Patents

Literature

49results about How to "Uniform tension distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

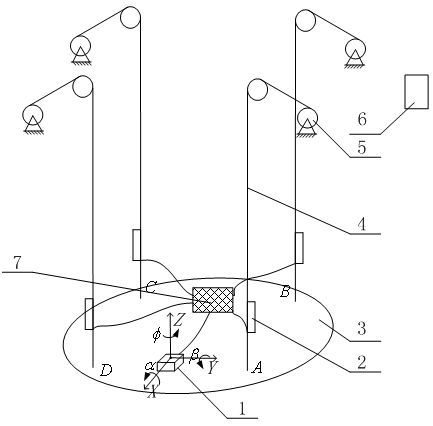

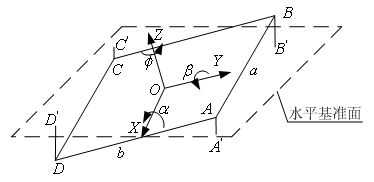

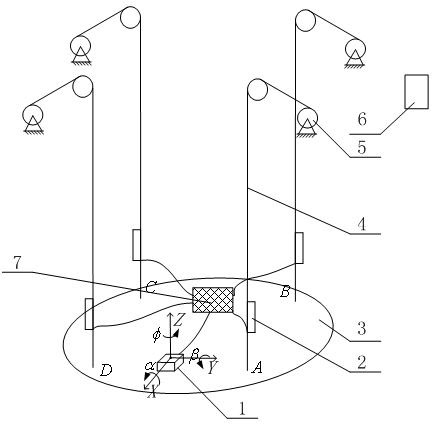

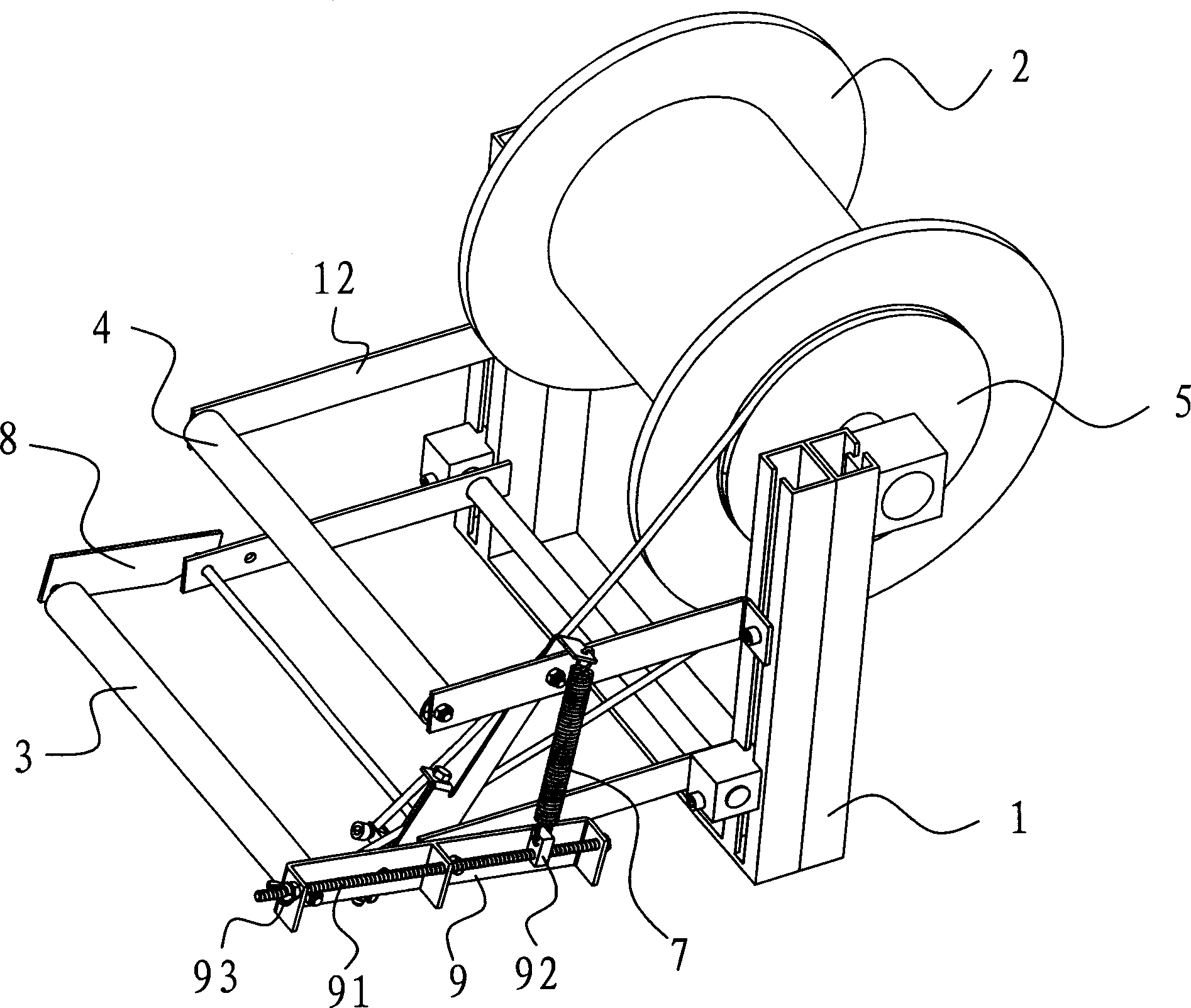

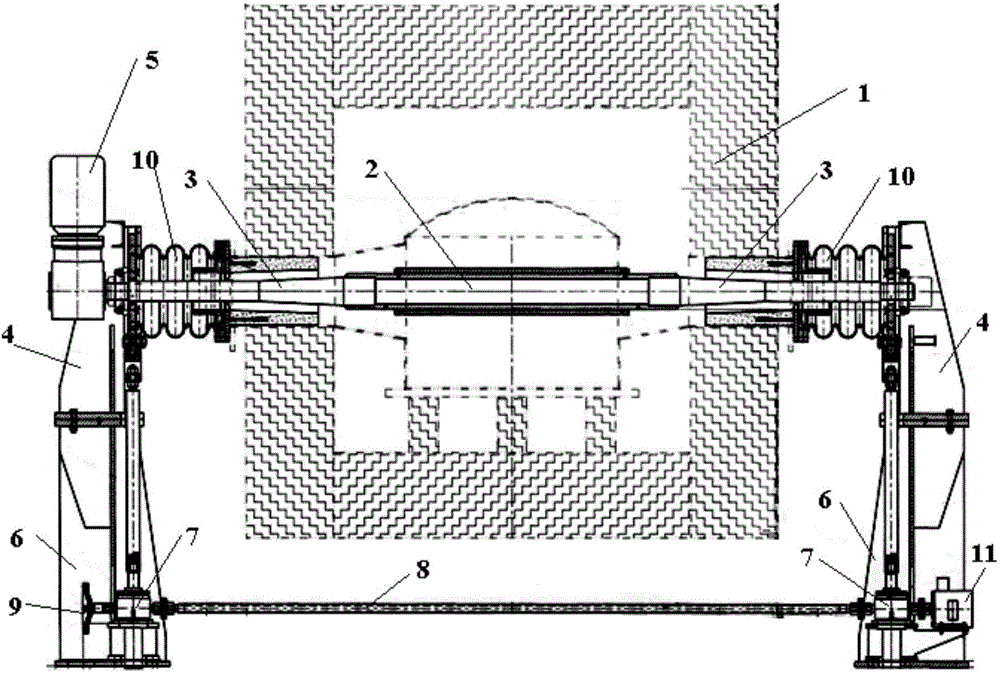

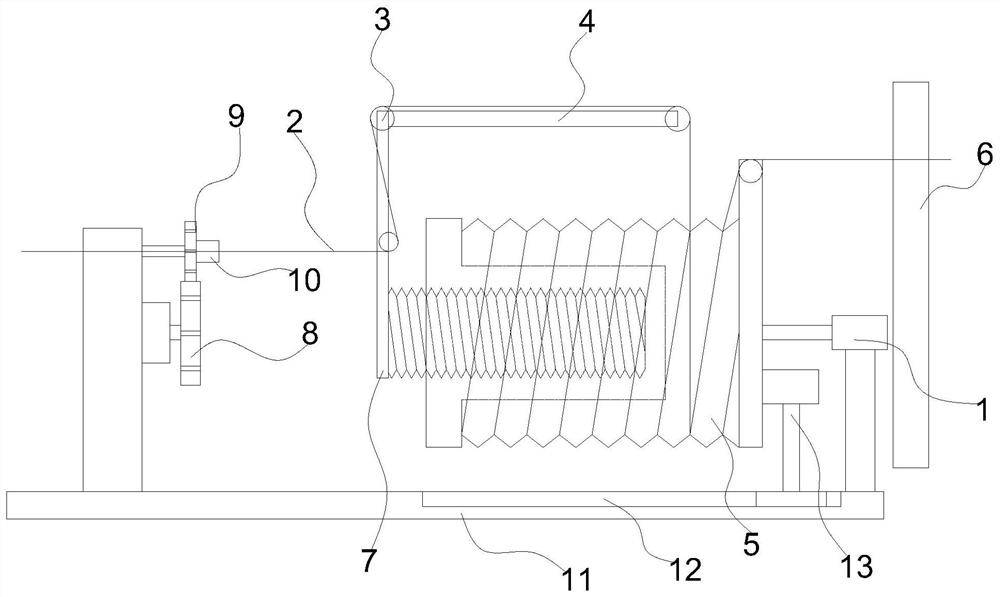

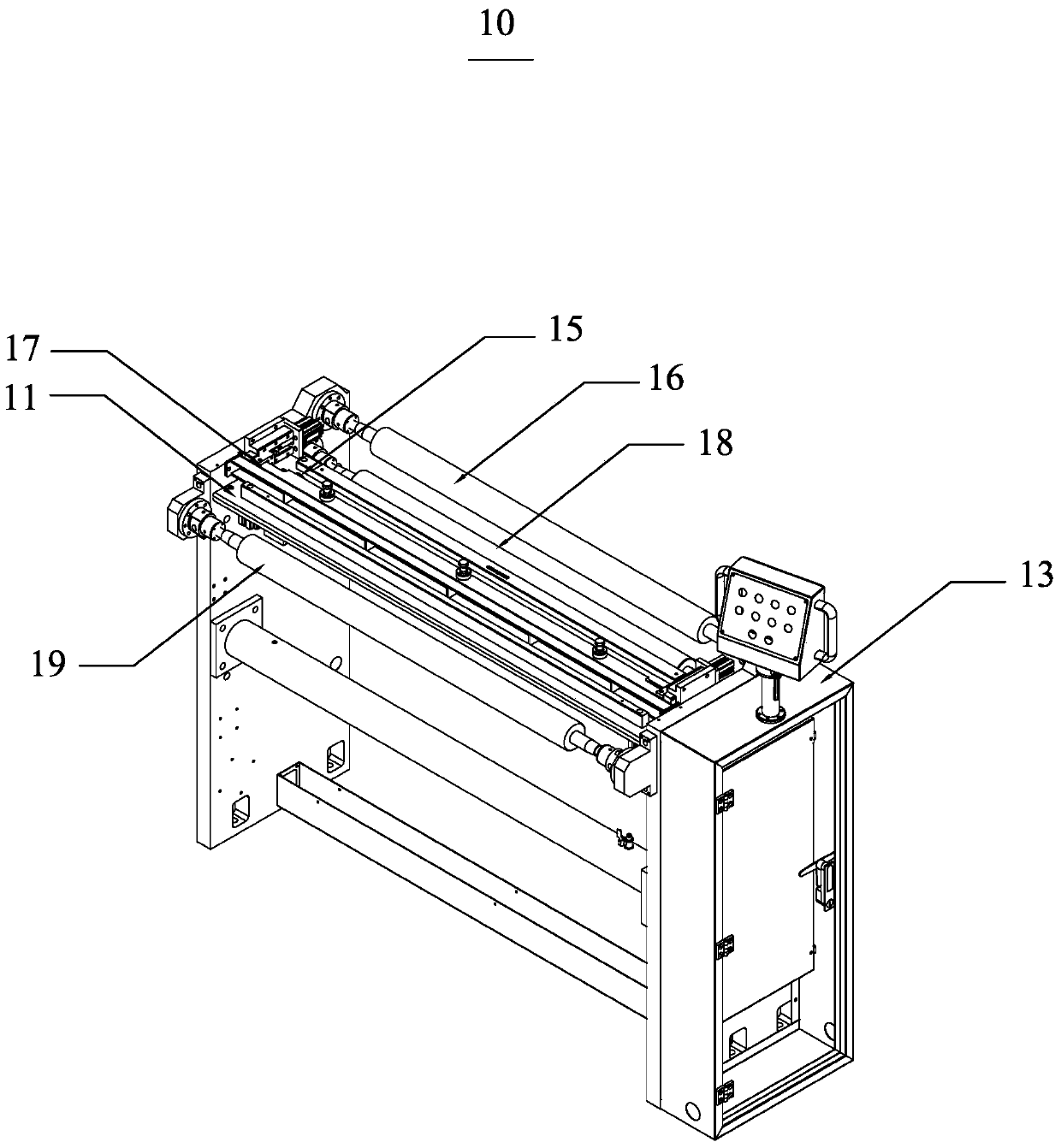

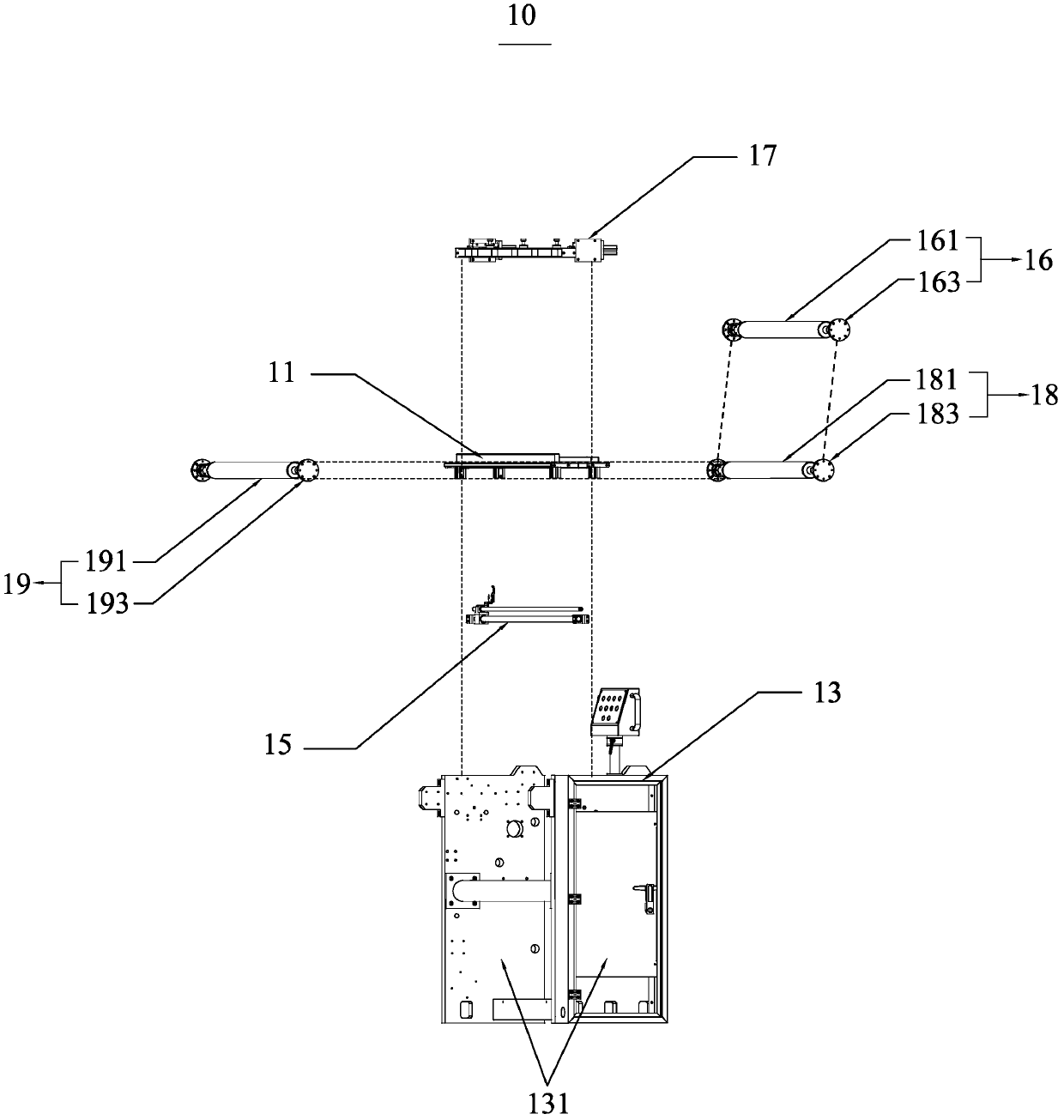

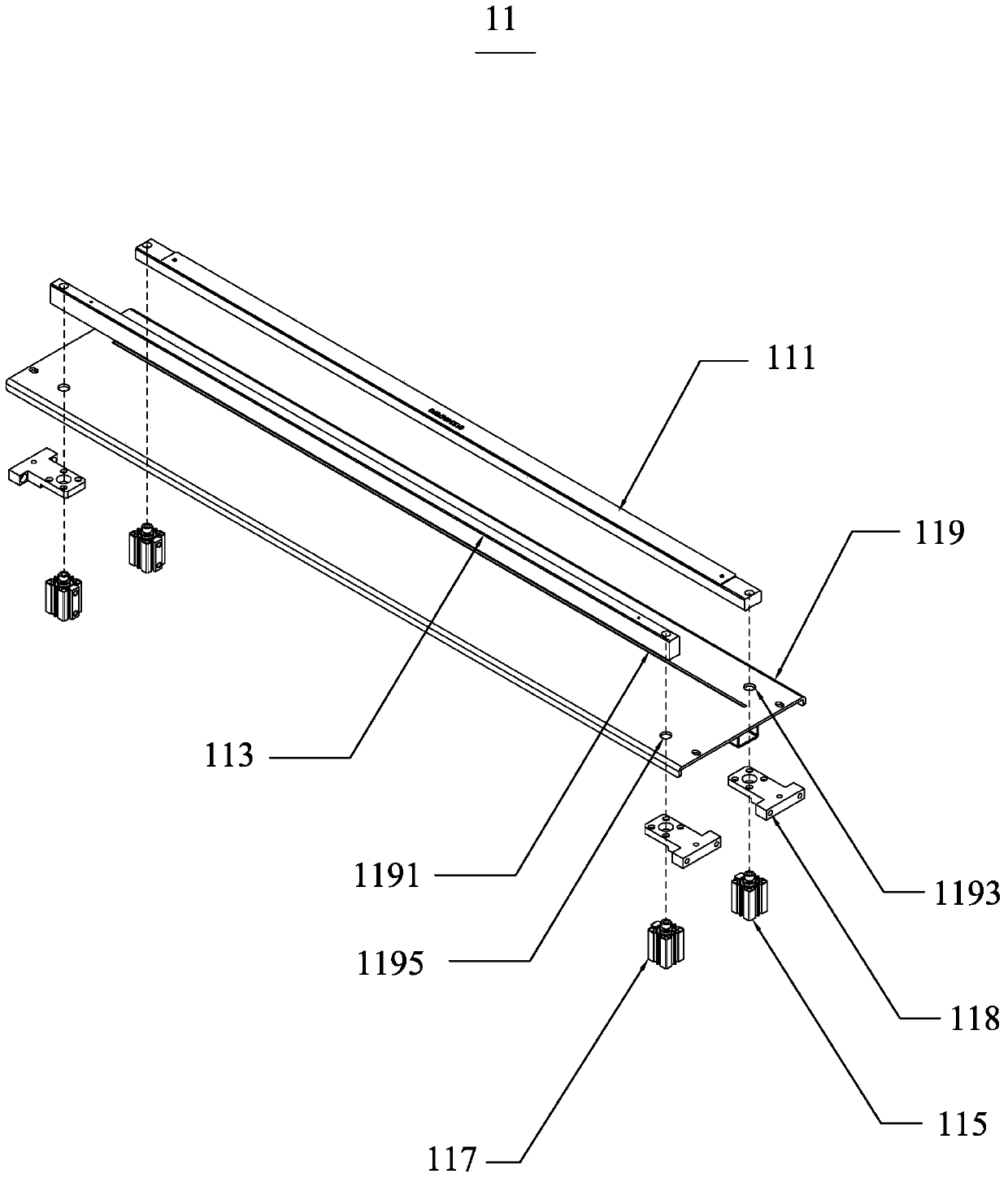

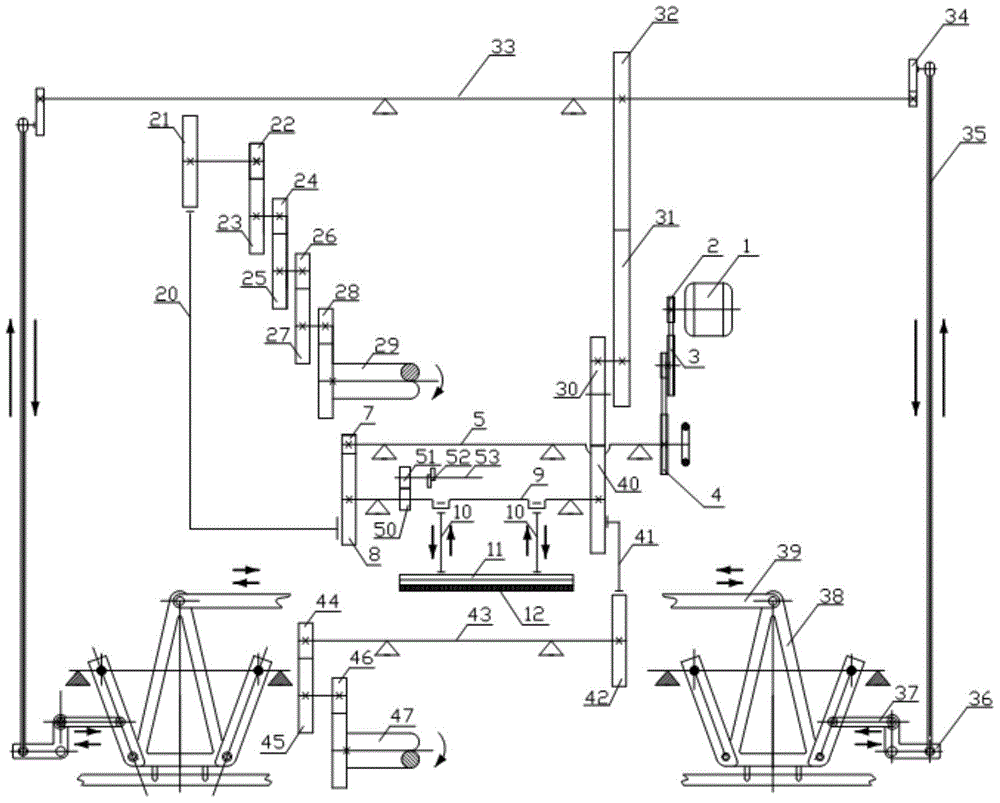

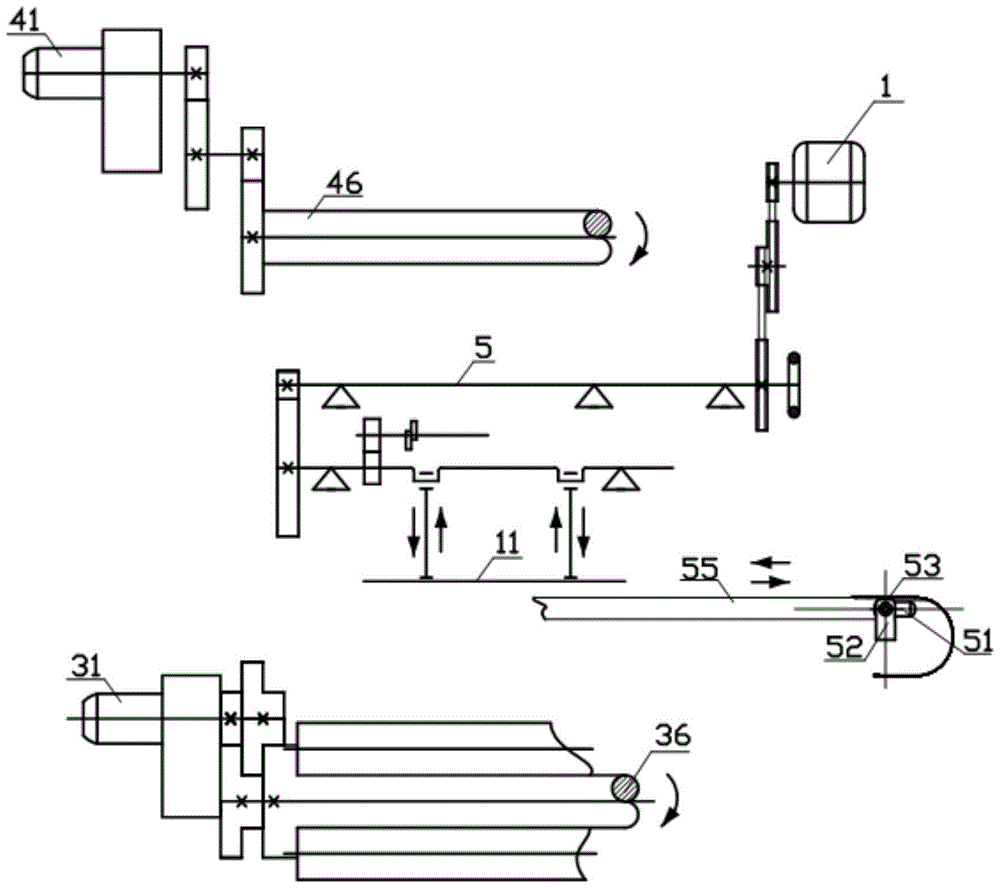

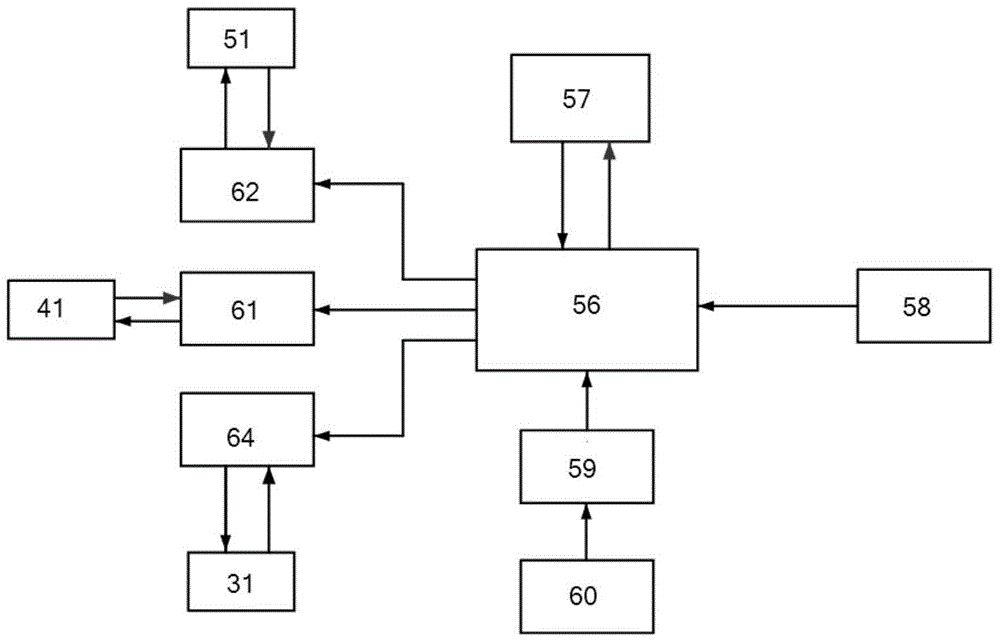

Automatic balance regulating system and method of hanging scaffold for vertical shaft construction

ActiveCN102602838AGuaranteed uptimeSolve the tiltWinding mechanismsProgrammable logic controllerControl system

An automatic balance regulating system and method of a hanging scaffold for vertical shaft construction is particularly suitable for a winch control system under control of PLC (programmable logic controller) and with variable frequency and regulable speed. The automatic balance regulating system comprises tension sensors arranged on suspension steel wire ropes, an attitude angle sensor installed on the hanging scaffold, a signal acquisition card and a PLC controller which is arranged in a winder chamber; PLC controller acquires signal of attitude angle of the hanging scaffold and signal of the tension of the steel ropes in real time through the attitude angle sensor and the tension sensors respectively, calculates length difference between the length of each of the four steel ropes and the average length thereof, as well as tension difference between the tension of each of the four steel ropes and the average tension thereof, then calculates regulating variables of rotating speed of four winches according to principle that length of each of the four steel ropes is closer to the average length at the same time, and tension of each of the four steel ropes is closer to the average tension at the same time, and furthermore drives the winches to regulate. According to the invention, the automatic balance regulating system can automatically regulate the hanging scaffold from an inclined pose to a horizontal state, and the distribution of tension of steel ropes from a non-uniform state to a balanced state.

