Patents

Literature

110results about How to "The process is simple and reasonable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

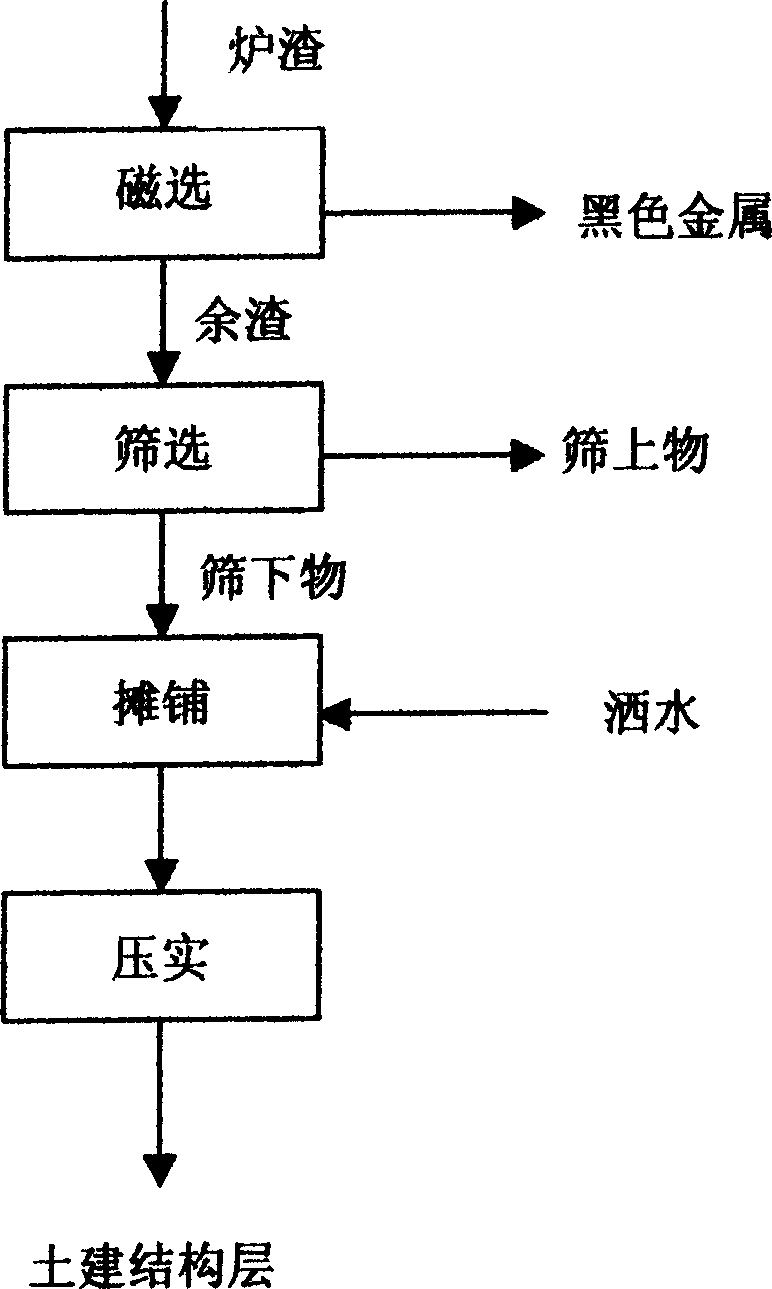

Method for making civil work engineering structure layer using domestic incinerator slag

The present invention relates to the comprehensive utilization technology of incinerated domestic garbage slag. The incinerated domestic garbage slag is first magnetically separated to separate out the ferric metals and then sieved with sieve of 19 mm size squared meshes. The subsieve fraction is used as aggregate for road base or as the covering material in landfill; and the single laid layer has thickness of 0.2-0.3 m and is spread while watering before being densified. The present invention has reasonable and simple technological process and low cost, and can cover 75 % over incinerated domestic garbage slag to form high quality civil work and some ferric metals.

Owner:TONGJI UNIV

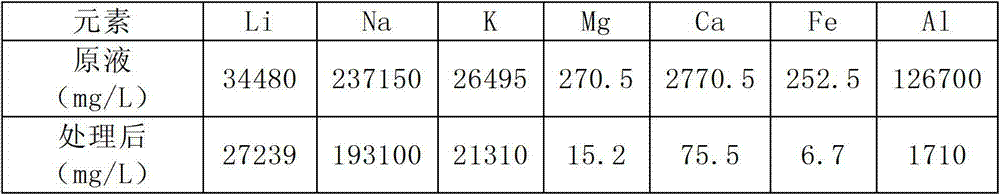

Method for extracting lithium from primary lithium-extraction solution of lithium ores

ActiveCN103114211AAbundant reserves of raw material resourcesThe process is simple and reasonableProcess efficiency improvementNanofiltrationInorganic salts

