Expressway guardrail cleaning device

A cleaning device and expressway technology, applied in road surface cleaning, cleaning methods, construction, etc., can solve problems such as difficulty in adapting to cleaning guardrails, shortened service life, rust damage, etc., to improve the working environment, prolong service life, and reduce wear and tear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

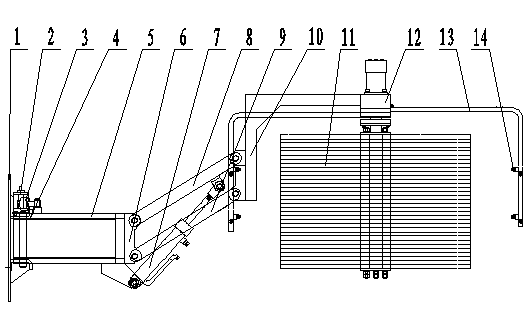

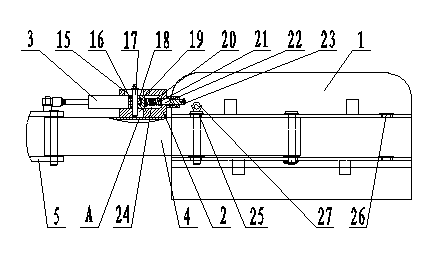

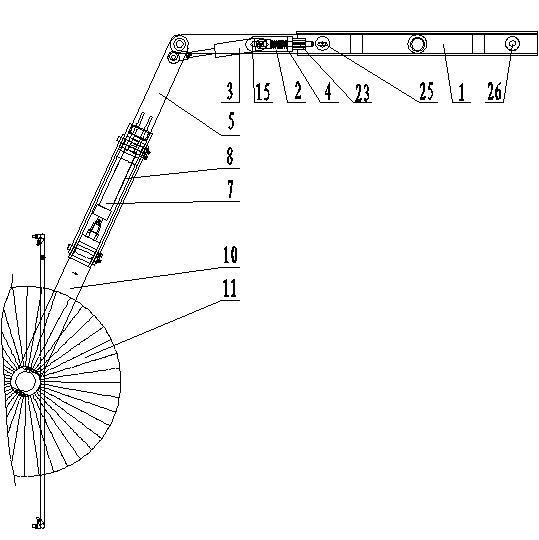

[0011] figure 1 , figure 2 with image 3 Among them, a highway guardrail cleaning device includes a connecting bracket 1 , a reversing arm 4 , a steering arm 5 , a connecting rod assembly, a spring 21 , a sweeping brush 11 and a sweeping brush support assembly 10 . The brush 11 is installed on the brush support assembly 10 , and the brush 11 is connected with the brush drive device 12 arranged on the brush support assembly 10 . The brush support assembly 10 includes a spray bar 13 and a nozzle 14 . One end of the reversing arm 4 is hinged with the center of the connecting bracket, and the two sides of the connecting bracket 1 are respectively provided with positioning holes, that is, a left positioning hole 25 and a right positioning hole 26 . The reversing arm 4 is provided with a reversing hole matching the left positioning hole 25 and the right positioning hole 26 of the connecting bracket 1 . When the reversing arm 4 is located on the left side of the connecting brack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com