Owner:CHINA UNIV OF MINING & TECH

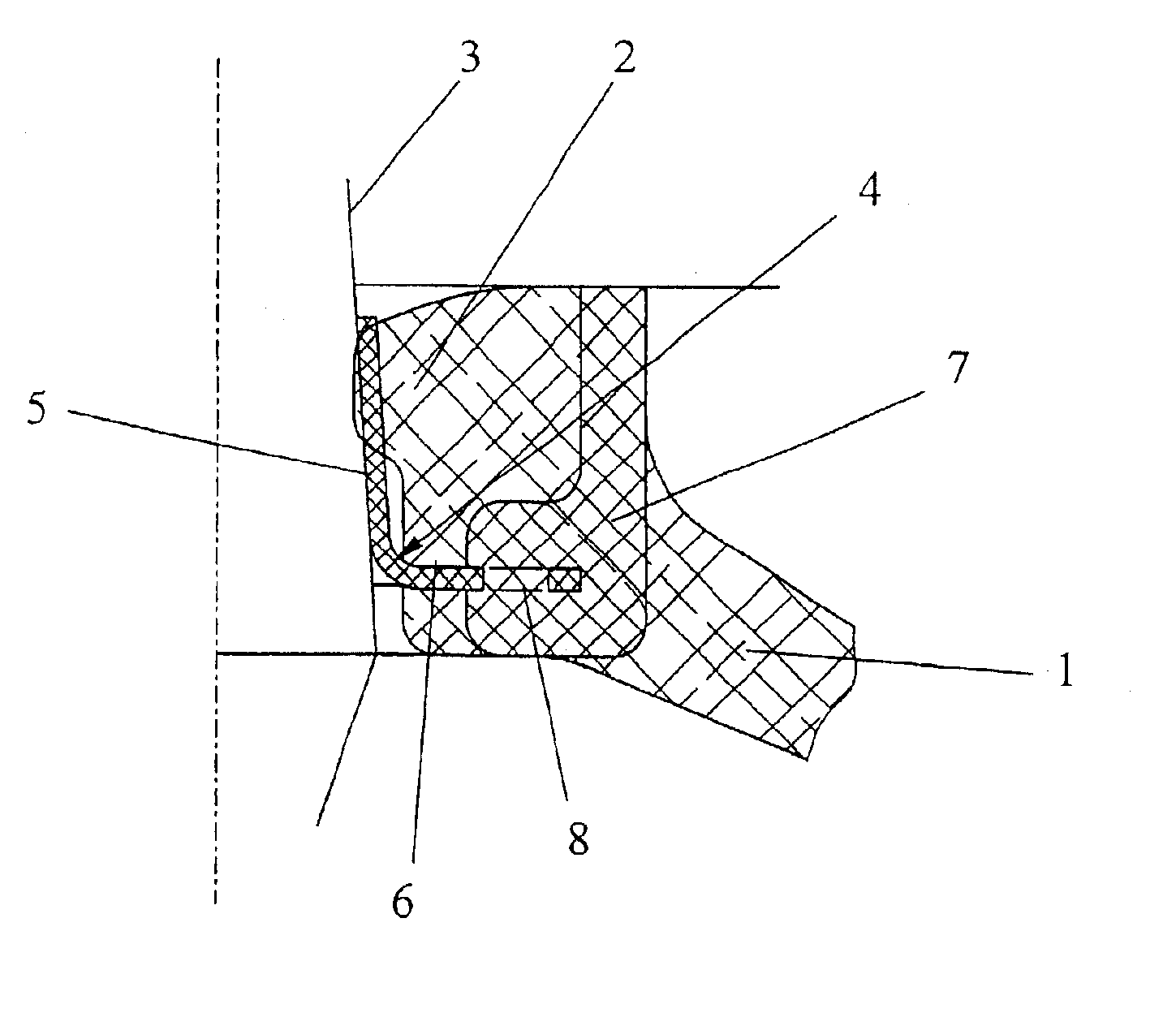

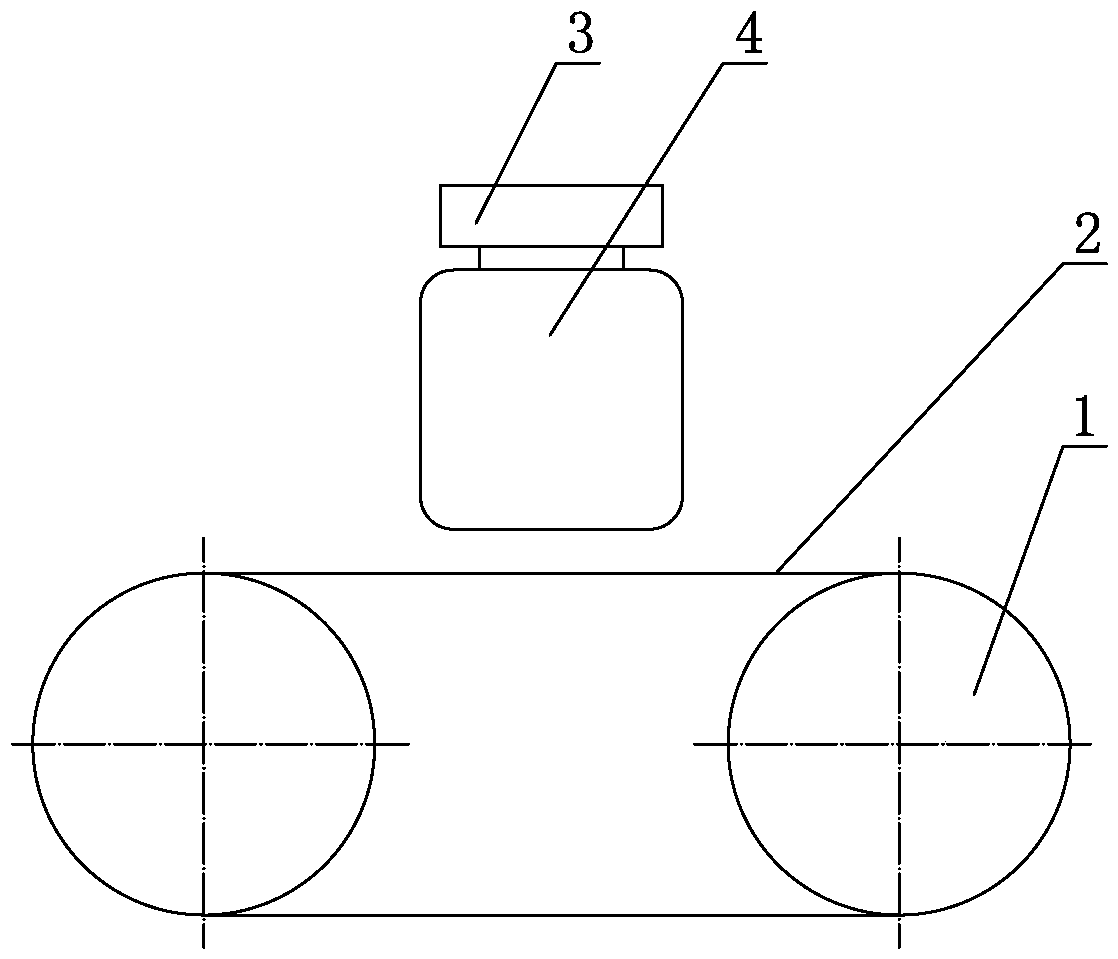

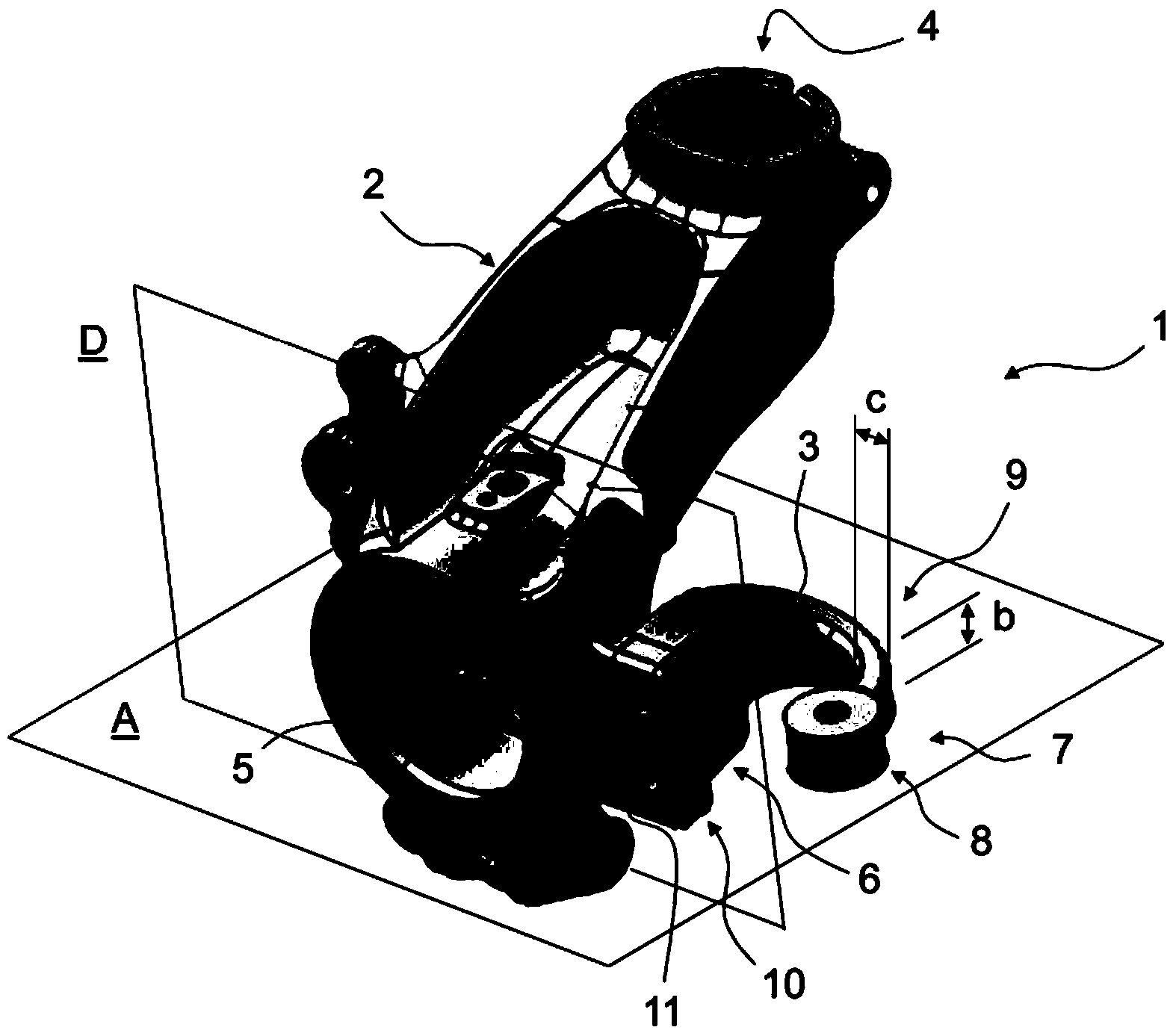

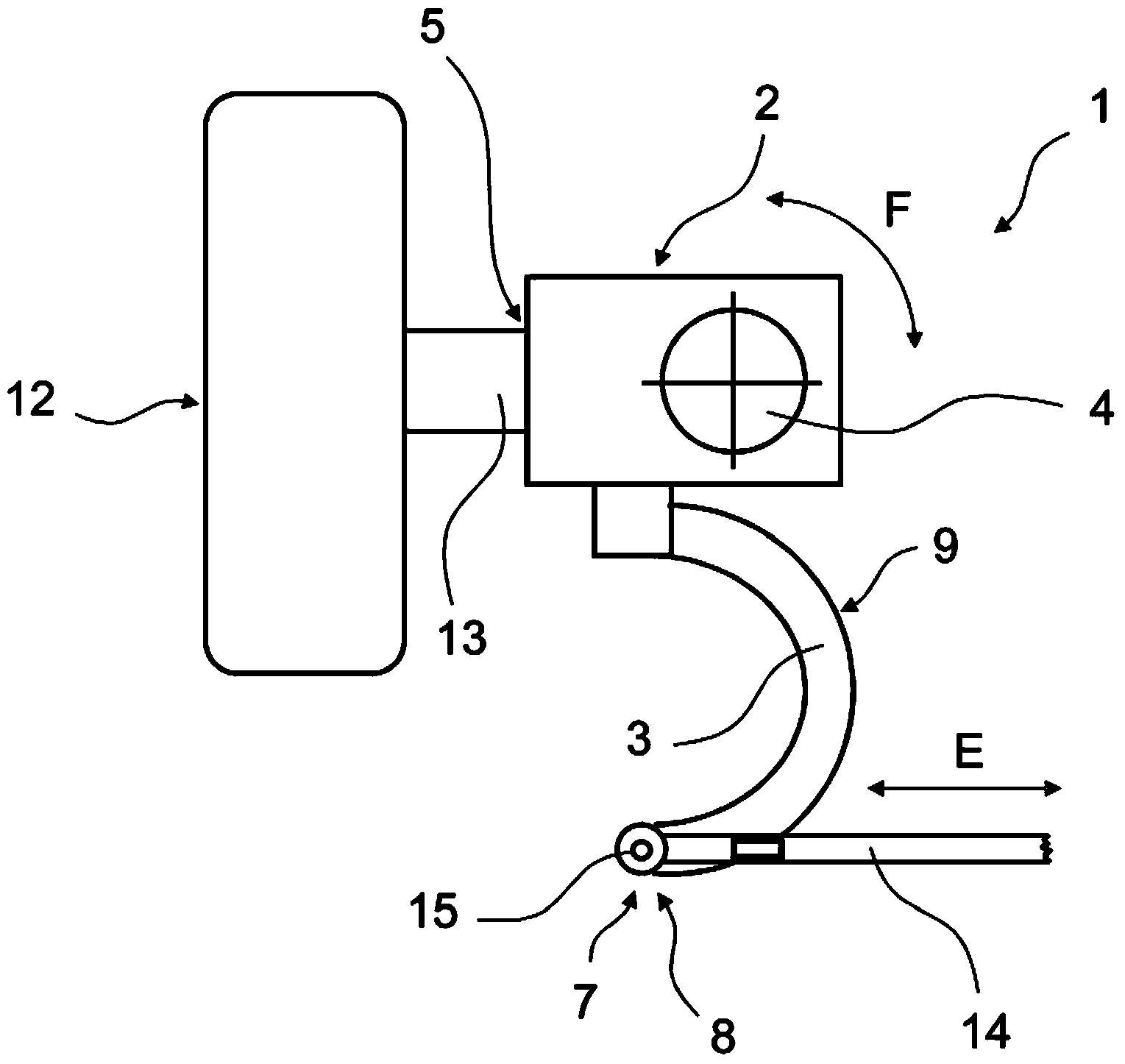

Ball- and -socket joint

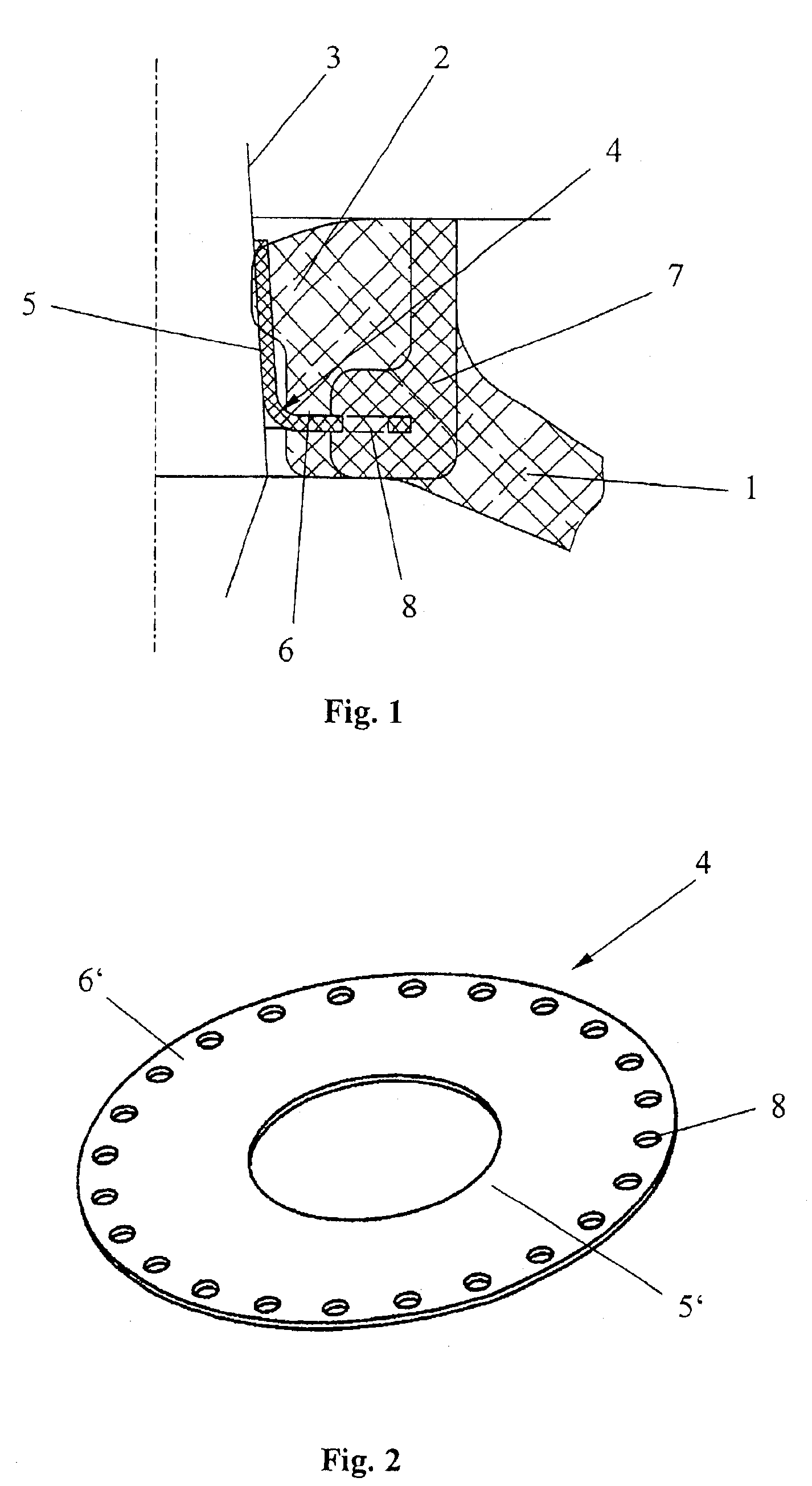

InactiveUS7070355B2Add seatsUniform tension distributionEngine sealsPipeline expansion-compensationSpherical formBall and socket joint

A ball-and-socket joint has a housing, a ball pivot (3) mounted pivotably in the housing, and a sealing bellows (1), which is fastened to the housing and is mounted on the ball pivot (3) slidably via a sealing ring (4) provided with two legs (5, 6). A first leg (5) of the two legs (5, 6) is in contact with the ball pivot (3) under tension and the second leg (6) meshes with the wall of the sealing bellows (1). The second leg (6) is, furthermore, fastened in an anchoring ring (7) arranged at least partially in the wall of the sealing bellows (1).

Owner:ZF LEMFOERDER METALLWAREN AG

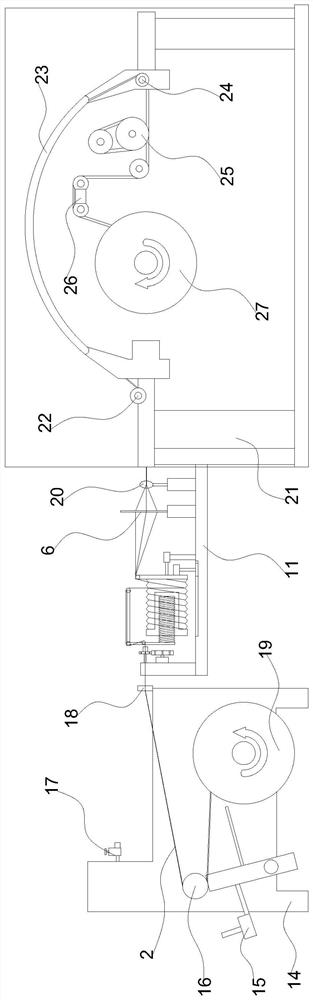

Tension control equipment

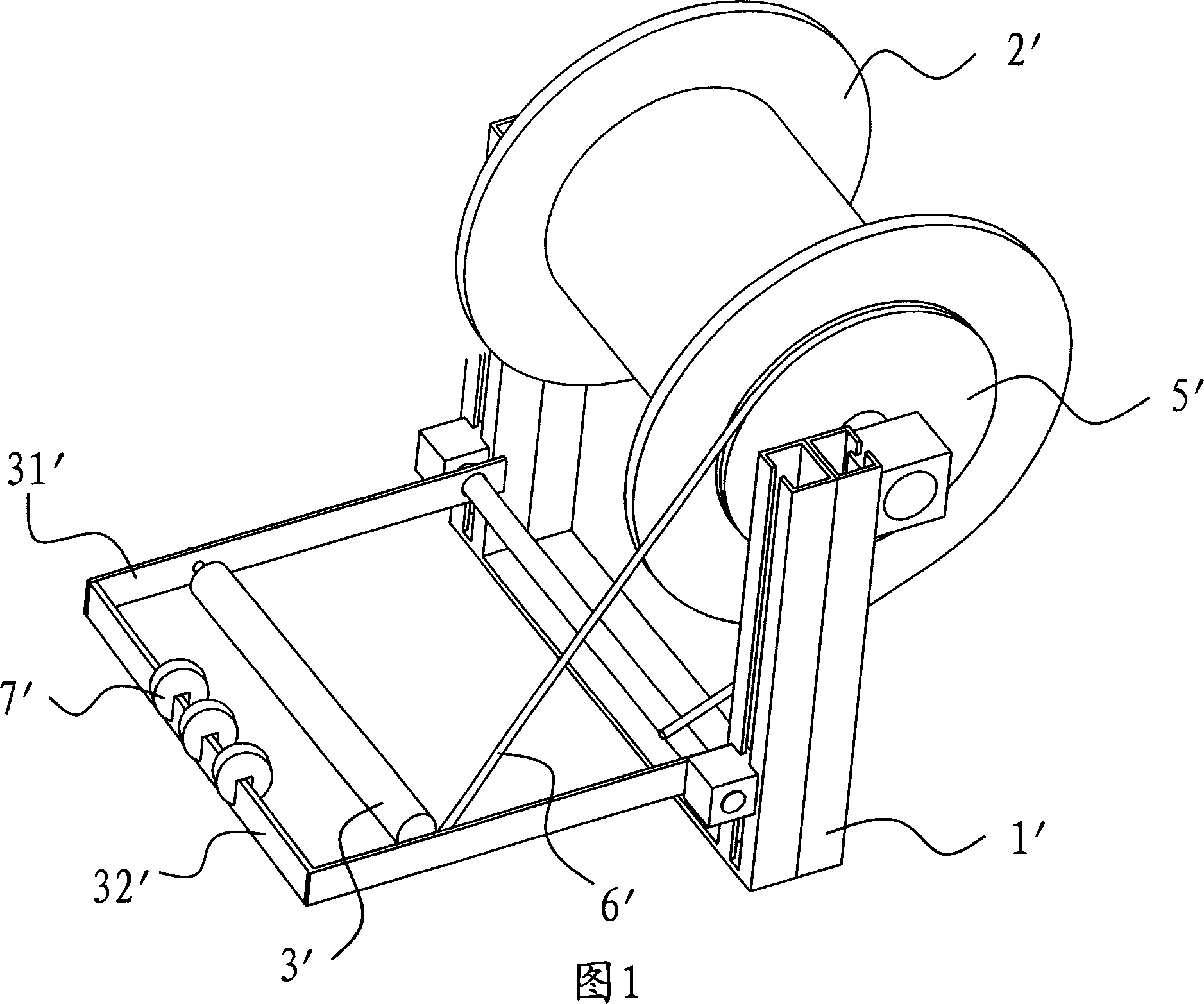

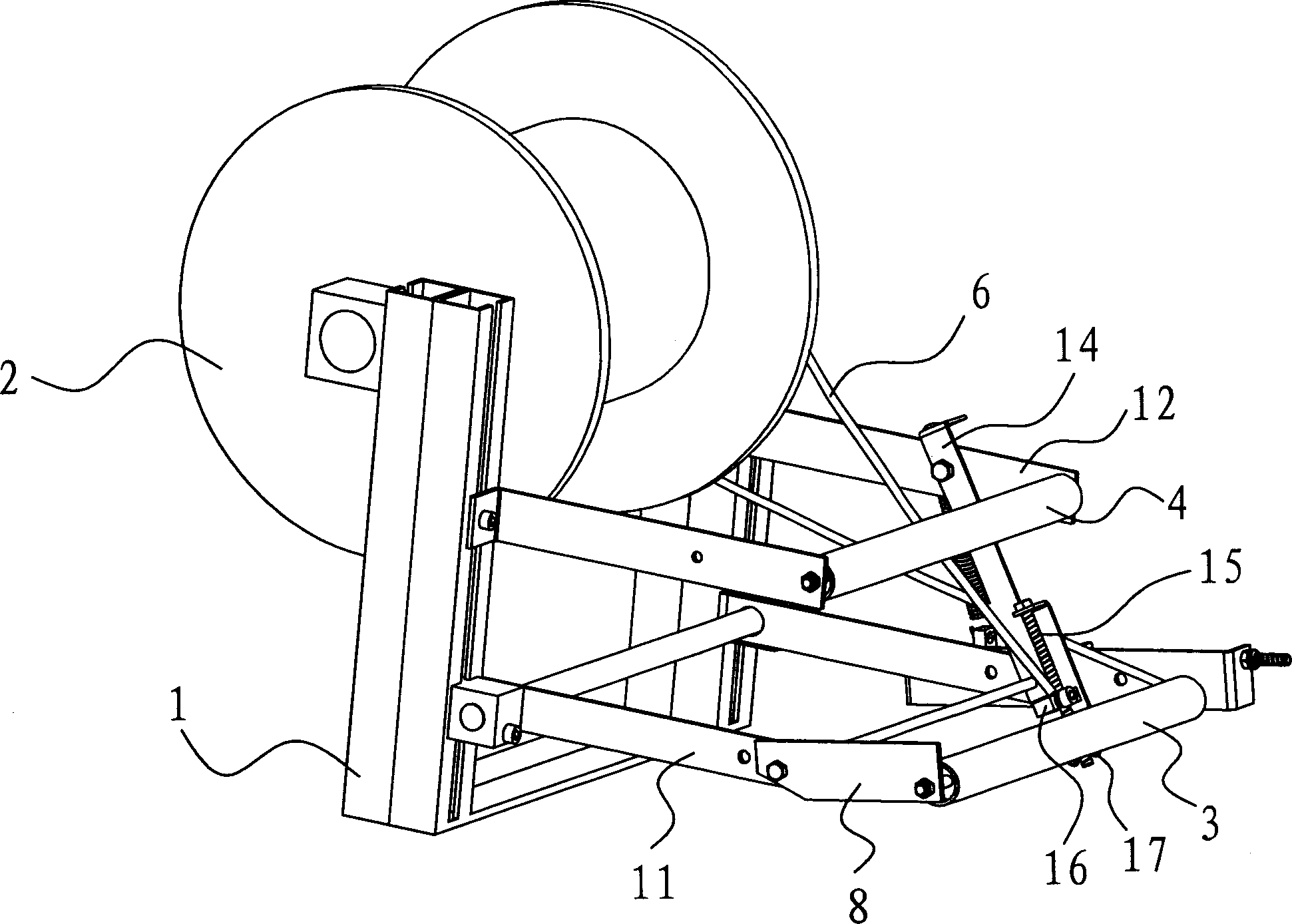

InactiveCN1916256AReduce brake resistanceUniform tension distributionAuxillary apparatusEngineeringControl theory