The invention relates to a method for extracting lithium from a primary lithium-extraction solution of lithium ores. The method comprises the following steps: (a) mixing inorganic salt with the primary lithium-extraction solution, removing the precipitates to obtain secondary lithium-extraction solution; (b) carrying out nanofiltration treatment on the secondary lithium-extraction solution, separating mono-valent cation salt solution from multi-valent cation salt solution; and (c) extracting lithium salt from the mono-valent cation salt solution. Other mono-valent and multi-valent salt separation solutions can be concentrated, crystallized or precipitated to obtain the corresponding salts. The invention provides a novel technology which is used for effectively recycling lithium from the lithium ores; the material resource storage capacity is abundant, the process flow is simple and reasonable, the operation is reliable and the energy consumption is low, so that the purpose of reducing the cost and the energy consumption is achieved.

Owner:宁波圣岛新材料有限公司

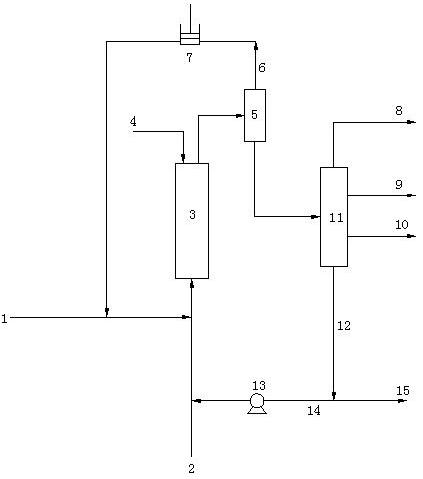

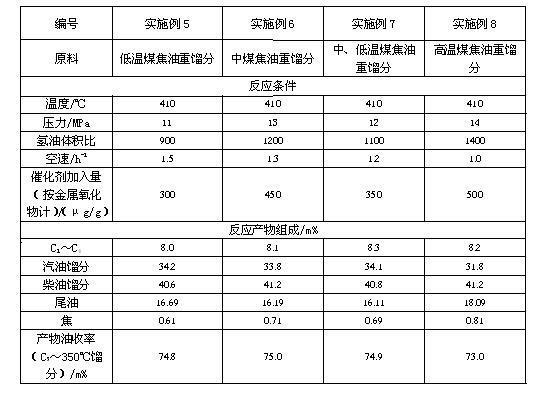

Coal tar heavy fraction fluidized-bed hydrocracking method and system thereof

InactiveCN101962572AIncrease profitSimple processTreatment with hydrotreatment processesLiquid productHydrogen

The invention relates to the field of coal chemical industry, in particular to a coal tar heavy fraction fluidized-bed hydrocracking method. The method comprises the following steps: the raw materials of coal tar heavy fractions are mixed with hydrogen and then enter a fluidized-bed reactor from the bottom thereof, and a supported catalyst enters the fluidized-bed reactor from the top thereof; under the action of the supported catalyst, the coal tar heavy fractions and the hydrogen carry out hydrocracking reaction in the fluidized-bed reactor; and the obtained reaction product is delivered from the top of the fluidized-bed reactor and then subject to gas-liquid separation, the separated hydrogen returns to the fluidized-bed reactor to be recycled, and the separated liquid product is subject to distillation separation to obtain gaseous hydrocarbon, gasoline fractions, diesel fractions and tail oil. In the invention, by directly adopting the fluidized-bed hydrocracking method, the coal tar heavy fractions can keep light weight, the yield of the fuel oil product hydrogenated by coal tar can be effectively increased, and blockage phenomenon of a catalyst bed layer can be effectively eliminated; and the method of the invention has the characteristics of simple and reasonable process, long-term operation, a small amount of the catalyst adopted, low cost, high yield of the oil generated by the product and good quality.

