Heat treatment method for improving fatigue resistance of Al-Cu-Mg alloy

A heat treatment method, al-cu-mg technology, applied in the field of heat treatment of metal materials, can solve the problems of weakening and reducing the fatigue resistance of alloys, so as to promote the closure effect, improve the fatigue resistance, and facilitate the reciprocating slip of dislocations Effect

Active Publication Date: 2014-01-22

CENT SOUTH UNIV

View PDF3 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

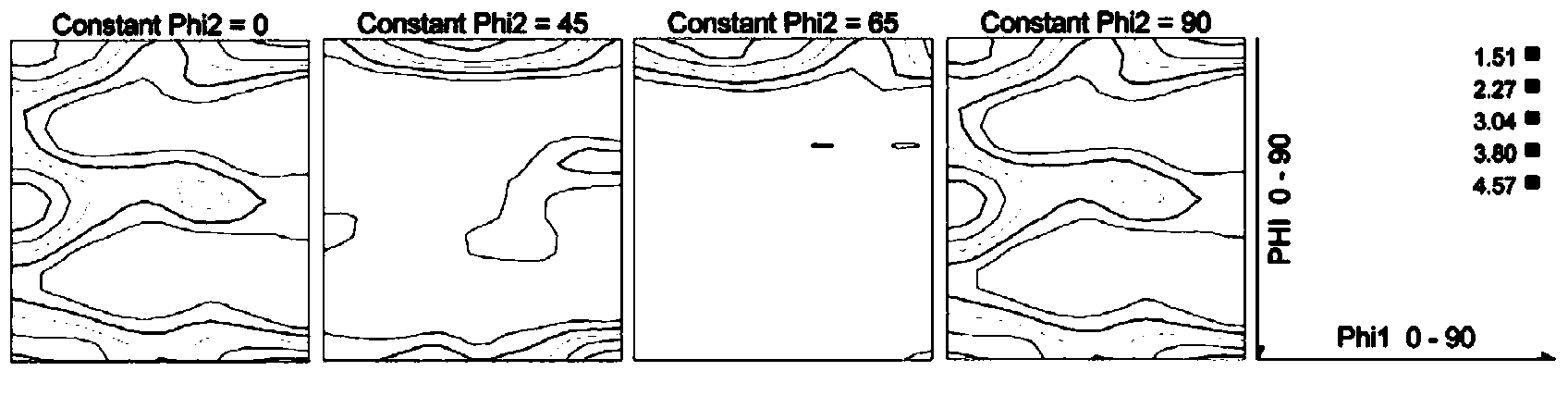

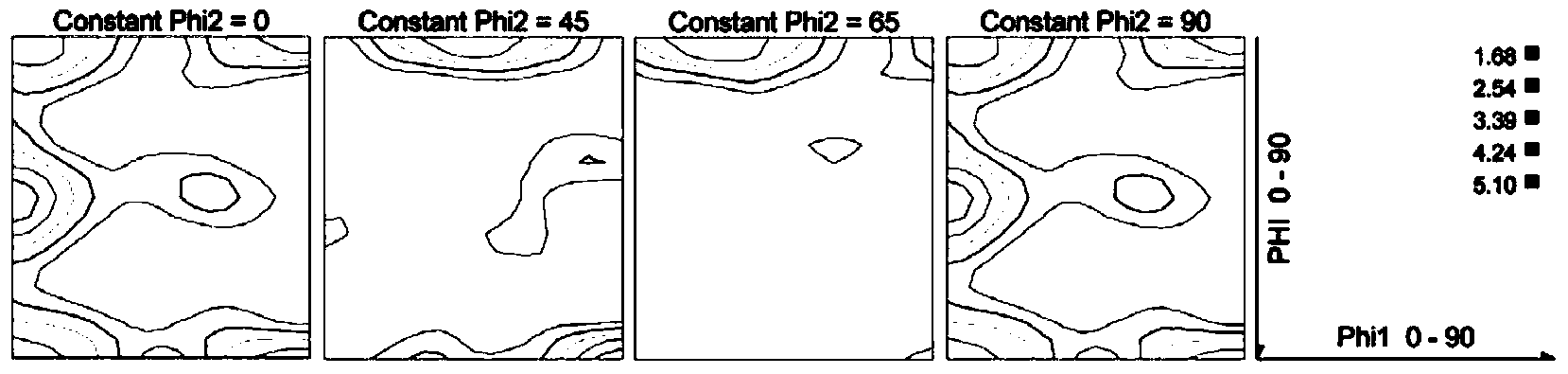

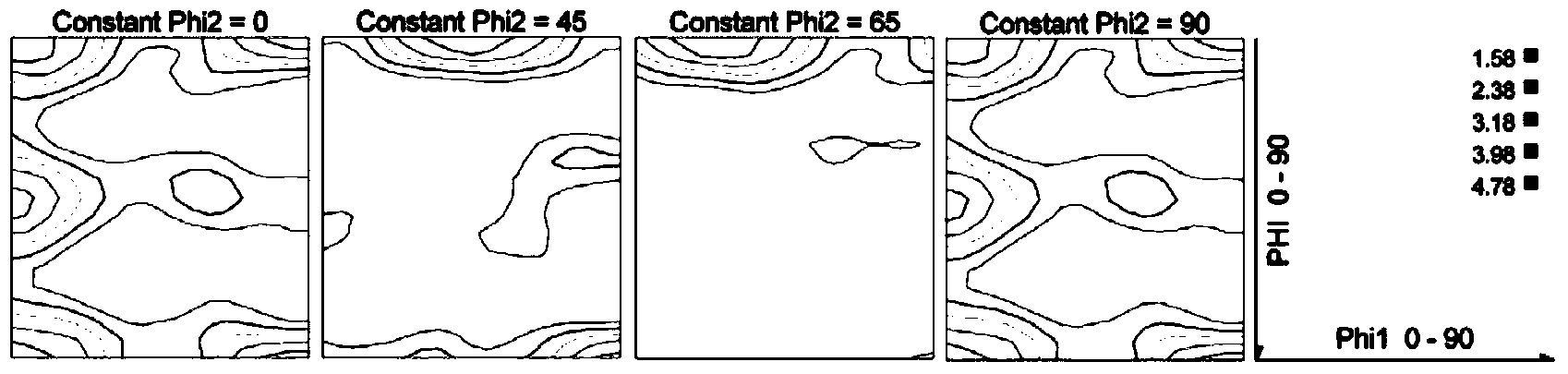

Studies have shown that the alloy can eliminate the dislocation entanglement in the cold-rolled state through solid solution. The conventional solution temperature of Al-Cu-Mg alloy is generally 490-500°C and the time is 0.5-2h, which can effectively eliminate the dislocation entanglement in the cold-rolled state. Dislocation entanglement configuration, however, with this treatment, the alloy will undergo complete recrystallization, which will weaken or even eliminate the Gaussian texture and reduce the fatigue resistance of the alloy. Therefore, a suitable solution quenching process is developed to make the alloy obtain a stronger It is an important method to improve the fatigue damage resistance of Al-Cu-Mg alloy, and it is of great importance to the application and development of the alloy in aerospace. the positive meaning of

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0029] The composition of alloy 1 is: Cu3.8%, Mg1.2%, Mn0.4%, Fe1 / 2 ,da / dN=2.1×10 -3 mm / cycle.

Embodiment 2

[0031] The composition of alloy 2 is: Cu4.2%, Mg1.5%, Mn0.4%, Fe1 / 2 ,da / dN=1.5×10 -3 mm / cycle.

Embodiment 3

[0033] The composition of alloy 3 is: Cu4.2%, Mg1.8%, Mn0.4%, Fe1 / 2 ,da / dN=1.6×10 -3 mm / cycle.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Login to View More

Abstract