The present invention provides a tension control device capable of ensuring that the tensile force is nearby constant value. Said tension control device includes the following several portions: machine frame and warp beam flange, vibrating roller, fixed roller, brake wheel, brake-and-clutch lining, spring, two swinging arms and rotary arm which are placed on the machine frame and tension regulation device. Besides, said invention also provides the working principle of said tension control device and its concrete operation method.

Owner:福建百宏聚纤科技实业有限公司

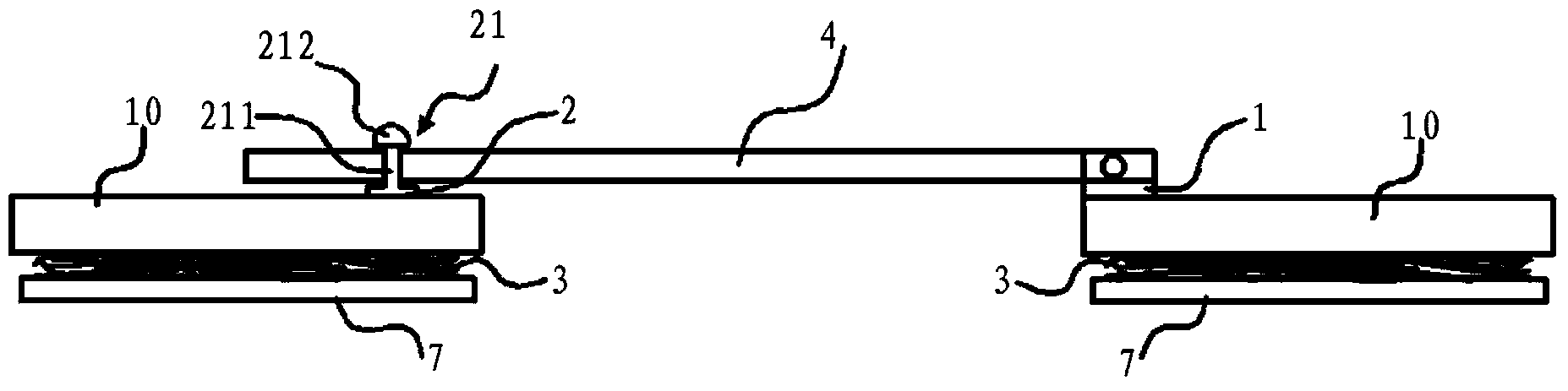

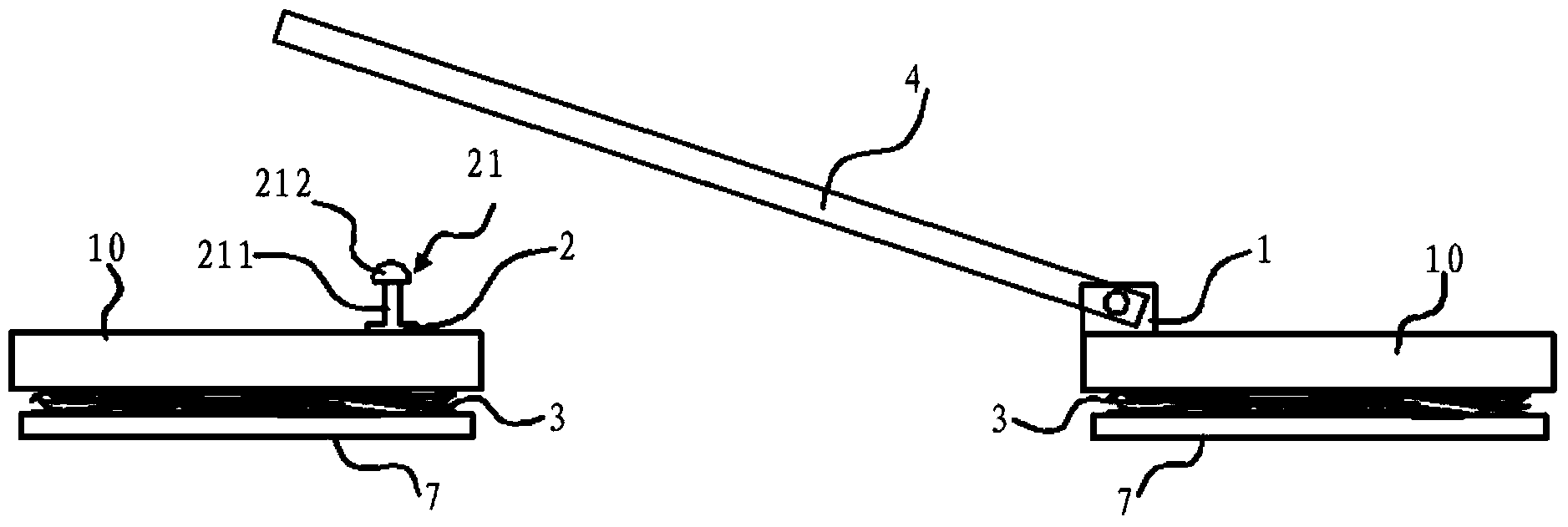

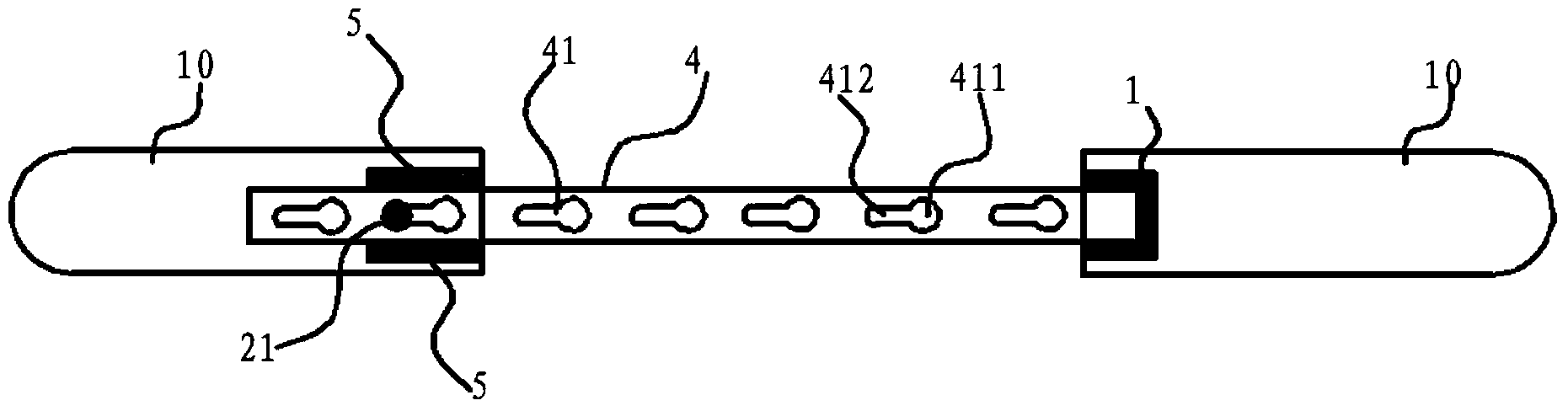

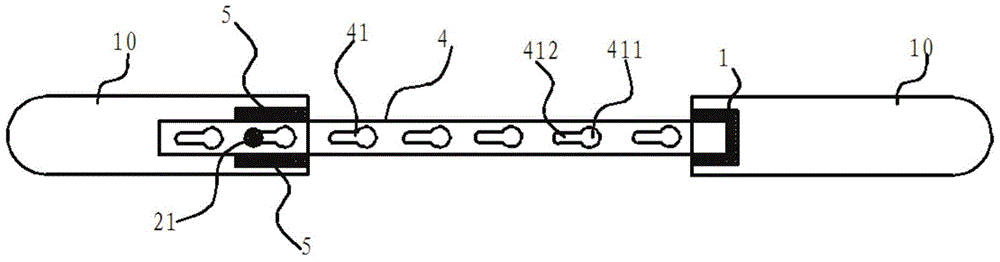

Adjustable device for fixing and easily replacing silica gel bar

The invention discloses an adjustable device for fixing and easily replacing a silica gel bar, which comprises a first fixed seat and a second fixed seat respectively positioned at two ends, wherein the first fixed seat and the second fixed seat are respectively fixed on respective adhesive patches; adhesive layers are arranged at the bottoms of the adhesive patches; a connecting strip is arranged on the first fixed seat; a plurality of clamping holes are formed in the connecting strip; clamping columns are arranged on the second fixed seat; the clamping columns can be clamped into the clamping holes. The adjustable device has the benefits that as the first fixed seat and the second fixed seat can be fixed on the two sides of the silica gel bar on a wound or a scar of a patient through respective adhesive layers; the clamping columns are clamped into the corresponding clamping holes of the connecting strip, so that the first fixed seat is connected with the second fixed seat and skin on two sides of the wound can be stitched without tension; as to the scar treatment, the silica gel bar covering the scar is fixed and compressed so as to prevent the silica gel bar from falling off, the curative effect is enhanced, and the silica gel bar covering the scar can be replaced conveniently at the same time. The adjustable device is suitable for wounds and scars with different sizes.

Owner:许晓曦

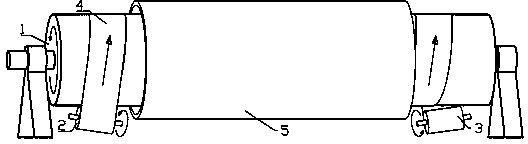

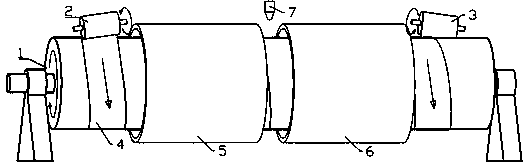

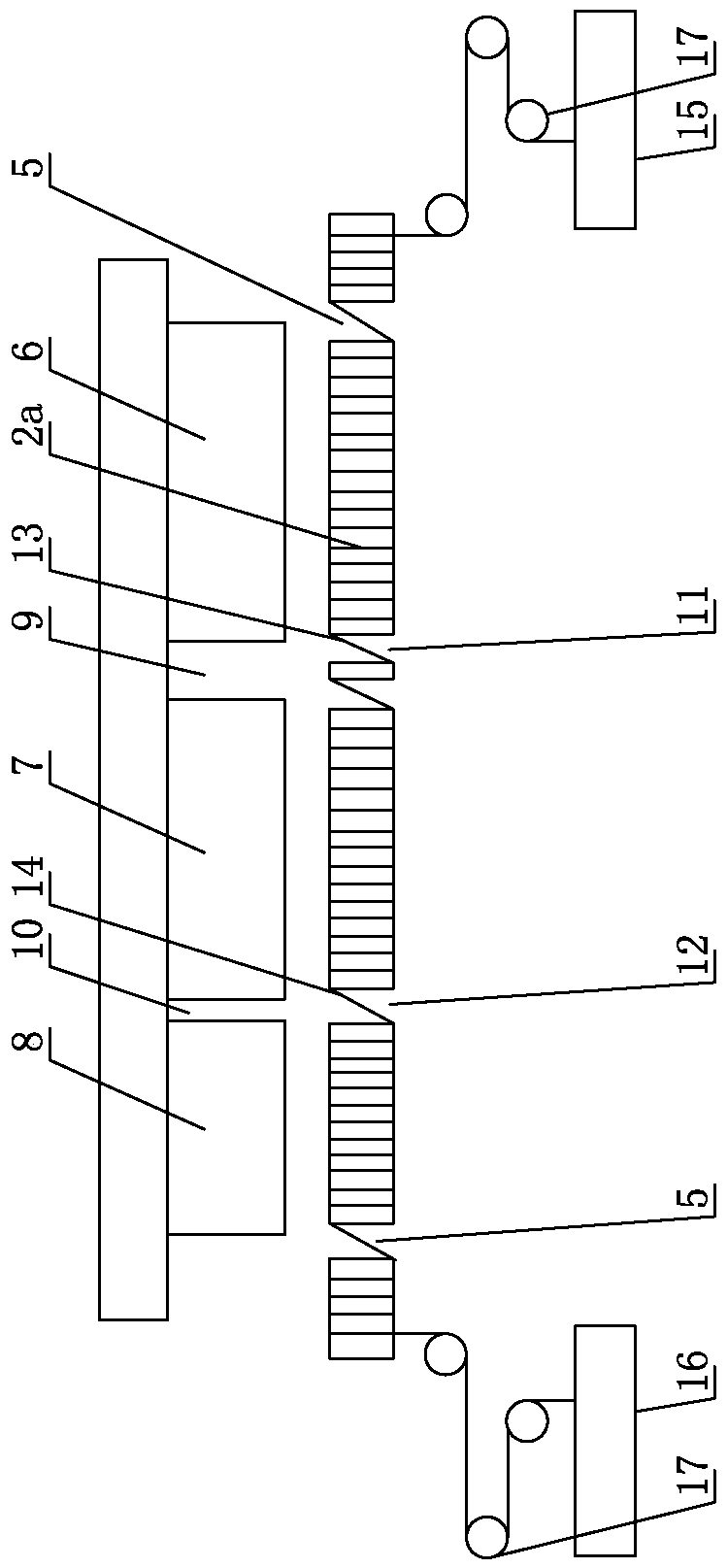

Flexible substrate foil roll-to-roll conveyer and conveying method

InactiveCN103436852AIncrease the areaShorten the lengthVacuum evaporation coatingSputtering coatingTemperature controlEngineering

The invention provides a flexible substrate foil roll-to-roll conveyer and conveying method, which are used in vacuum coating equipment and can enlarge a processing region area during a stable material conveying process so as to improve equipment productivity. According to the invention, flexible substrate foil is tightly jointed to and wound on the outer surface of the roller of a winding mechanism in a spiral way, the flexible substrate foil is driven to rotate to advance in a screw type through the rotation of the winding mechanism, through coordination with actions of an unwinding mechanism and a winding mechanism, the flexible substrate foil roll-to-roll conveying process is achieved. A coating or processing device can be arranged in a space on the circumference of the middle part of the winding mechanism according to requirements. The interior of the winding mechanism is provided with a device with heating and cooling functions, or the winding mechanism serves as a ground joint, and the winding mechanism not only has a function of providing a power source for conveying material, but also has a function of controlling the temperature of the flexible substrate foil. According to the invention, parallel tandem arrangement can be performed conveniently, and the purpose of adjusting procedures or expanding productivity can be achieved.