Owner:DALIAN UNIV OF TECH

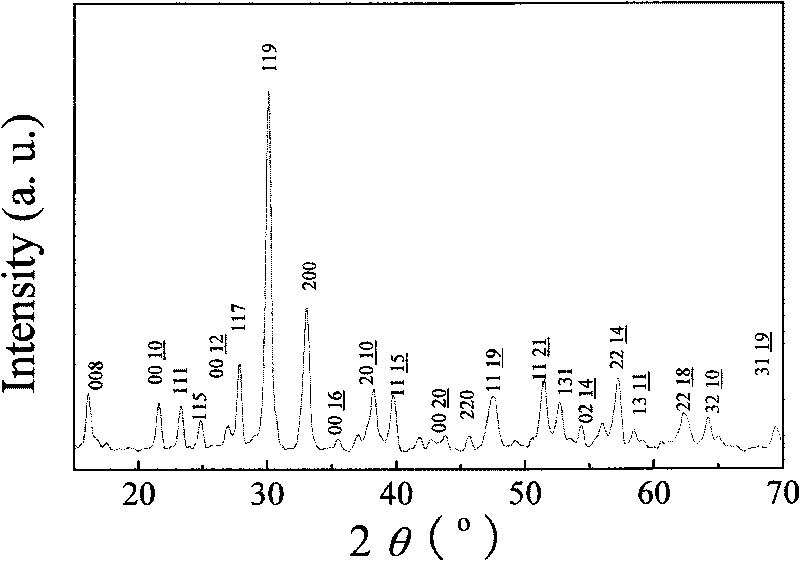

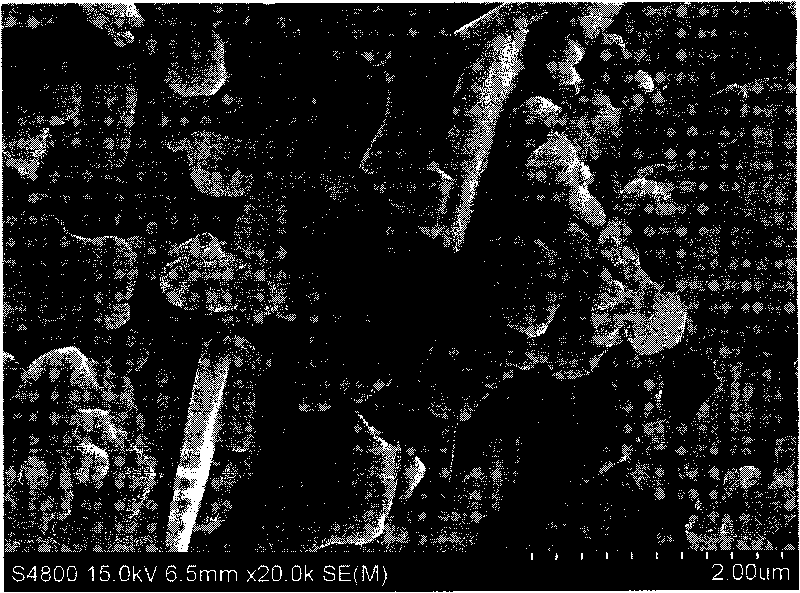

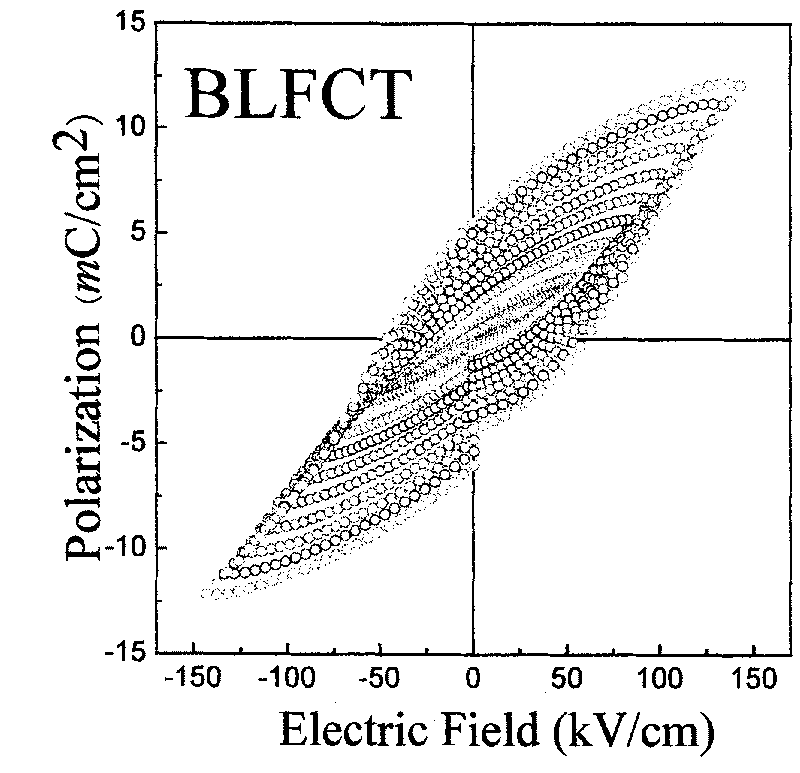

Layered structure ferrotitanium lanthanum bismuth cobaltate ceramic with multiferroic and preparation method thereof

InactiveCN101704669AImproved ferroelectric and magnetic propertiesThe process is simple and reasonableLayered structureLanthanum

The invention relates to a layered structure ferrotitanium lanthanum bismuth cobaltate ceramic with multiferroic and a preparation method thereof, relating to the technical field of oxide ceramic material preparation. The method comprises the following steps: firstly preparing Bi3.25L0.75Ti3O15 powder, then implanting BiCoO3 and BiFeO3 in Bi3.25L0.75Ti3O15 to form Bi4.25L0.75Fe0.5Co0.5Ti3O15 ceramic. In the obtained BLFCT sample, the octahedral arrangement of Fe-O and Co-O is relatively orderly so that the local coupling between Fe-O-Co and La-O-Co / Fe can be obtained and the ferroelectric property and magnetic property of the sample can be improved. The ceramic of the invention has simple and reasonable technology and good compatibility with the current technology, and the sample preparation temperature is much lower than the preparation temperature of the current technology so as to greatly reduce the energy consumption, thus the ceramic is applicable to industrial production.

