes. The two flange plates can shift in the axial direction in a driven mode, so that the too small or too large pressing force due to the fact that bolts extend due to thermal expansion and difference of thickness expansion amounts of the flange plates is compensated, the purpose of effective sealing is achieved, moreover, pre-tightening force borne by the bolts can be reduced on the premise of not increasing the number of the bolts, and reliability and economy of the flanged connection component are improved.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

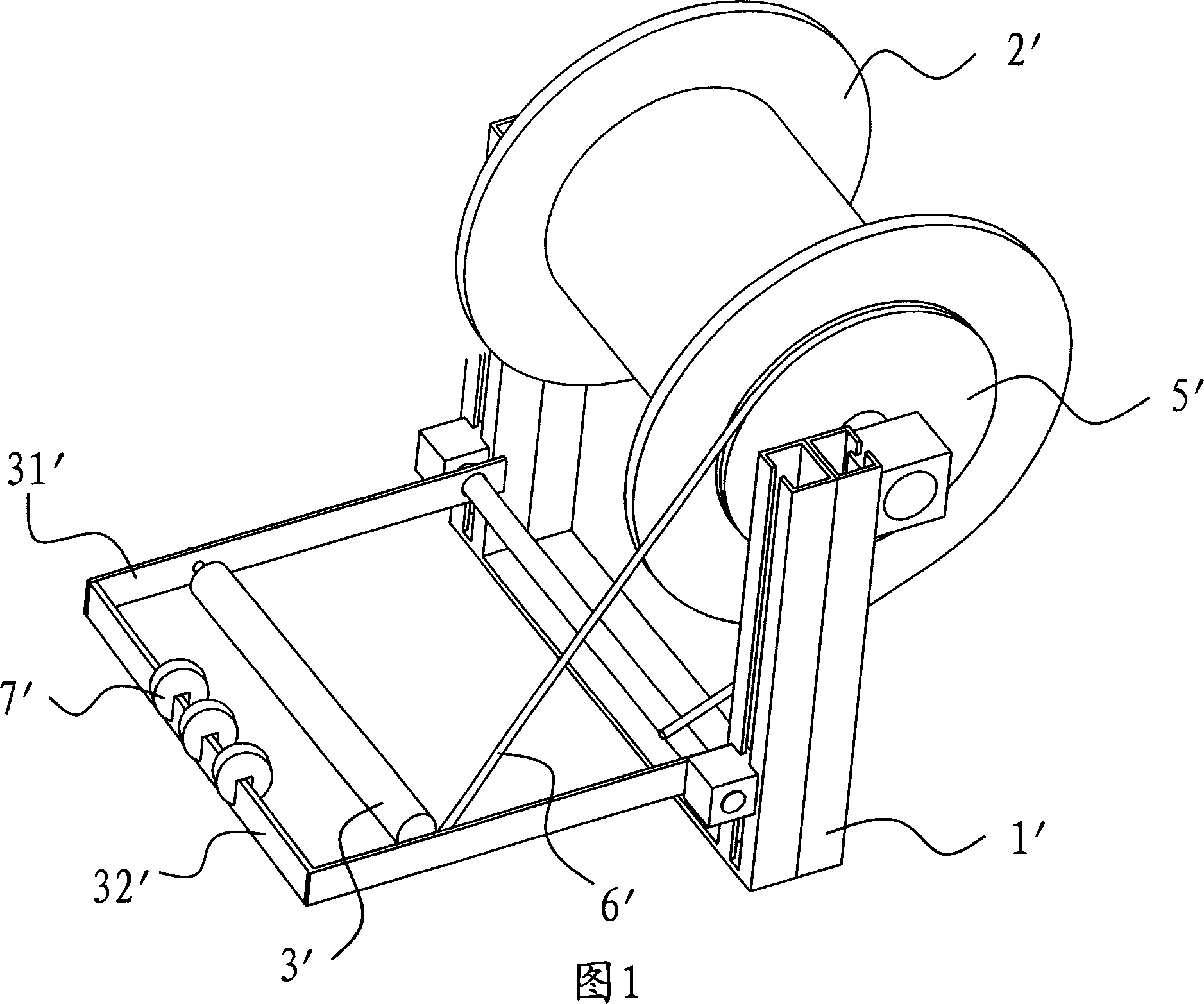

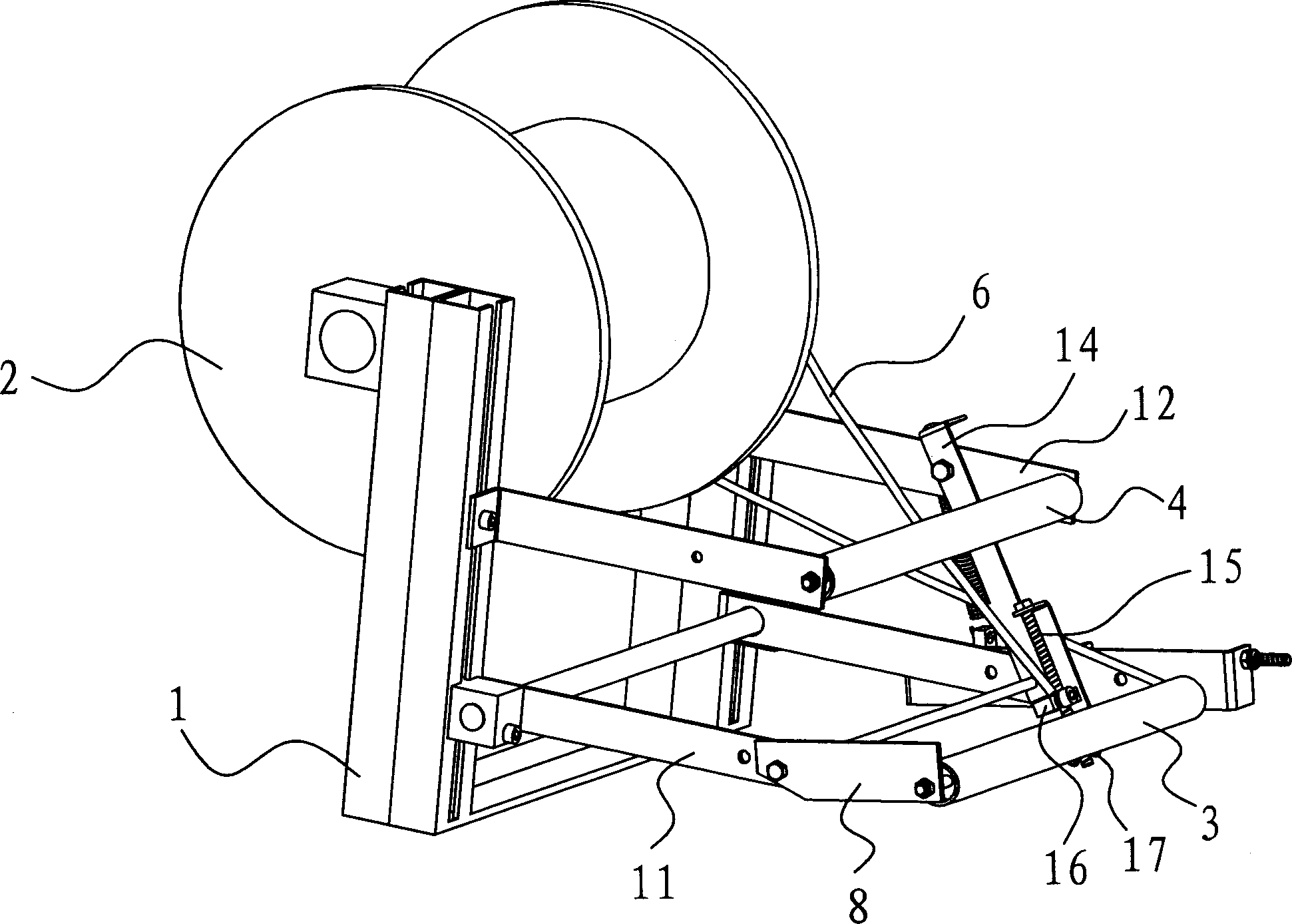

Tension control equipment

InactiveCN1916256AReduce brake resistanceUniform tension distributionAuxillary apparatusEngineeringControl theory

The present invention provides a tension control device capable of ensuring that the tensile force is nearby constant value. Said tension control device includes the following several portions: machine frame and warp beam flange, vibrating roller, fixed roller, brake wheel, brake-and-clutch lining, spring, two swinging arms and rotary arm which are placed on the machine frame and tension regulation device. Besides, said invention also provides the working principle of said tension control device and its concrete operation method.

Owner:福建百宏聚纤科技实业有限公司

Control valve for oil atomizer

ActiveCN104265532AOpen quicklyQuick closeFuel injection apparatusMachines/enginesEngineeringControl room

The invention relates to a control valve for an oil atomizer. The control valve comprises electromagnets, a sealing bolt pin, electromagnet springs, an armature, an armature guide rod, control valve bases, a restriction orifice and an oil atomizer body. The control valve is characterized in that the sealing bolt pin is arranged in inner holes of the control valve bases; a high-pressure sealing face is formed by the outer circle surface of the sealing bolt pin and the inner holes of the control valve bases; a valve chamber is defined by the sealing bolt pin, the control valve base and the restriction orifice and is communicated with a control chamber through an oil outlet path; the sealing bolt pin is in rigid connection with the armature guide rod and is pressed on a supporting face at the upper end of the restriction orifice under downward elastic force of the electromagnet springs; a closed portion is arranged on the lower end face of the sealing bolt pin; a high-pressure sealing face is formed by the supporting face of the lower end of the closed portion and the supporting face of the upper end of the restriction orifice; a blind hole is formed in the center of the restriction orifice; an oil returning cavity is formed between the blind hole and the lower end face of the sealing bolt pin and is communicated with an oil returning channel. The control valve can be closed only through small spring pre-tightening force.

