Cloth feeding method of digital printing and flat screen printing integrated machine

A technology of flat screen and all-in-one machine, which is applied in the field of cloth feeding of digital and all-in-one machine, which can solve the problems such as the flatness of gray cloth cannot be adjusted, the internal tension fluctuation of gray cloth is large, and the contact time is short.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following is a specific implementation of a preferred embodiment of the present invention. A cloth feeding method for an all-in-one digital, peace and network machine, comprising the following steps:

[0015] 1) On the computer operation interface, set the effective width of the nozzle group of the digital printing machine for a single scan of the inkjet and the flat screen printing machine scraper to be consistent with the size of the intermittent positioning of the printing guide belt;

[0016] 2) Turn on the input signal from the printing tape guide servo controller to drive the frequency conversion motor of the A-type unwinding device to feed the cloth;

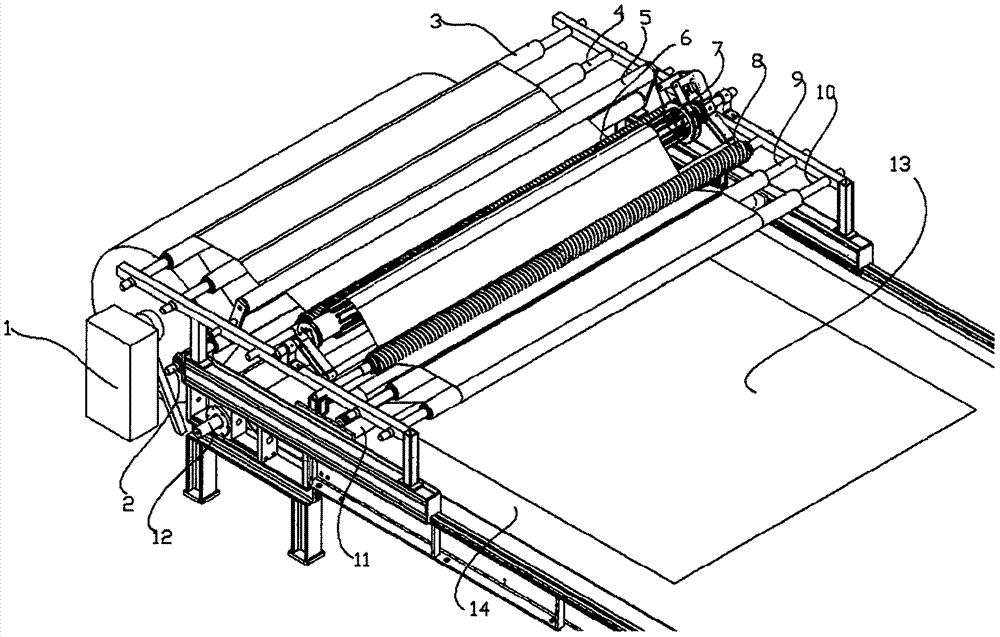

[0017] 3) The grey cloth (13) enters the first cloth guide roller (2) from the A-type unwinding device (1), and then passes through the second cloth guide roller (3), the third cloth guide roller (4) and the angle adjustment roller (5) ), then to the first spinning roller (6), edge correction device (7), then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com