Fe-Mn-Si shape memory alloy check bolt and manufacturing and using methods thereof

A fe-mn-si, memory alloy technology, used in bolts, screws, nuts and other directions, can solve the problems of changing the nature of detachable connections, inconvenient use, high cost and difficult to promote, etc., to achieve good self-locking anti-loosening performance, Easy to install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with specific embodiments.

[0039] Select smelting raw materials and mix according to the following ratio (mass percentage of chemical components):

[0040] Mn: 16.86%; Si: 4.50%; Cr: 10.30%; Ni: 5.29%; Vacuum ZG-0.025 thyristor intermediate frequency induction melting furnace smelting, the vacuum degree is 10 -2 Torr. After the raw material is melted and kept warm for 30 minutes to make it even, cast it into a 15Kg ingot in a metal mold. In order to eliminate the inhomogeneity of the composition of the ingot, after the ingot is homogenized and annealed at 1200°C for 24 hours, the surface scale is removed, the cap is cut off, and then heated to 1100°C for 1 hour and then hot forged. For round bar blanks, the initial forging temperature is 1050°C, and the final forging temperature is not lower than 900°C; wire and straighten it.

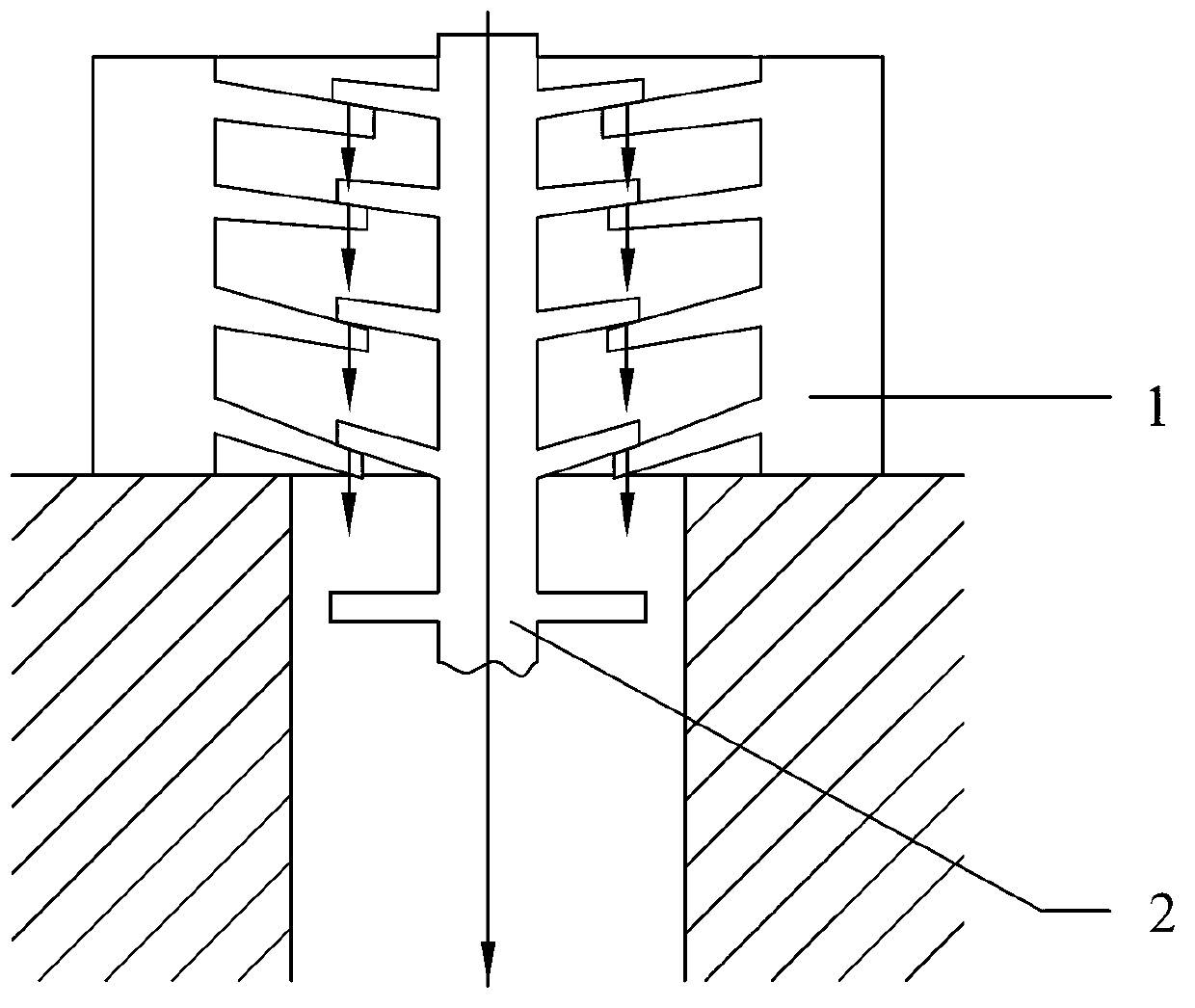

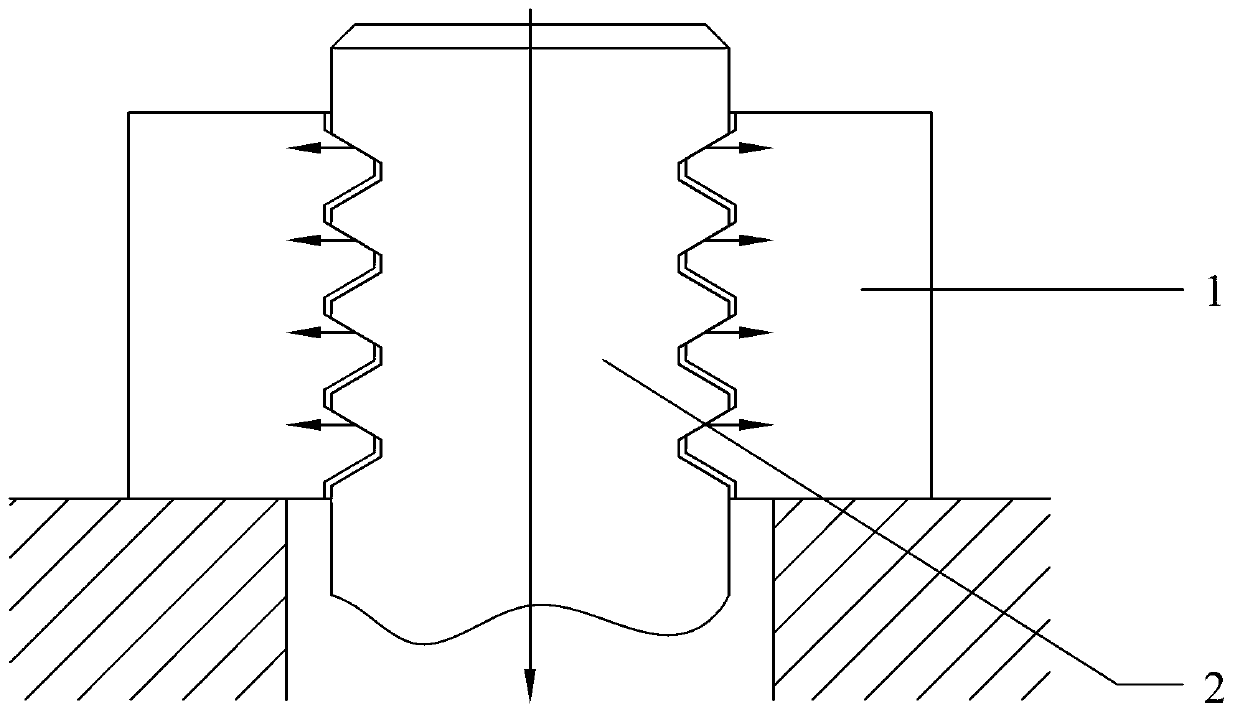

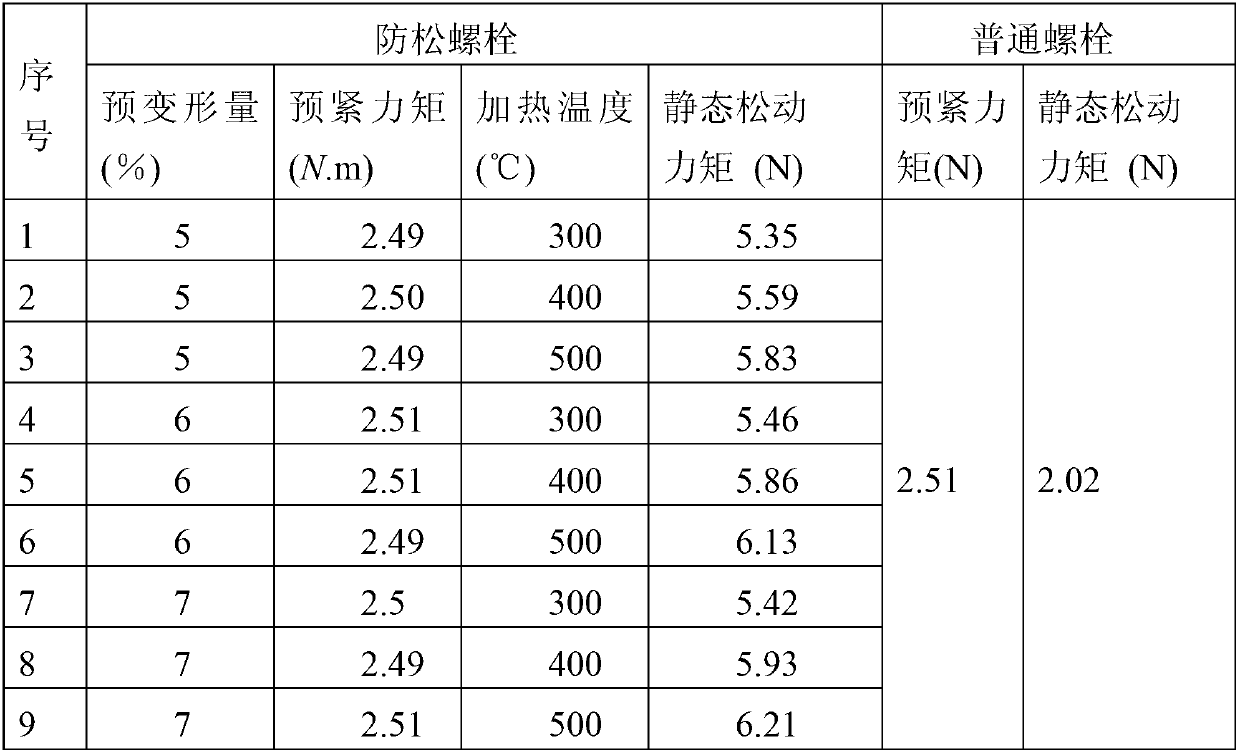

[0041] The process of machining Fe-Mn-Si shape memory alloy bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com