Owner:CHINA FAW LIMITED WUXI FUEL INJECTIONEQUIP RES INST +1

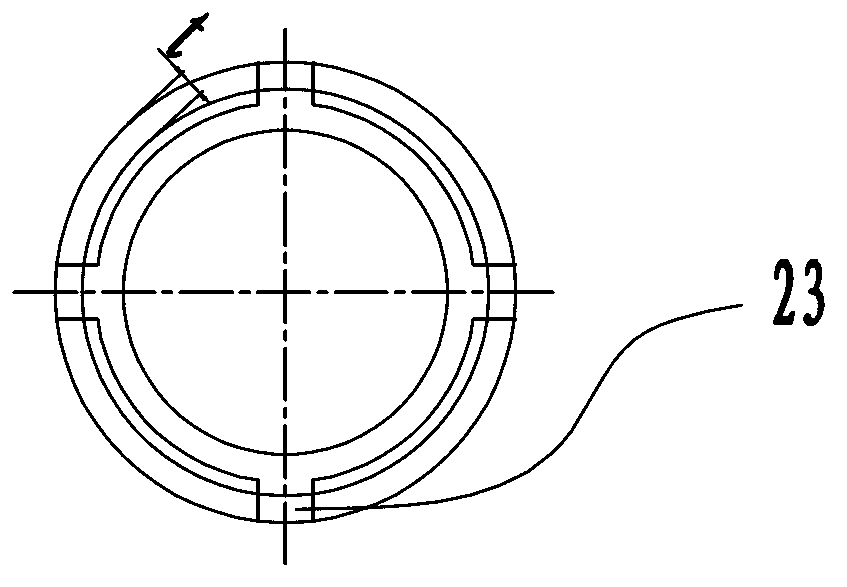

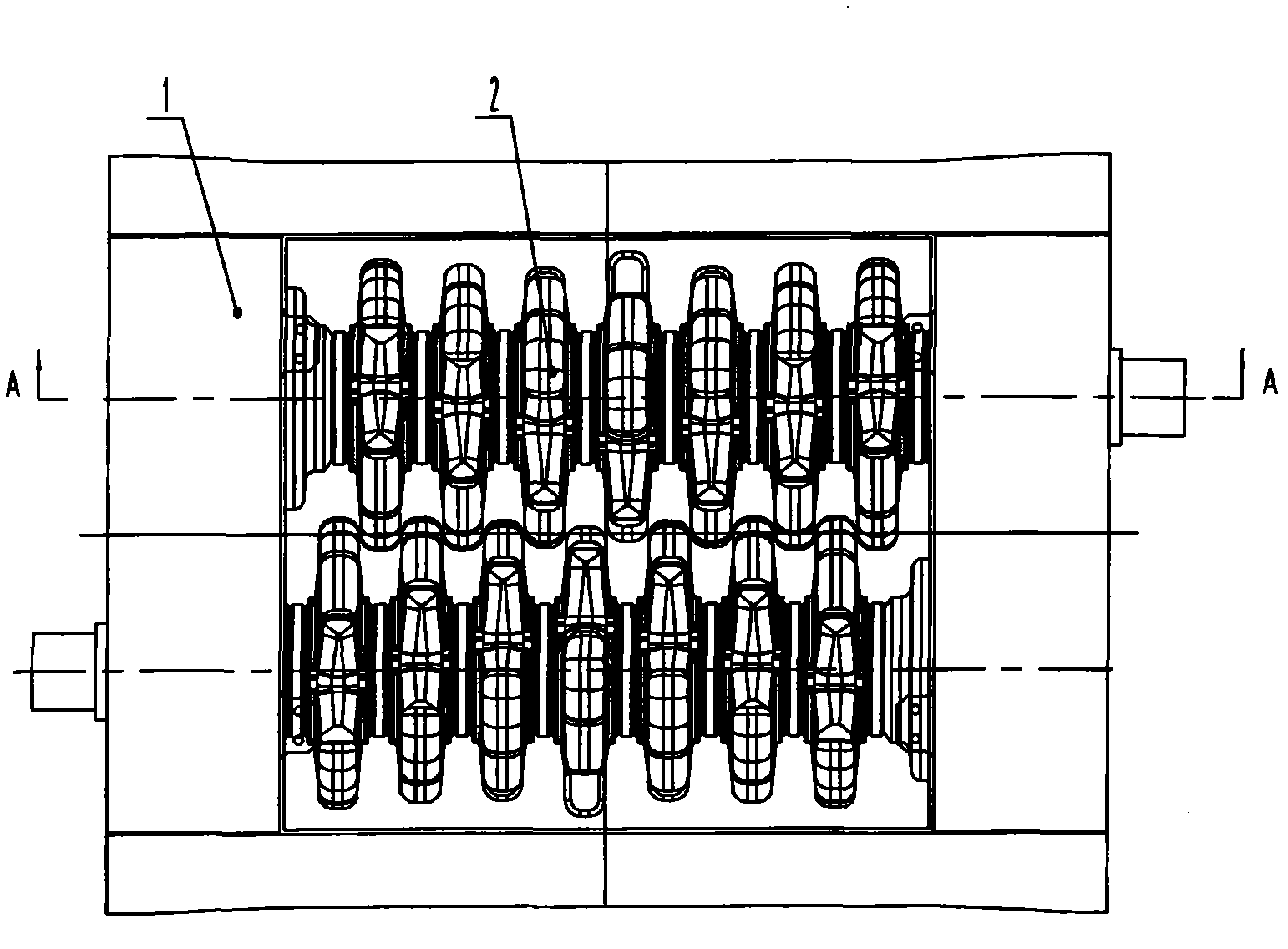

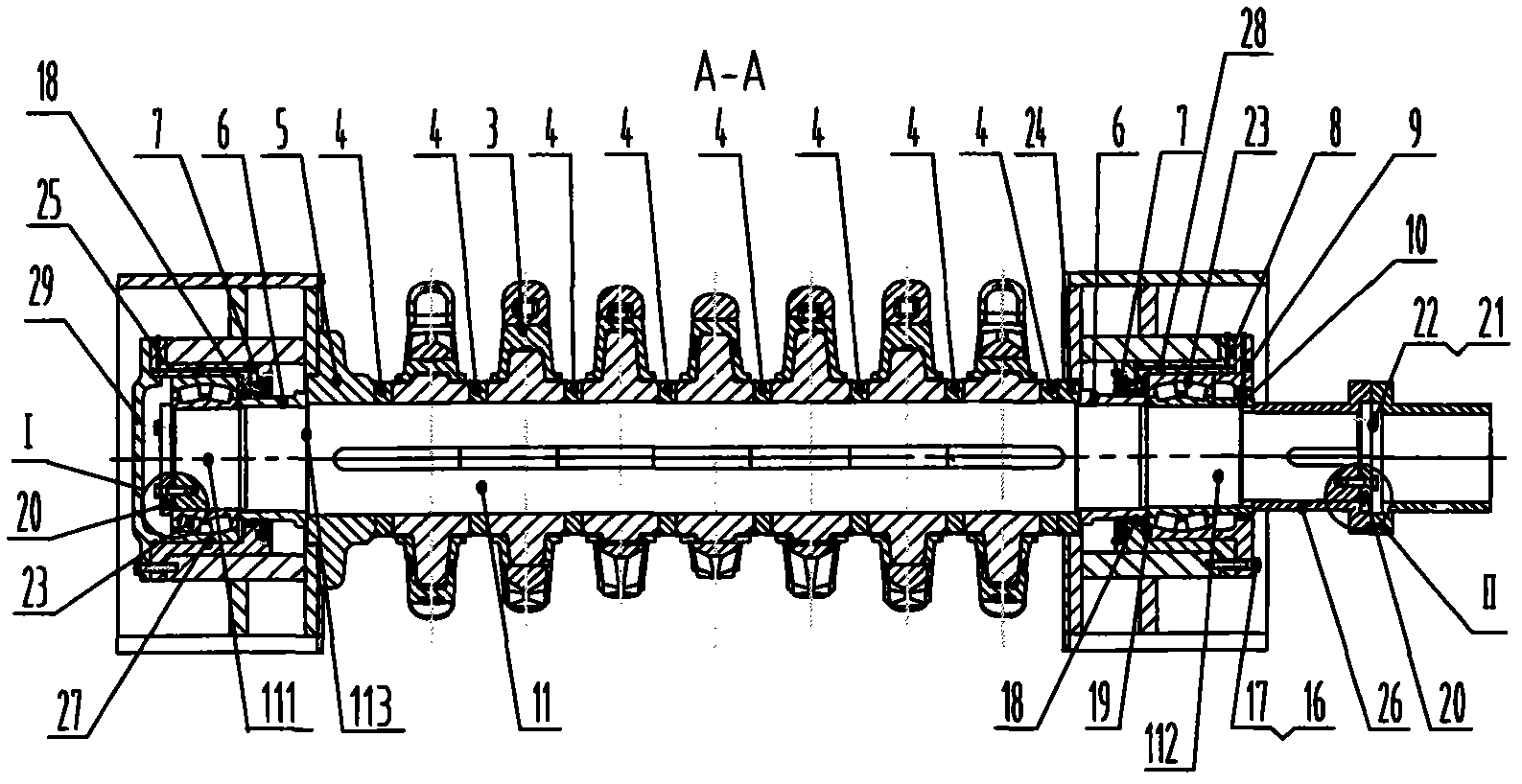

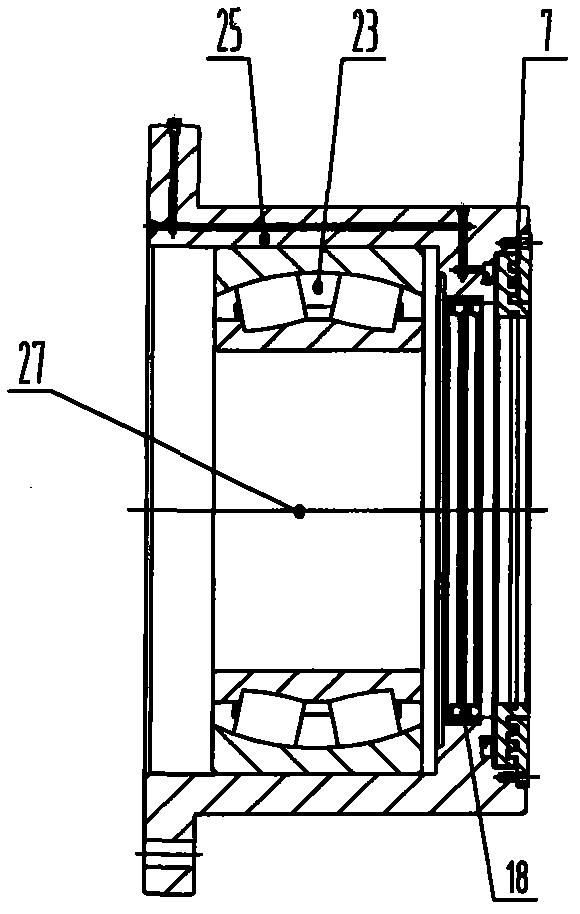

Axial positioning device of crushing roller

The invention provides an axial positioning device of a crushing roller, which relates to a crushing machine and solves the problems that in the prior art, the installation and the maintenance of the crushing roller are difficult, and the equipment operation reliability is poor. The axial positioning device comprises high-strength locking screw nuts, a plurality of high-strength round head propping and pushing screws and two high-strength propping and pushing gaskets, wherein the circumferential rings of the two end surfaces of the high-strength locking screw nuts are provided with a plurality of threaded holes, the two locking screw nuts are respectively matched and connected with external screw threads of the fixing end and the floating end of a roller shaft, one propping and pushing gasket is arranged between the locking screw nuts and a bearing arranged at the floating end, the other propping and pushing gasket is arranged between the locking screw nuts and a No. IV isolation ring, and the round head propping and pushing screws are connected with the threaded holes arranged on the end surfaces of the locking screw nuts. The axial positioning device is used for the axial positioning of the crushing roller of a double-tooth roller crushing machine, the service life of parts can be prolonged, in addition, the installation and the maintenance can be conveniently and fast carried out, and the production efficiency of equipment is greatly improved.