Owner:胡增鑫

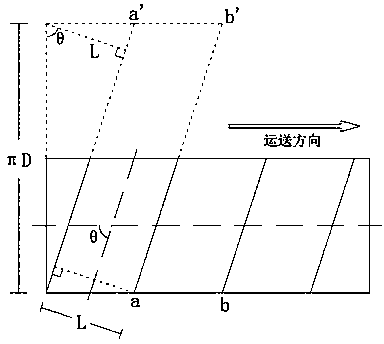

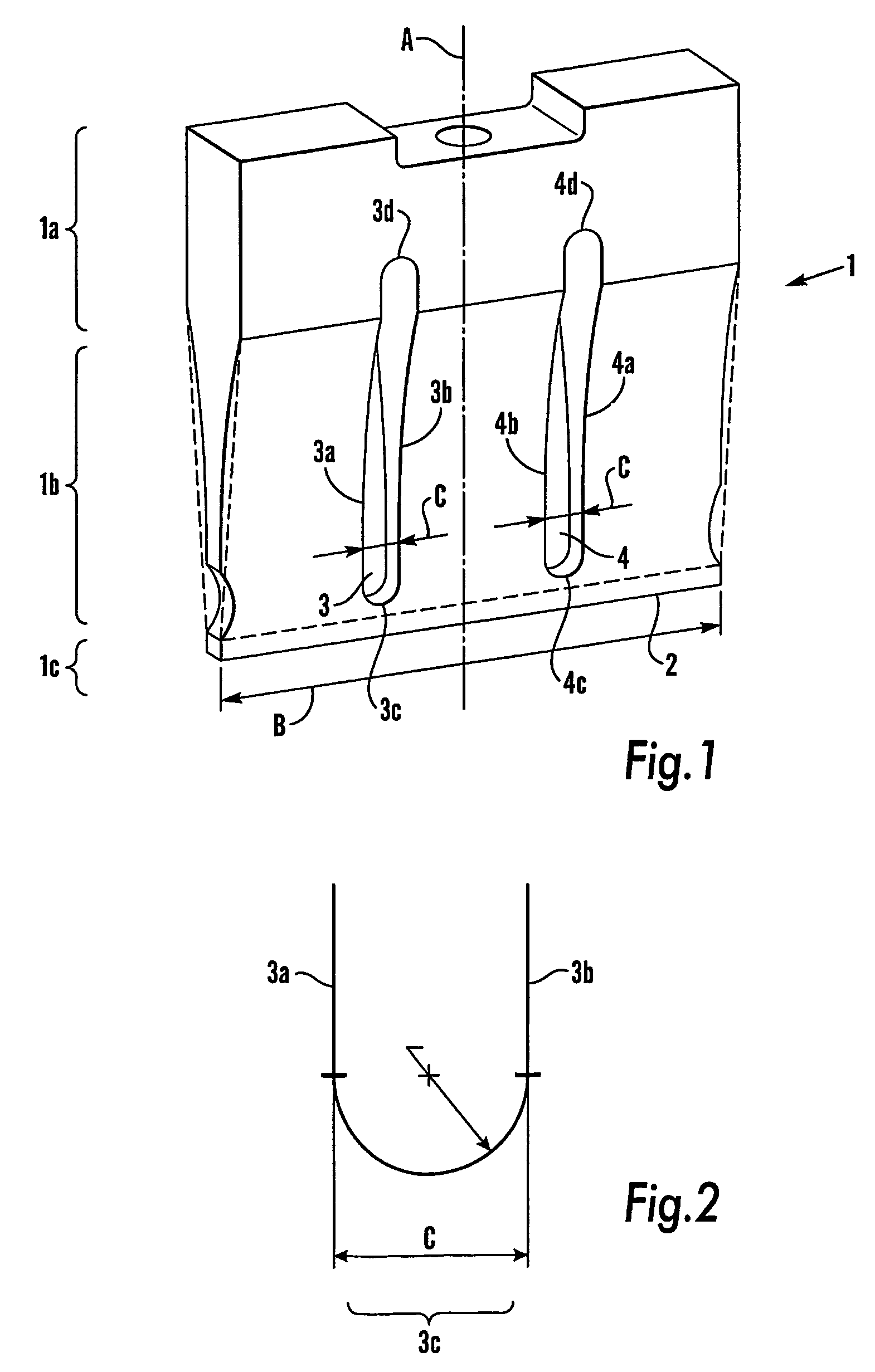

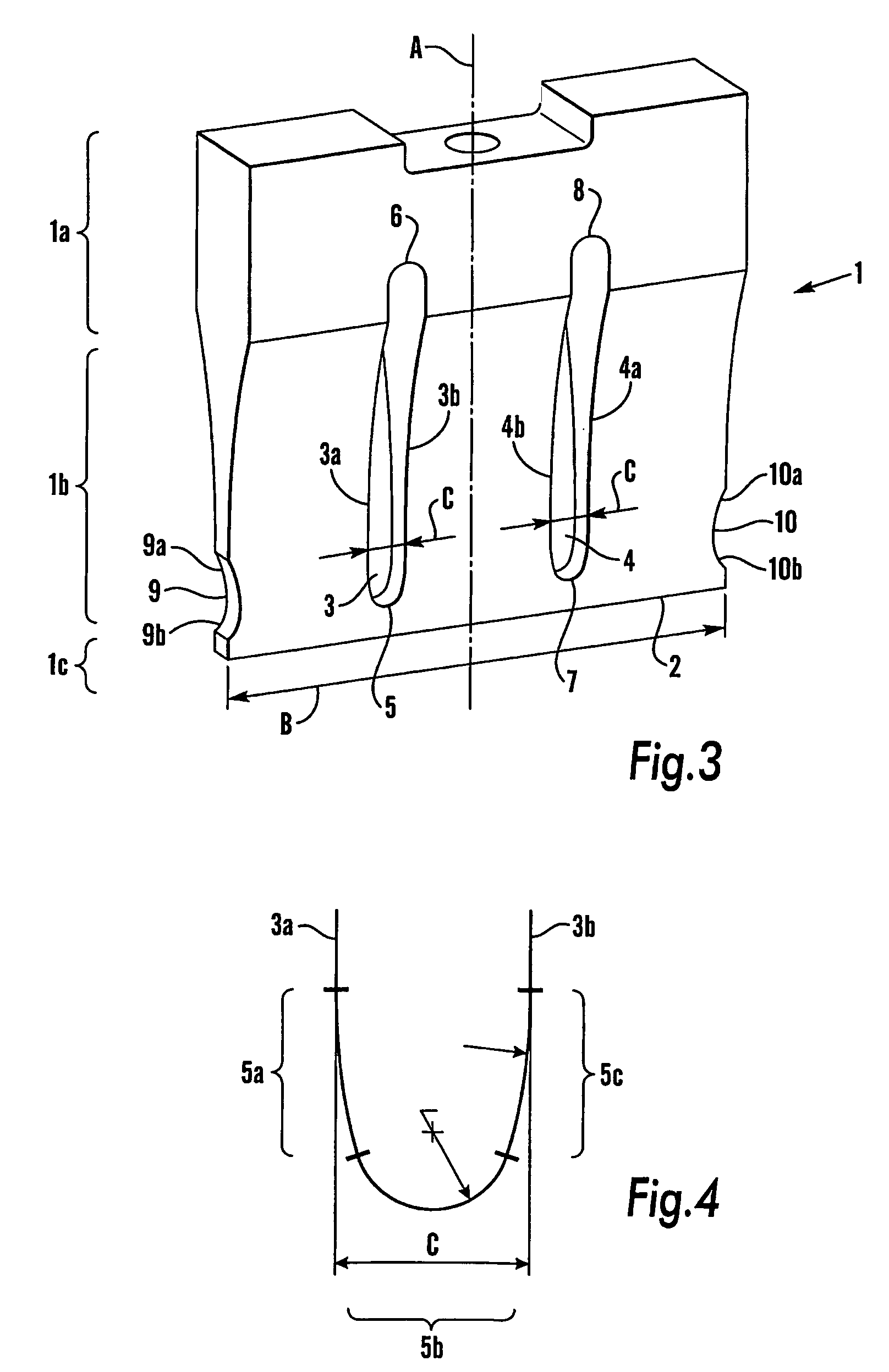

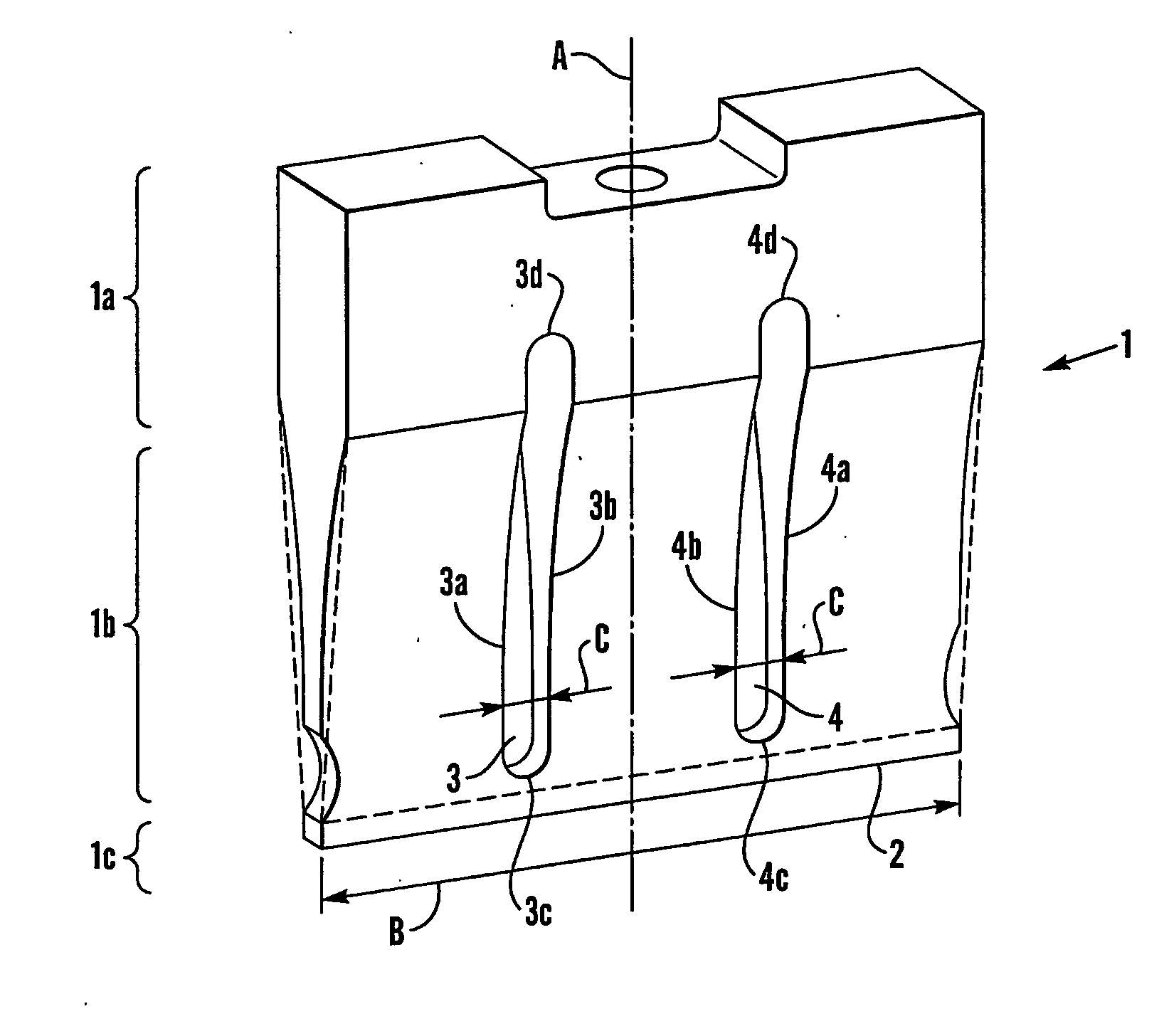

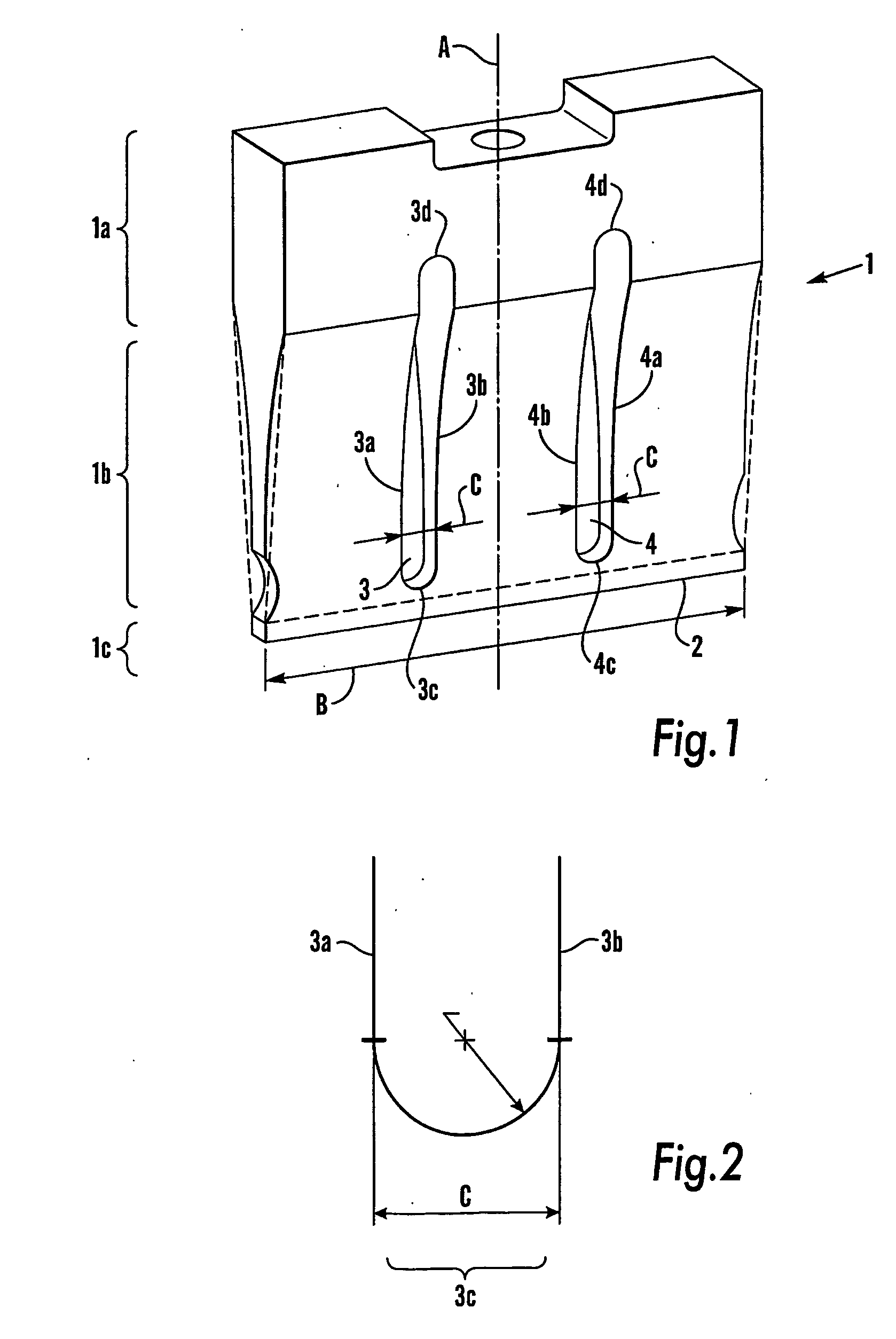

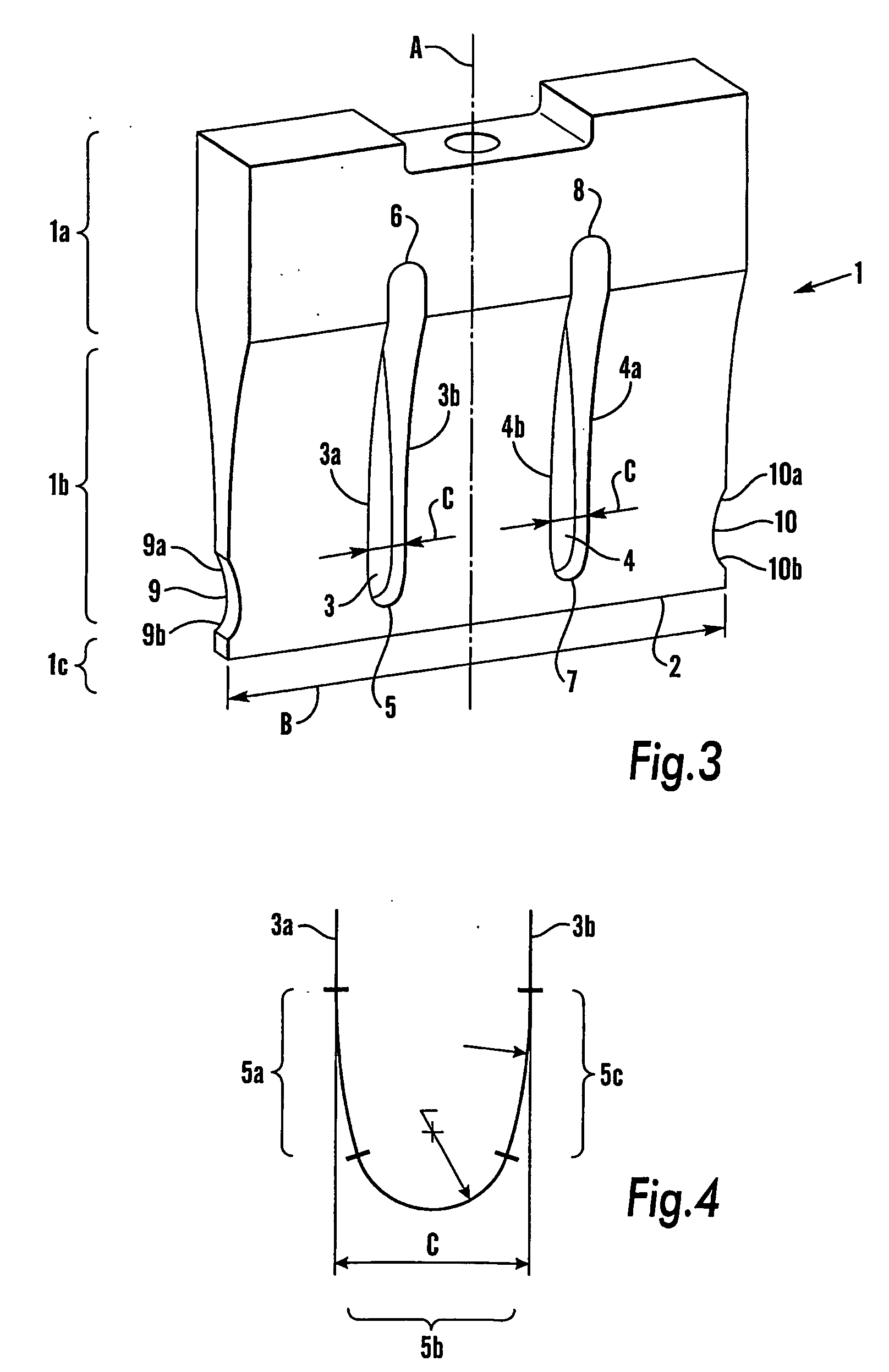

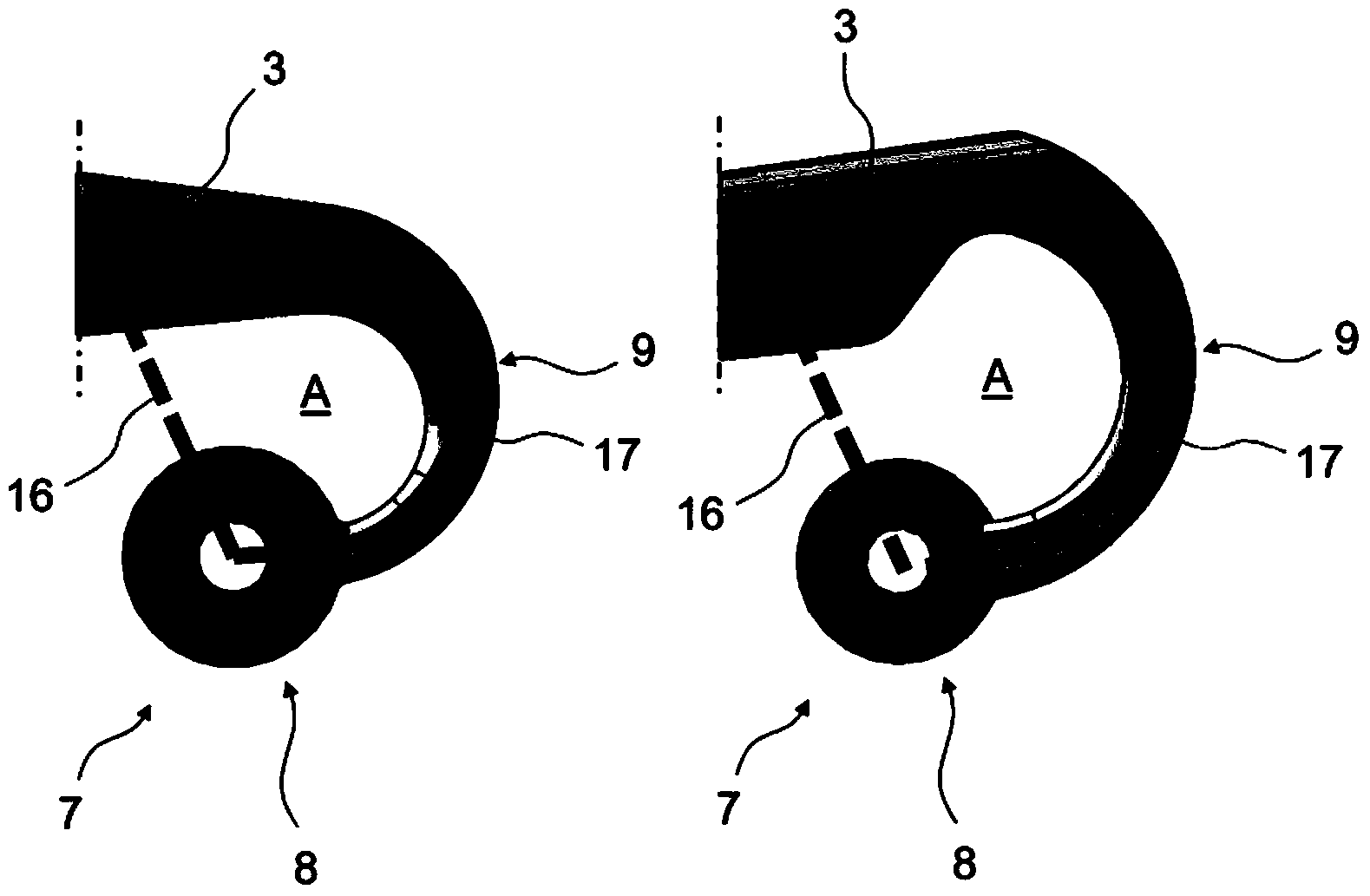

Ultrasound horn

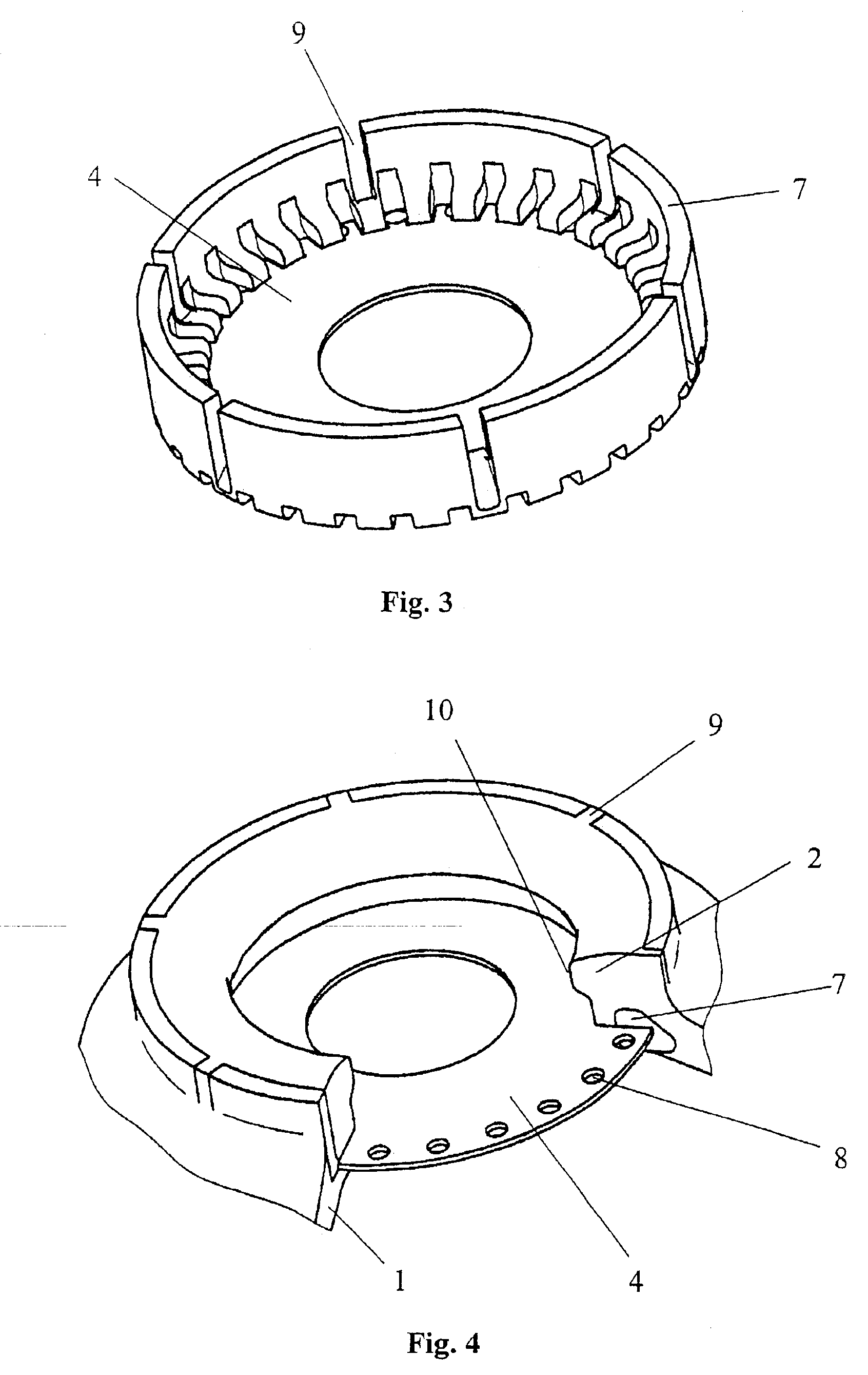

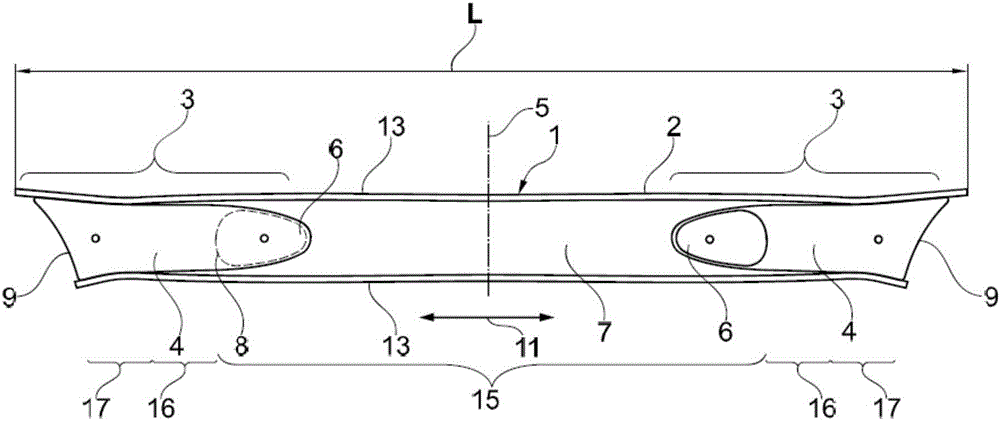

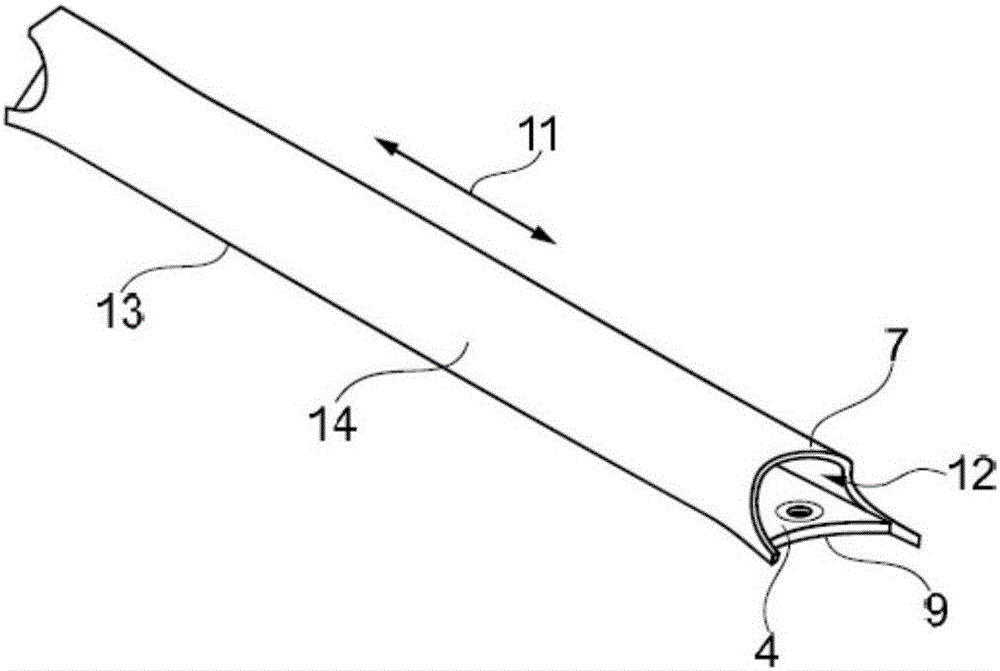

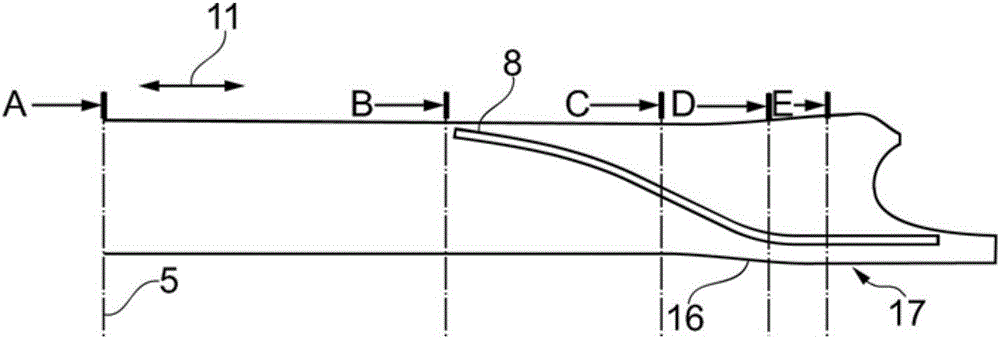

InactiveUS7122097B2Uniform tension distributionReduce maximum tensionLaminationLamination apparatusUltrasoundElectrical and Electronics engineering

The invention relates to an ultrasound horn comprising a fixing section (1a), a sealing section (1c) and a transfer section (1b) extending therebetween, one or more elongate recesses (3, 4) being formed at least in the transfer section (1b), and said recesses (3, 4) extending in a direction (A) between the fixing section (1a) and the sealing section (1c). Said recesses (3, 4) have a rounding-off encompassing, along the rounding-off, at least a first portion (5a, 7a) with a first radius of curvature, a second portion (5b, 7b) with a second radius of curvature and a third portion (5c, 7c) with a third radius of curvature. The invention also relates to a novel forming of the transfer section (1b) and recesses (9, 10) at the ends of the sealing section (1c).