Owner:YANGZHOU UNIV

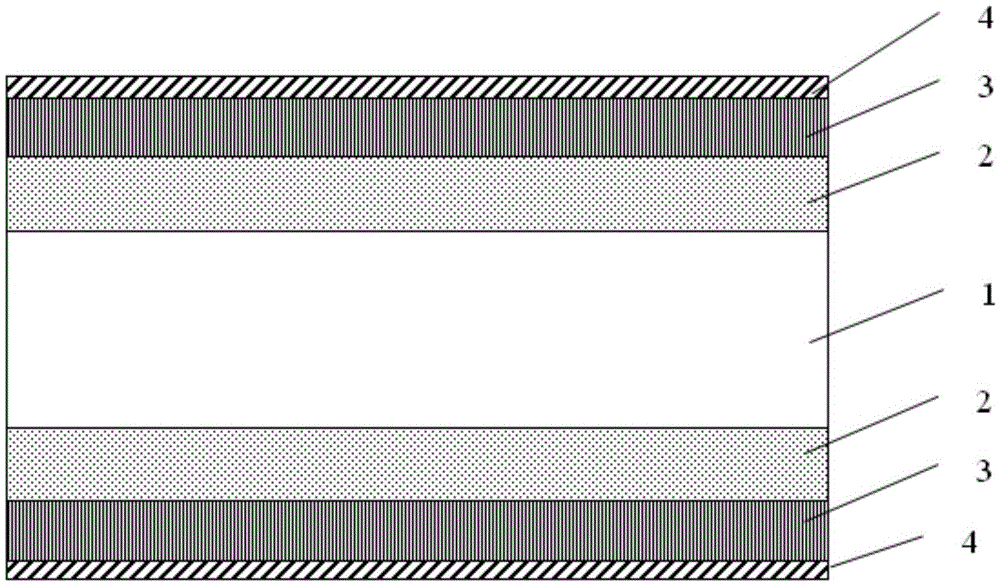

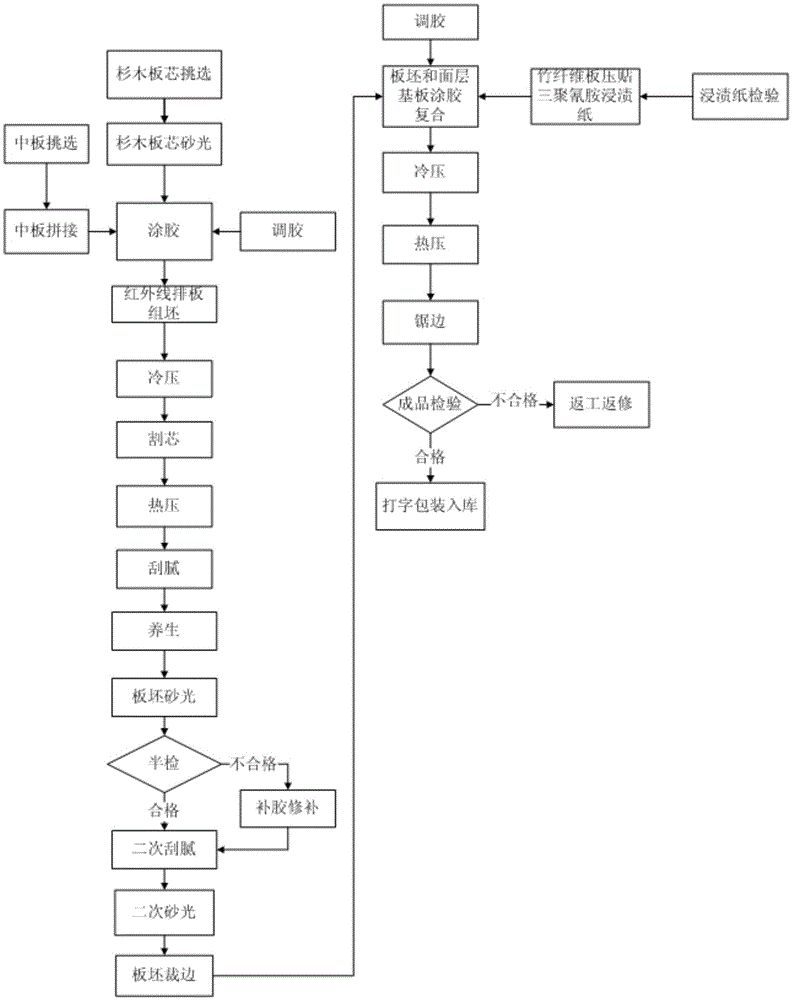

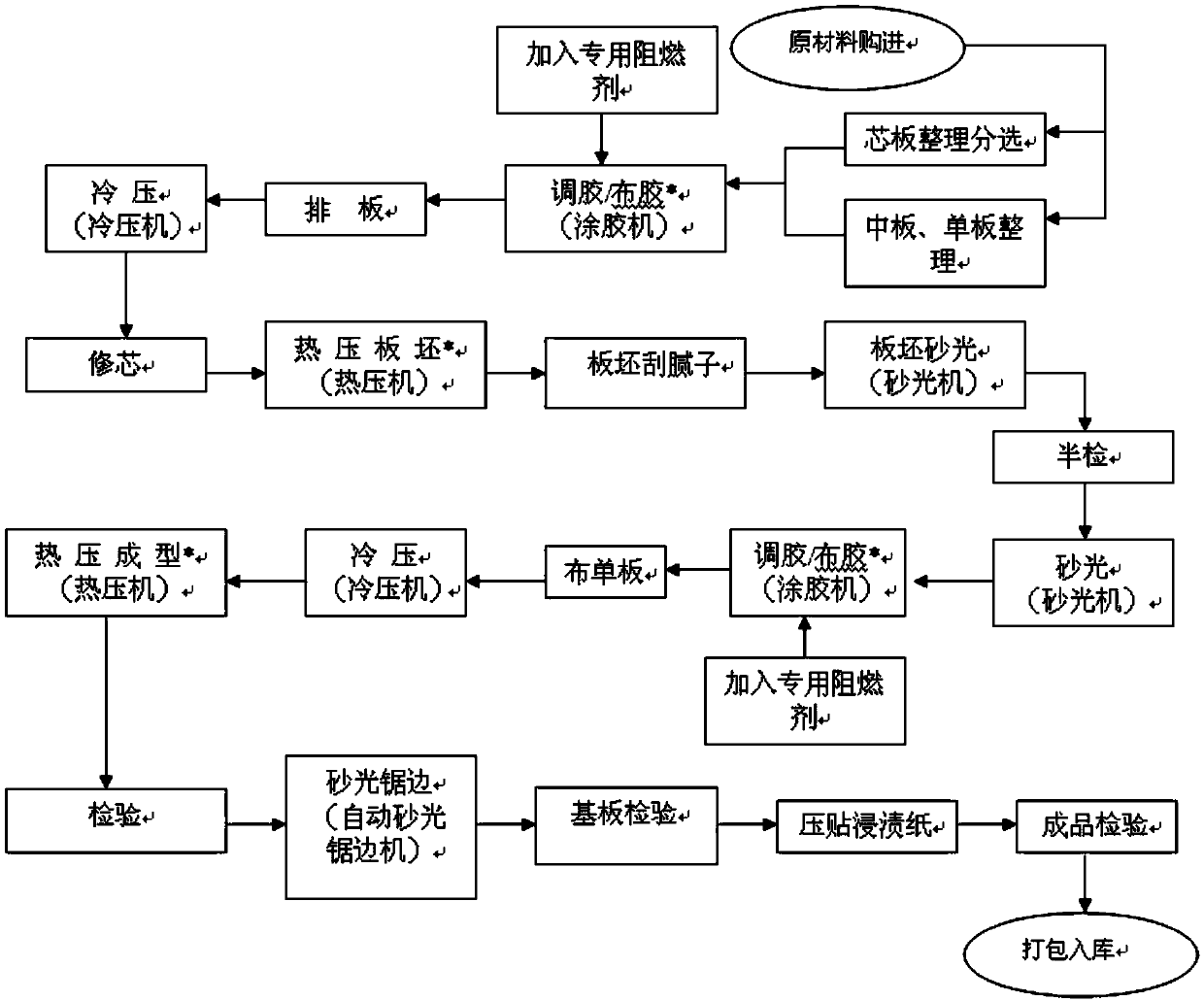

Novel solid ecological bamboo board and production process thereof

InactiveCN105415457AThe process is simple and reasonableShort production processOther plywood/veneer working apparatusWood veneer joiningEnvironmentally friendlySolid wood

The invention belongs to the field of board machining and provides a novel solid ecological bamboo board and a production process thereof. The novel solid ecological bamboo board comprises a cedarwood board core, middle boards, bamboo fiber boards and melamine impregnated paper. The upper surface and the lower surface of the cedarwood board core are covered with the middle boards through gluing and integrally pressed to form a board blank; the melamine impregnated paper is stuck to the bamboo fiber boards in a pressed mode to integrally form surface-layer substrates; the upper surface and the lower surface of the board blank are gelatinized and coated with the surface-layer substrates and integrally formed through hot pressing to obtain a finished product. The novel solid ecological bamboo board and the production process thereof have the advantages that 1, a novel assembly structure is adopted, and the hardness, nail-holding ability, static bending strength and surface evenness of the board are greatly improved; and 2, the bamboo fiber boards are adopted for the surface-layer substrates, the fracturing resistance and the thermocycling resistance of melamine ecological boards are greatly improved, and thus the melamine ecological board can meet the all-weather all-region using requirement; besides, the finished product is low in formaldehyde content, economical, environmentally friendly, and the advantages of water resistance, mould resistance, inflaming retarding, moth resistance and the like are achieved at the same time.