Owner:TAIYUAN HEAVY IND

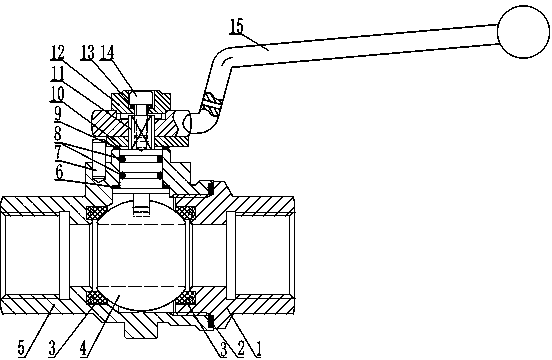

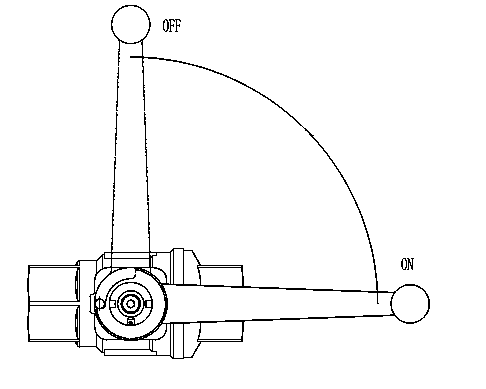

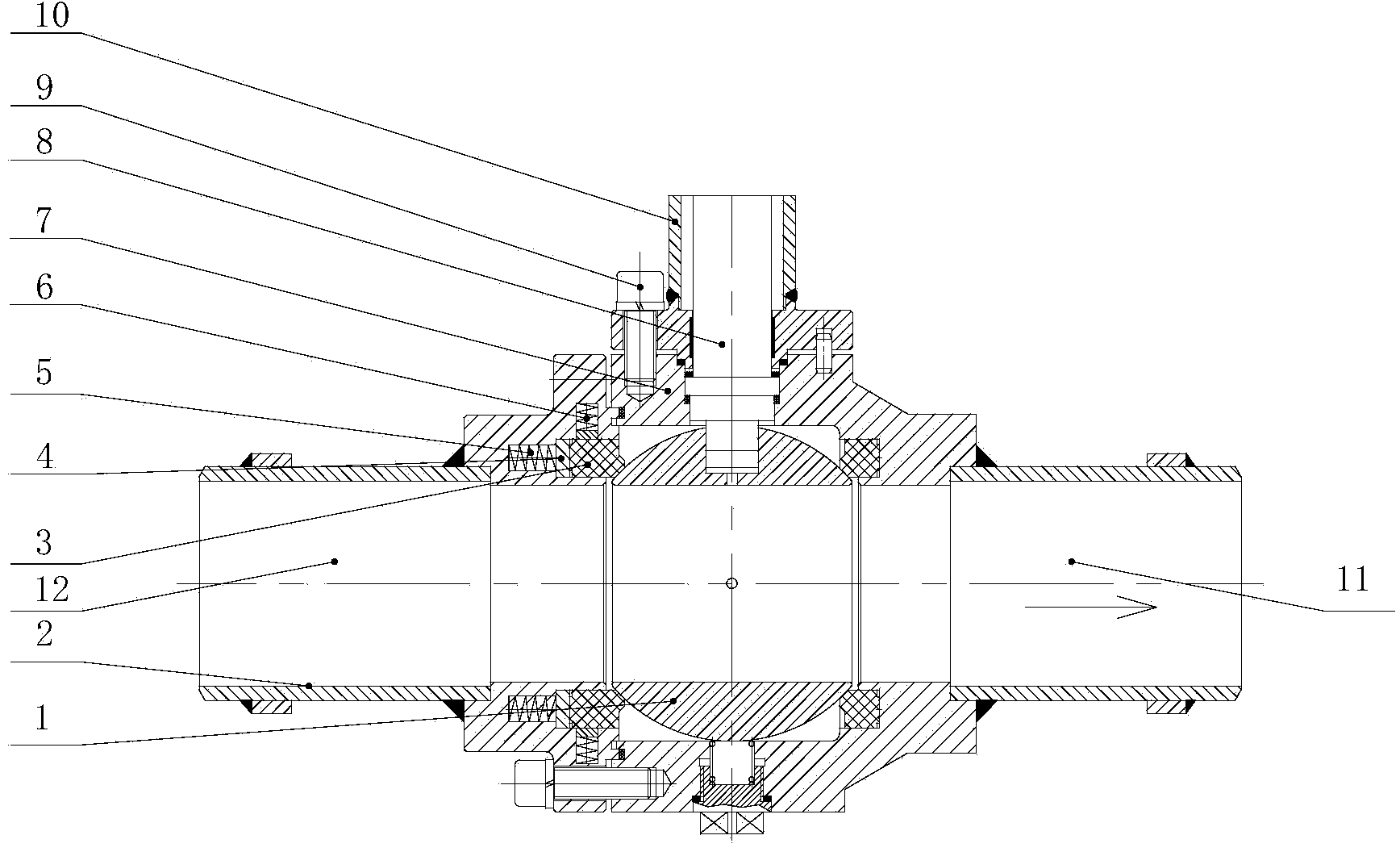

Cutout cock for rail car

A cutout cock for a rail car comprises a ball core for opening and cutting off an air supply pipeline. Special rubber composite type ball sealing gaskets are arranged on the two sides of the ball core. After a cock body is in butt joint with a connector, the ball core is located in the cock body. The cock body and the connector are sealed by a connector sealing gasket. A valve rod is installed on the upper portion of the ball core. The valve rod and the cock body are rotationally sealed by double O-shaped rings. A lower valve rod flat gasket is arranged on the contact surface of the valve rod and the end face of the cock body and used for reducing the friction of the contact surface of the valve rod and the end face of the cock body. An upper valve rod flat gasket is cushioned on the upper end face of the cock body, and then a check ring is installed. The upper valve rod flat gasket is used for reducing the friction of the valve rod and the upper end face of the cock body. A handle and a compressing cap are installed on the upper portion of the check ring and then the handle is fixed to the valve rod. The cutout cock can be normally used at the environmental temperature of -50 DEG C, compared with an existing applied cutout cock, the cutout cock is wider in application environmental temperature range and more reliable in sealing performance, the pretightening force of the ball sealing gaskets is much smaller than the pretightening force of a teflo sealing base, spanning torque of the handle is accordingly reduced, and the cutout cock is easy to operate.

Owner:ZHEJIANG JINZI MACHINERY&ELECTRICAL

Cooling device of plastic thin film processing device

The invention provides a cooling device of a plastic thin film processing device and belongs to the technical field of machinery. The cooling device solves the problem of complex operation of a cooling roller in a thin film processing line. The cooling device includes two pedestals and a roller arranged therebetween. One end of the roller is sealed while the other one end is opened. A rotational portion is arranged on the sealed end and is axially fixed to the corresponding pedestal. A liquid inlet pipe is installed in the opened end and comprises a liquid inlet portion, which is axially arranged along the roller, and a liquid outlet portion, which is arranged in the radial direction of the roller. The outer end of the liquid inlet portion is stretched out from the opened end and is fixed to the corresponding pedestal. A ring-shaped connection portion is arranged on the edge of the inner end of the liquid inlet portion. A sealing ring is arranged between the connection portion and the roller. A refrigerating chamber is formed between the connection portion and the inner wall of the roller. The liquid inlet portion is communicated with a refrigerating system. The refrigerating system works so that a refrigerant cyclically flows in the refrigerating chamber. The cooling device is convenient to operate.

Owner:TIANJIN KAKA TECH CO LTD

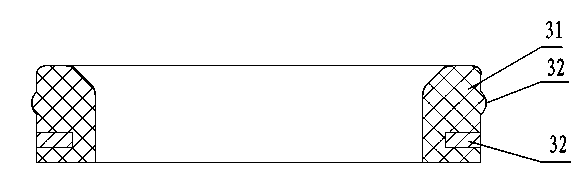

Shield tunnel line segment lining structural stiffness gear-drive reinforcing device

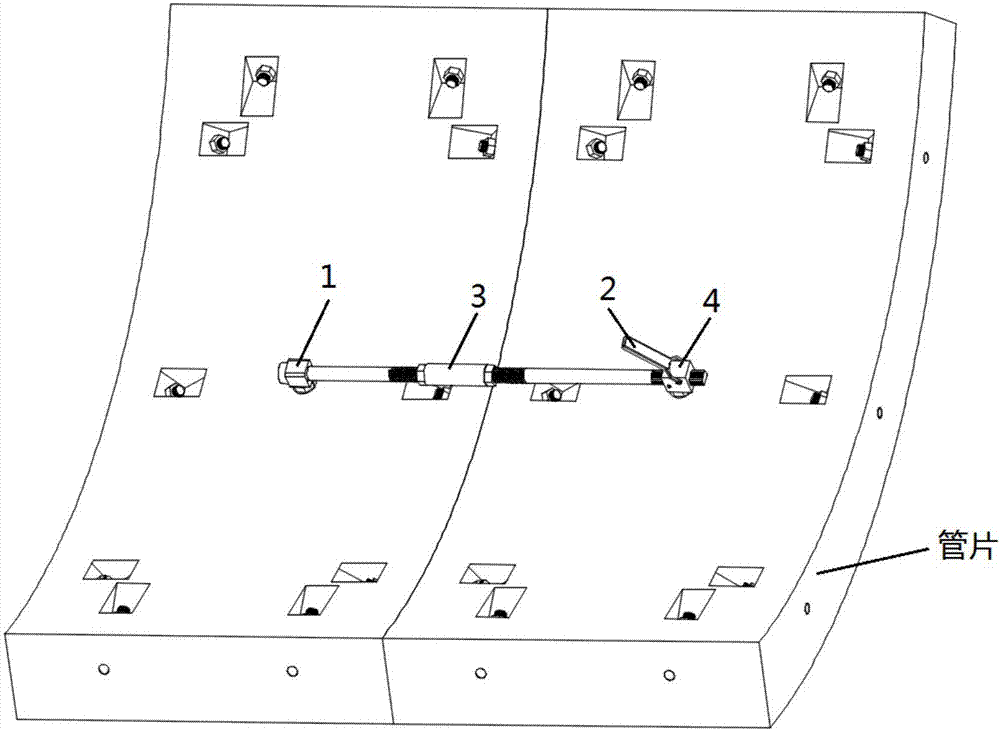

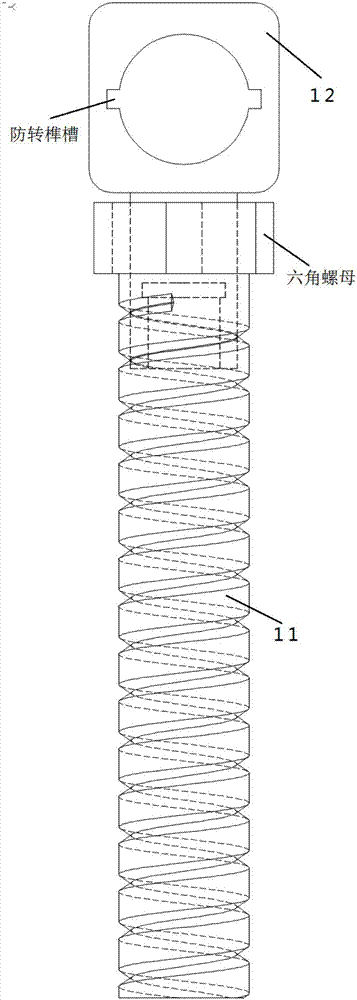

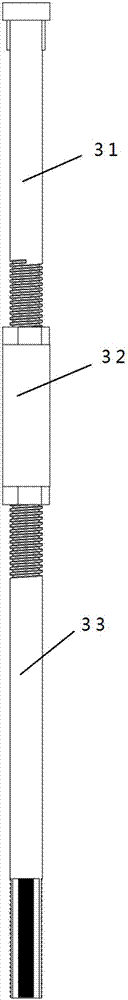

PendingCN107143350AIncrease joint stiffnessPrevent reboundUnderground chambersTunnel liningWrenchEngineering

The invention relates to a shield tunnel line segment lining structural stiffness gear-drive reinforcing device, comprising a fixed end (1), a loading end (4), a reinforcing tie rod (3) and a releasable loading lever (2), wherein the fixed end (1) and the loading end (4) are fixedly connected to adjacent pipe rings respectively; the fixed end (1) is connected with the loading end (4) through the reinforcing tie rod (3). The reinforcing tie rod (3) comprises a fixed end reinforcing tie rod (31), a loading end reinforcing tie rod (33) and a release sleeve (32), and two threads matching respectively with external threads of the fixed end reinforcing tie rod (31) and loading end reinforcing tie rod (33) are arranged in the release sleeve (32); one end of the loading end reinforcing tie rod (33) is provided with an external thread matching with an internal thread of the release sleeve (32), and the other end of the loading end reinforcing tie rod (33) is a loading rack and barbed racks on its two sides.

