A torsion cross beam, in particular for a composite steering axle and a motor vehicle comprising the torsion cross beam

A technology for torsion beams and beams, applied in the direction of vehicle springs, vehicle components, axles, etc., can solve problems such as unfavorable tension peaks and complicated manufacturing of torsion beams.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

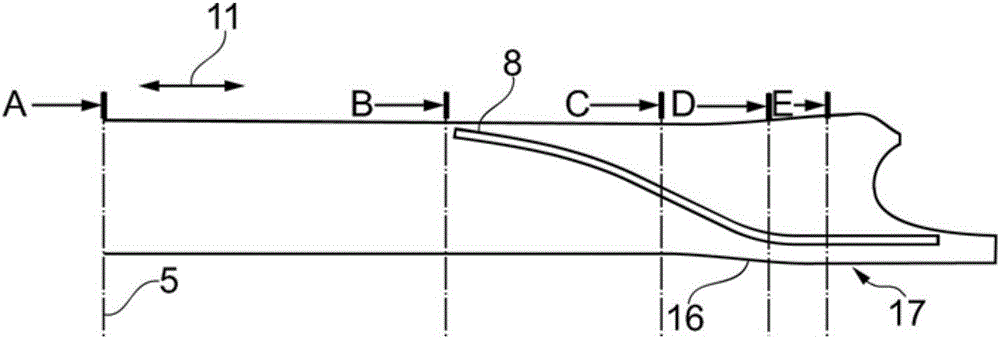

[0030] Figure 9 The unfavorable tension distribution of the torsion beam according to the prior art is shown. Such a twist beam according to the prior art with regard to its construction type is a twist beam in which an insert element is inserted into the end region of an open twist beam profile. The abutment area 100 is shown schematically. In the abutment area 100 the end of the insert element pointing towards the longitudinal center of the twist beam rests against the inside of the twist beam profile. In the abutment area, the insert element and the torsion beam profile are formed in a planar manner. In the case of prescribed loading, an unfavorable tension peak 101 occurs adjacent to the abutment region 100 .

[0031] in this case, Figure 9 A printout is shown of the tension distribution that has been built by the tension build operation using the finite element method. Such unfavorable tension peaks are intended to be prevented, which are caused by the use of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com