Filter stick suction resistance stabilizing device and method thereof

A technology of stabilizing device and filter rod, which is applied in the direction of e-liquid filter, application, tobacco, etc., can solve the problems of filter rod shrinkage, different density and pressure, and large change of filter rod suction resistance, so as to improve processing quality and ensure Tension distribution, the effect of meeting production needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

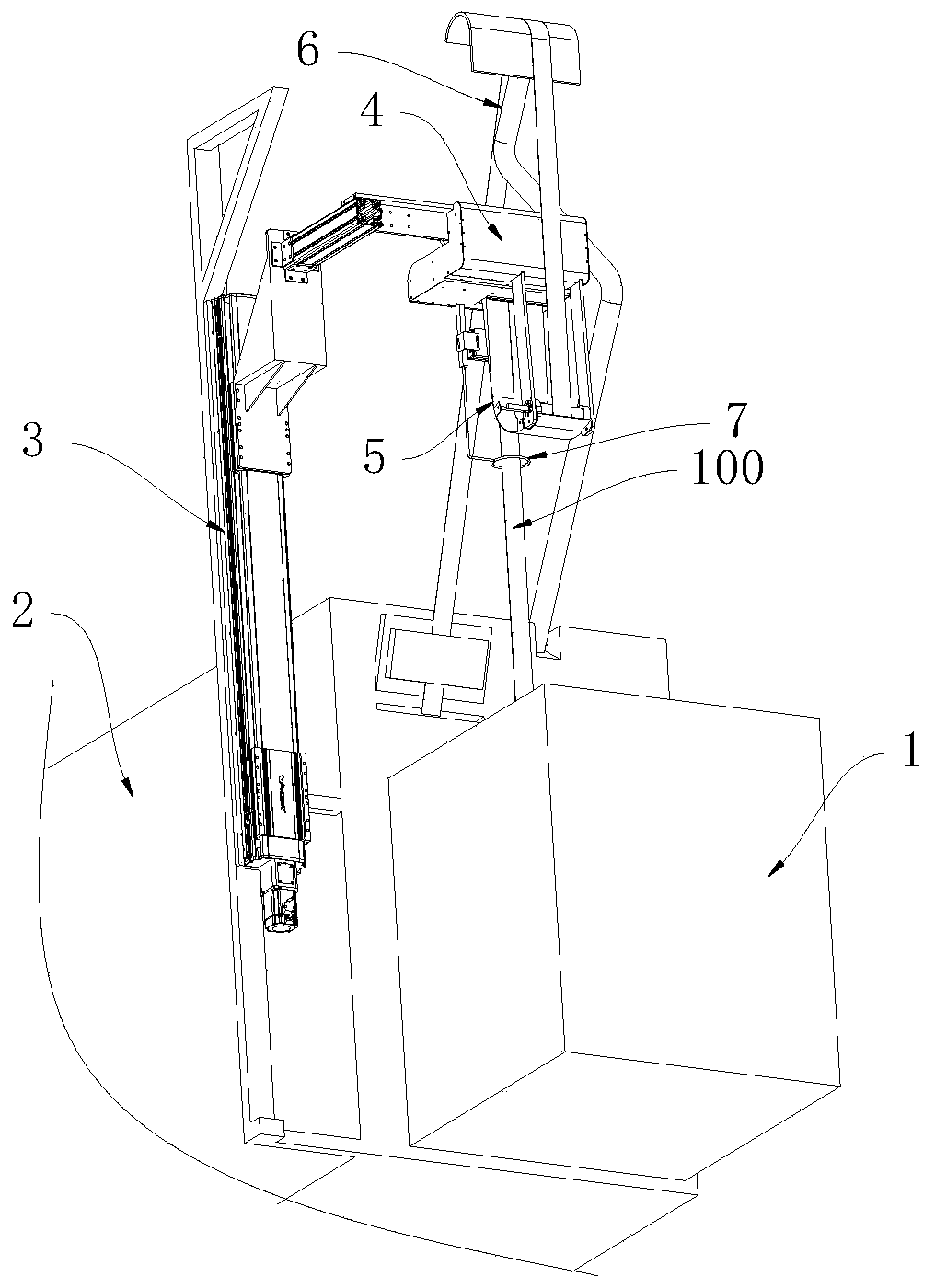

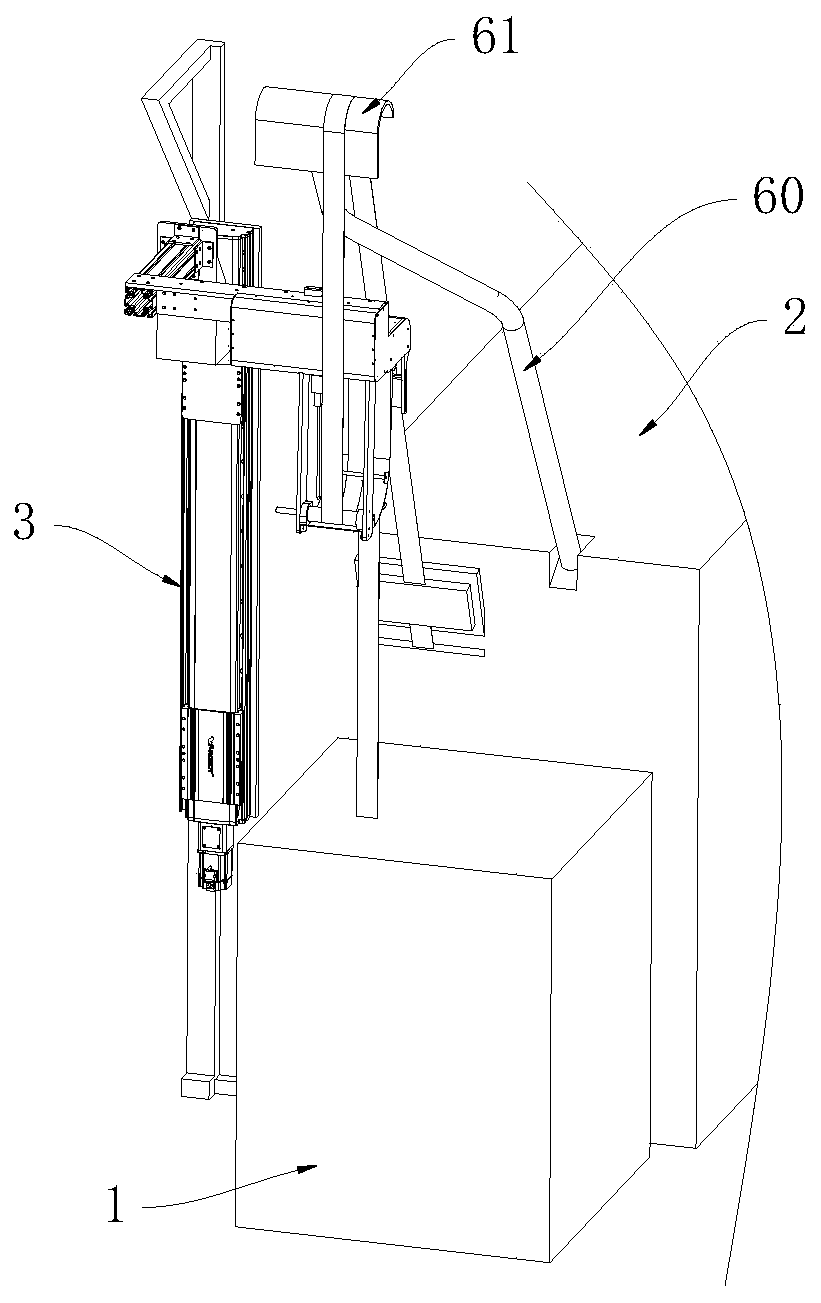

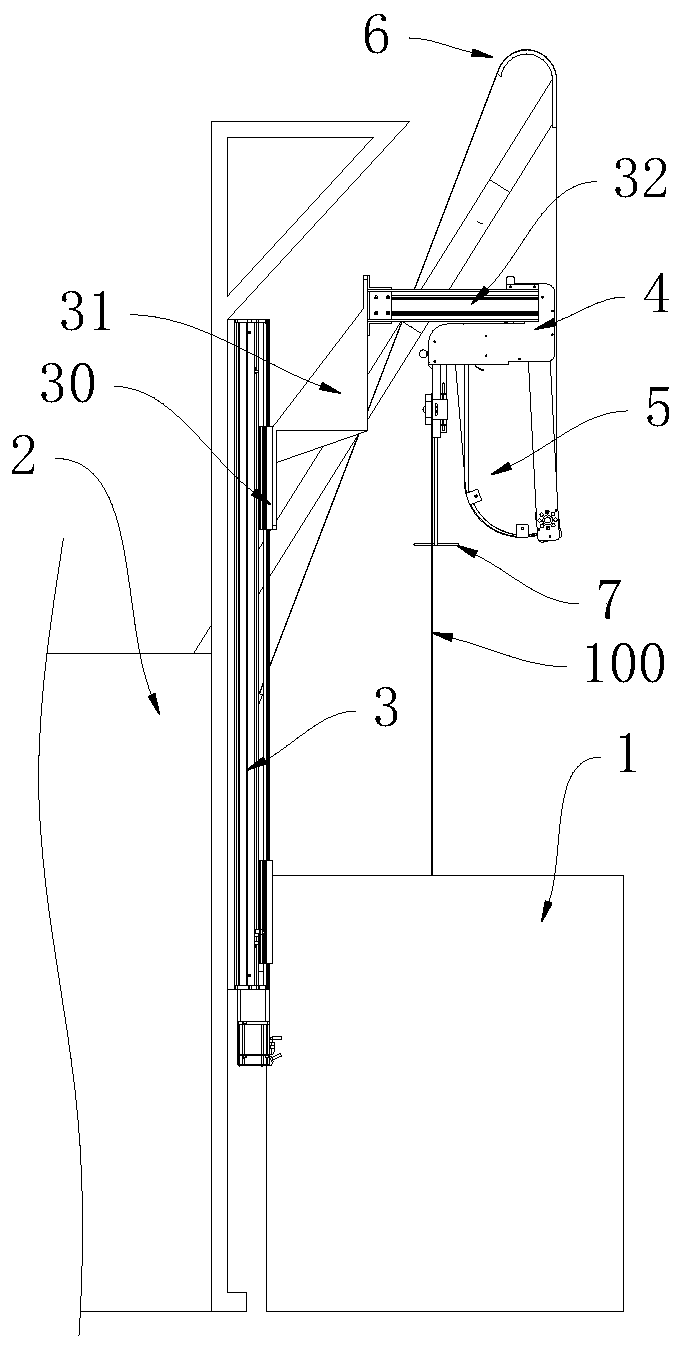

[0038] This embodiment proposes a filter rod suction resistance stabilization device, combined with Figure 1 to Figure 7 As shown, the filter rod suction resistance stabilizing device is located between a tow feeding device 1 and a filter rod forming device 2, and the filter rod suction resistance stabilizing device includes:

[0039] A lifting device 3 is installed on the base of the filter rod forming device 2, and the lifting device 3 is used to perform a lifting action;