Owner:TIANJIN UNIV

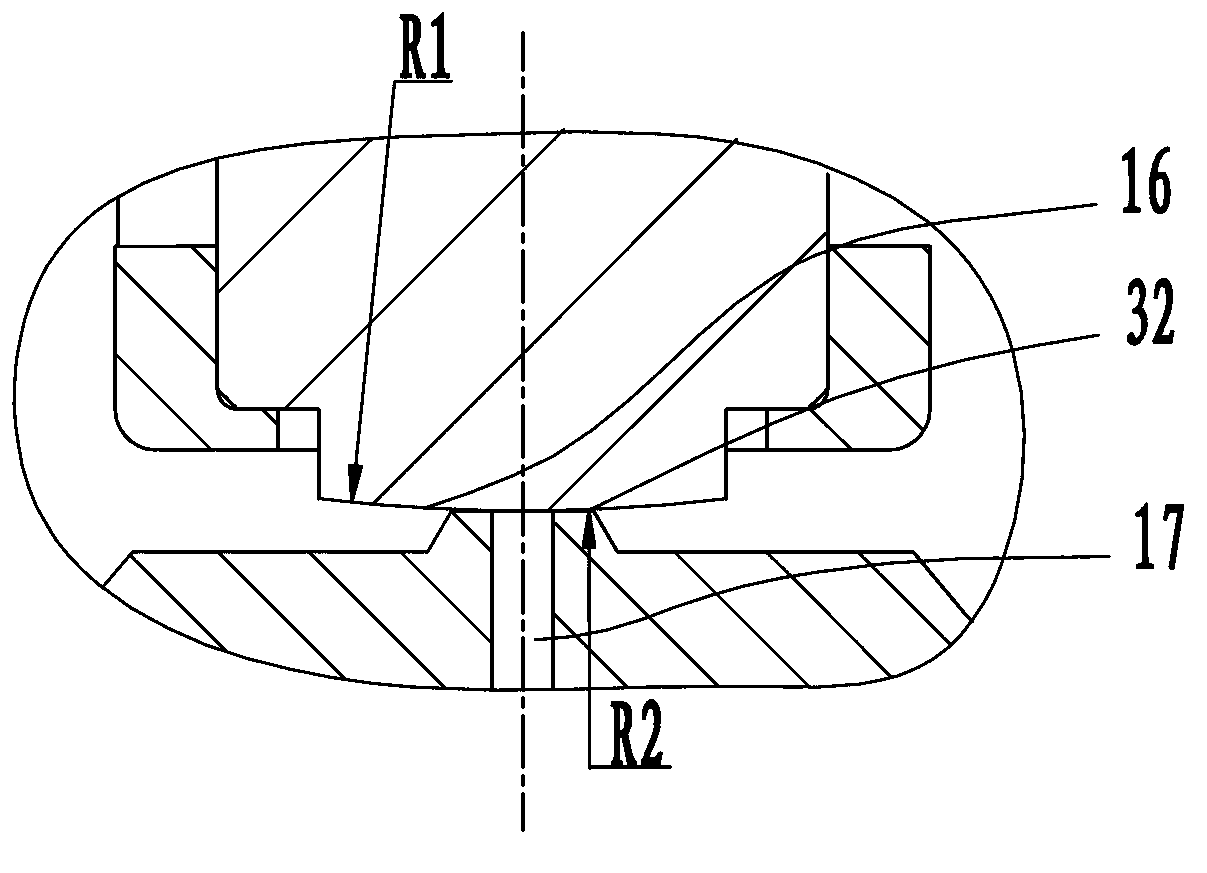

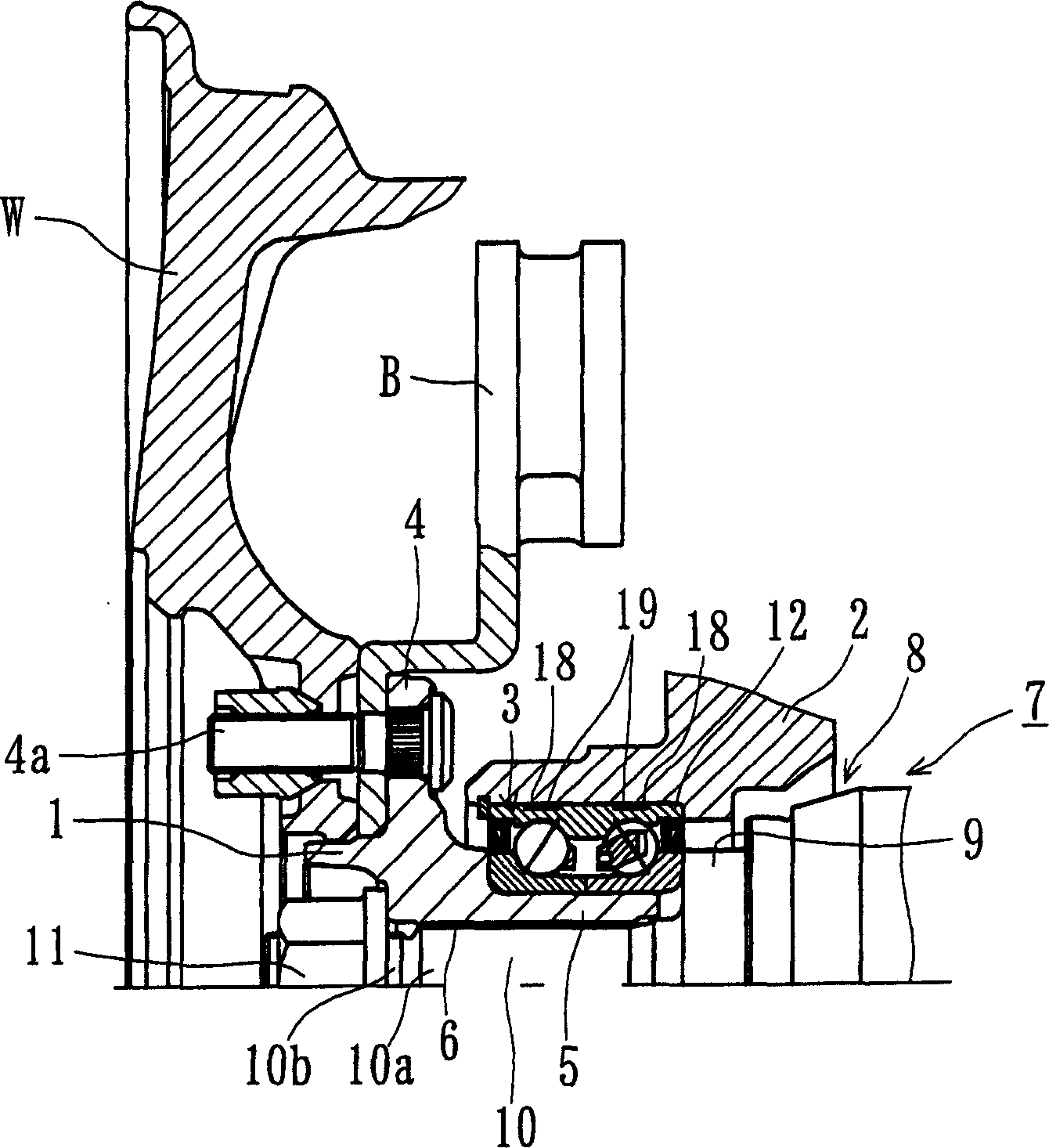

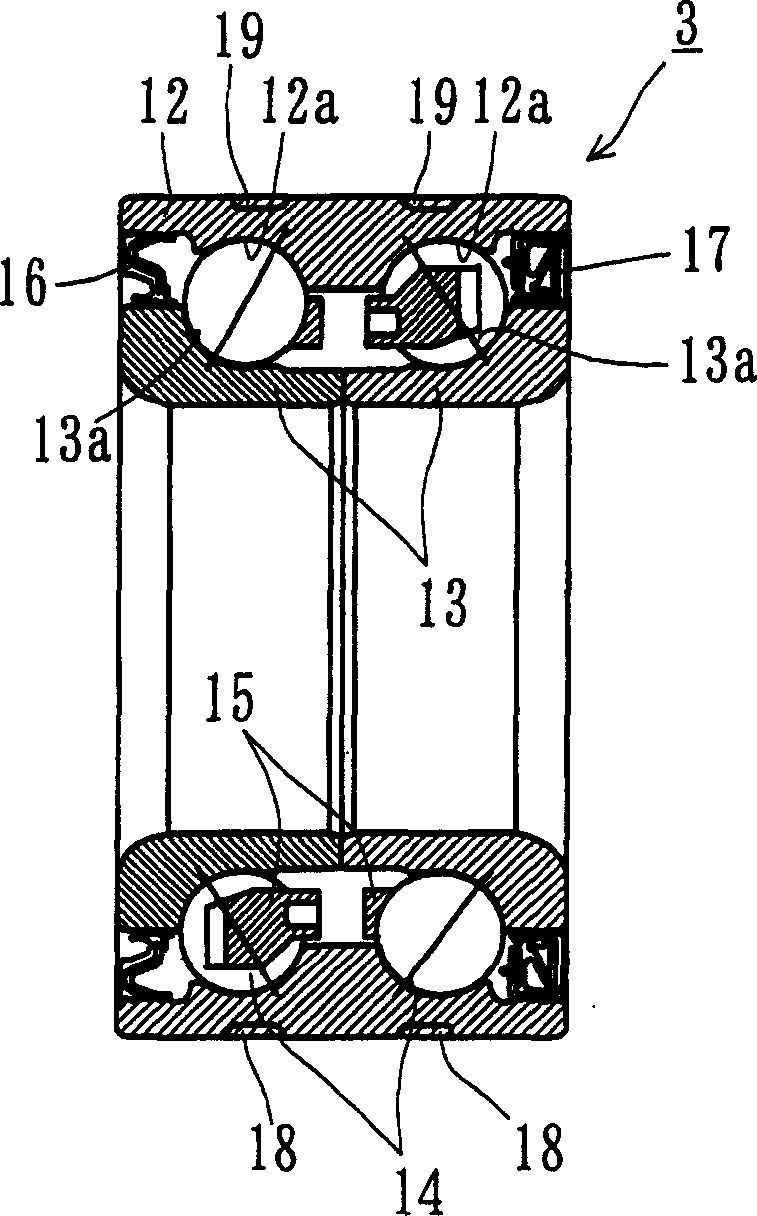

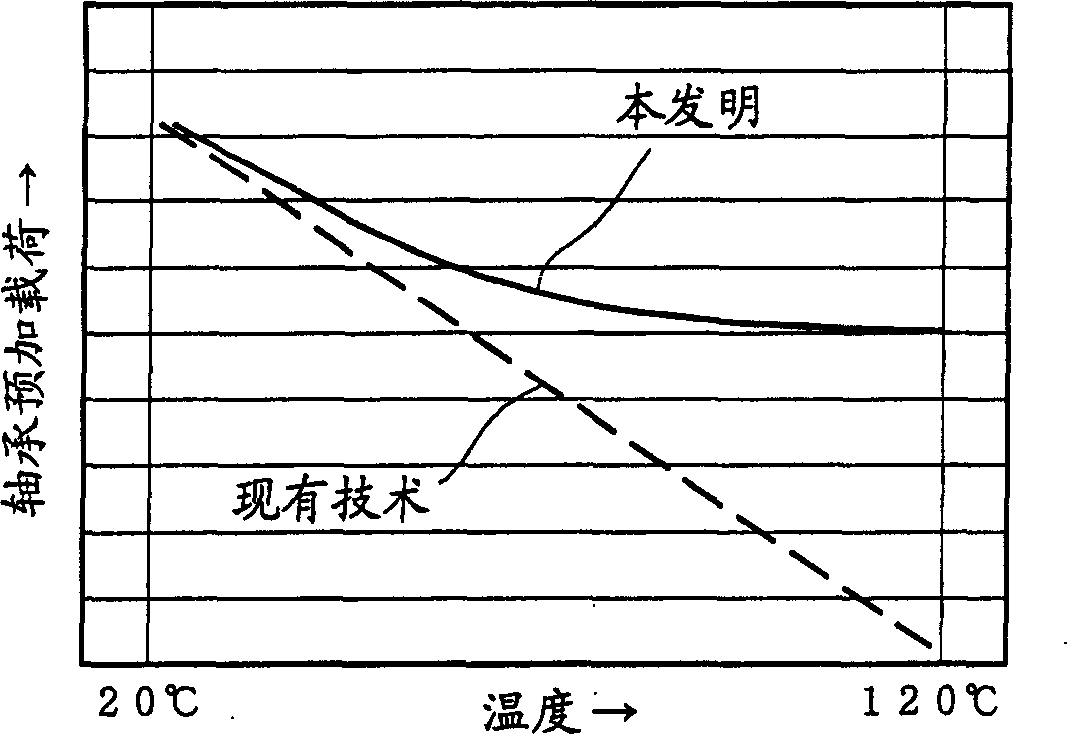

Bearing device for wheel

InactiveCN1886600AReduction of suppressed fit interferencePrevent creepRolling contact bearingsBearing componentsDouble rowKnuckle

To provide a bearing device for a wheel installed on a light-weight light alloy knuckle and capable of preventing preload reduction and bearing creep from occurring due to temperature rise. This bearing device for the wheel comprises a hub wheel (1) integrally having a wheel mounting flange (4) at one end and having a small diameter step part (5) axially extending from the wheel mounting flange (4) formed therein, a wheel bearing (3) formed of a double row bearing disposed in the small diameter step part (5), and the knuckle (2) forming a suspension device and formed of a light alloy. The wheel bearing (3) is press-fitted into the knuckle (2) at a specified interference, and the hub wheel (1) is rotatably pivoted on the knuckle (2). A pair of annular grooves (18) are formed in a loading area on the outer periphery of the outer ring (12) of the wheel bearing (3), and resin bands (19) formed of a heat resistant polyamide synthetic resin and having a coefficient of linear expansion of 8 to 16 x 10<-5> / DEG C are filled in the annular grooves (18) by injection molding.

Owner:NTN CORP

Pit foundation supporting structure for mining

The invention discloses a pit foundation supporting structure for mining. The pit foundation supporting structure comprises a bolt, an adjusting module and a through hole; the adjusting module is arranged at one end of the upper portion of a base plate, and a supporting plate is arranged at the other end of the upper portion of the base plate; a spring cavity is formed in one end of the interior of the adjusting module, and a lead screw is arranged at the other end of the interior of the adjusting module; a spring clamping plate is arranged at the end, close to the lead screw, of the interiorof the spring cavity; and a spring is arranged on one side of the spring clamping plate, and a torsion head is arranged at the end, away from the spring cavity, of the lead screw. The pit foundation supporting structure has the beneficial effects that the pretightening force of the spring can be determined according to the geological softness degree of a foundation pit, the torsion head is operated to rotate clockwise to pressurize the spring, the pretightening force of the spring is increased, otherwise, the pretightening force of the spring is decreased, the extruding force resulting in deformation of the supporting structure through the foundation pit wall is adjusted, the deformation space is reserved for the supporting structure, the supporting structure is protected, and the situation that the supporting structure is damaged due to the geological reason and excessively-large extruding force to the following supporting plate by the foundation pit wall is avoided.