Owner:ZHEJIANG SHENGHUA YUNFENG GREENEO

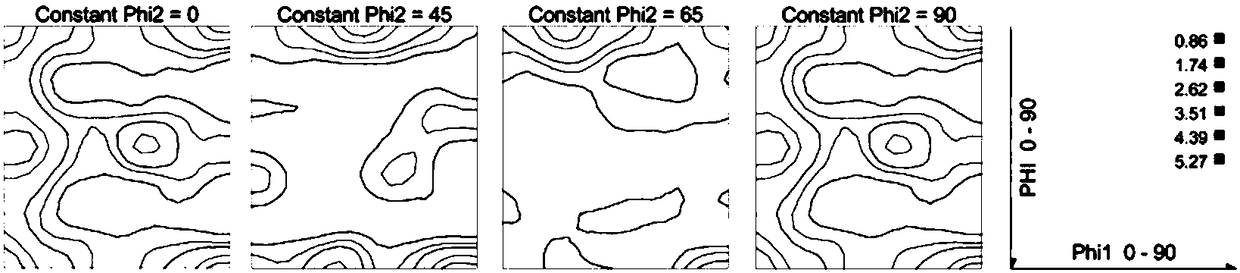

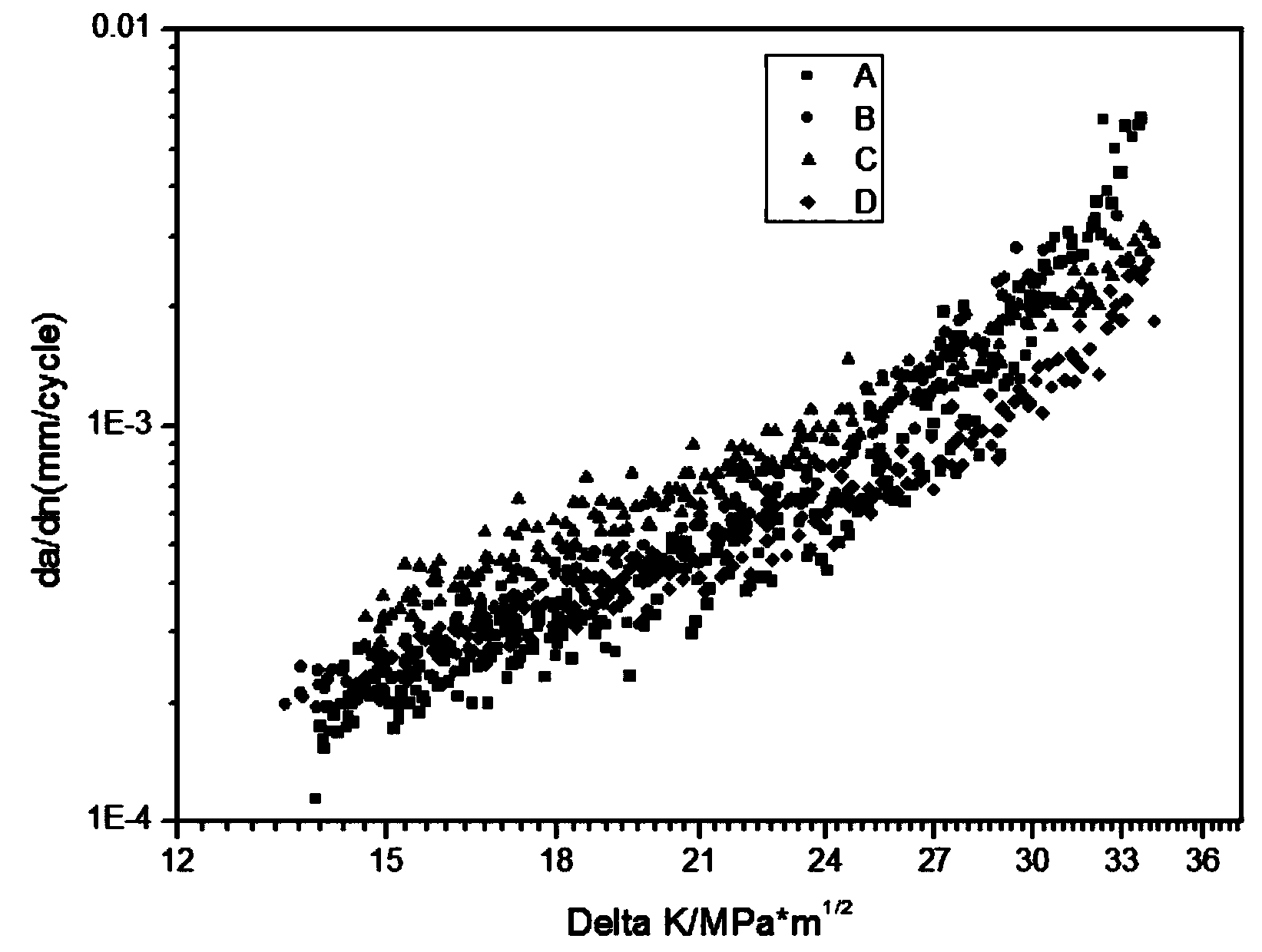