[0040] A tow pulling device 4 is installed on the lifting end of the lifting device 3 and is located above the tow feeding device 1, and the tow pulling device 4 is used for the output of the tow feeding device 1 applying a traction force to the bundle, and then pulling the tow 100 outward;

[0041] A tow buffer device 5 includes an arc-shaped wire storage tank 50 extending downward from the bottom of the tow pulling device 4, and at least one buffer bar 51 is fixed on the inner side of the arc-shaped w...

Embodiment 2

[0058] This embodiment proposes a production control system of a filter rod suction resistance stabilizing device, combining Figure 1 to Figure 4 , Figure 12 , Figure 18 to Figure 20 As shown, the filter rod suction resistance stabilizing device is arranged between a tow feeding device 1 and a filter rod forming device 2, and the filter rod suction resistance stabilizing device includes a lifting device 3, a tow traction device 4, a filament A tow buffer device 5 and a tow support frame 6, the tow feeding device 1 is used to output the tow 100, the filter rod forming device 2 is used to process the tow 100 into a filter rod, the lifting device 3 is installed on the base of the filter rod forming device 2, the tow pulling device 4 is installed on the lifting end of the lifting device 3 and is located above the tow feeding device 1, and the tow buffer The device 5 includes a tension sensor 53, the tow pulling device 4 is used to pull the tow 100 output by the tow feeding de...

Embodiment 3

[0083] This embodiment proposes a tow pulling device, combined with Figure 8 to Figure 11 As shown, the tow traction device 4 includes a traction bracket 40, and the traction bracket 40 is provided with a driving roller 41, a driven roller 42 and a traction driving mechanism 43 for driving the driving roller 41 to rotate, The driving roller 41 and the driven roller 42 are arranged side by side, and the two are pressed against each other. A tow guide ring 7 is fixed below the traction bracket 40, and the tow 100 passes through the tow guide ring 7 from bottom to top. , the tow 100 passes between the driving roller 41 and the driven roller 42 from the top end, when the driving roller 41 rotates, by the cooperation of the driving roller 41 and the driven roller 42 And pulling the tow 100 , and then conveying the tow 100 to the lower side of the driving roller 41 and the driven roller 42 .

[0084] In the above structure, the close cooperation between the driving roller 41 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com