Owner:TETRA LAVAL HLDG & FINANCE SA

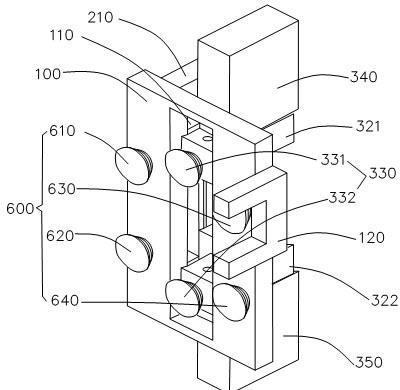

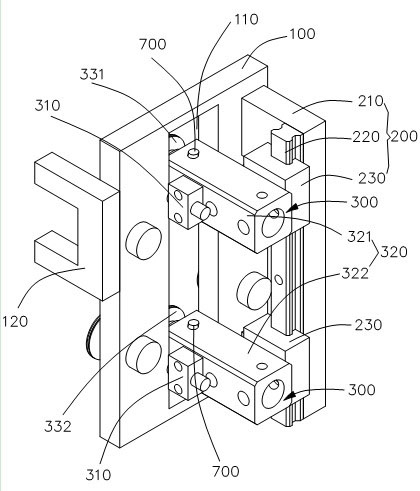

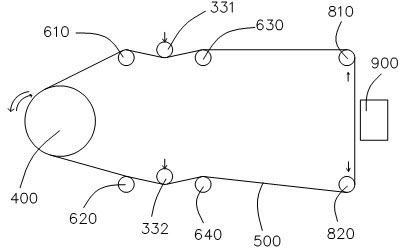

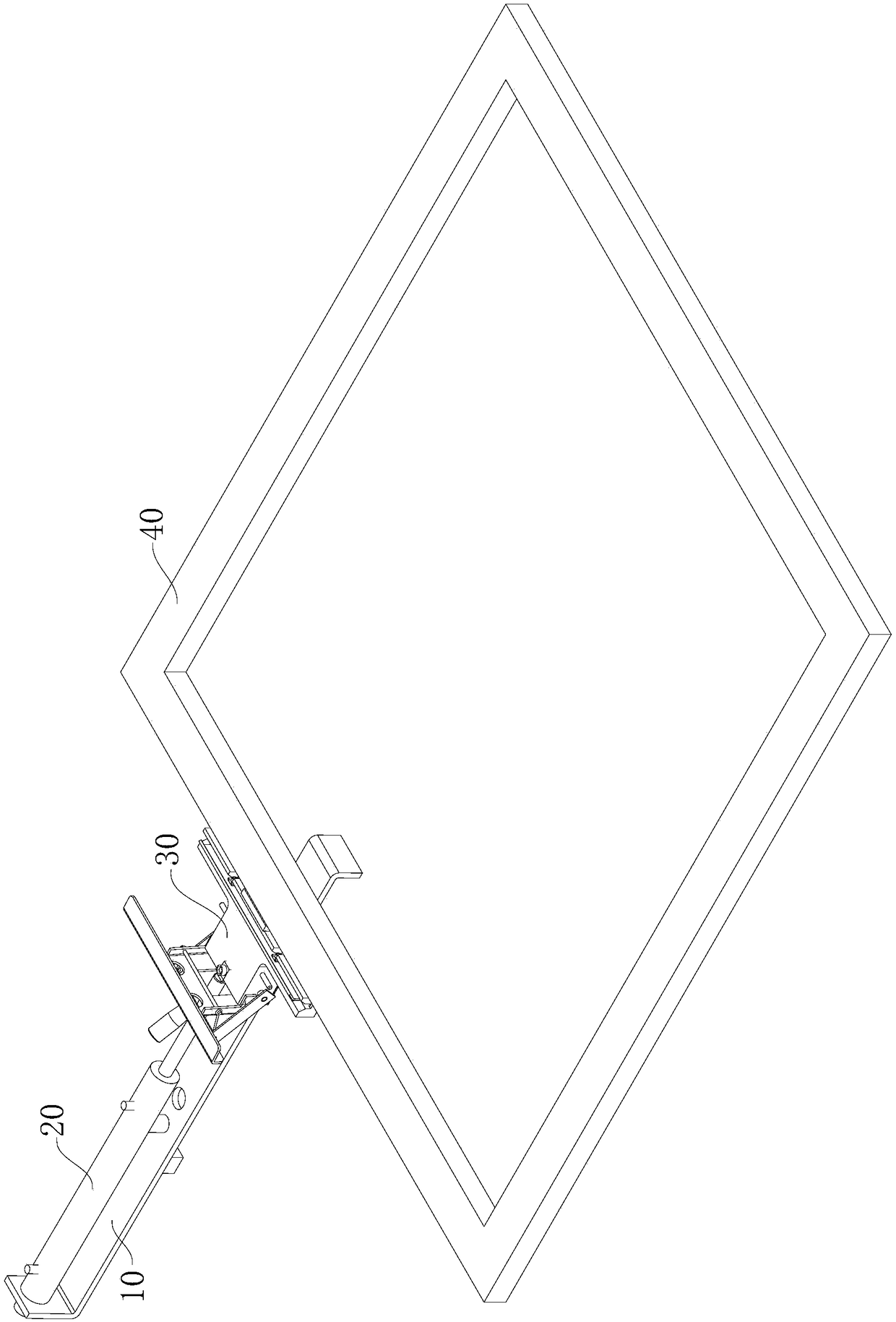

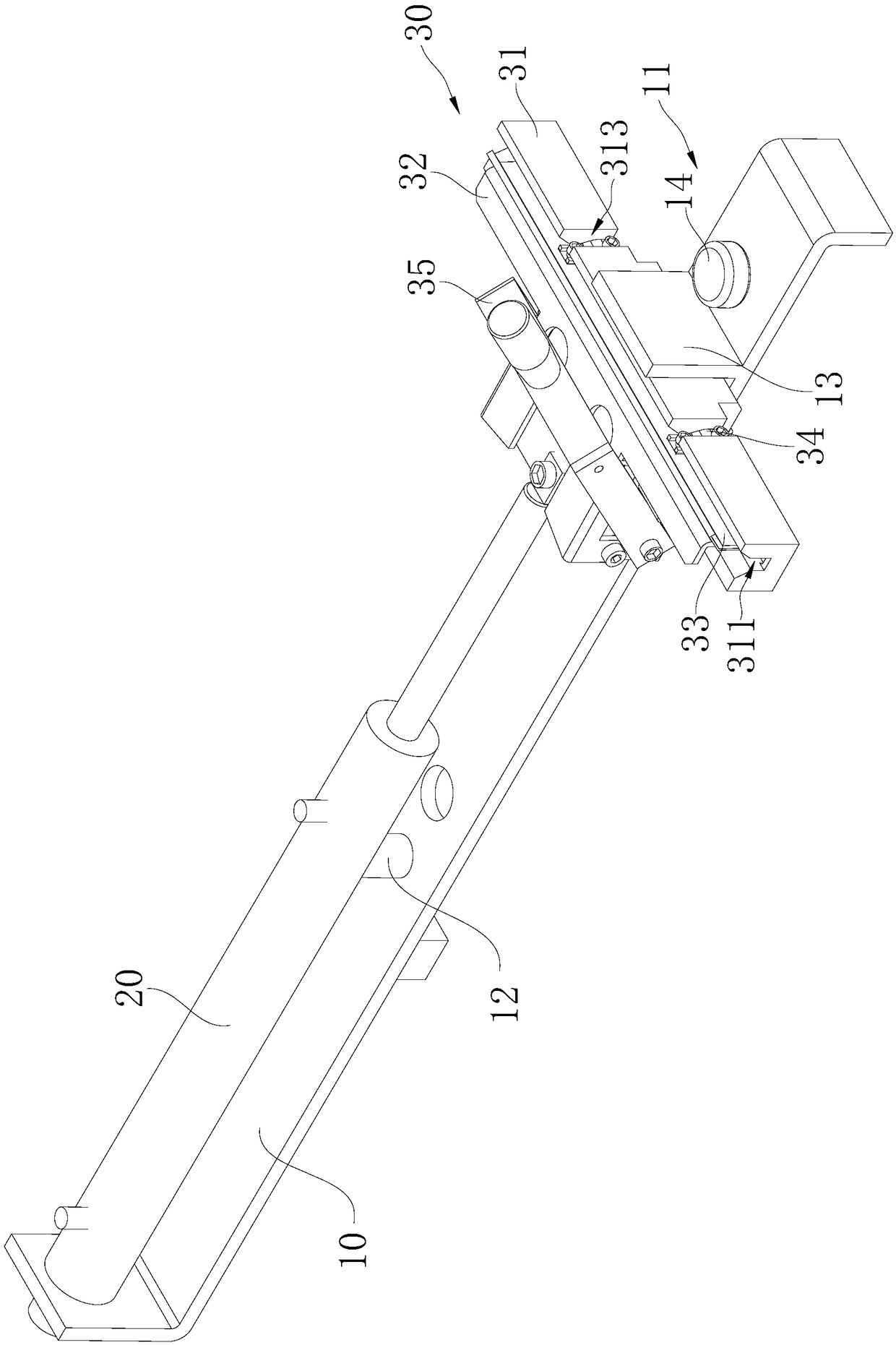

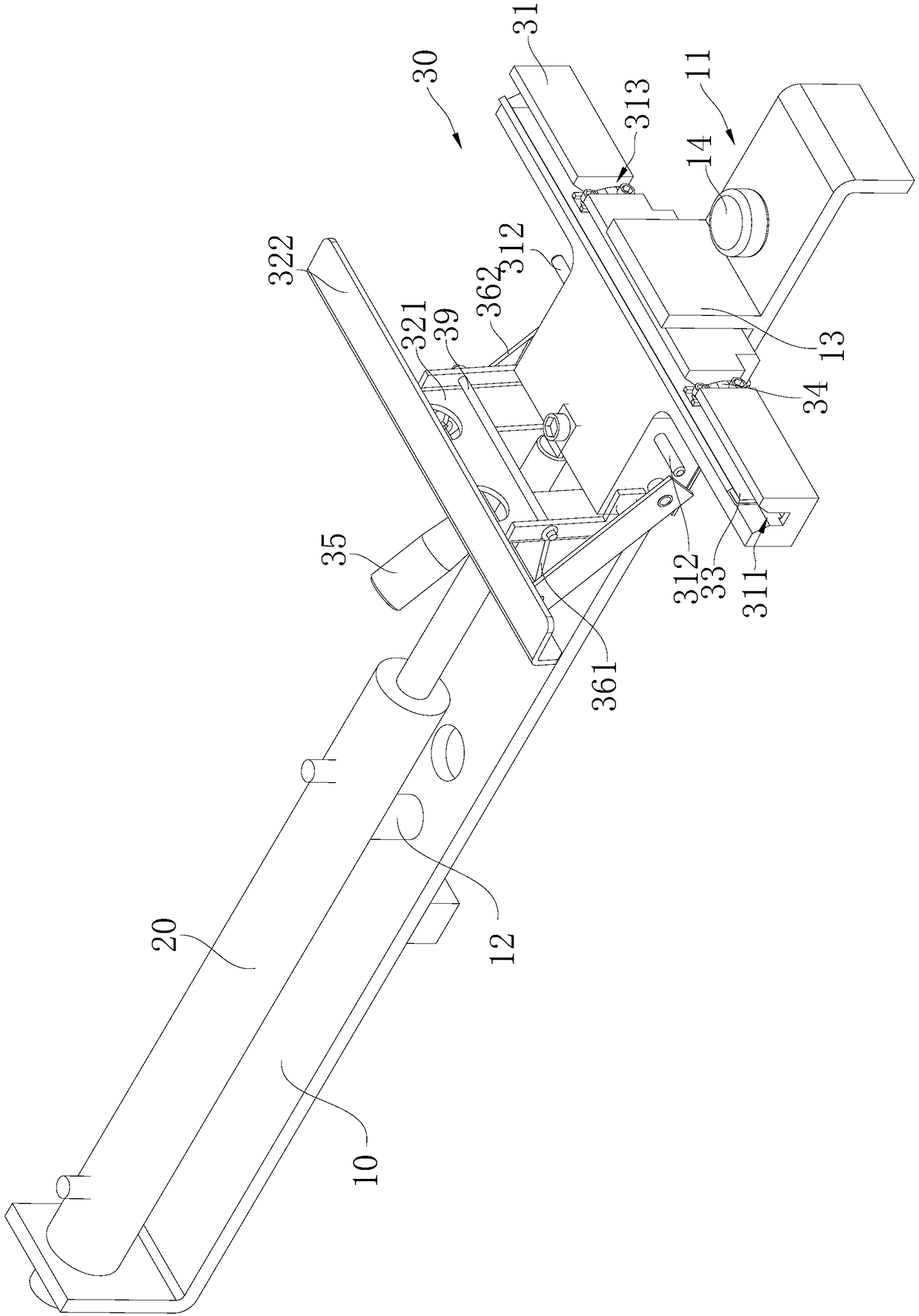

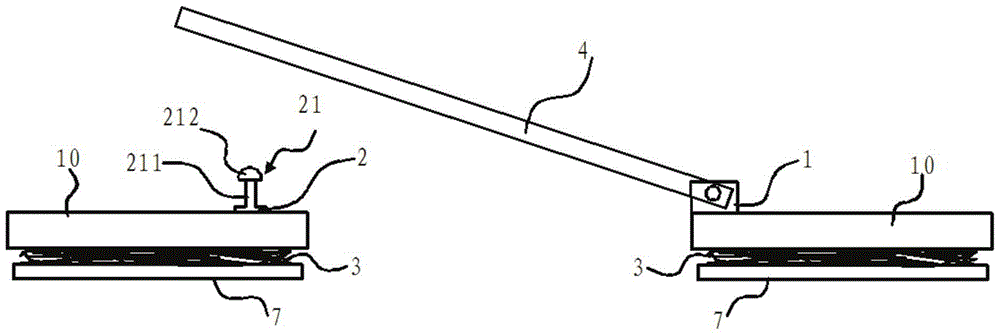

Cutting device suitable for adjustment of diamond wire mesh and cutting method

InactiveCN110466082AStable tensionUniform tension distributionFine working devicesMechanical engineeringWire mesh

The invention discloses a cutting device suitable for adjustment of a diamond wire mesh and a cutting method, and belongs to the field of photovoltaic products. According to the cutting device, the cutting wire mesh is arranged between two wire guiding wheels, a plurality of crystal rods are fixedly mounted on a crystal holder, edge cutting gaps are formed in the first end and the tail end, at thewire guiding wheels, of the cutting wire mesh correspondingly, the two edge cutting gaps correspond to the edge of the left side of the crystal rod located on the left side, and the edge of the rightside of the crystal rod located on the right side correspondingly, and a first diamond wire at the wire inlet end and a first diamond wire at the wire outlet end of the cutting wire mesh are arrangedwith the corresponding crystal rods in a staggered mode. The method comprises the steps that the crystal holder moves downwards, thus all the crystal rods descend at the speed of 2.0-2.2 mm / min, allthe crystal rods start to be cut after making contact with the cutting wire mesh, and the first crystal rod, the second crystal rod and the third crystal rod are cut simultaneously through the cuttingwire mesh. The first wire at the wire inlet end and the first wire at the wire outlet end of the cutting wire mesh can be prevented from being broken; and by adjusting the length of the cutting gaps,the crystal rods of different lengths can be quickly switched to be cut.

Owner:扬州续笙新能源科技有限公司

High capacity rectangular flexible cable and preparation technology thereof

InactiveCN102063957AIncrease capacityHigh tensile strengthNon-insulated conductorsFlexible cablesCarrying capacityElectrical conductor

The invention discloses a high capacity rectangular flexible cable and a preparation technology thereof. The preparation technology of the high capacity rectangular flexible cable is characterized in that the lamination copper bar is superposed with 2 layers or more than 2 layers copper bar, and carrys out by adopting approximate common round cable pay-off equipment to pay-off, a conductor outer layer formed by the lamination copper bar is an insulating layer, the insulating layer is extruded by a cable extrusion machine with a rectangular extruding mold, and the cross section of the high capacity rectangular flexible cable is rectangular or approximately rectangular. The high capacity rectangular flexible cable has the advantages that the capacity is higher, and the current carrying capacity is larger: the cross section of the cable is rectangular, if the cross section is same, the rectangular cable has larger electric current than that of the round cable; the bending radius is smaller: the bending radius is smaller than that of the round cable with the same cross section; the high capacity rectangular flexible cable is convenient to install: manual installation requires smaller space, and special equipment is not required in installation; the high capacity rectangular flexible cable is more convenient to connect, a terminal is not required to install, and installation time is saved; and the tensile strength is extremely high: because the rectangular cable conductor uses the copper bar, and the strain distribution on the width of the cable is uniform.

Owner:NANJING QUANXIN CABLE TECH

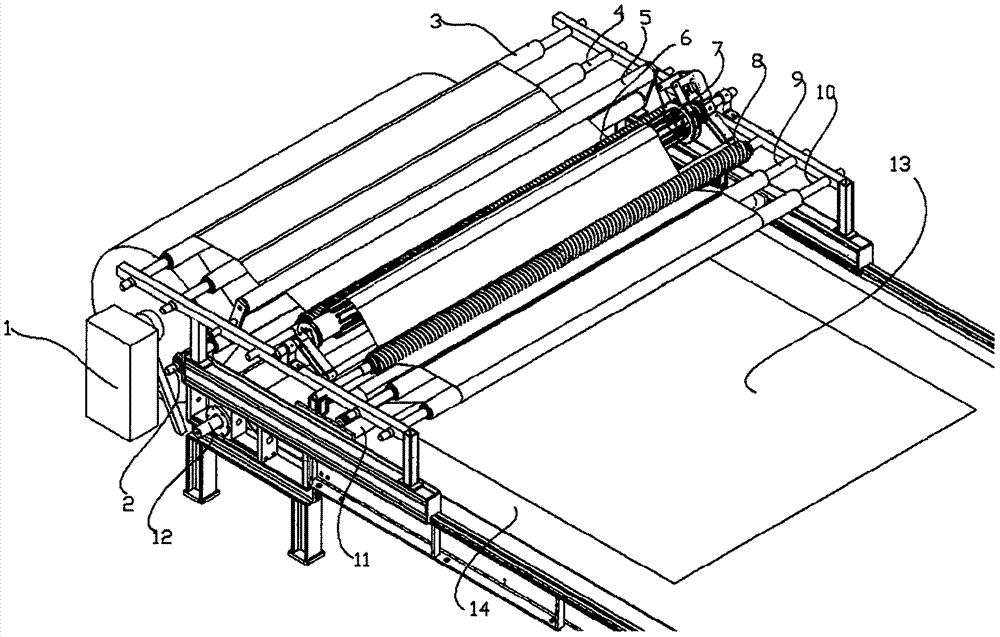

Cloth feeding method of digital printing and flat screen printing integrated machine

InactiveCN106986217AImprove flatnessUniform tension distributionWebs handlingScreen printingDevice type

The invention discloses a cloth feeding method for a digital and flat screen integrated machine. The method belongs to the technical field of textile printing. The method enables the nozzle group of the digital printing machine to scan the effective width of the inkjet in a single scan, and the scraper of the flat screen printing machine to scrape once. The printing width, the intermittent positioning width of the printing guide belt, and the cloth feeding length of the A-type unwinding device are consistent. The steps of the cloth feeding method of the digital flat screen integrated machine are as follows: the gray cloth enters the first cloth guide roller from the A-type unwinding device, Then go through the second cloth guide roller, the third cloth guide roller and the angle adjustment roller, then to the first wire dividing roller, the edge correction device, then to the second dividing roller, the fourth cloth guiding roller, the fifth cloth guiding roller, And then to the floating press roller; due to the large contact area and long time of the floating press roller, the tension distribution of the gray fabric on the surface of the guide belt is even and the flatness is good, which greatly improves the printing quality.

Owner:温泉

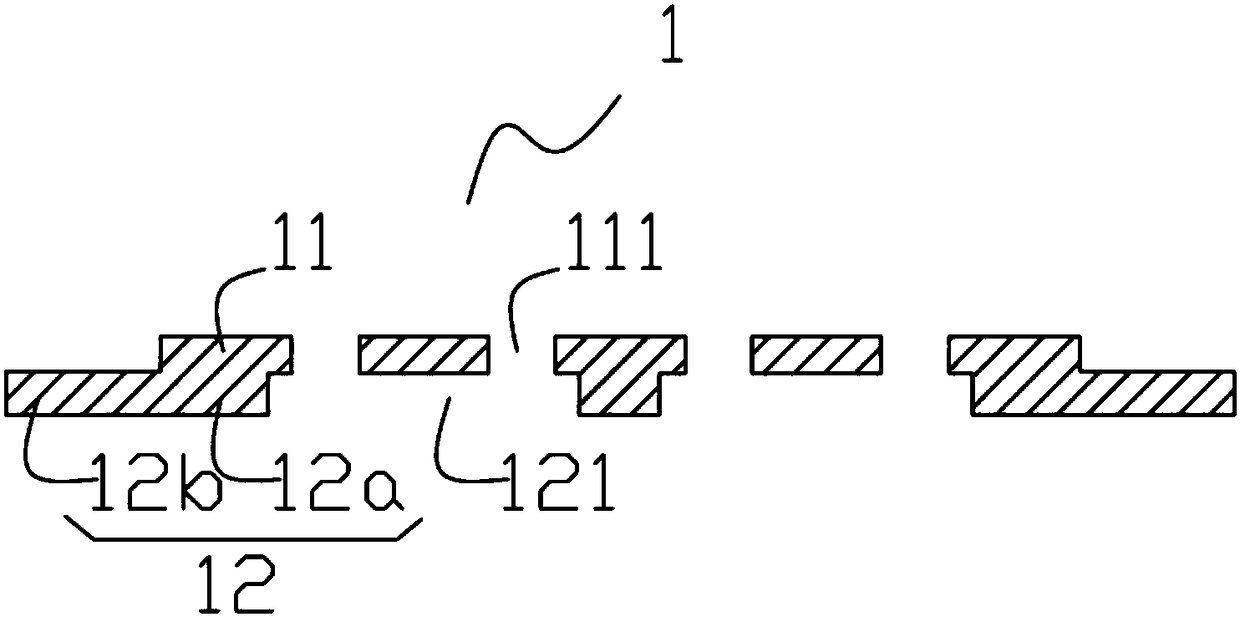

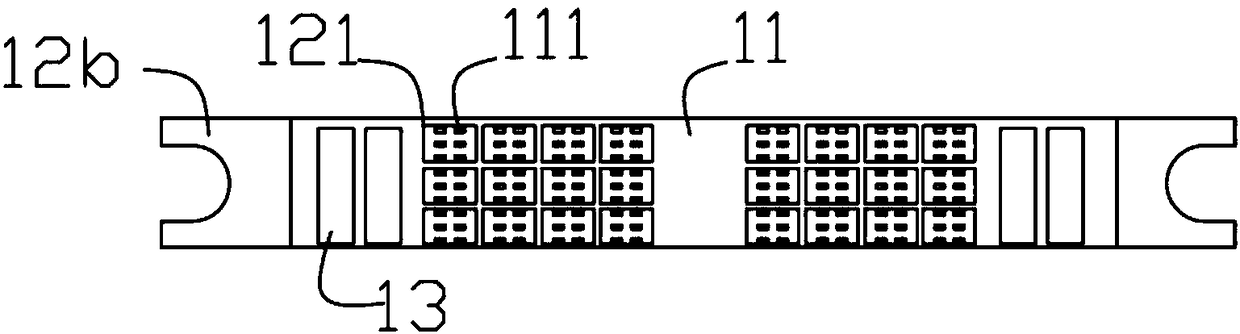

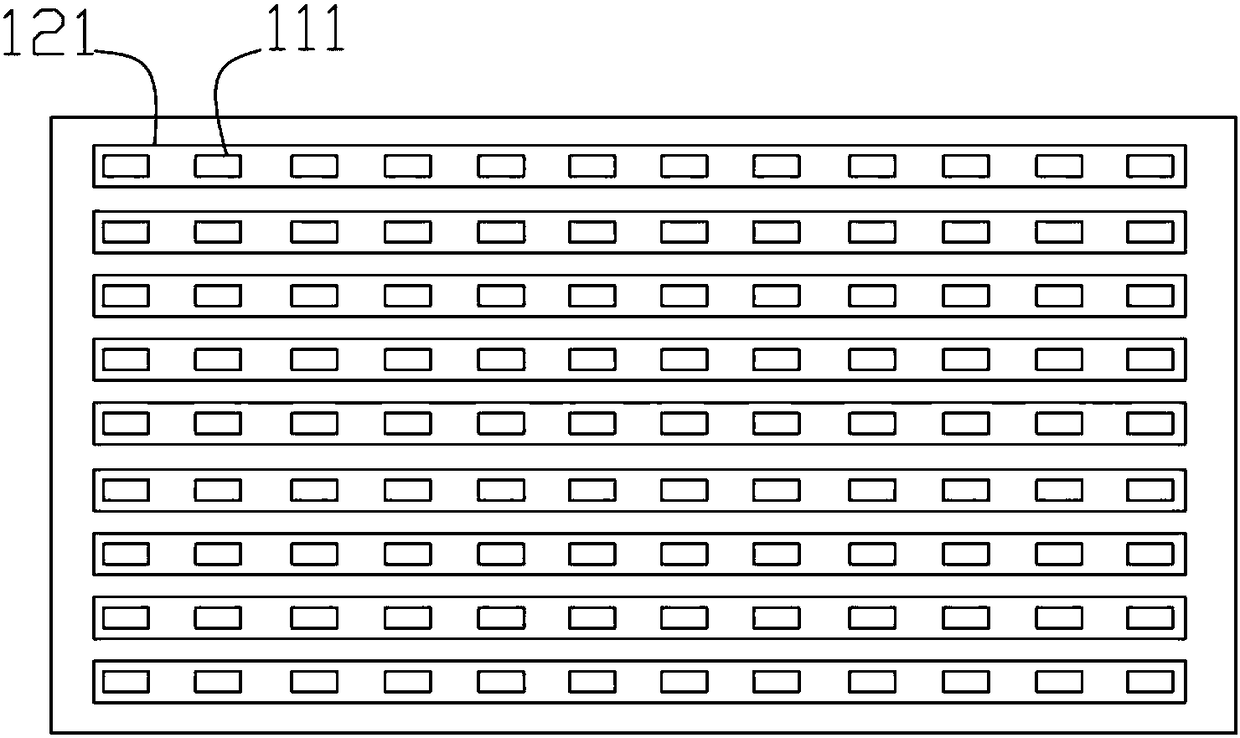

Mask plate and making method thereof

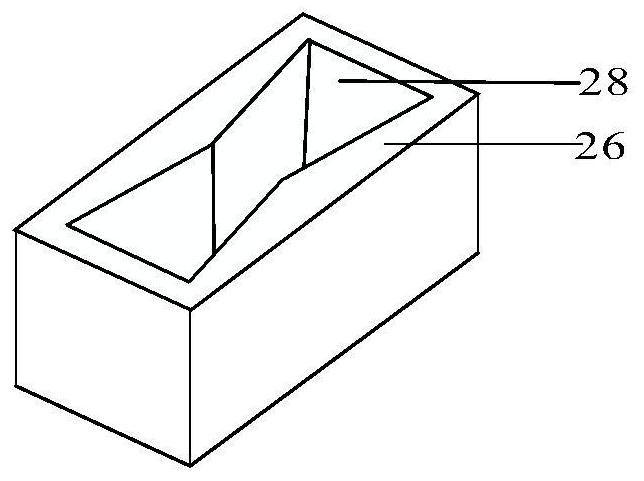

ActiveCN108281575AUniform tension distributionHigh mechanical strengthVacuum evaporation coatingSolid-state devicesWrinkle skinEngineering

The invention provides a mask plate and a making method thereof. The mask plate comprises a graph layer and a stretching layer, a first opening is formed in the graph layer, the stretching layer comprises a stretching portion and two clamping portions, the stretching portion is arranged on a first face of the graph layer, a second opening is formed in the stretching portion, orthographic projection of the second opening on the first face of the graph layer completely covers that of the first opening, and the two clamping portions respectively protrude from two opposite sides of the first faceof the graph layer. Inside stress uniformity can be improved, and mechanical strength is improved, so that wrinkles can be reduced.