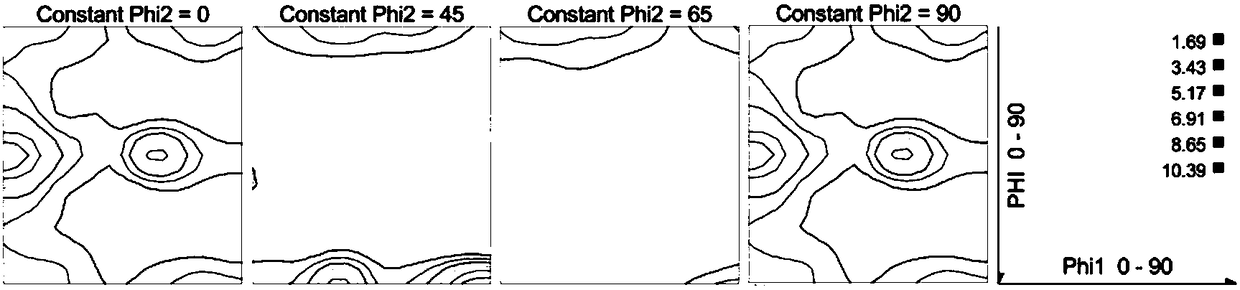

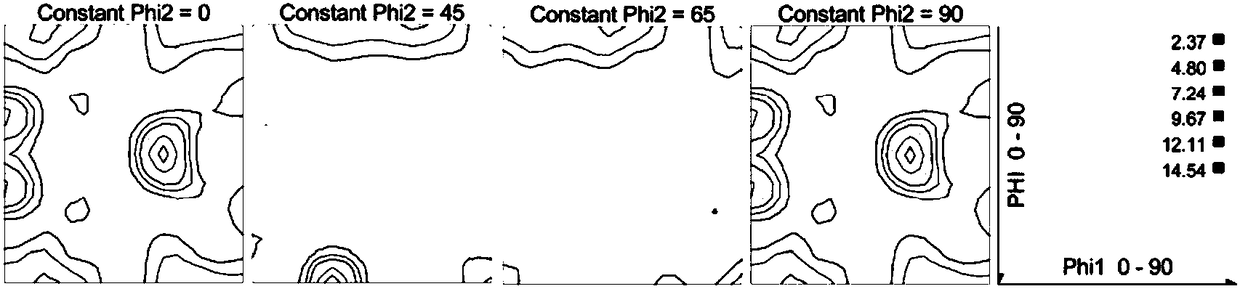

