A Servo Control System of a Weaving Machine

A technology of servo control system and net weaving machine, applied in the field of servo control system, can solve problems affecting the flexibility of net weaving machine, adjustment of warp let-off mechanism, and increasing equipment complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

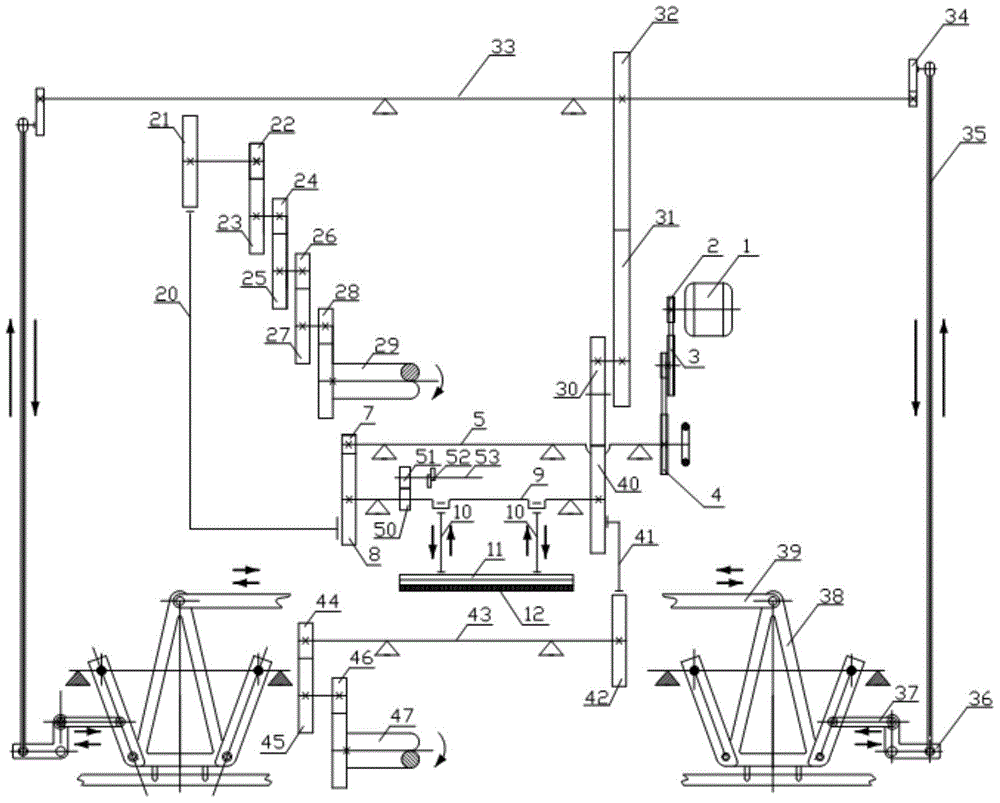

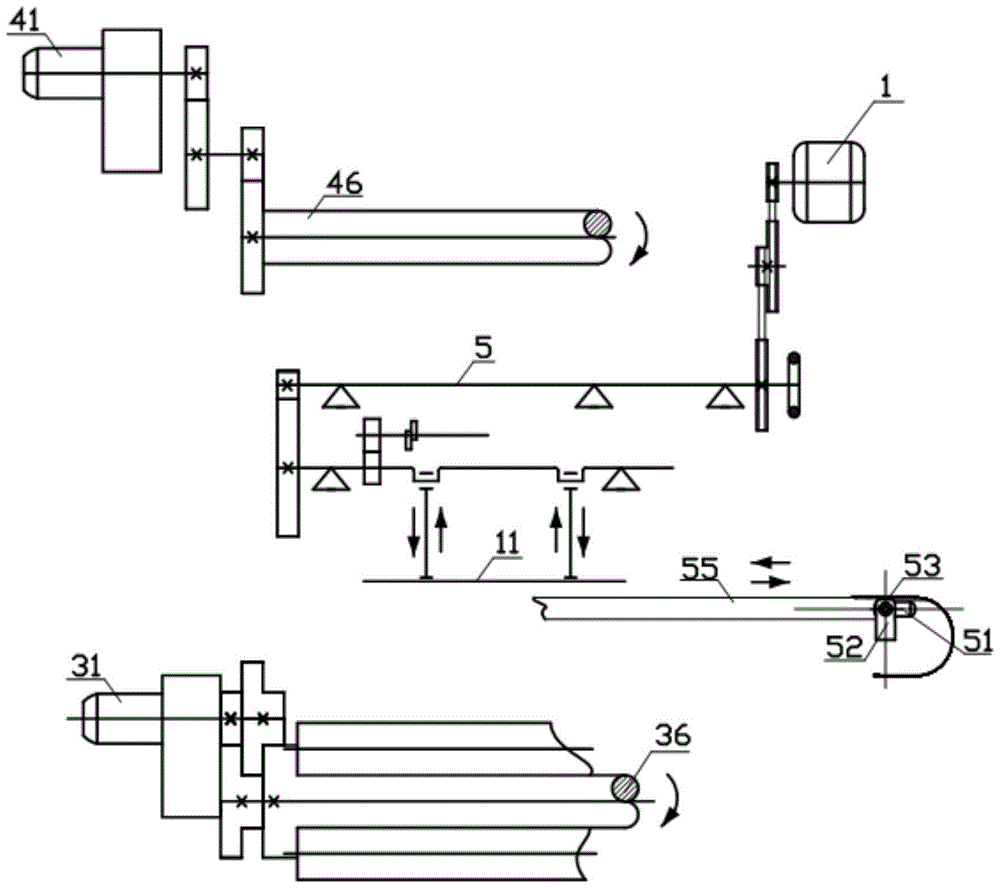

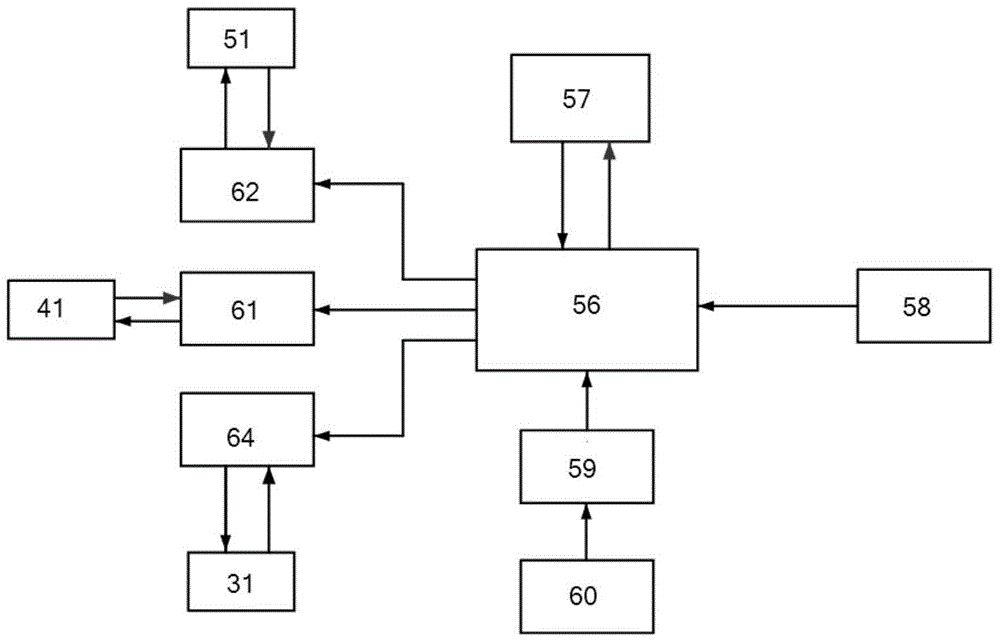

[0039] Such as figure 2 with image 3 As shown, the present invention provides a servo control system of a net weaving machine, and the net weaving machine includes a warp let-off shaft 46, a main shaft 5 and a kendo 11, and the warp let-off shaft 46, the main shaft 5 and the kendo 11 are mutually Arranged in parallel and arranged in sequence, the main shaft 5 is connected to the kendo 11 through a first transmission mechanism, and the first transmission mechanism is designed to drive the kendo to move closer or closer to the main shaft when the main shaft rotates. away from the linear reciprocating motion, and every time the main shaft rotates one circle, the kendo makes a linear reciprocating motion; the servo control system includes: a main motor 1, which is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com