Tension control equipment

A tension control and adjustment device technology, which is applied in the direction of textile, textile, papermaking, and weaving auxiliary equipment, can solve the problems of large belt tension differences, different judgments, and low product quality, and achieve uniform tension distribution and reduced rotational resistance. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

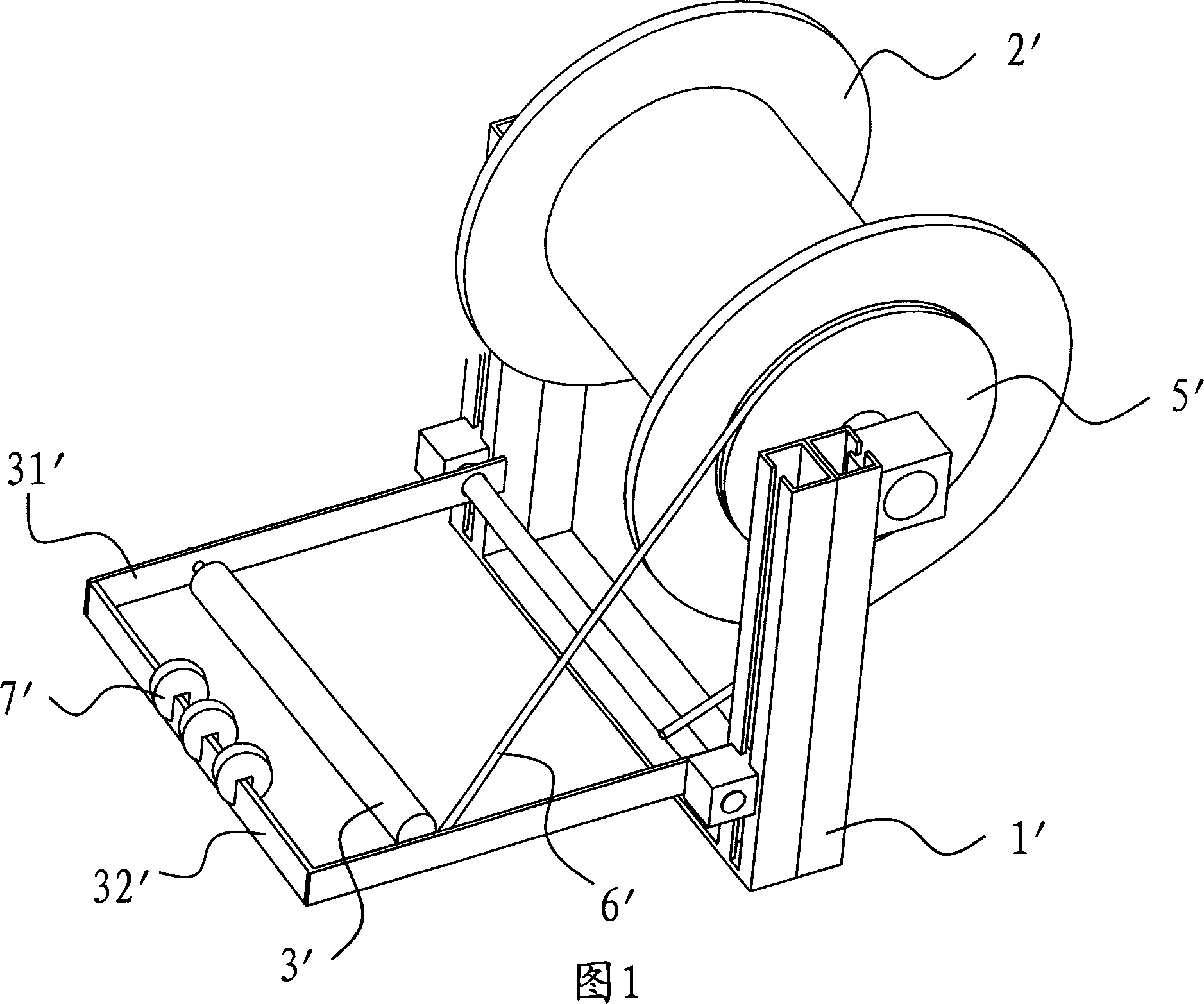

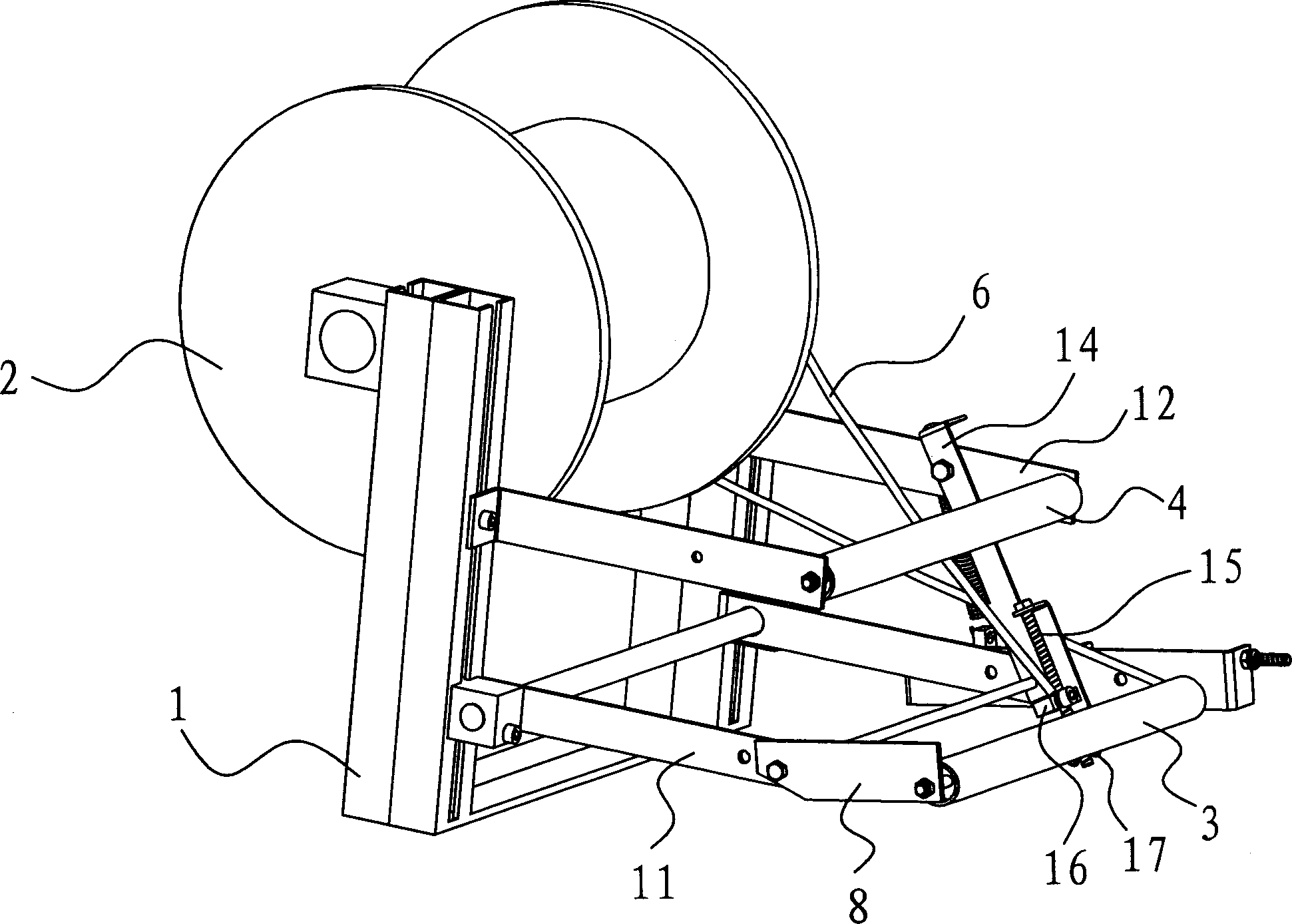

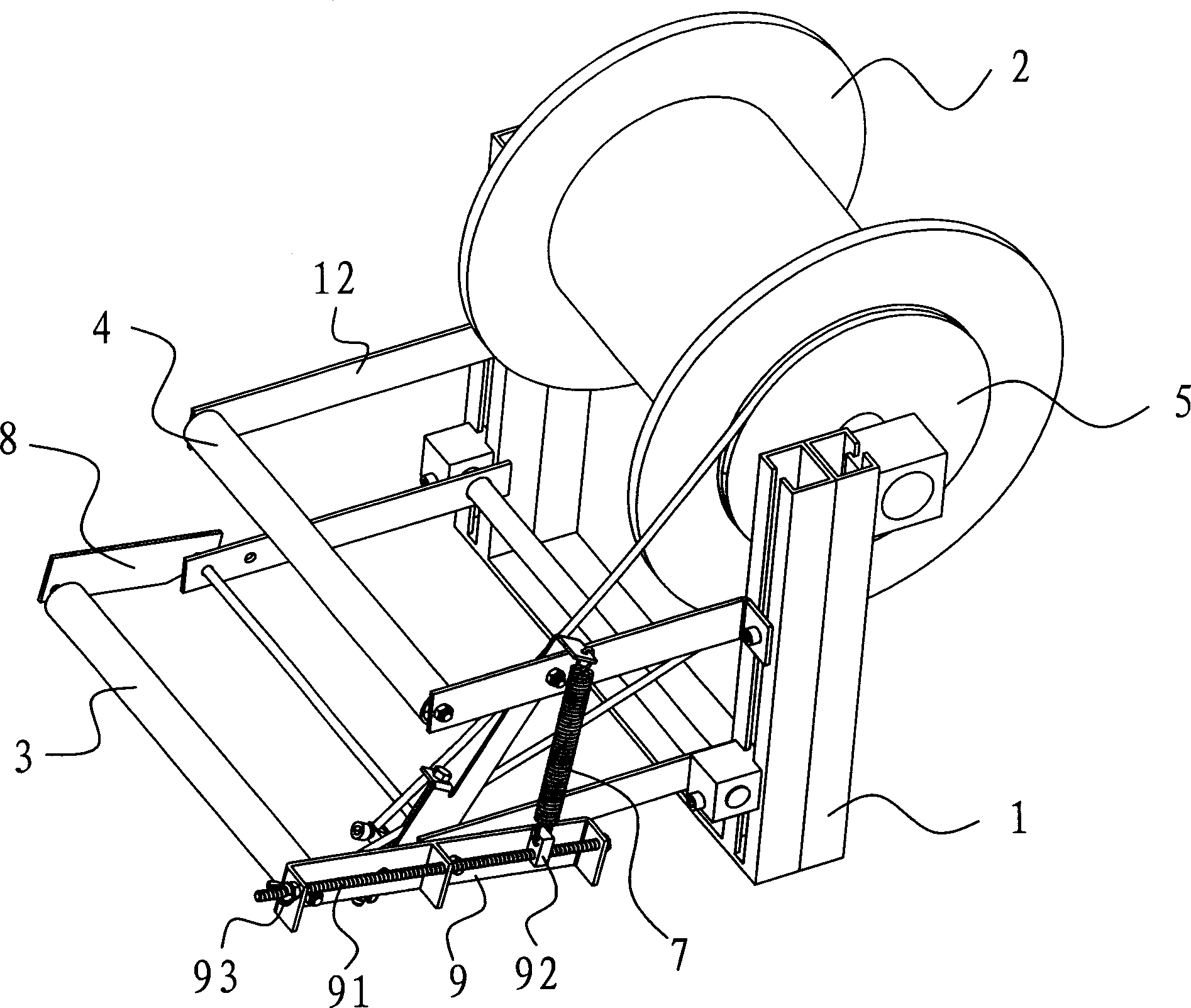

[0015] refer to figure 2 , image 3 , Figure 4 , the embodiment provides a tension control device for elastic uncoiling, which includes a frame 1, a pan head 2, a swing roller 3, a fixed roller 4, a brake wheel 5, a brake band 6, a spring 7, two swing arms 8, a rotating arm9. The cross-section of the pan head 2 is an inverted "I"-shaped structure, and the concave part in the middle is used to wind the rubber band. Applying a pulling force on the end can drive the pan head 2 to rotate against the frictional force of the rolling bearing to complete the uncoiling process of the elastic band. The frame 1 is provided with two support arms 11, the two support arms 11 are perpendicular to the axis of the central axis of the pan head 2 and are respectively located on the frame 1 at the axial ends of the pan head 2. The two swing arms One end of 8 is respectively hinged to the far-end of these two support arms 11, and described swing roller 3 is rotatably arranged on the non-hinge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com