A heat treatment method for improving fatigue resistance of Al-Cu-Mg alloy comprises: performing high-temperature short-time (505-535 DEG C / 1-25 min) solution hardening treatment on cold-rolled sheets, then performing natural aging at room temperature for 96 h or more. The aluminium alloy capable of being treated by the heat treatment method comprise the components: Cu, Mg, Ti and Al. The technology is simple and reasonable; and through high-temperature short-time solution hardening treatment, the alloy obtains relatively high goss texture components. Because most of crystal faces {111} of crystal grains in the alloy with high goss texture is positioned or close to the direction of the maximum external shearing stress, the reciprocating sliding of dislocation is promoted and a persistent slip band is easy to generate in the alloy, and thus the plasticity induction closure effect of fatigue crack is enhanced and the damage accumulation is reduced, also the crack deflection is promoted, and thus the fatigue crack spreading rate of the alloy is reduced and the fatigue resistance of the alloy is improved.

Description

technical field [0001] The invention discloses a heat treatment method for improving the anti-fatigue performance of an aluminum alloy, in particular to a high-temperature solution quenching heat treatment method capable of improving the anti-fatigue performance of an Al-Cu-Mg alloy. It belongs to the field of heat treatment of metal materials. Background technique [0002] Al-Cu-Mg series aluminum alloys are widely used in aviation flight devices. With the development of aviation technology, especially with the development of damage tolerance design theory, Al-Cu-Mg alloys are required to have excellent fatigue resistance. performance. At the same time, aluminum alloys used in aviation have encountered strong challenges from composite materials. The development of aluminum alloys that are resistant to fatigue damage is of great significance for the application and development of this alloy in the aviation field in the future. [0003] According to the existing research, t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22F1/057

Inventor 刘志义夏鹏李福东鲁璐青林茂

Owner CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com