Mask plate and making method thereof

A manufacturing method and mask technology, which are used in semiconductor/solid-state device manufacturing, ion implantation plating, coating, etc., can solve the problems of mask wrinkles and poor mechanical strength, reduce wrinkles, improve mechanical strength, The effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to enable those skilled in the art to better understand the technical solution of the present invention, the mask provided by the present invention and its manufacturing method will be described in detail below with reference to the accompanying drawings.

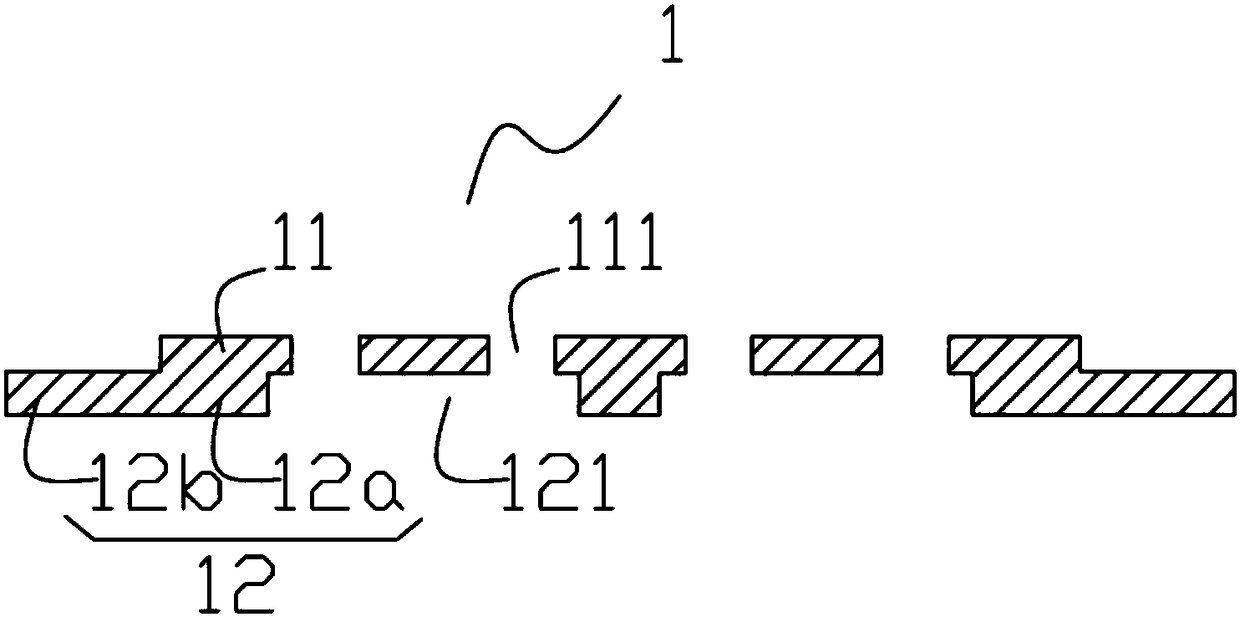

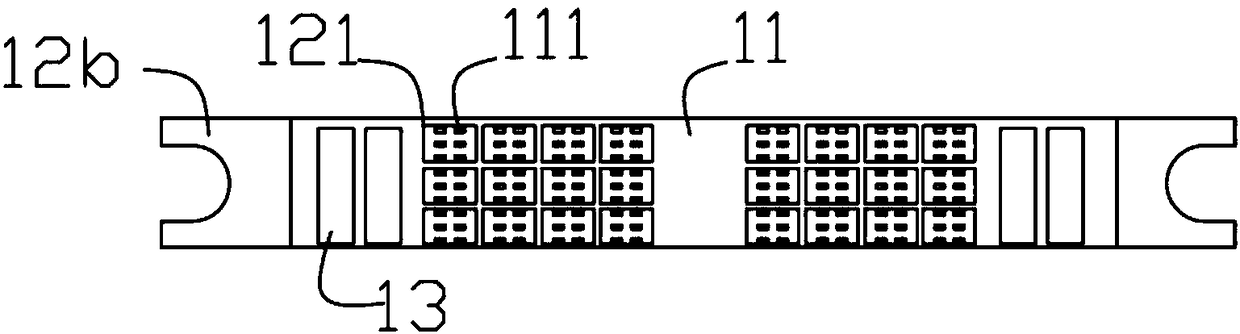

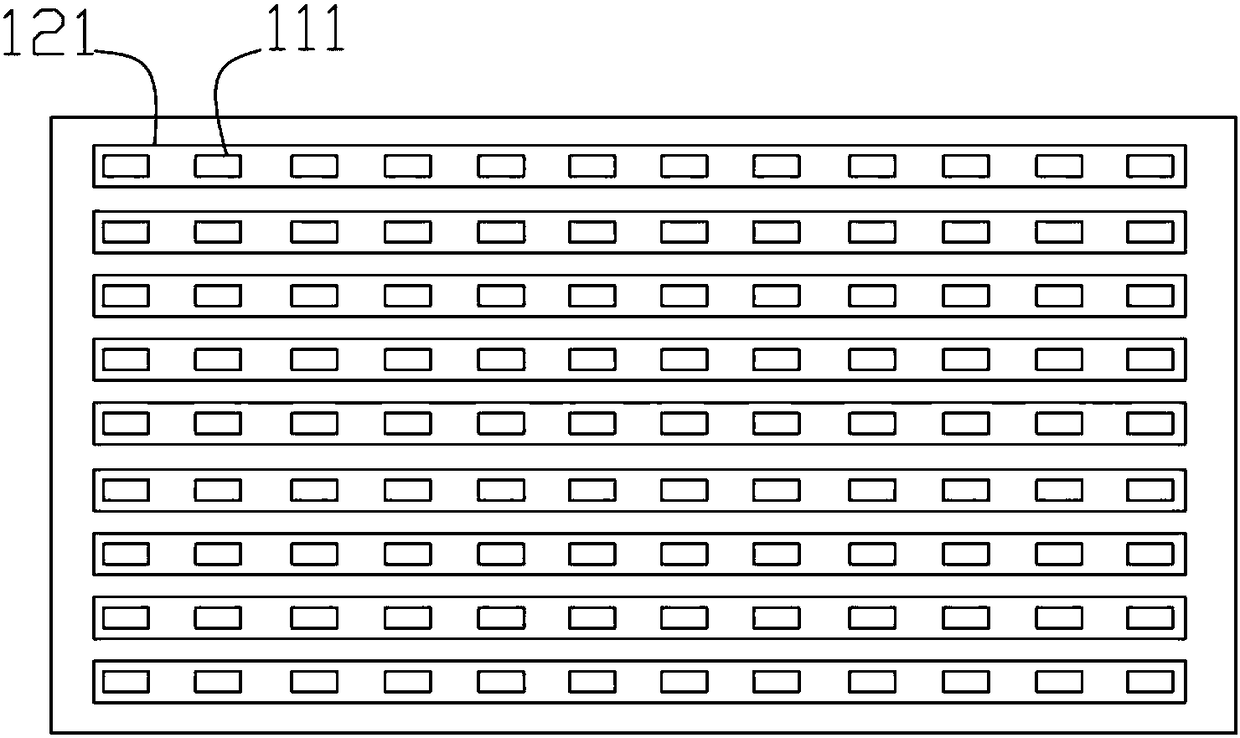

[0039] Please also refer to figure 1 and figure 2 , the mask plate 1 provided by the first embodiment of the present invention includes a pattern layer 11 and a tensile layer 12, wherein the pattern layer 11 is used as a mask plate to be in contact with the substrate when performing an evaporation process, and the pattern layer 11 A first opening 111 is provided in the center for forming thin film patterns deposited on the substrate. The stretched layer 12 faces away from the substrate during the vapor deposition process, and includes a stretched portion 12a and two clamping portions 12b, wherein the stretched portion 12a is arranged on the first surface ( figure 1 On the lower surface of the graphic laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com