Owner:成都伍加玖网络科技有限公司

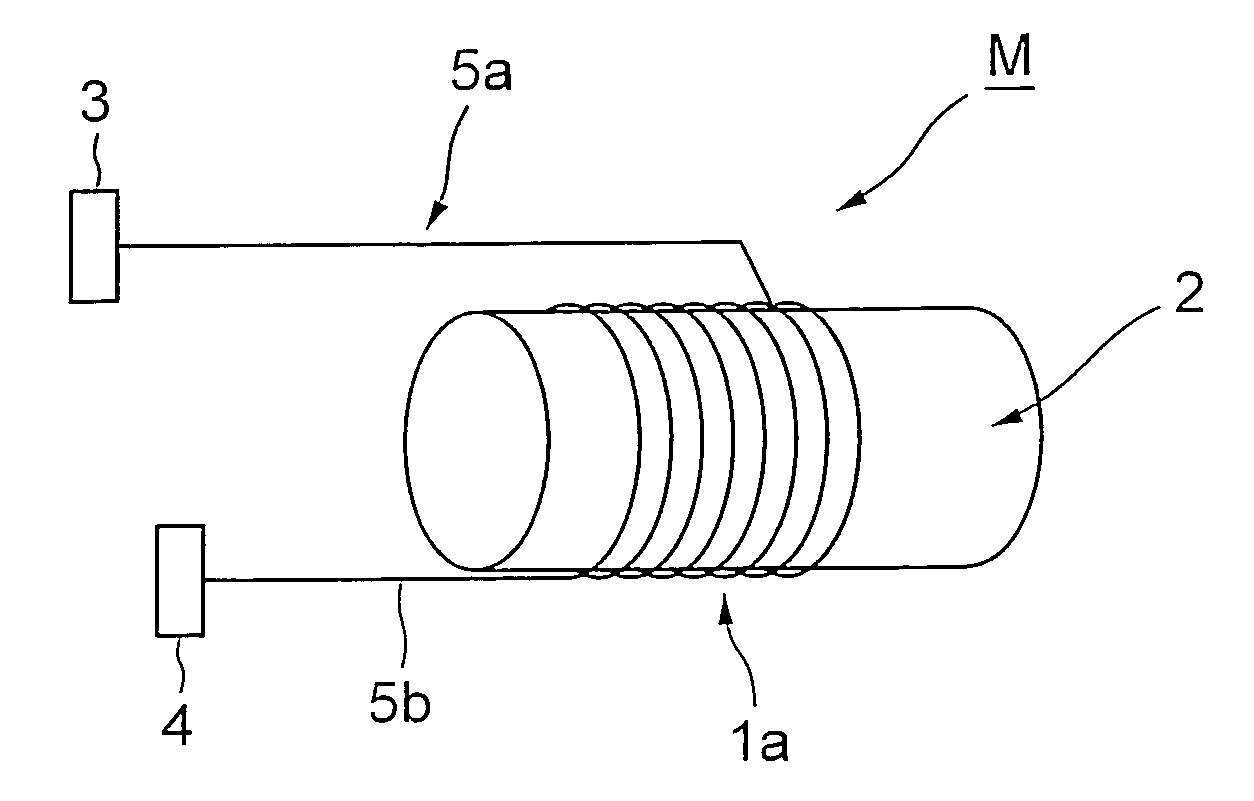

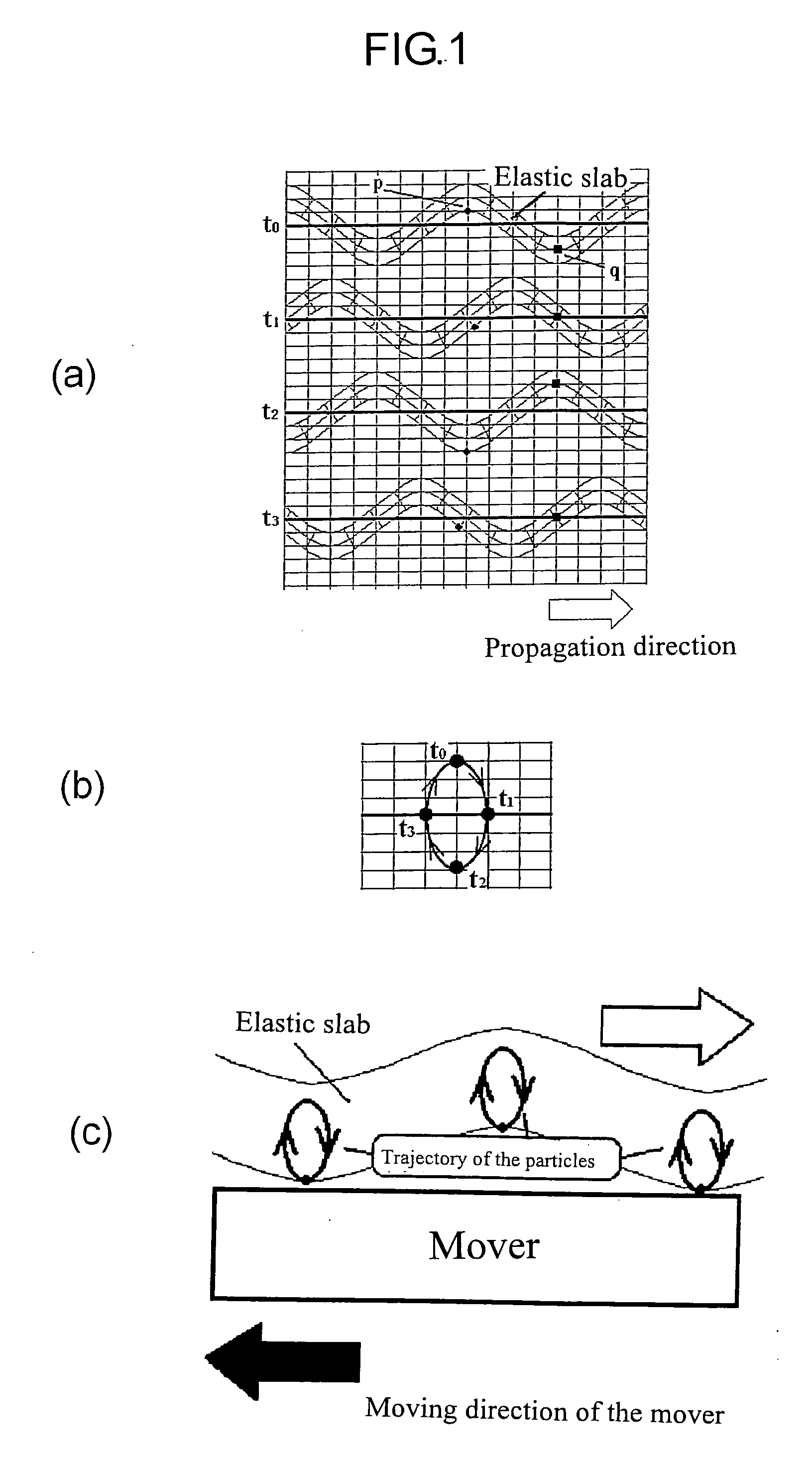

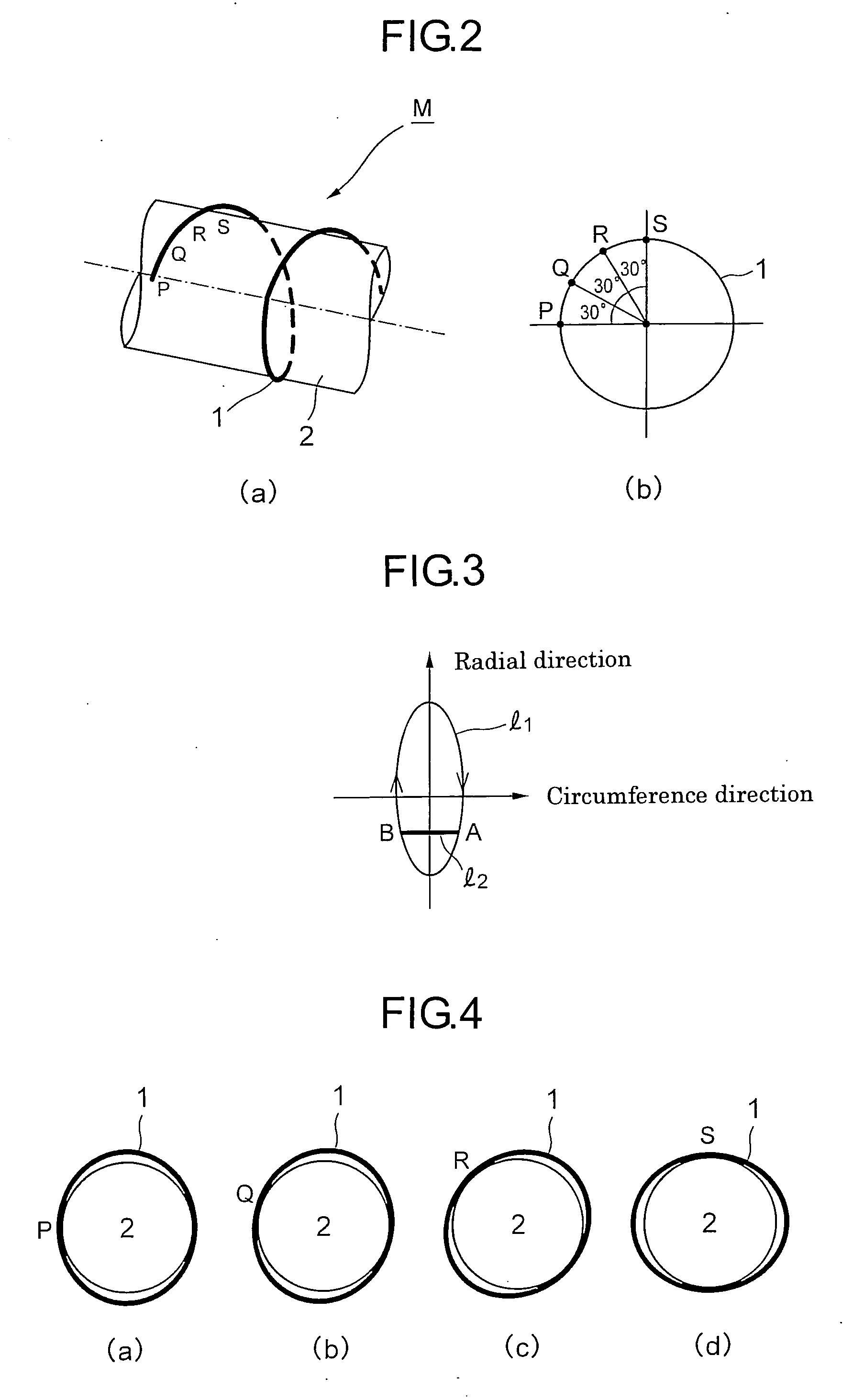

Ultrasonic Motor

InactiveUS20080001500A1Small preloadPiezoelectric/electrostriction/magnetostriction machinesNanotechnologyIn planeHelical coil

The present invention relates to an ultrasonic motor comprising a stator formed by using an acoustic waveguide of helical coil shape or an acoustic waveguide of in-plane spiral coil shape, so that a rotor placed in close proximity to, or in close contact with the coil is rotated, traveled, or performed curved line movement by the propagation of the wave on the stator, thereby eliminating the provision of a preload spring and an absorber, simplifying the structure of the motor, reducing the size of the motor, and enabling to work in a liquid environment without water proofing and rotation of a hollow tube.

Owner:MORIYA TADASHI +1

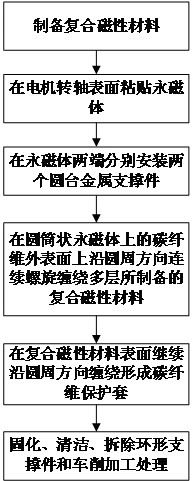

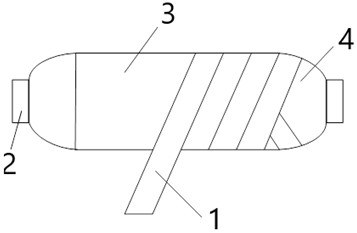

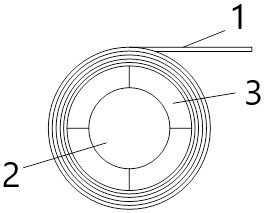

High-speed permanent magnet synchronous motor composite rotor spiral winding preparation method

ActiveCN111835161AReduce concentrated stressWinding is effectiveManufacturing stator/rotor bodiesCoils manufactureAutomotive engineeringMagnetic powder

The invention belongs to the field of motor rotor manufacturing, and particularly relates to a high-speed permanent magnet synchronous motor composite rotor spiral winding preparation method which comprises the following steps: preparing a composite magnetic material; adhering the inner surface of the permanent magnet to the surface of the motor spindle; connecting and mounting circular