Owner:BOE TECH GRP CO LTD

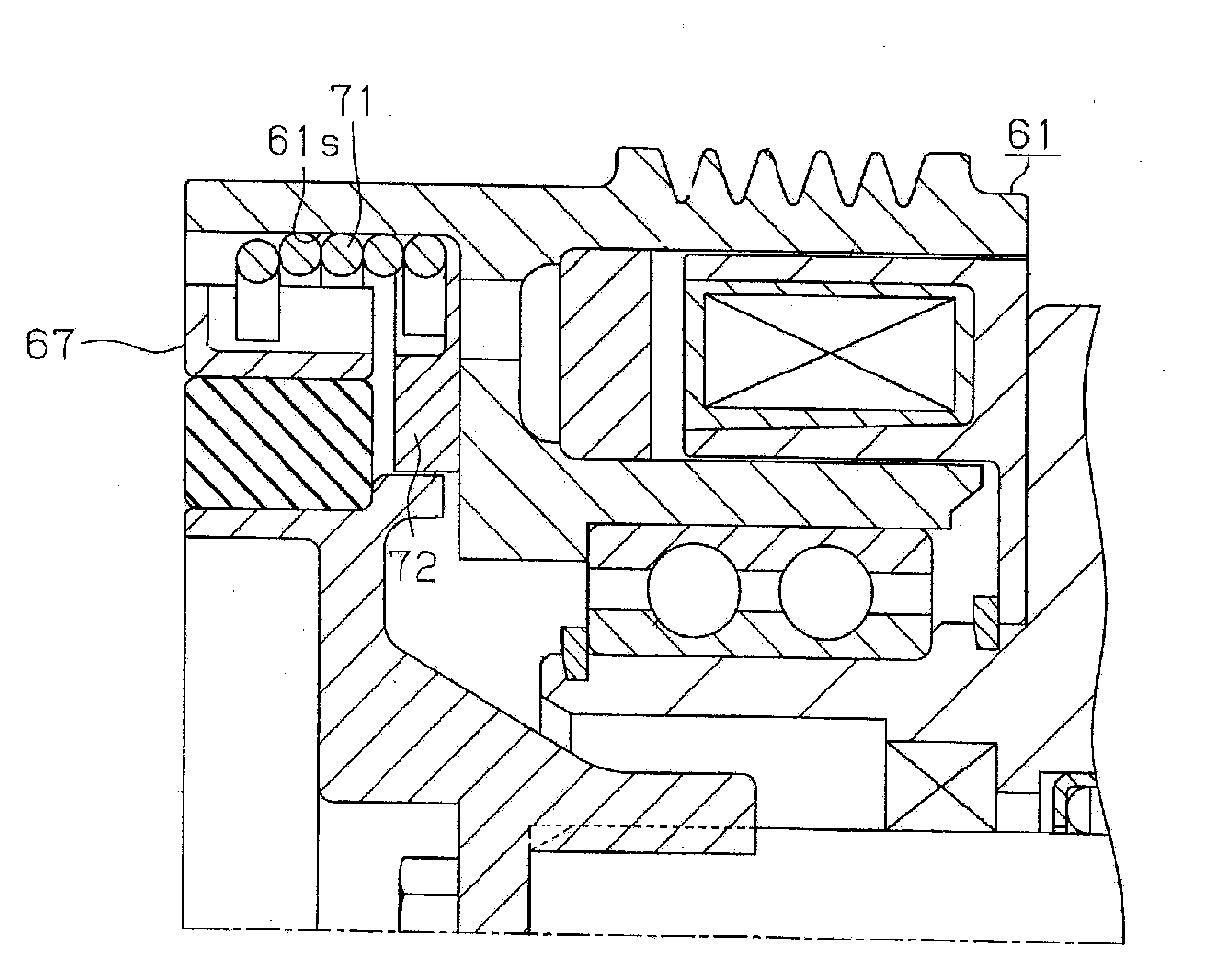

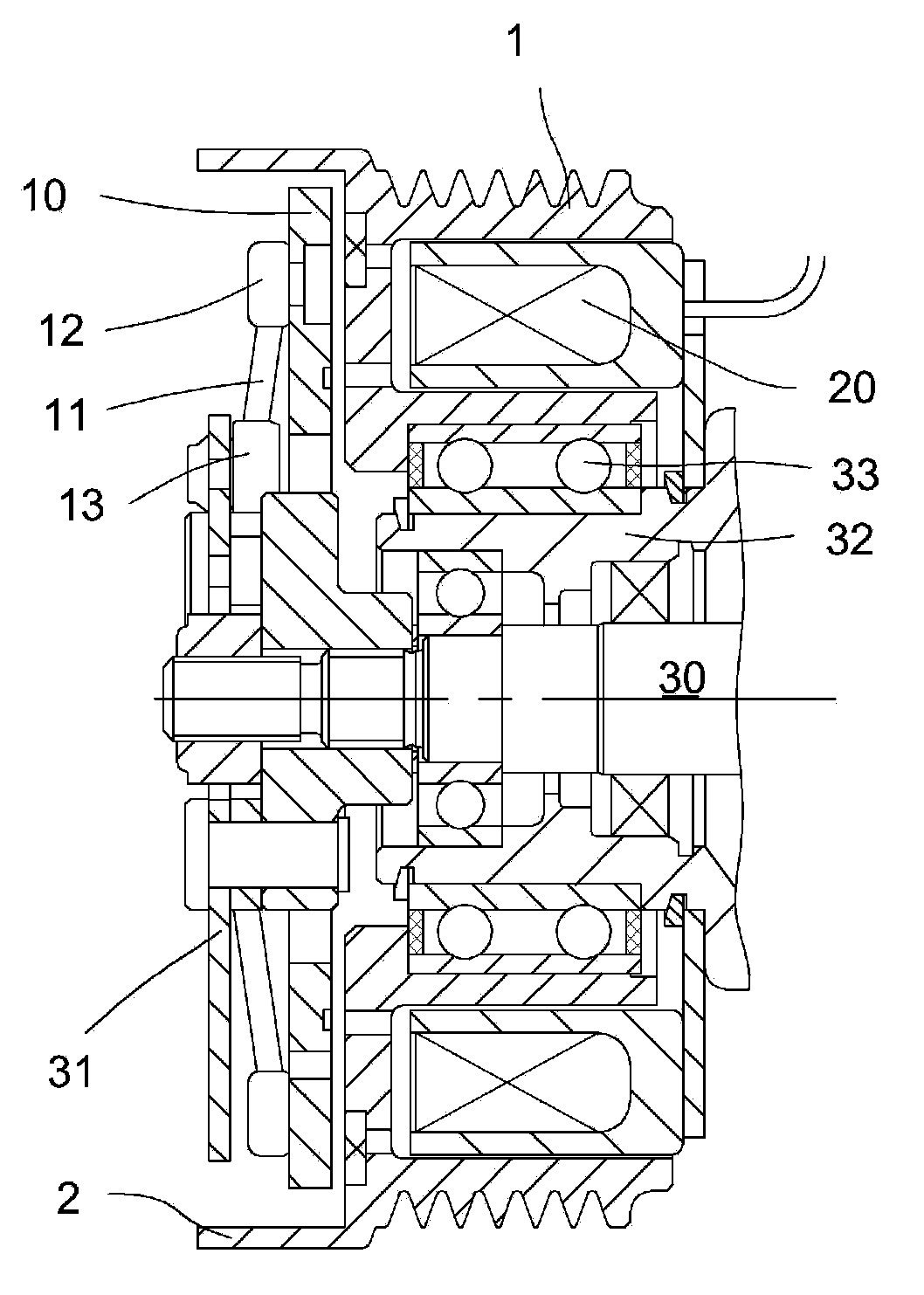

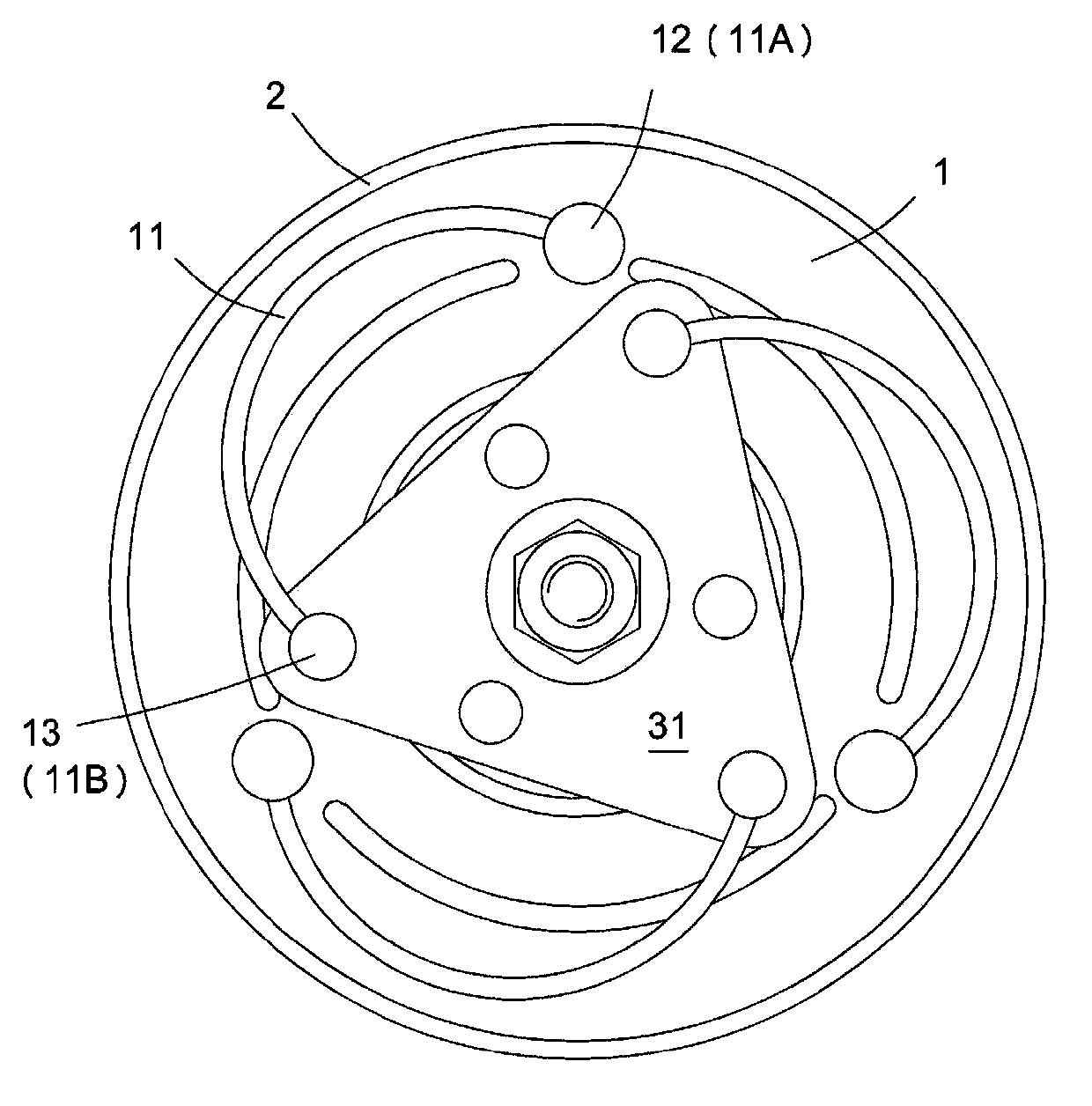

Electromagnetic clutch

InactiveCN103867600APrevent slippingUniform tension distributionPositive displacement pump componentsMagnetically actuated clutchesElastomerElectromagnetic clutch

The invention discloses an electromagnetic clutch which can prevent slipping. The electromagnetic clutch comprises a first rotating member, a second rotating member, a sucker arranged relative to the first rotating member and an excitation coil arranged on the first rotating member and is characterized in that at least three elastomers are connected between the sucker and the second rotating member, one end of every elastomer is connected with the sucker, and the other end of every elastomer is connected with the second rotating member, the first rotating portion is provided with contact portions, and the first rotating member sucks the sucker through the excitation coil, so that when the sucker rotates relative to the second rotating member, the elastomers achieve radial deformation and are in contact with the contact portions of the first rotating member to generate friction which can prevent slipping of the sucker and the first rotating member.

Owner:SANDEN HUAYU AUTOMOTIVE AIR CONDITIONING CO LTD

Ultrasound horn

InactiveUS20050028942A1Reduce tension levelUniform tension distributionLaminationLamination apparatusUltrasoundMechanical engineering

The invention relates to an ultrasound horn comprising a fixing section (1a), a sealing section (1c) and a transfer section (1b) extending therebetween, one or more elongate recesses (3, 4) being formed at least in the transfer section (1b), and said recesses (3, 4) extending in a direction (A) between the fixing section (1a) and the sealing section (1c). Said recesses (3, 4) have a rounding-off encompassing, along the rounding-off, at least a first portion (5a, 7a) with a first radius of curvature, a second portion (5b, 7b) with a second radius of curvature and a third portion (5c, 7c) with a third radius of curvature. The invention also relates to a novel forming of the transfer section (1b) and recesses (9, 10) at the ends of the sealing section (1c).

Owner:TETRA LAVAL HLDG & FINANCE SA

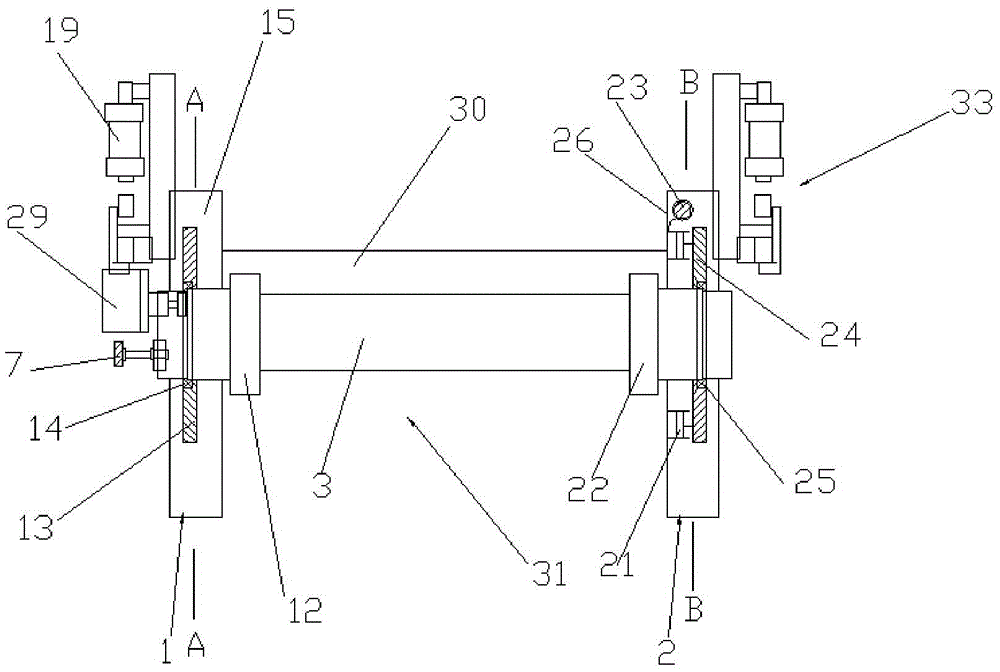

Wire-feeding mechanism for medium-speed wire cutter

InactiveCN102615365AAdjustable positionUniform tension distributionElectrical-based machining electrodesEngineeringWire cutter

A wire-feeding mechanism for a medium-speed wire cutter comprises a wire storage drum, an electrode wire, a frame and a guide wheel disposed on the frame. The electrode wire is wound on the wire storage drum and the guide wheel. A guide rail mechanism is connected to the frame, a tension device is connected to the guide rail mechanism and the tension device slides along the guide rail mechanism. The tension device comprises a balancing weight, a balancing weight support and a tension wheel, wherein the balancing weight is disposed on the balancing weight support and the tension wheel is disposed at the end of the balancing weight support. The wire feeding mechanism is simple in structure, reasonable in design, low in manufacture cost, stable in operation, can control tension of the electrode wire effectively, no shaking or deformation of the electrode wire occurs, tension is distributed evenly at each support of the electrode wire, so that machining precision of workpieces are increased and guaranteed.

Owner:东莞汉为智能技术有限公司

Articulated connection for transferring a steering movement onto a vehicle wheel

ActiveCN104108420AUniform tension distributionIncrease the lengthSteering linkagesResilient suspensionsEngineeringControl theory

Owner:FORD GLOBAL TECH LLC

Circular screen head of circular screen printer

InactiveCN105584200AReduce tensionEasy to change screenScreen printersMechanical engineeringEngineering

The invention discloses a circular screen head of a circular screen printer. The circular screen head comprises a circular screen, a transmission side circular screen head body and a pump side circular screen head body. Two or more oil cylinders, a pump side screen head bearing seat, a pump side screen heat shaft bushing and an injecting oil cylinder connected with all the oil cylinders are arranged in the pump side circular screen head body. The telescopic ends of all the oil cylinders are connected with the pump side screen head bearing seat. The pump side screen head bearing seat is connected with the pump side screen head shaft bushing through a matched circular screen bearing. The telescoping direction of all the oil cylinders is parallel to the axis of the circular screen. The pump side screen head shaft busing is connected with the other end of the circular screen and is coaxial with the circular screen. The moving direction of the pump side screen head shaft bushing is consistent with the axial direction of the circular screen. The circular screen head has the advantages of being simple in structure, reasonable, ingenious in design, easier to control and the like.

Owner:SUZHOU RUIRI TEXTILE SCI & TECH

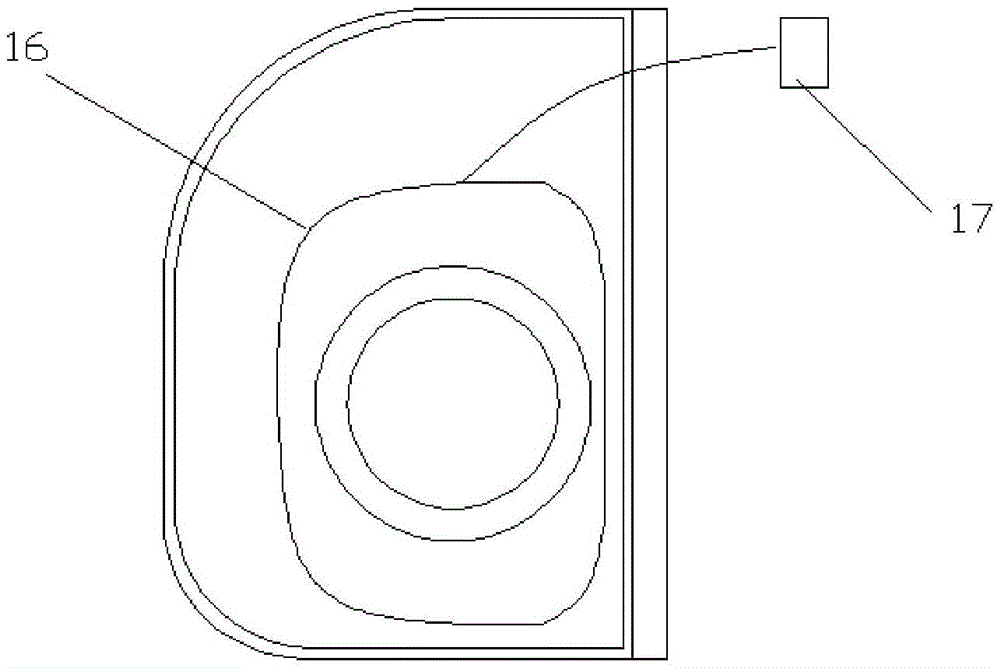

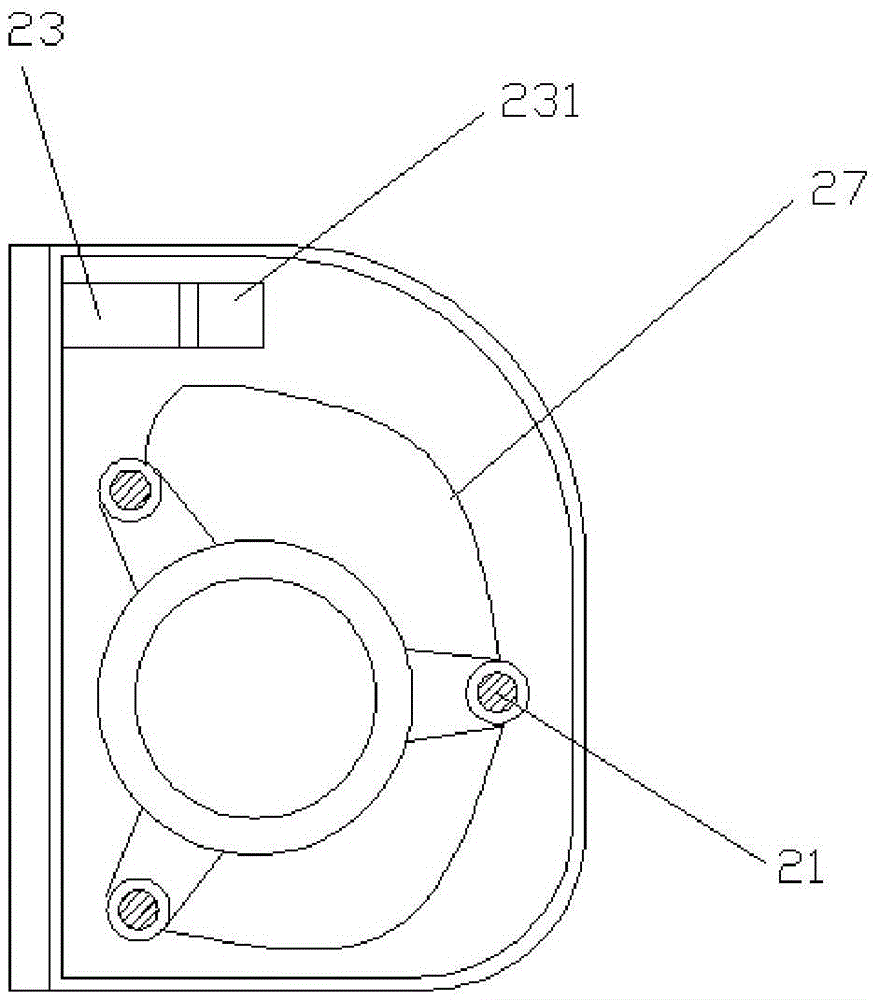

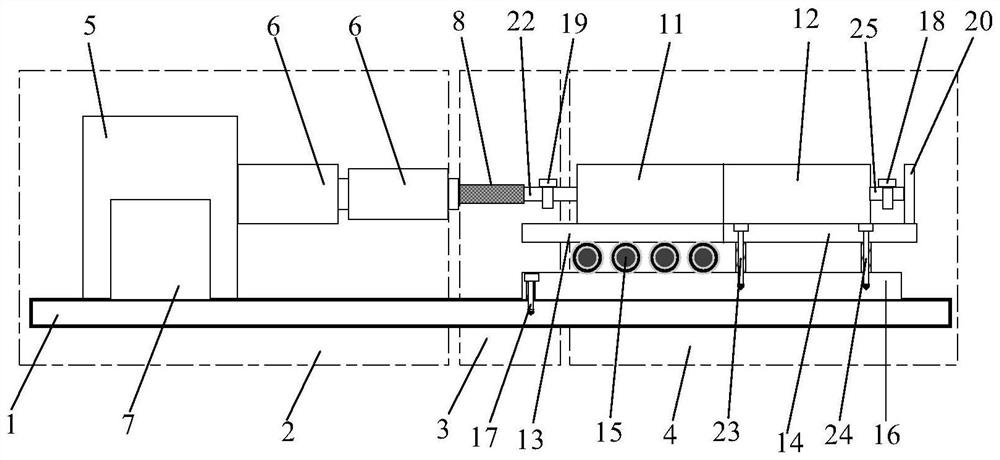

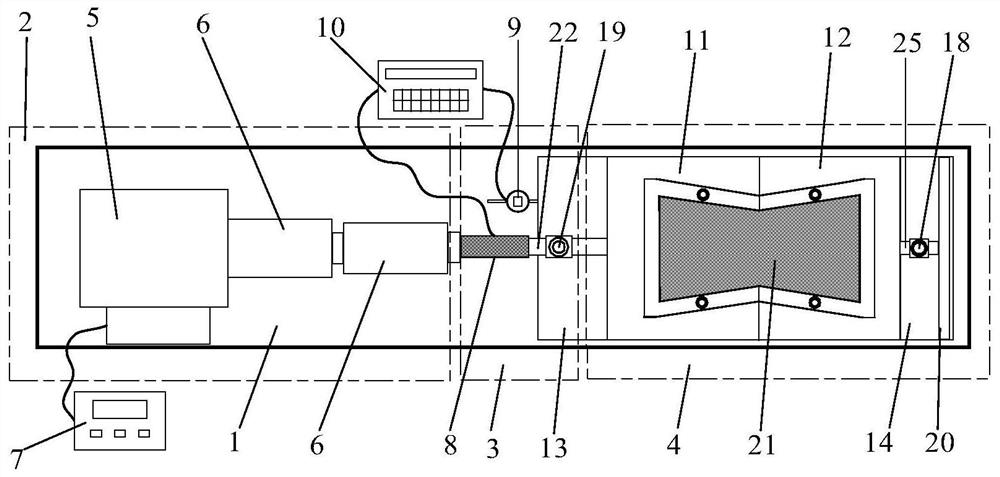

Cement soil uniaxial tensile tester and test method

InactiveCN112964553ATensile strength test has little effectReduce the rate of changeMaterial strength using tensile/compressive forcesSoil scienceSoil cement

The invention relates to a cement soil uniaxial tensile tester and test method, and belongs to the field of cement soil sample test equipment. A dynamic loading system, a measuring system and a sample positioning and stretching system are arranged on a test main body platform of the tester; the sample positioning and stretching system is used for placing a detected cement soil sample; and the dynamic loading system drives the sample positioning and stretching system, and the measuring system is used for collecting tension and displacement change data of the sample positioning and stretching system. According to the cement soil uniaxial tensile tester, the loading mode is a strain control mode; and compared with a traditional uniaxial tensile test device, the tester can measure the complete cement soil tensile stress-strain relation curve, and analyzes the influence of the loading rate on the cement soil tensile property, so comparison is performed to select the loading rate with the minimum influence on the tensile strength test of the cement soil sample.

