Flexible substrate foil roll-to-roll conveyer and conveying method

A flexible substrate and conveying device technology, applied in the field of vacuum coating, can solve the problems of internal defects of deposited films, substrate foil flutter, low tensile performance, etc., to reduce equipment length and space requirements, less tension adjustment mechanism, convenient The effect of system upgrade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

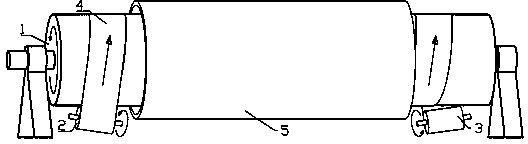

[0038] figure 1 It is a schematic diagram of Embodiment 1 of the present invention, illustrating the working principle of the conveying device and conveying method of the present invention.

[0039] The flexible substrate foil 4 unwound by the unwinding mechanism 2 is wound from one end of the winding mechanism 1 along a counterclockwise spiral, reaches the other end of the roller after several weeks, and is fixed to the winding mechanism 3 . With the rotation of the winding mechanism 1, the unwinding mechanism 2 and the winding mechanism 3 (the direction is shown in the figure), the flexible substrate foil 4 is continuously rolled out from the unwinding mechanism 2, and rotates forward along the helical line (the direction is as shown in the figure). As shown in the figure), it is finally involved in the winding mechanism 3 to complete the entire roll-to-roll delivery process.

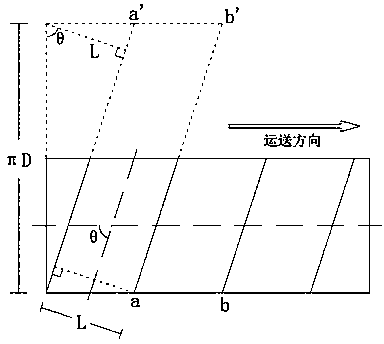

[0040] Figure 5 It is a schematic diagram of the geometric relationship of Embodiment 1 of the...

Embodiment 2

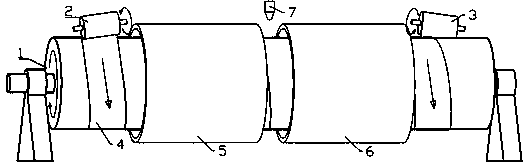

[0047] figure 2 It is a schematic diagram of Embodiment 2 of the present invention.

[0048] On the basis of Embodiment 1, take the cylindrical shape around the winding mechanism 1 as an example to represent the available coating / processing area 5 of the present invention. According to different coating / processing technology requirements and device types, the shape of the processing area can be A rectangular plate, an arc plate or other forms surrounding the winding mechanism 1.

[0049]

Embodiment 3

[0051] image 3 It is a schematic diagram of Embodiment 3 of the present invention.

[0052] In Embodiment 3, the flexible substrate foil 4 is wound along a clockwise helical line, and the corresponding rotation directions of the winding mechanism 1 , the unwinding mechanism 2 and the winding mechanism 3 are shown in the figure. At the same time, the coating / processing area is divided into two sections: coating / processing area 5 and coating / processing area 6, so that different types of coating / processing technologies can be carried out in stages without complex steering mechanisms. Necessary isolation devices (not shown in the figure) can be set in the middle area, or the probe 7 of an online thin film detection and analysis instrument can be set.

[0053]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com