truncatedcone metal supporting pieces at two ends of the permanent magnet; continuously and spirally winding multiple layers of prepared composite magnetic materials on the outer surface of the carbon fiber ofthe permanent magnet in the circumferential direction, and applying a pre-tightening force in the winding process; and after winding of the composite magnetic material is completed, continuously performing winding at the surface of the composite magnetic material to form a carbon fiber protective sleeve, then performing curing, cleaning, circular truncated cone metal supporting piece dismountingand turning treatment sequentially, and preparing the composite rotor. In the spiral winding process, it can be guaranteed that each layer of magnetic powder adhesive film is evenly distributed, particularly, the problem of interlayer continuous winding can be solved, and the problem that due to continuous winding, the end of the rotating shaft is wrinkled in a winding mode or time is wasted in the cutting and re-winding process is fundamentally solved.

Owner:BEIHANG UNIV +1

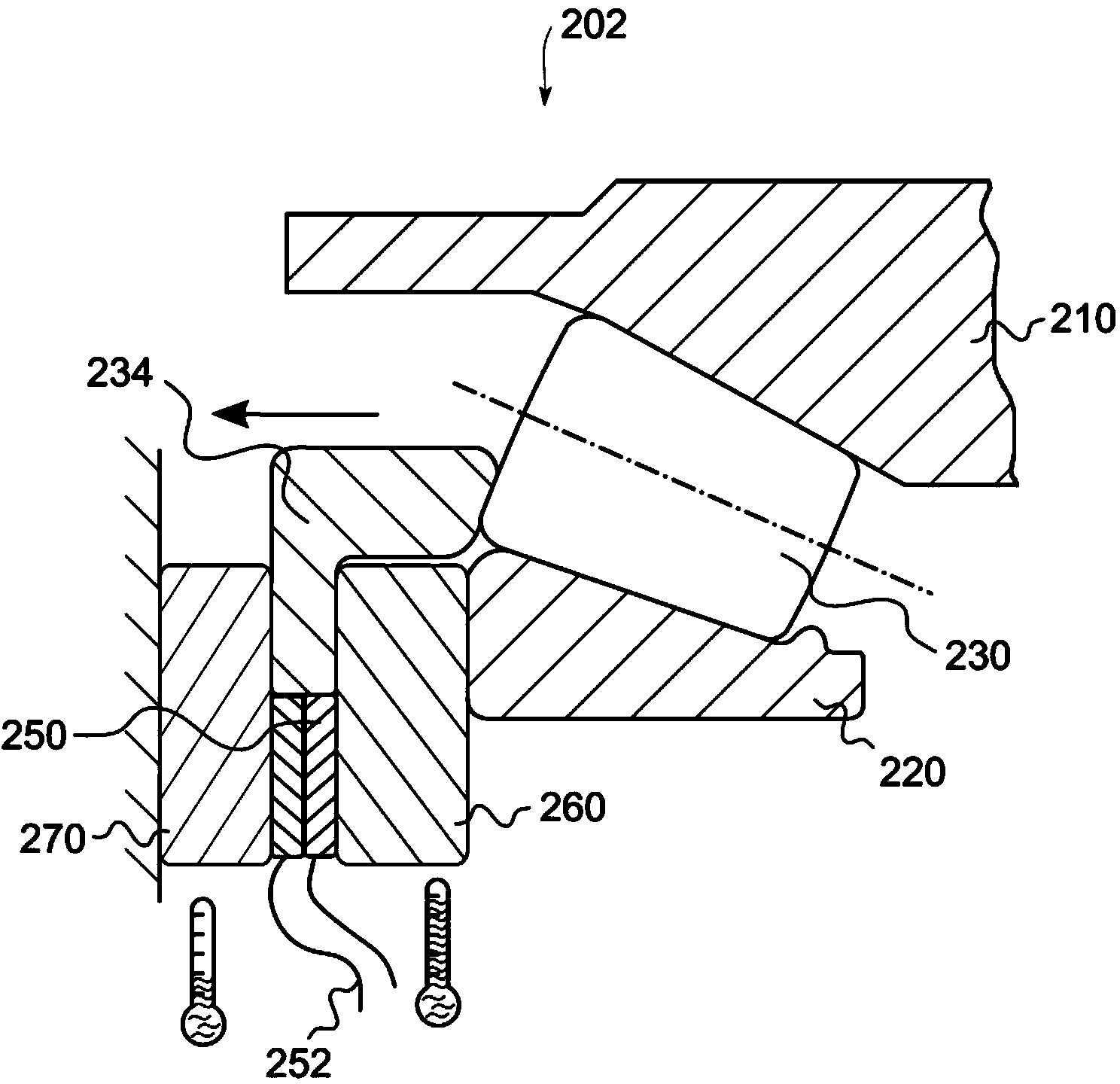

Bearing system and method for operating a bearing system

InactiveCN104343830AReduce maintenanceExtend your lifeRoller bearingsBearing assemblyMechanical engineeringEngineering

A bearing system for supporting components that are movable relative to one another includes at least one bearing and a preload mechanism for changing a preload of the at least one bearing based on an operating state of the bearing system, where the preload mechanism includes, for example, a piezoelectric element, a Peltier element, an expansion material or a micromechanical element.