Owner:SOUTHEAST UNIV

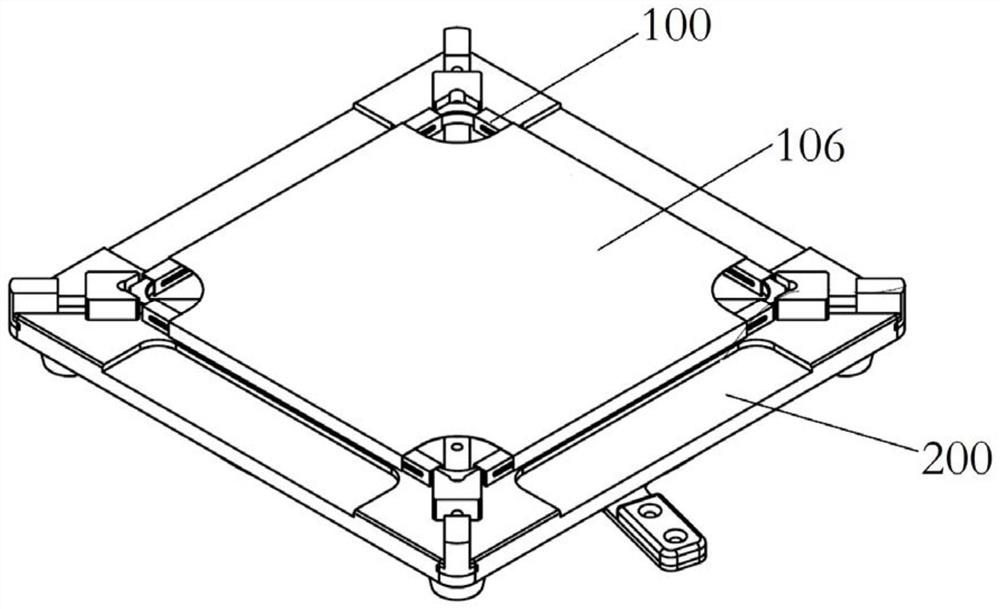

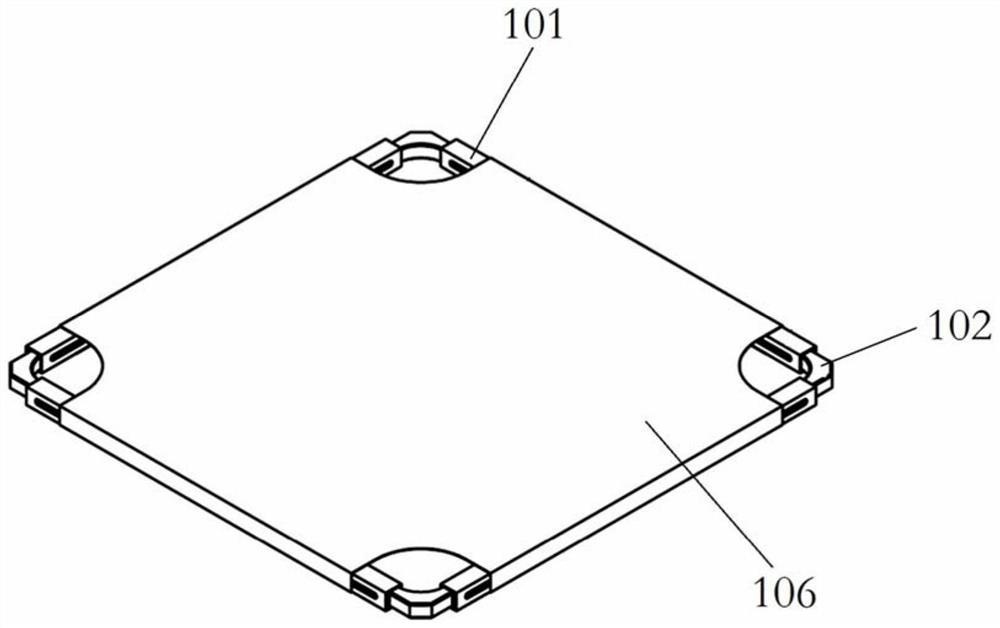

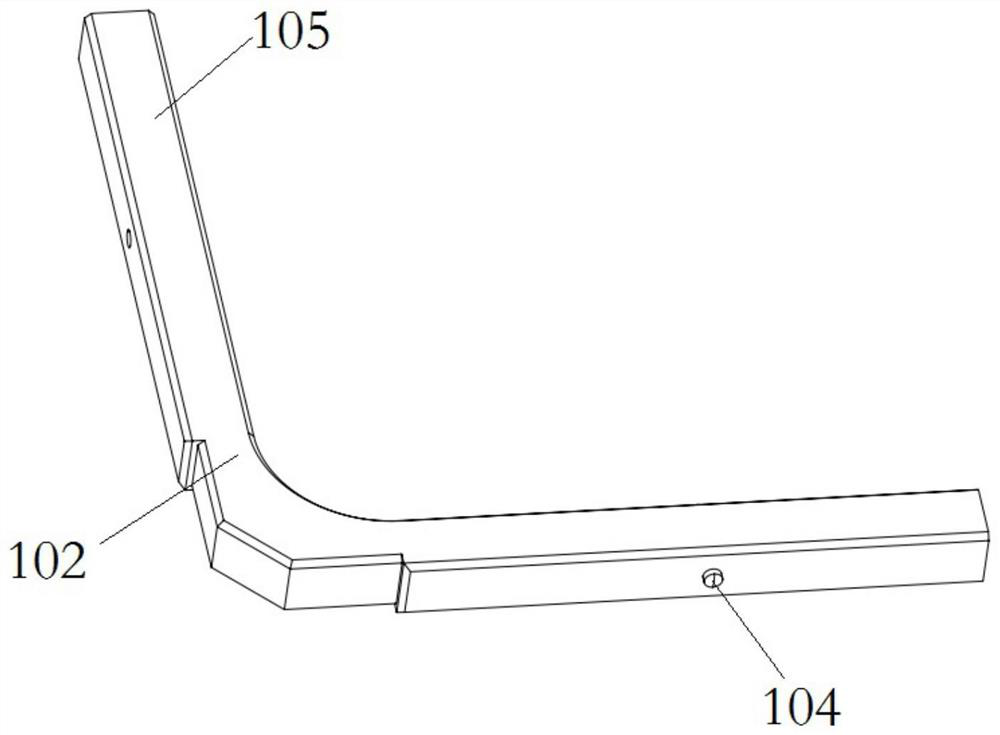

Tightening mechanism for wafer cleavage, film tightening assembly and film tightening method

PendingCN113183341ASave human effortImprove work efficiencySemiconductor/solid-state device manufacturingFine working devicesStructural engineeringMechanical engineering

The invention provides a tightening mechanism for wafer cleavage, a film tightening assembly and a film tightening method, and belongs to the technical field of cleavage. The tightening mechanism for wafer cleavage comprises: a base and four jacking blocks; the front surface of the base is used for placing a film tightening frame; the four jacking blocks are arranged at four corners of the front face of the base at intervals; the jacking blocks are arranged on the base in a driven and sliding mode; the jacking blocks have a first state of being close to the center of the base and also have a second state of being far away from the center of the base; and the jacking blocks are suitable for being propped against the film tightening frame. According to the tightening mechanism for wafer cleavage, the position and the shape of the film tightening frame are fixed through switching of the jacking blocks between the first state and the second state, and then a cutting-up film is bonded to the film tightening frame; and only one worker is needed to easily complete the process, manpower is saved, and the working efficiency is improved.

Owner:精良(北京)电子科技有限公司

Servo control system for netting machine

The invention discloses a servo control system for a netting machine. The servo control system comprises a main motor, an encoder, a tension sensor and a let-off servo motor, wherein the main motor is used for driving a main shaft to continuously rotate; the encoder is used for detecting the rotation angle of the main shaft; the tension sensor is used for detecting an actual tension value of a warp wound on a let-off shaft; the let-off servo motor drives the let-off shaft to rotate; and within each work cycle, the controller lastingly receives a detection signal of the encoder, controls the let-off servo motor to work in the manners as follows: when the main shaft is at the position of zero degrees, the let-off servo motor drives the let-off shaft to begin to rotate until the let-off shaft rotates the selected angle alpha i; and when the main shaft rotates to 180 degrees, the tension sensor detects an actual tension value, the controller compares the actual tension value with a tension set value, and sends out a next control signal according to the comparison result, and the let-off shaft rotates the selected angle alpha i+1 in the next work cycle. According to the servo control system for the netting machine, adjusting and weaving processes of the let-off value are collaboratively carried out; and uniform tension distribution of the fabric is ensured.

Owner:河北英凯模金属网有限公司

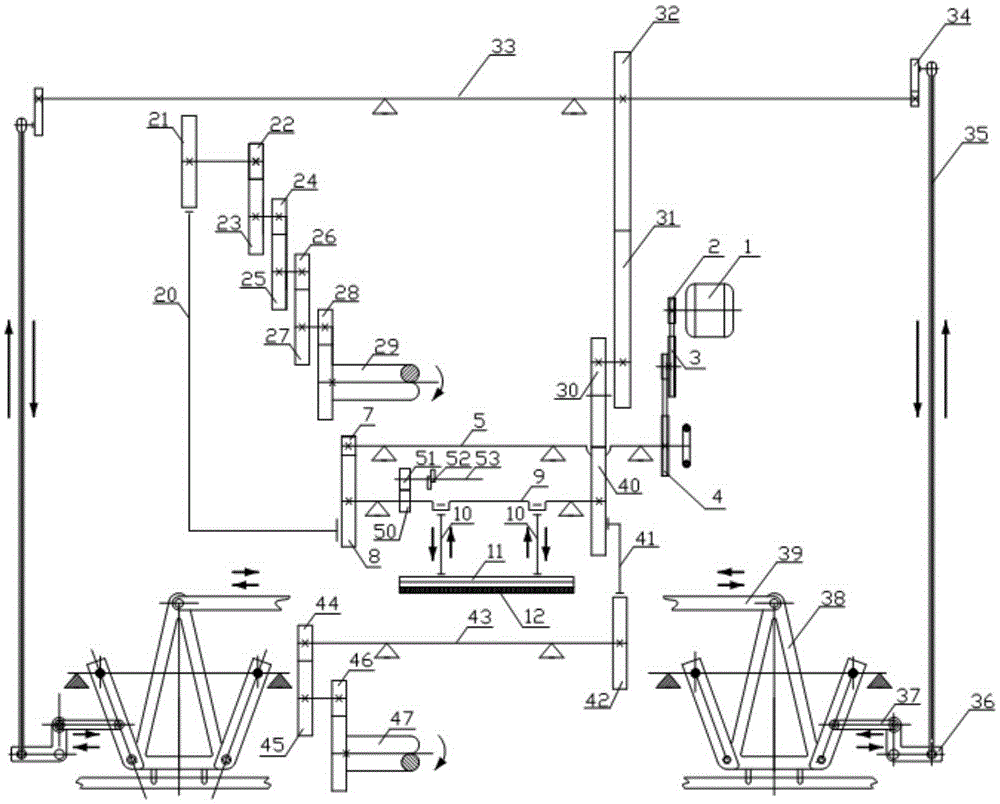

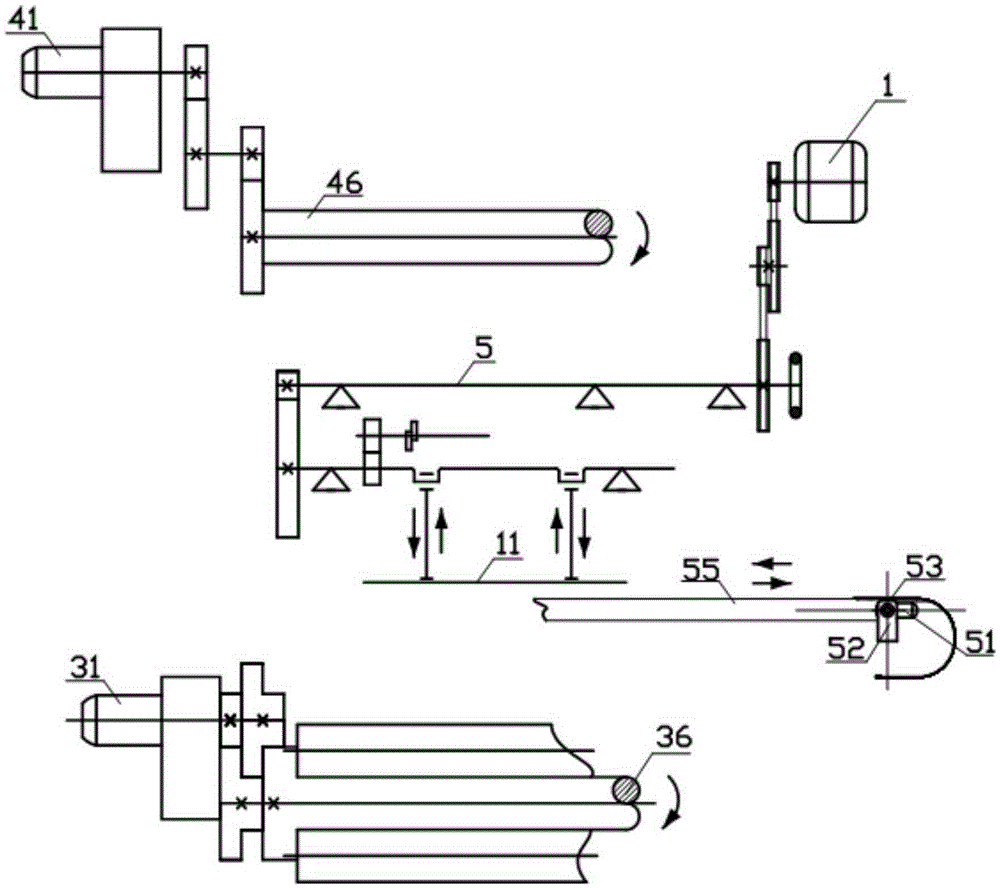

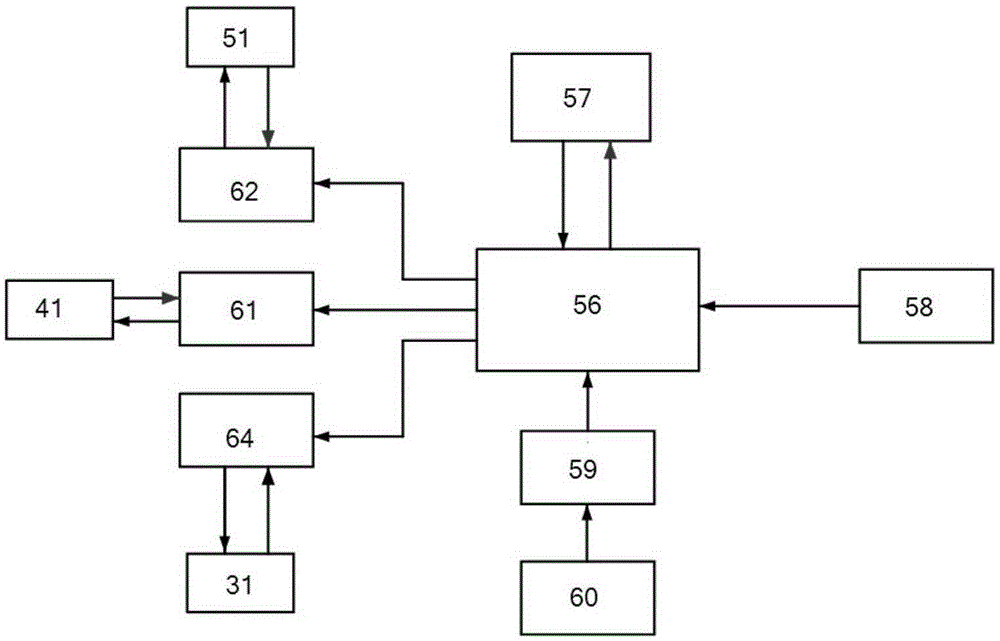

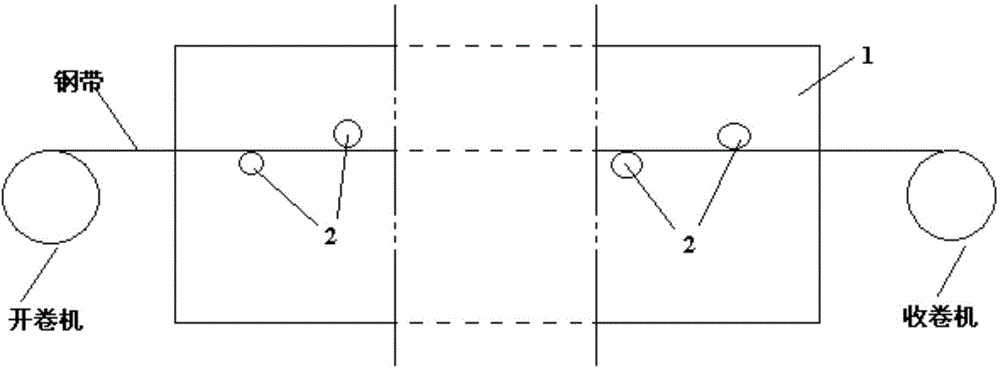

Crease-resistant carrier roller device in cold-rolled precise strip steel heating furnace

ActiveCN104099463APrevent saggingUniform tension distributionFurnace typesHeat treatment furnacesFixed frameEngineering

The invention relates to a crease-resistant carrier roller device in a cold-rolled precise strip steel heating furnace. The device comprises a furnace body, wherein strip steel penetrates through the furnace body, carrier rollers which are arranged in an upper-and-lower alternating manner are installed on the strip steel, connecting shafts are mounted at two ends of each carrier roller, the connecting shafts extend out of two sides of the furnace body to be installed on lifting frames and connected with a main motor installed on one side surface of the furnace body, the lifting frames are symmetrically arranged on guide rails of fixed frames on left and right sides of the furnace body and move up and down along with the guide rails, lifting mechanisms are mounted on the fixed frames to control the lifting frames to move up and down, the lifting mechanisms on the left and right sides of the furnace body are connected with two ends of a transmission shaft respectively to rise and fall synchronously, and the lifting mechanisms on two sides are connected with lifting motors and rotating handles respectively and adjust heights of the lifting frames through the lifting motors or the rotating handles. According to the device, the carrier rollers are arranged in the heating furnace, the strip steel is prevented from drooping, and the tension of the strip steel can be divided into multiple segments under the action of the carrier rollers, so that the distribution of the tension of the strip steel in the width direction is more uniform, and the probability of cramps is decreased.

Owner:SHANGHAI STAL PRECISION STAINLESS STEEL

Silk screen production device

PendingCN109109440AUniform tension distributionImprove bonding qualityForme preparationEngineeringTextile

The invention belongs to the technical field of glass production industry and particularly relates to a silk screen production device. The silk screen production device comprises a support plate, a driving mechanism and a clamping mechanism used for clamping silk screen cloth, wherein a silk screen frame positioning area is arranged at the first end of the support plate; the clamping mechanism isin sliding connection with the support plate and is adjacent to the silk screen frame positioning area; the driving mechanism is fixedly mounted on the second end of the support plate; the driving endof the driving mechanism is fixedly connected with the clamping mechanism so as to drive the clamping mechanism to move close to and away from the silk screen frame positioning area. According to thesilk screen production device, the silk screen cloth in tightening state is adhered to a silk screen frame in a production process of a silk screen plate; the adhesion quality of the silk screen cloth and the silk screen frame is greatly improved; the size of the tension of the silk screen cloth is adjusted by only adjusting the movement distance of the driving mechanism; the silk screen production device is simple and convenient to operate; the silk screen printing effect of the glass is improved.

Owner:XINYI AUTOMOBILE PARTS TIANJIN CO LTD

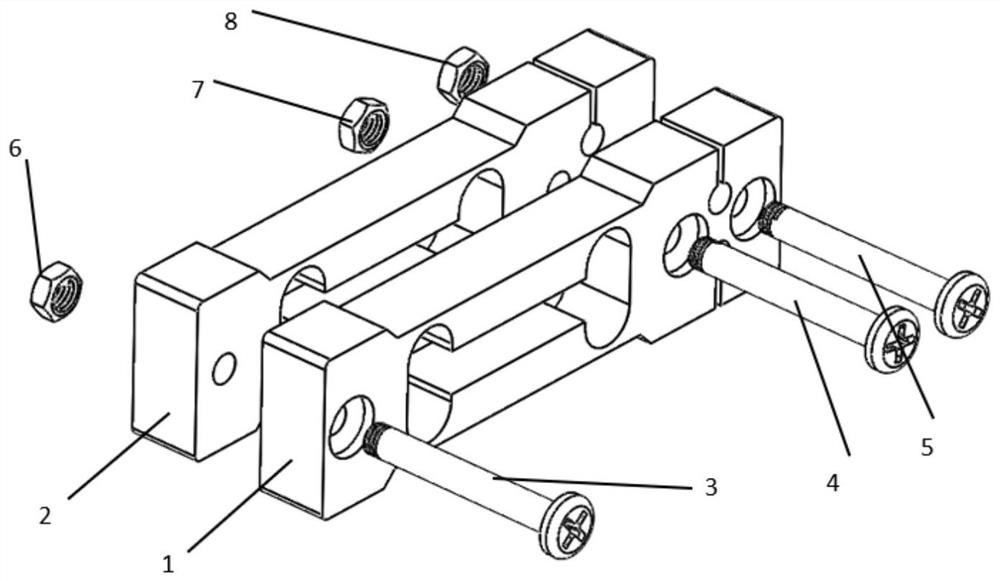

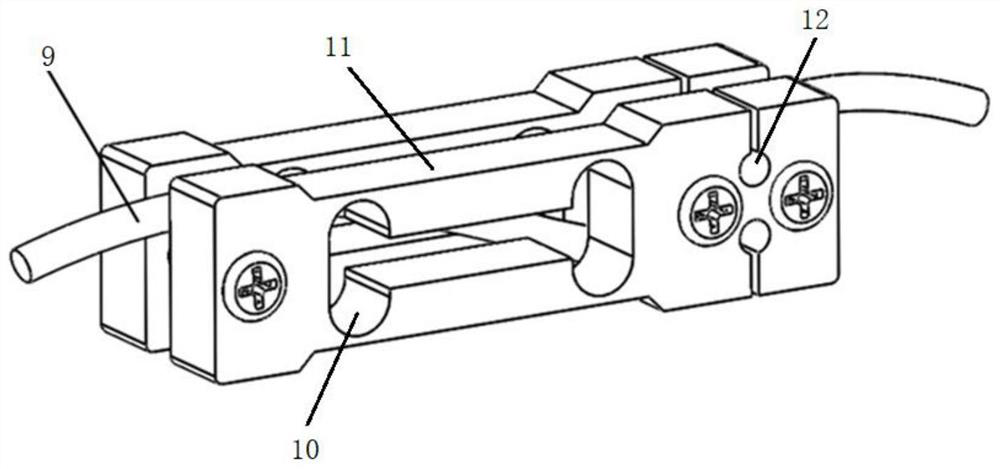

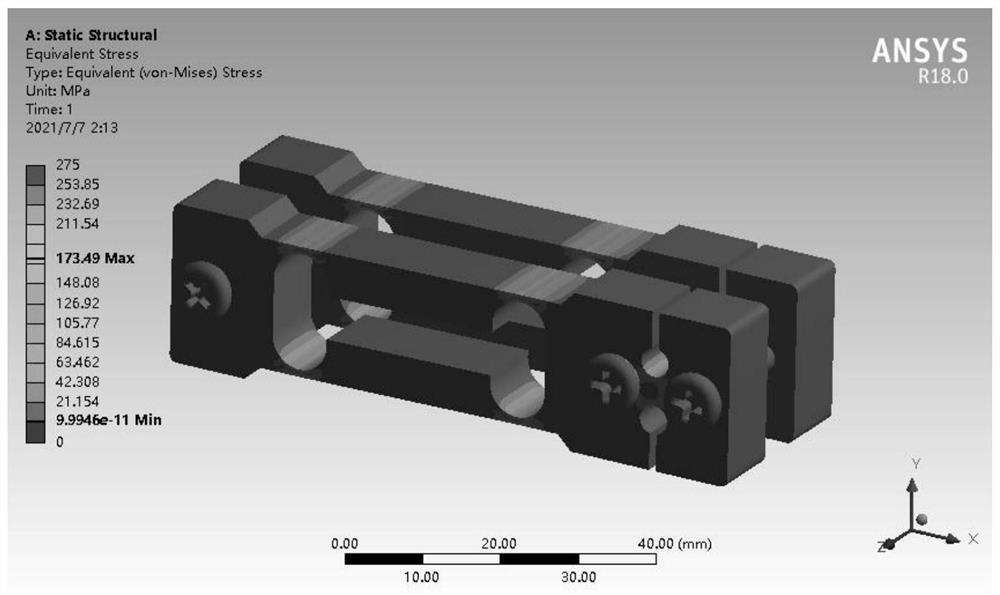

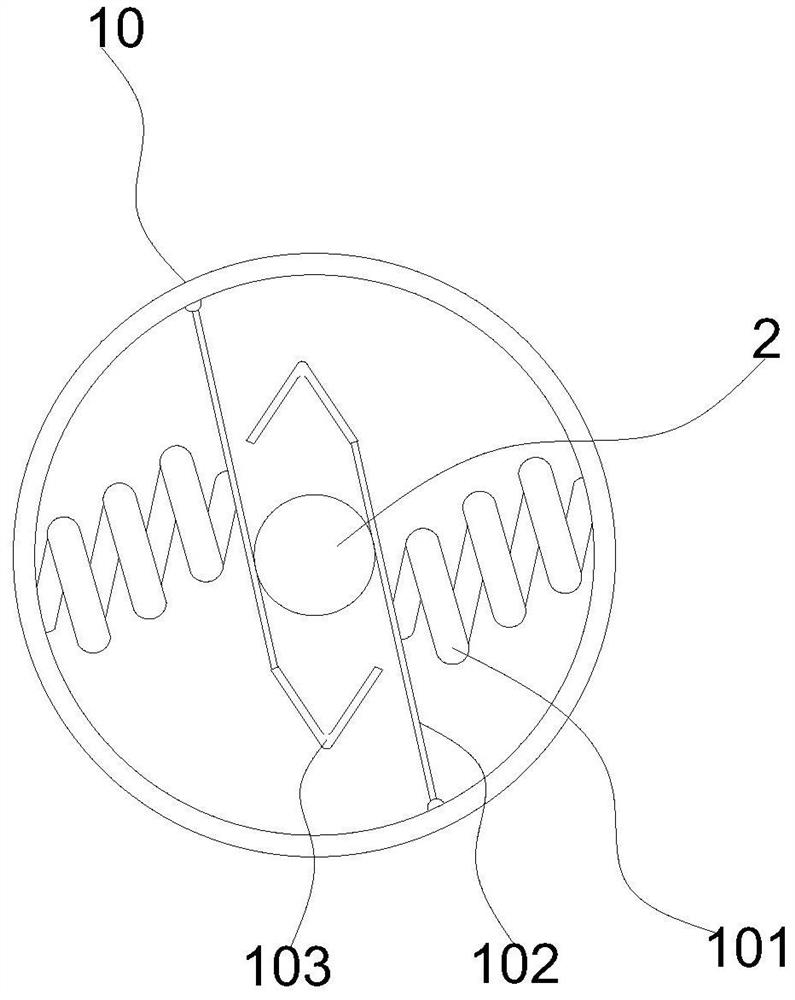

A non-invasive parafoil control rope tension sensor

ActiveCN113790842BDoes not affect flight safetyDoes not affect working statusForce measurementApparatus for force/torque/work measurementEngineeringControl theory

The invention discloses a non-invasive parafoil control rope tension sensor, which comprises two elastic beams, three fixing components and four strain gauges; Through groove, two trapezoidal grooves and two force balance grooves; fixing assembly consists of screws, sockets and nuts. The invention adopts a split structure to facilitate the installation and disassembly of the sensor on the parafoil control rope, and the non-invasive design of the side pressure type does not damage the structure of the control rope. The layout of the same elastic beams on both sides can make the force even and improve the measurement accuracy. While meeting the requirements of the measurement range of the control rope tension, the overall size of the sensor is small and light in weight, which is more suitable for the work requirements of the parafoil flight situation, and solves the problem that the tension of the parafoil control rope is difficult to measure in real time.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A storage type pay-off tension stabilizing device

ActiveCN112279007BChange the tensionUniform tension distributionFilament handlingDistribution frameClassical mechanics

