Circular screen head of circular screen printer

A rotary screen printing and rotary screen technology, applied in the field of rotary screen head, can solve the problems of affecting the running speed of the production line, poor control of precision, and low production efficiency, so as to achieve good control of screen printing paste effect and convenient adjustment of tension of the screen , Ingenious design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

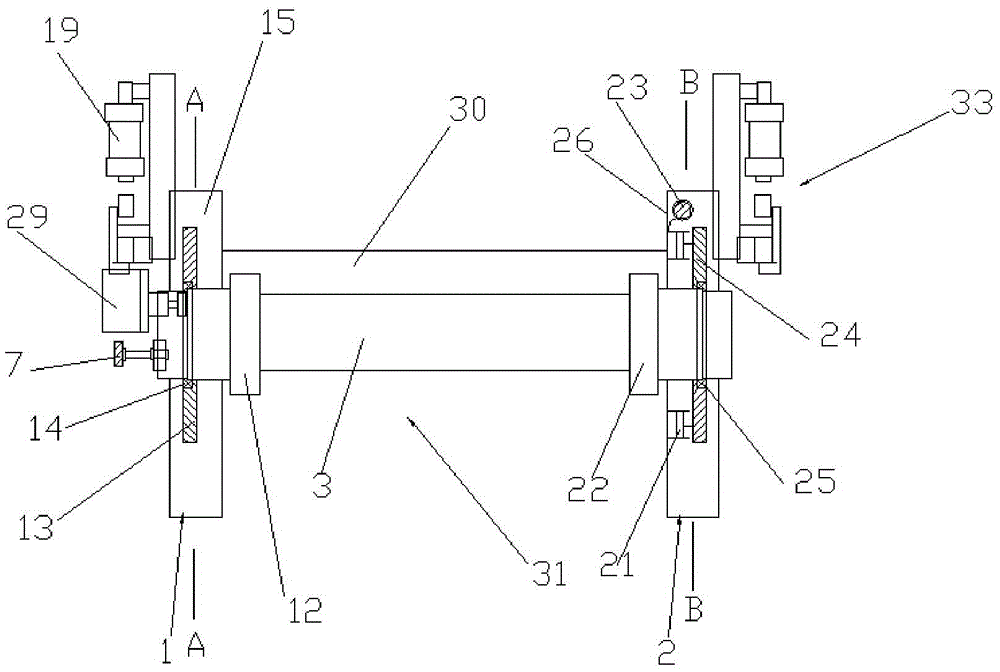

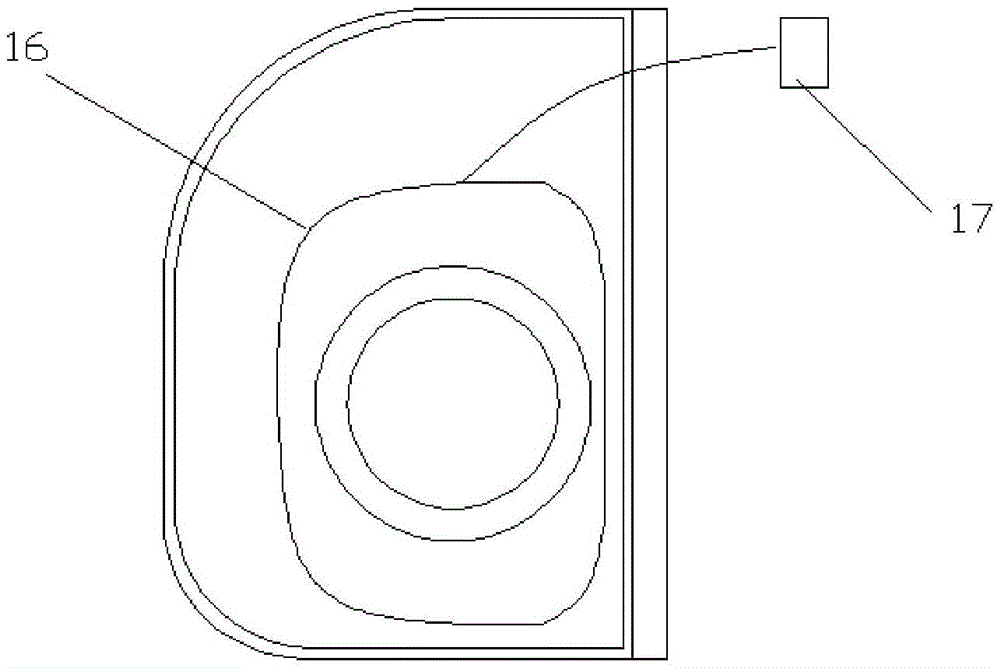

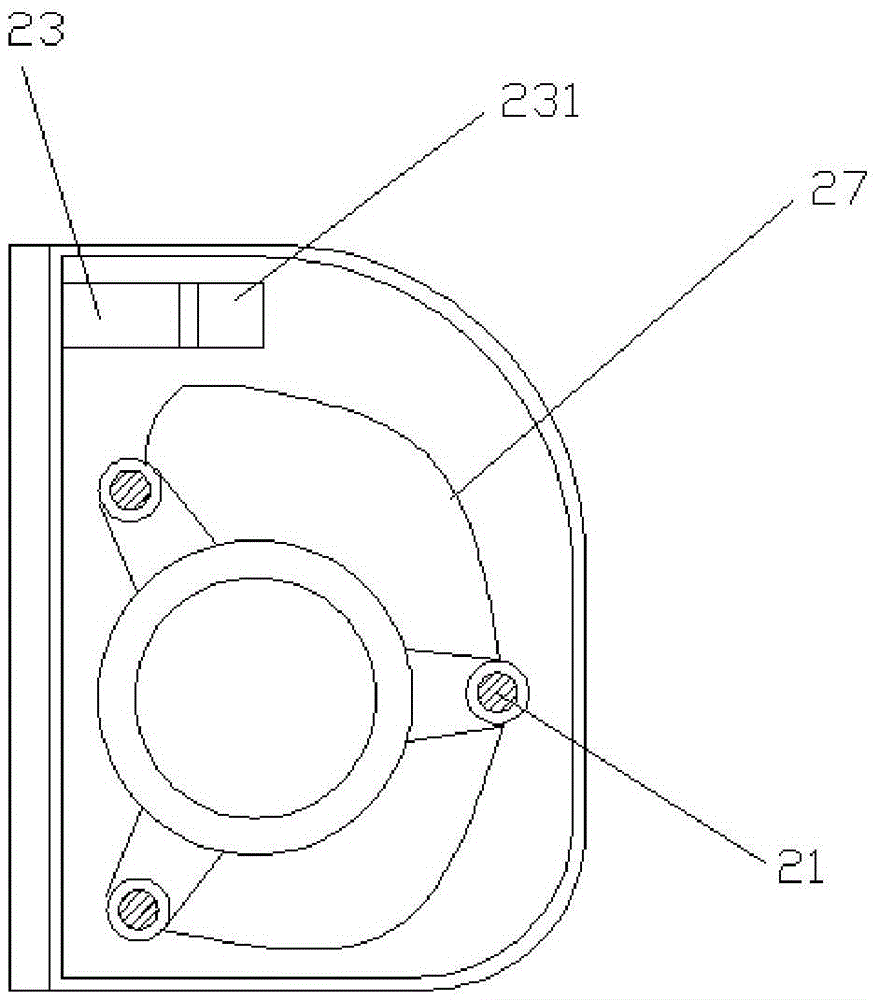

[0019] Such as Figure 1 to Figure 4 The rotary screen head of a rotary screen printing machine shown includes a rotary screen 3, a transmission side rotary screen head 1 and a pump side rotary screen head 2, and is characterized in that the pump side rotary screen head 2 is provided with More than two oil cylinders 21, a pump side net head bearing seat 24, a pump side net head bushing 22 and an oil injection cylinder 23 connected with each oil cylinder, the telescopic ends of each oil cylinder are connected with the pump side net head bearing seat, and the pump side The screen head bearing seat is connected with the pump side screen head bushing through the matching cylinder bearing, the expansion and contraction direction of each oil cylinder 21 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com