Owner:AB SKF

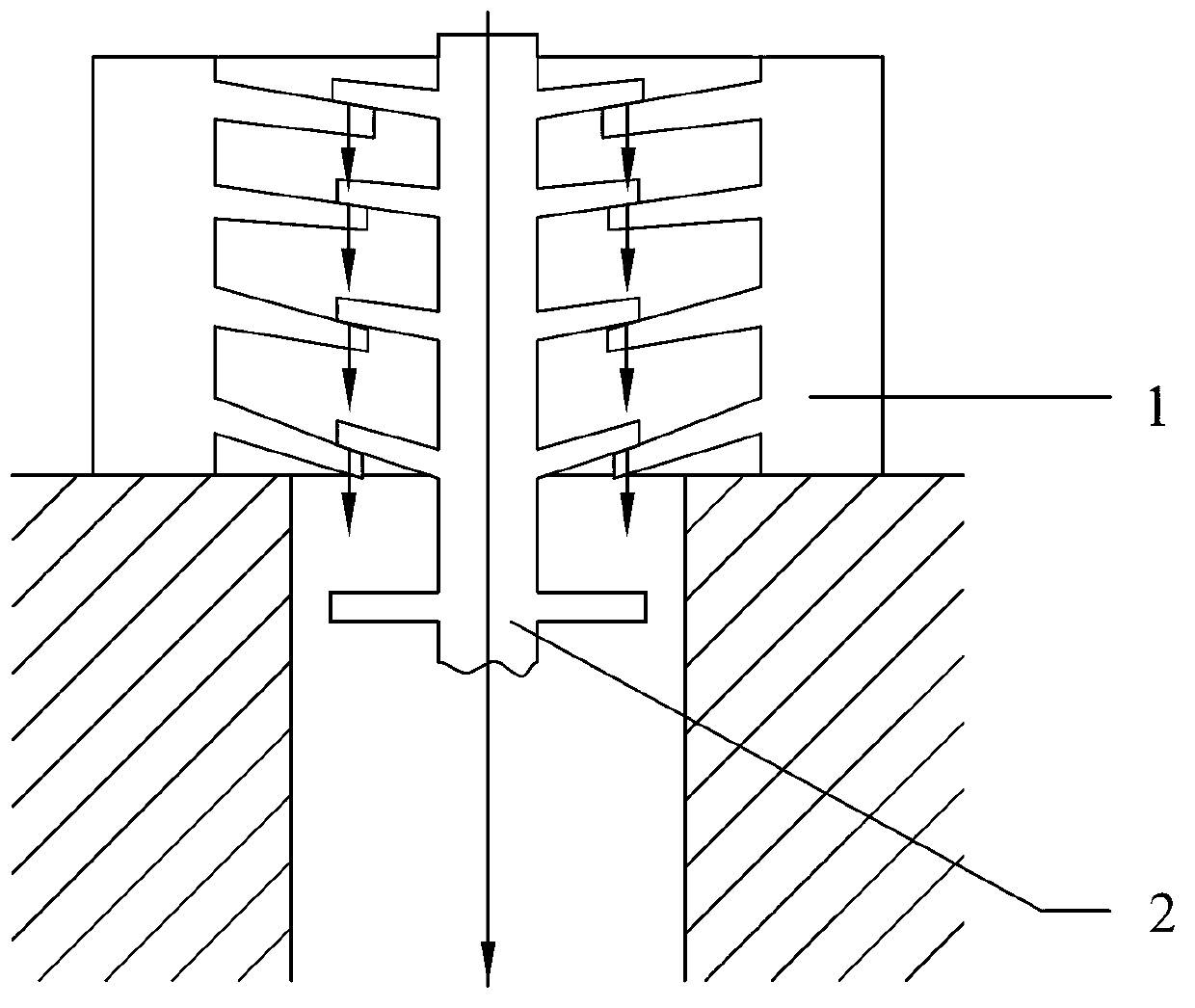

Low-temperature spherical valve

The invention discloses a low-temperature spherical valve which comprises a main valve body, a side valve body, a sphere, a valve cover assembly and a valve rod, wherein the main valve is provided with an outlet channel and a sphere mounting chamber; the side valve body is provided with an inlet channel; the sphere is mounted in the sphere mounting chamber; the side valve body is fixed on the main valve body and covers the sphere; the side valve body is provided with a plurality of spring mounting holes extending in the direction that a medium flows, and a circular caulking groove; the spring mounting holes are communicated with the caulking groove; a compensation spring and a gasket are mounted in each spring mounting hole; a sphere gasket is mounted in the caulking groove and is in extrusion seal fit with the sphere; the sphere and the sphere mounting cavity are sealed through the sphere gasket; the valve cover assembly is fixed on the main valve body; the valve rod penetrates through the valve cover assembly and is fixedly connected with the sphere. The low-temperature spherical valve increases the balancing force to the sphere gasket, still has favorable sealing performance when the sphere gasket is subjected to low-temperature shrinkage distortion, and thus is suitable for being used in pipelines of low-temperature media.

Owner:ZHANGJIAGANG FURUI SPECIAL EQUIP CO LTD

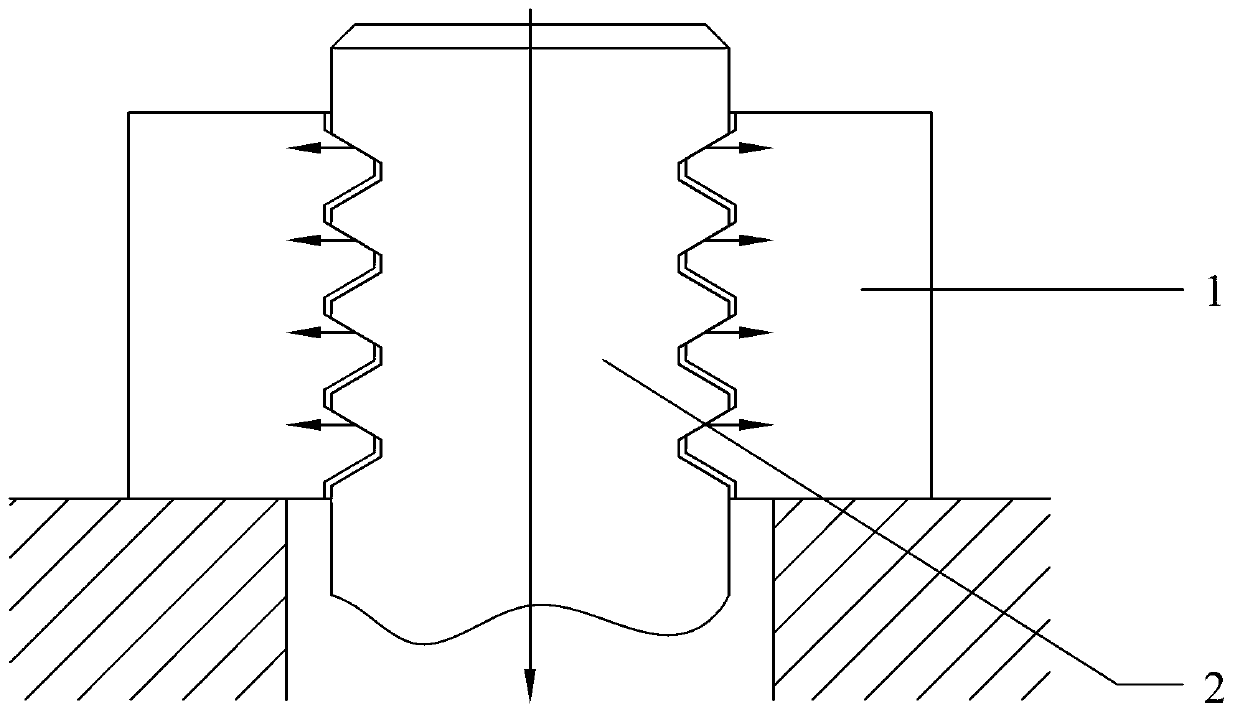

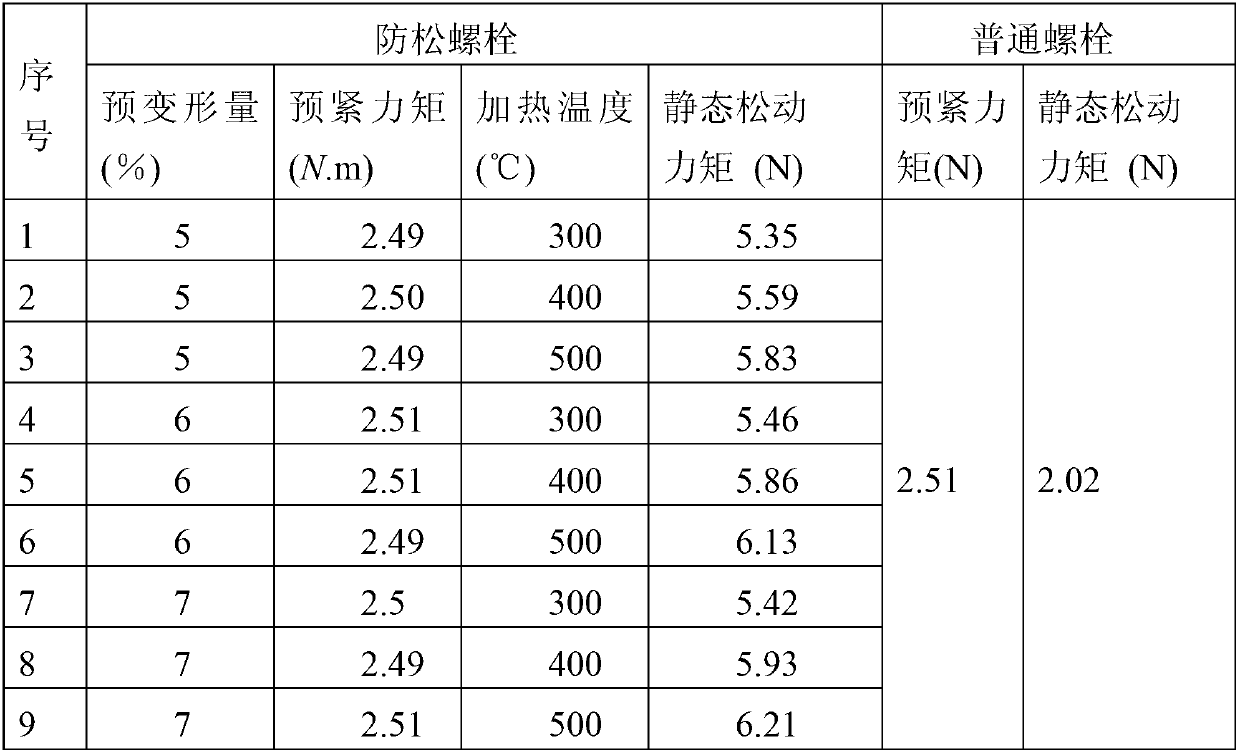

Fe-Mn-Si shape memory alloy check bolt and manufacturing and using methods thereof