Owner:铜陵顶科线材有限公司

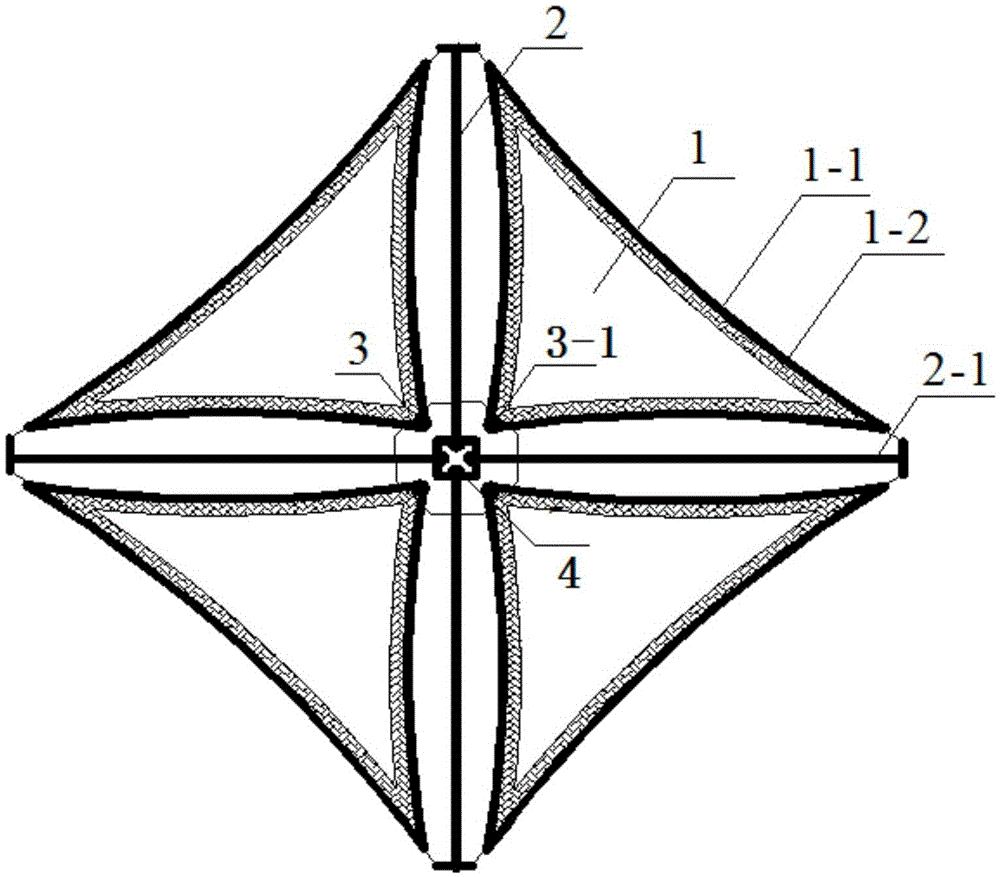

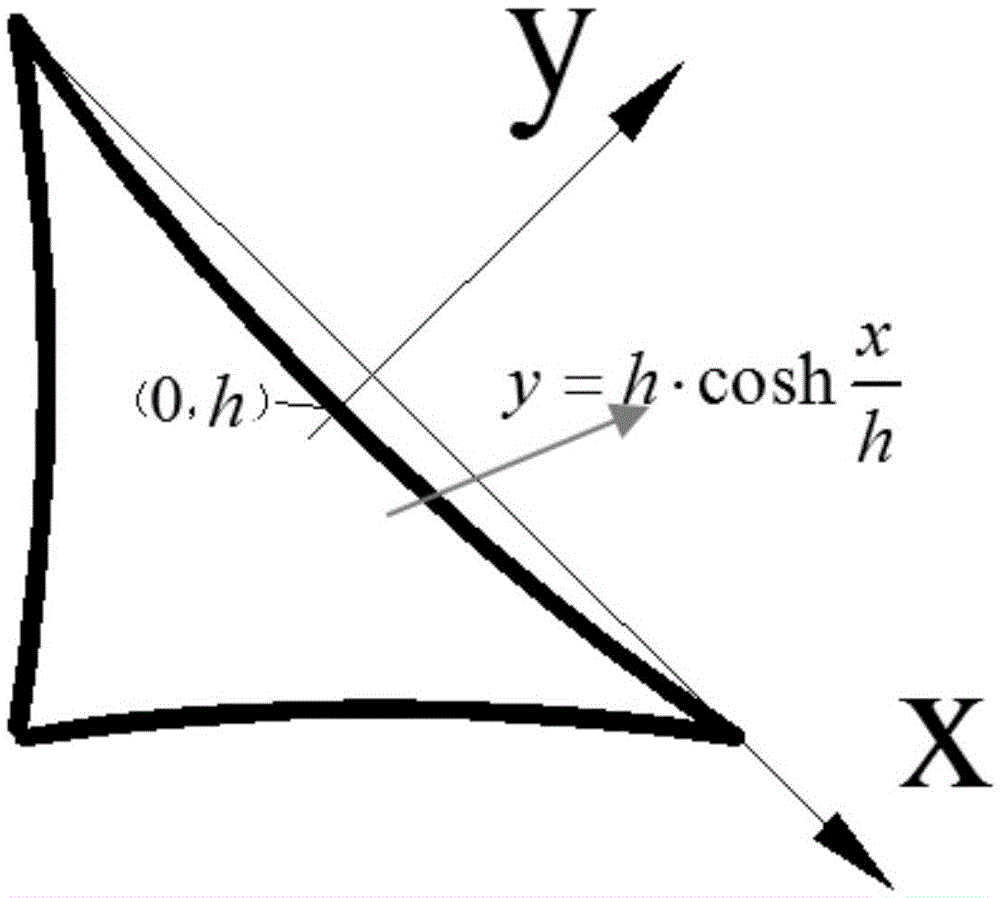

A controllable and orderly inflation self-supporting solar sail structure

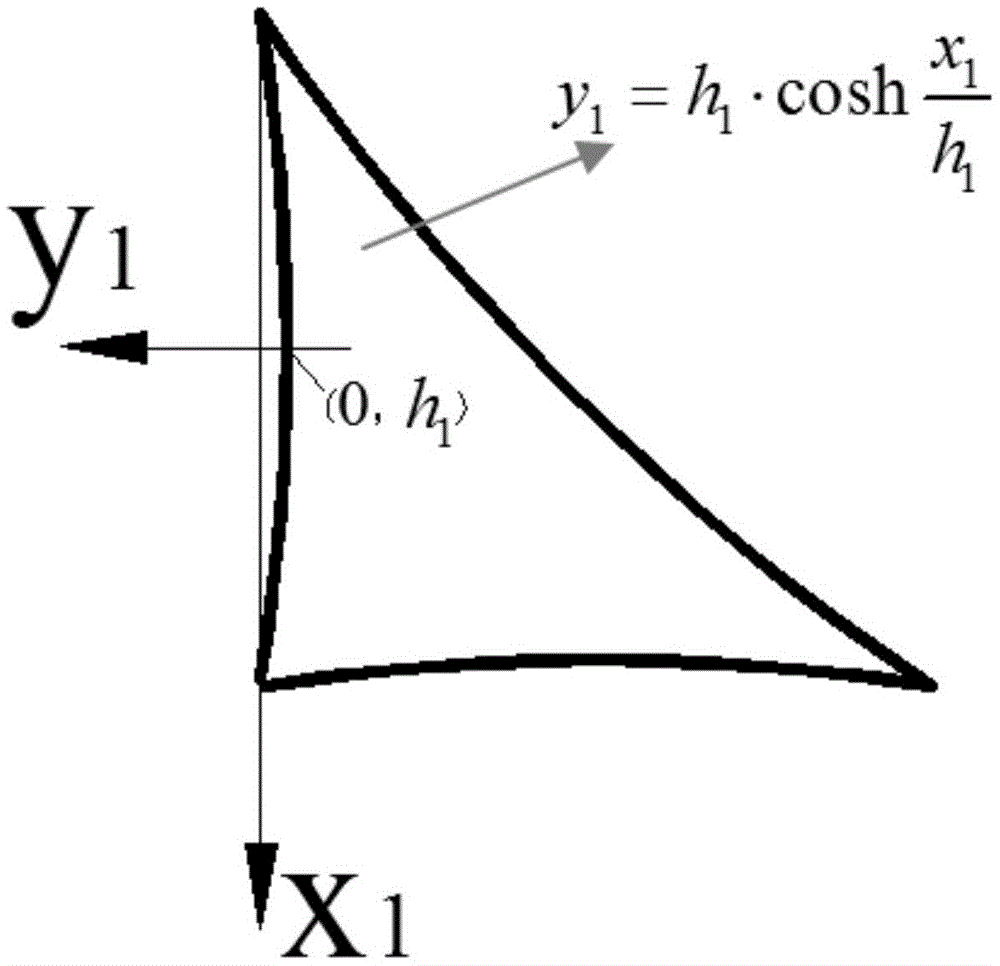

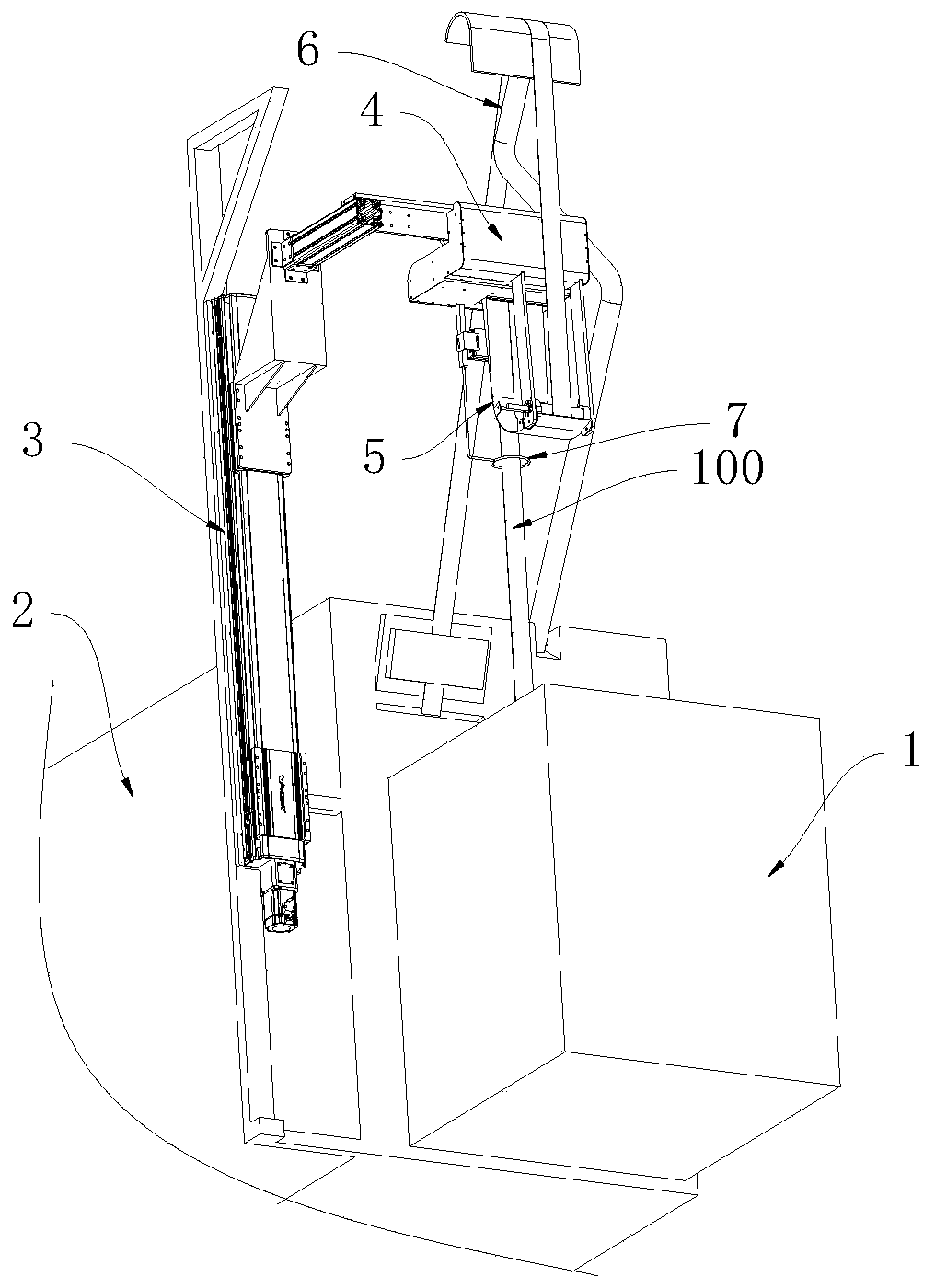

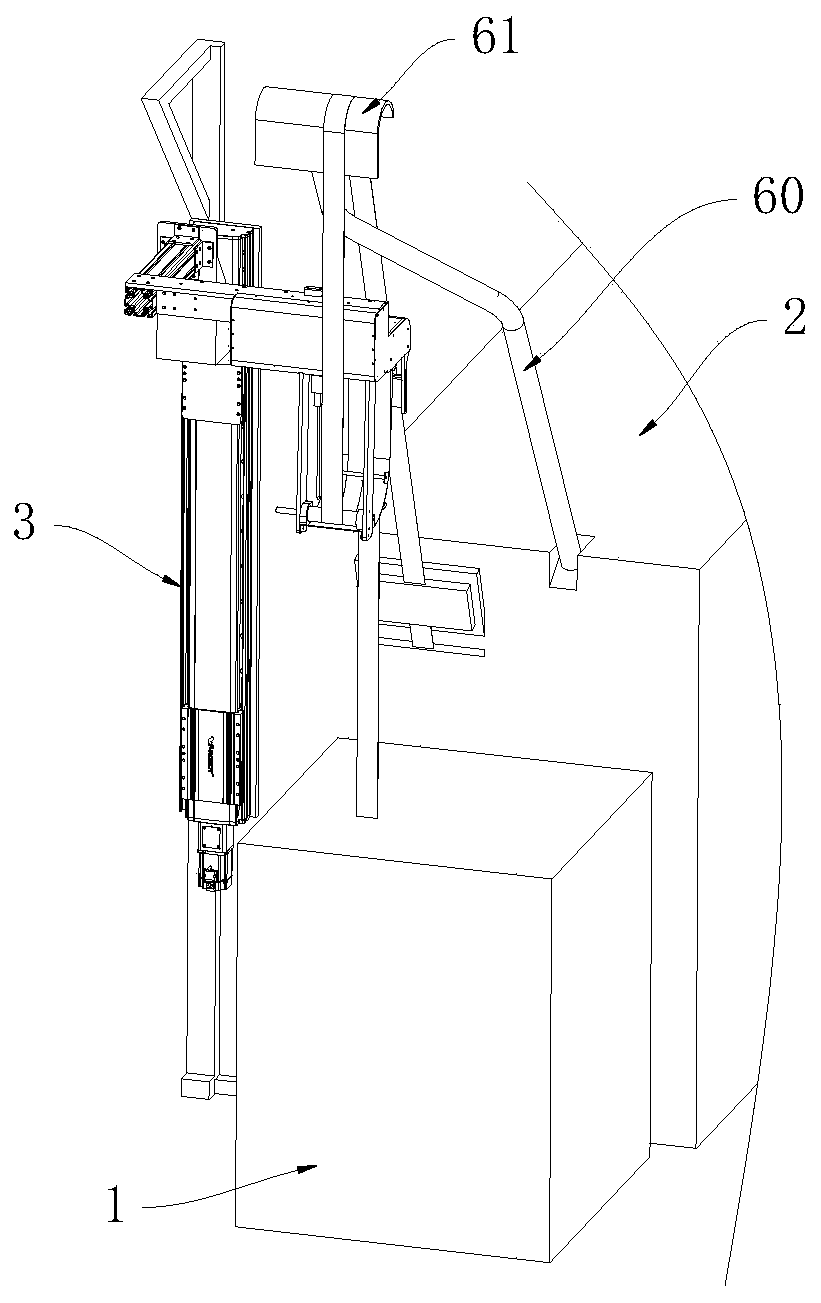

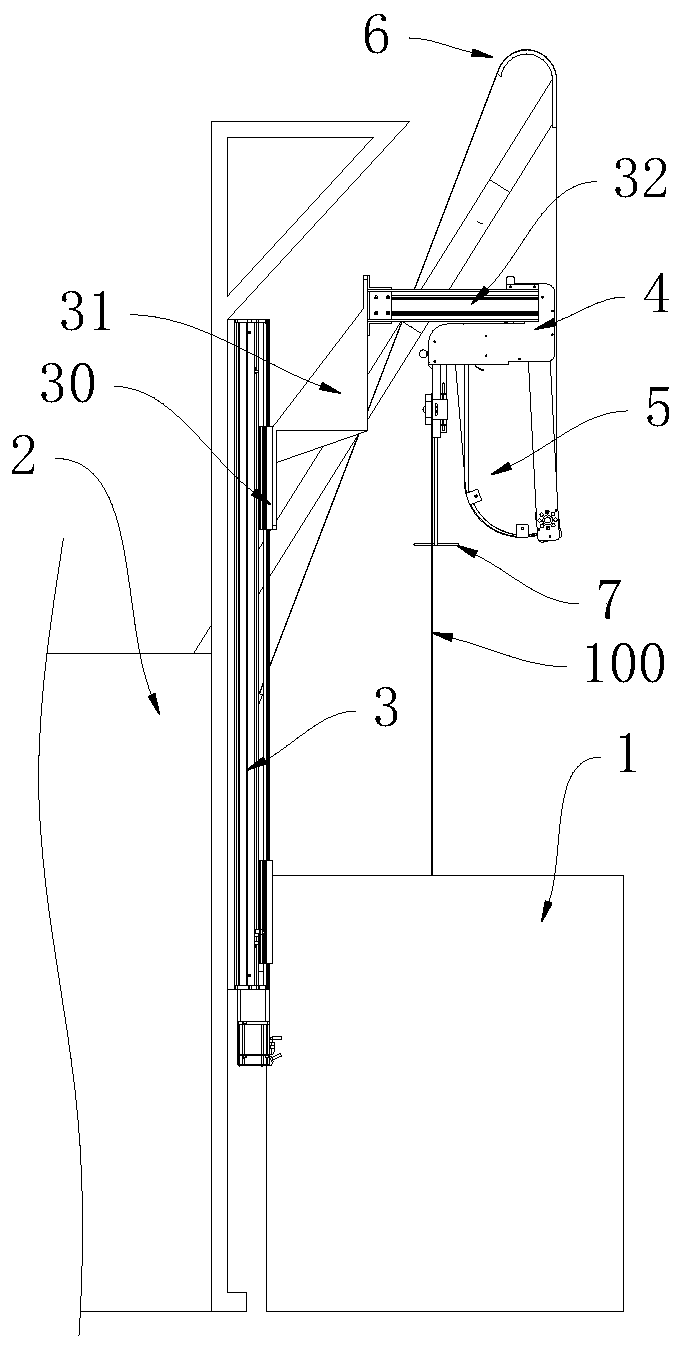

ActiveCN104627389BUniform tension distributionStable and smooth on-orbit deploymentCosmonautic power supply systemsSolar sailEngineering

The invention relates to the field of spaceflight and discloses a controllably and orderly inflated self-supporting type solar sail structure. A sail surface approximately triangle-shaped and formed by three curves is adopted, the sail surface can be unfolded in orbit stably and orderly, and distribution gradient of internal plane stress forced on the sail surface after unfolding is reduced by 20%; a support ring with the inner diameter equal to a winding shaft is arranged at the position of rectangular vertice of the sail surface, and concentrated stress of the sail surface can be lowered; a circular opening enclosed by 4n (n is larger than or equal to 3, and n is an integer) sawteeth, and no relative movement between the vertice of the sail surface and the winding shaft can be guaranteed; four sets of inflated extension arms used for supporting the sail surface are unfolded, each set is formed by two extension arms, straightness of the inflated extension arms and rigidity of the inflated extension arms after being unfolded can be improved, the rigidity of the structure is two times of that of a structure with a single extension arm, and unfolding stability of the extension arms is improved.

Owner:HARBIN INST OF TECH

Filter stick suction resistance stabilizing device and method thereof

ActiveCN111150095AImprove processing qualityReduce adverse effectsTobacco smoke filtersClassical mechanicsEngineering

The invention discloses a filter stick suction resistance stabilizing device, which comprises a lifting device used for perfroming lifting movement; a tow traction device used for applying traction force to the tows output by a tow feeding device; a tow buffer device comprising an arc-shaped tow storage groove extending downwards from the bottom of the tow traction device, wherein at least one buffer stop lever is fixed to the inner side of an arc-shaped tow storage groove, and a gap allowing tows to penetrate through is formed between the buffer stop lever and the arc-shaped tow storage groove; a tow supporting frame, wherein the first end of the tow supporting frame is installed on a machine base of the filter stick forming device, the second end of the tow supporting frame extends to the position above the tow traction device, and tows pulled out by the tow traction device penetrate through the tow buffering device, then extend upwards, bypass the second end of the tow supporting frame and then are conveyed to a feeding port of the filter stick forming device. According to the invention, balanced tension distribution and consistent tow density in the tow conveying process can beensured, so that the filter stick processing quality is improved.

Owner:深圳市联君科技股份有限公司

Preparation method of polyurethane mounting pad

ActiveCN105518067BUniform thicknessUniform pressureAbrasion apparatusLapping toolsHardnessCompressibility

This disclosure relates to a method for preparing a polyurethane mounting pad comprising the steps of: wet-solidifying a resin composition comprising polyurethane resin and a DMF solvent; and immersing the wet-solidified product in an aqueous solution comprising an acid catalyst or a base catalyst. According to the present invention, long and large pores may be uniformly formed inside of the prepared pad, thus affording low hardness, excellent compressibility, and the like, and more uniform thickness, pressure distribution or tension distribution and the like may be exhibited over the whole area of the pad, thus providing a polyurethane mounting pad that can realize more uniform and high efficiency polishing.

Owner:LG CHEM LTD

Adjustable silicone strip fixing and easy replacement device

The invention discloses an adjustable device for fixing and easily replacing a silica gel bar, which comprises a first fixed seat and a second fixed seat respectively positioned at two ends, wherein the first fixed seat and the second fixed seat are respectively fixed on respective adhesive patches; adhesive layers are arranged at the bottoms of the adhesive patches; a connecting strip is arranged on the first fixed seat; a plurality of clamping holes are formed in the connecting strip; clamping columns are arranged on the second fixed seat; the clamping columns can be clamped into the clamping holes. The adjustable device has the benefits that as the first fixed seat and the second fixed seat can be fixed on the two sides of the silica gel bar on a wound or a scar of a patient through respective adhesive layers; the clamping columns are clamped into the corresponding clamping holes of the connecting strip, so that the first fixed seat is connected with the second fixed seat and skin on two sides of the wound can be stitched without tension; as to the scar treatment, the silica gel bar covering the scar is fixed and compressed so as to prevent the silica gel bar from falling off, the curative effect is enhanced, and the silica gel bar covering the scar can be replaced conveniently at the same time. The adjustable device is suitable for wounds and scars with different sizes.

Owner:许晓曦

Material receiving mechanism, reverse osmosis membrane production equipment and material receiving method

ActiveCN106044327BGuaranteed tensionUniform tension distributionWebs handlingReverse osmosisEngineering

The invention relates to a receiving mechanism, reverse osmosis membrane production equipment and a receiving method. The receiving mechanism is used for receiving a first membrane and a second membrane in coil replacement, and comprises a clamping device; and the clamping device clamps the first membrane and the second membrane to keep the first membrane and the second membrane in a tension state. The invention further provides the receiving method; the receiving method adopts the receiving mechanism to receive materials; and the receiving method comprises the following steps: (S1) free ends of the first membrane and the second membrane are tailored; and (S2) the clamping device clamps the free ends of the first membrane and the second membrane to keep the first membrane and the second membrane in the tension state for receiving the materials. The invention further provides the reverse osmosis membrane production equipment adopting the receiving mechanism. The receiving mechanism, the reverse osmosis membrane production equipment and the receiving method, provided by the invention, have the advantages of positioning of the membranes in the tension state after material receiving and balanced tension distribution on the membranes.

Owner:SHENZHEN HAONENG TECH

A torsion cross beam, in particular for a composite steering axle and a motor vehicle comprising the torsion cross beam

InactiveCN106314062AUniform tension distributionNo bendInterconnection systemsWheel manufactureEngineeringInsertion element

A torsion cross beam having a torsion cross beam profile in which the insert element is inserted into an end region of the torsion beam profile to form a closed cross-sectional space, wherein the insertion element is directed at the end of the longitudinal center of the torsion cross beam to form an abutment region of the torsion cross beam profile so as to fit the profile base of the torsion cross beam profile in the direction towards the end; at least in the abutment area of the torsion cross beam profile against the base of the profile, the profile base has a first cross-sectional space; the cross-section of the first cross-sectional space is curved and has a curvature greater than zero; the profile base has a curved cross-sectional space in the abutment region, and the torsion cross beam together with the insertion element form a substantially quadrilateral second cross-sectional space in the end region; and when viewed in the longitudinal direction, the torsion cross beam profile has a transition zone between the abutment region and the free end of the torsion cross beam.

Owner:FORD GLOBAL TECH LLC

A Servo Control System of a Weaving Machine

The invention discloses a servo control system for a netting machine. The servo control system comprises a main motor, an encoder, a tension sensor and a let-off servo motor, wherein the main motor is used for driving a main shaft to continuously rotate; the encoder is used for detecting the rotation angle of the main shaft; the tension sensor is used for detecting an actual tension value of a warp wound on a let-off shaft; the let-off servo motor drives the let-off shaft to rotate; and within each work cycle, the controller lastingly receives a detection signal of the encoder, controls the let-off servo motor to work in the manners as follows: when the main shaft is at the position of zero degrees, the let-off servo motor drives the let-off shaft to begin to rotate until the let-off shaft rotates the selected angle alpha i; and when the main shaft rotates to 180 degrees, the tension sensor detects an actual tension value, the controller compares the actual tension value with a tension set value, and sends out a next control signal according to the comparison result, and the let-off shaft rotates the selected angle alpha i+1 in the next work cycle. According to the servo control system for the netting machine, adjusting and weaving processes of the let-off value are collaboratively carried out; and uniform tension distribution of the fabric is ensured.

Owner:河北英凯模金属网有限公司

Method for preparing polyurethane support pad

ActiveCN105518067AUniform thicknessUniform pressureAbrasion apparatusLapping toolsPolymer scienceHardness

The present invention relates to a method for preparing a polyurethane support pad, the method comprising the steps of: wet-coagulating a resin composition comprising a polyurethane resin and a DMF solvent; and dipping the wet-coagulated product in an aqueous solution comprising an acid catalyst and a base catalyst. According to the present invention, it is possible to provide a polyurethane support pad capable of showing low hardness, excellent compressibility and the like by uniformly forming long and large pores inside the prepared pad, showing more uniform thickness, pressure distribution, tension distribution or the like all over the pad, and thereby implementing more uniform and efficient polishing.

Owner:LG CHEM LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com