InactiveCN103103456ASave operating spaceGood self-locking and anti-loosening performanceNutsBoltsShape-memory alloyMaterials science

The invention discloses a Fe-Mn-Si shape memory alloy check bolt and manufacturing and using methods thereof. The Fe-Mn-Si shape memory alloy check bolt is characterized by comprising the following ingredients by weight percent: 0.02-1.2% of C, 13-24.9% of Mn, 2-6% of Si, 1-7% of Ni, 0.5-12% of Cr, 0-2% of V and the balance of Fe. The performance of the check block provided by the invention is superior to that of a common bolt; and the check bolt has good anti-loosening effect, and is especially suitable for the occasions that the internal operation space of a machine is small and thread connection of other anti-loosening measures cannot be easily carried out.

Owner:DALIAN MARITIME UNIVERSITY

Overflow valve

ActiveCN102734248AImprove use reliabilityExtended service lifeServomotor componentsEngineeringMotion range

The invention discloses an overflow valve comprising a valve body, a main valve seat, a main valve core, a pilot valve seat, a pilot valve core, a main valve spring, a pilot valve spring, a pilot valve seat installation hole and a pilot valve seat limit part, wherein the main valve seat is fixedly sleeved in the valve body, and the pilot valve seat is movably sleeved in the pilot valve seat installation hole and is provided with a pilot valve oil inlet; and the pilot valve seat limit part is used for limiting the motion range of the pilot valve seat, so that the motion stroke of the pilot valve seat is shorter than that of the pilot valve core. Compared with the prior art, with the adoption of the overflow valve, abrasion of the pilot valve core and the pilot valve seat is small, and the pre-pressure of the pilot valve spring is small, so that the using reliability of the overflow valve can be greatly improved, and the service life of the overflow valve can be greatly prolonged.

Owner:浙江高宇液压机电有限公司

Latching device for a rotationally or translationally movable operating element

ActiveCN104011615ALow costReduce wearControlling membersLimiting/preventing/returning movement of partsContact lineSliding contact

The latching device for a rotationally or translationally movable operating element is provided with a resiliently mounted latching projection (32) and with a latching guideway (24) which is in sliding contact with the latching projection (32) and which has a plurality of latching depressions (26) with latching elevations arranged between them. The latching depressions (26) and the latching elevations (28) form a substantially corrugated latching path (30) along which the latching projection (32) slides during a relative movement between latching guideway (24) and latching projection (32). The latching projection (32) has a surface (44) which contacts the latching path (30) along at least one contact line (40, 42) running substantially transversely to the longitudinal extent of the latching path (30). When sliding along the latching path (30), the latching projection (32) experiences an upward and downward movement with periodic change of the orientation of its contact line (40, 42) with respect to the latching guideway (24). The surface of the latching path (30) has a change of inclination which follows the change of orientation of the contact line (40, 42) of the latching projection (32) during its upward and downward movement.

Owner:BEHR HELLA THERMOCONTROL

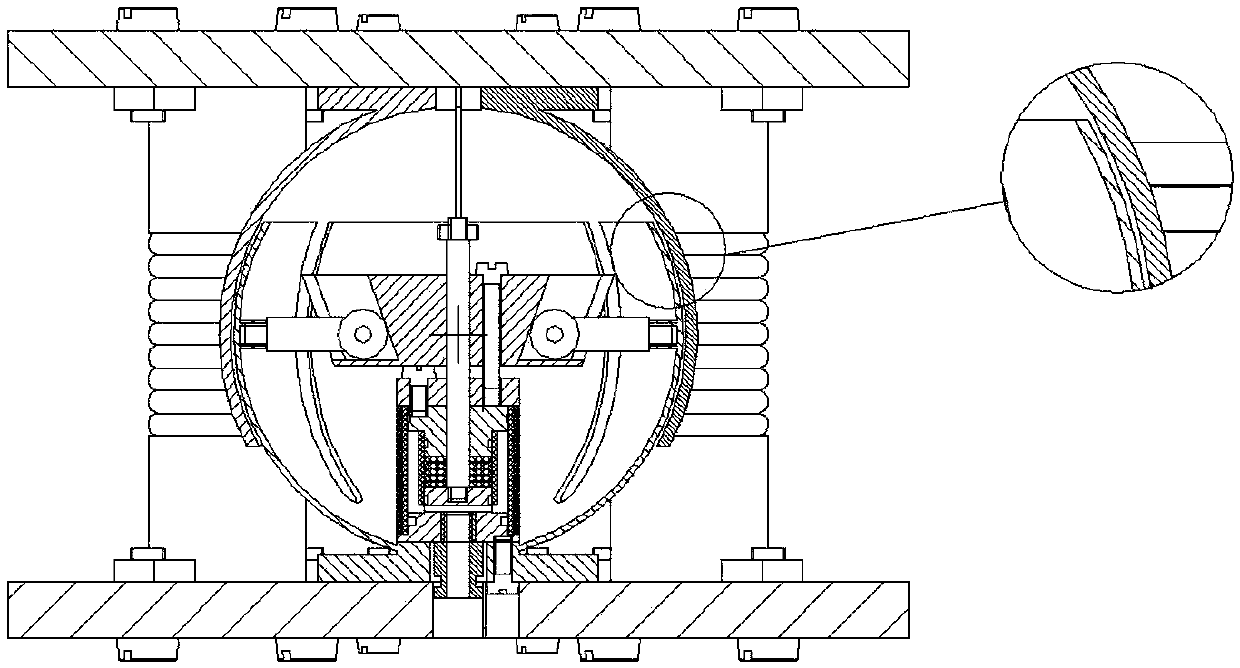

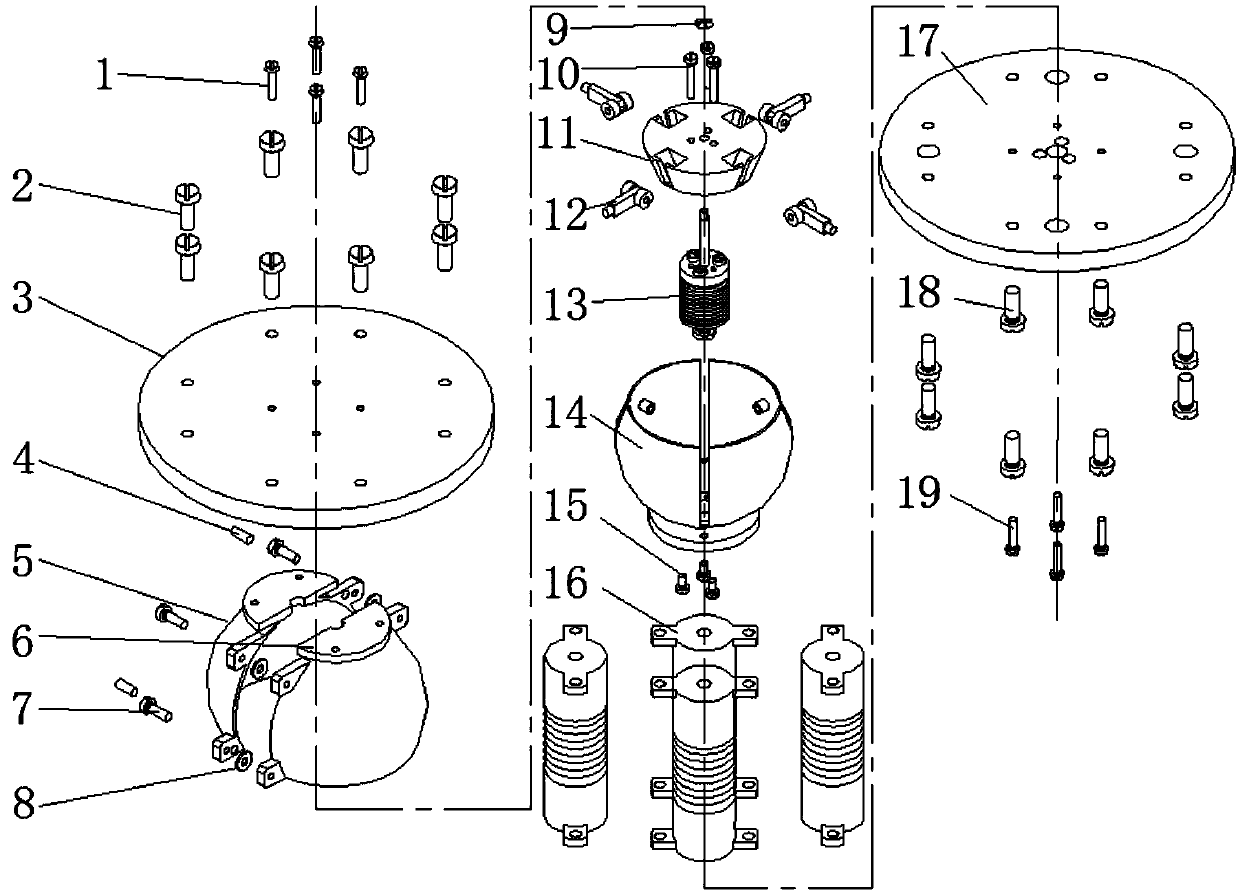

Pneumatic flexible wrist with elastic hemispherical braking device

ActiveCN111283727ASolve the lack of flexibilityGuaranteed coincidenceProgramme-controlled manipulatorJointsEngineeringMechanical engineering

The invention relates to a pneumatic flexible wrist with an elastic hemispherical braking device, belongs to a robot-driven executing device, is applied to a robot wrist component and an executing mechanism, and aims to solve the problems of large size, insufficient flexibility, difficulty in realizing posture keeping and the like in existing motor-driven, hydraulic and pneumatic flexible joints.The pneumatic flexible wrist is structurally characterized in that an inner elastic hemisphere, a ball seat, a flexible axial driver and artificial muscles are arranged between upper and lower flangesof a wrist; wrist braking force is determined by assembly pre-tightening force between the inner elastic hemisphere and the ball seat; the flexible wrist is in a braking state when not working, so that the posture of a robot can be kept well under different loads; after pressure gas is introduced into the flexible axial driver, the wrist can release the braking state or adjust the braking force as required; the flexible wrist has two degrees of freedom, namely, pitching and swinging in a working state; and the pneumatic flexible wrist has flexibility and an overload protection function.

Owner:BEIHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com