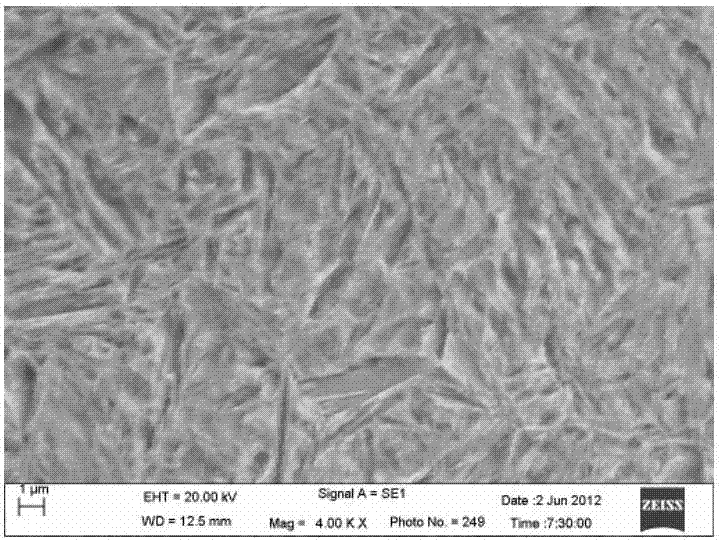

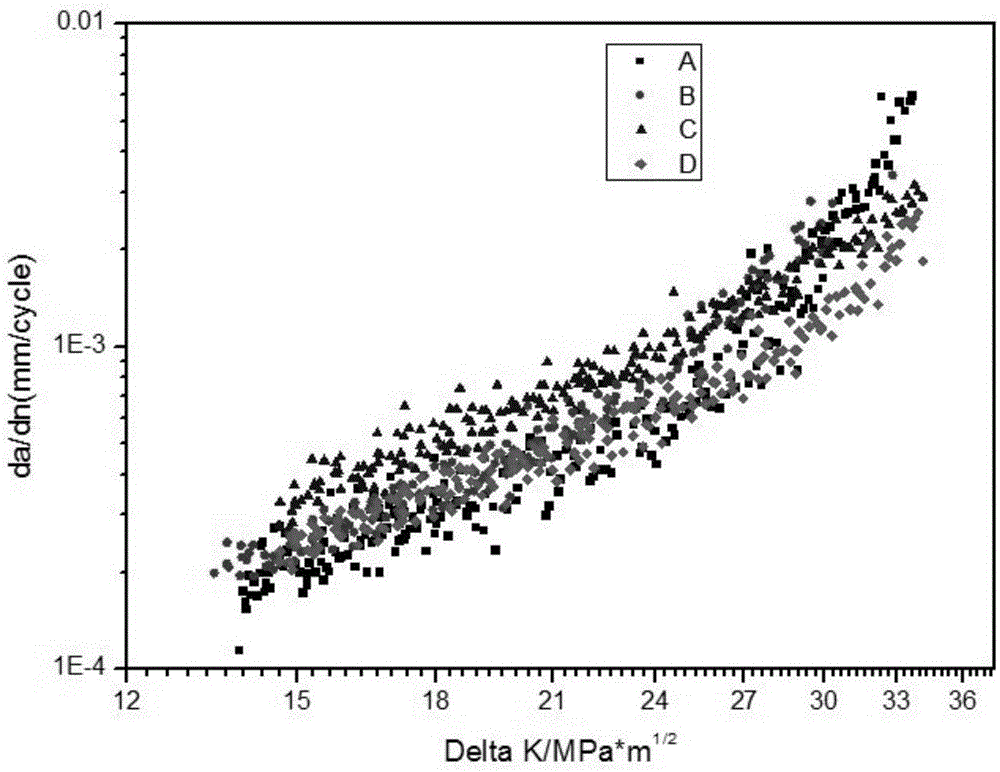

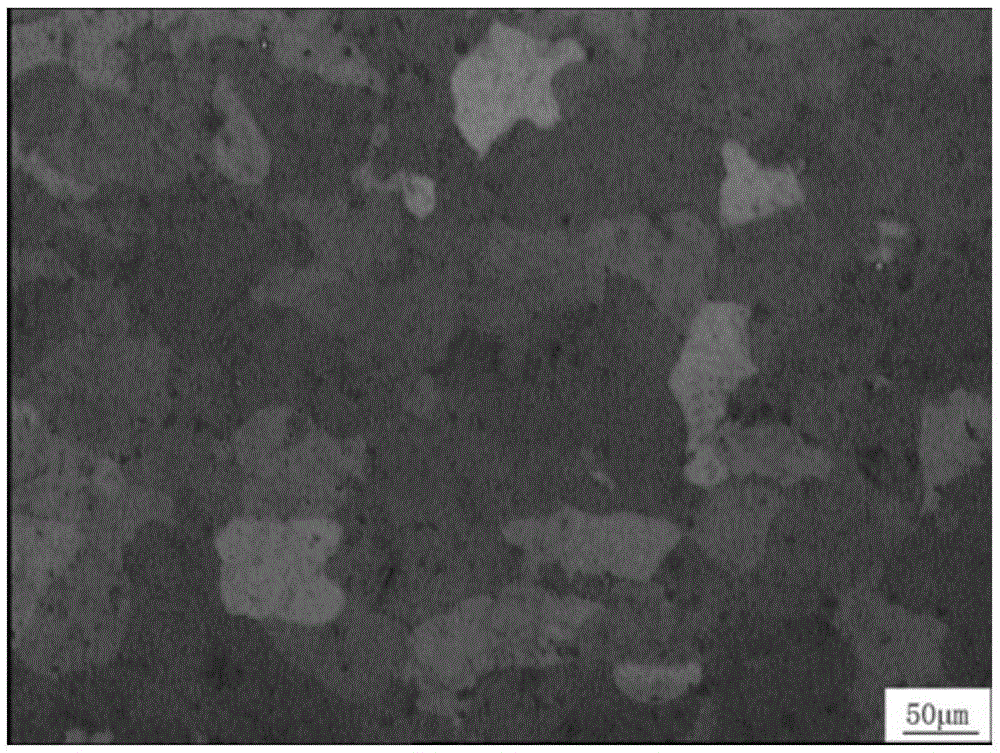

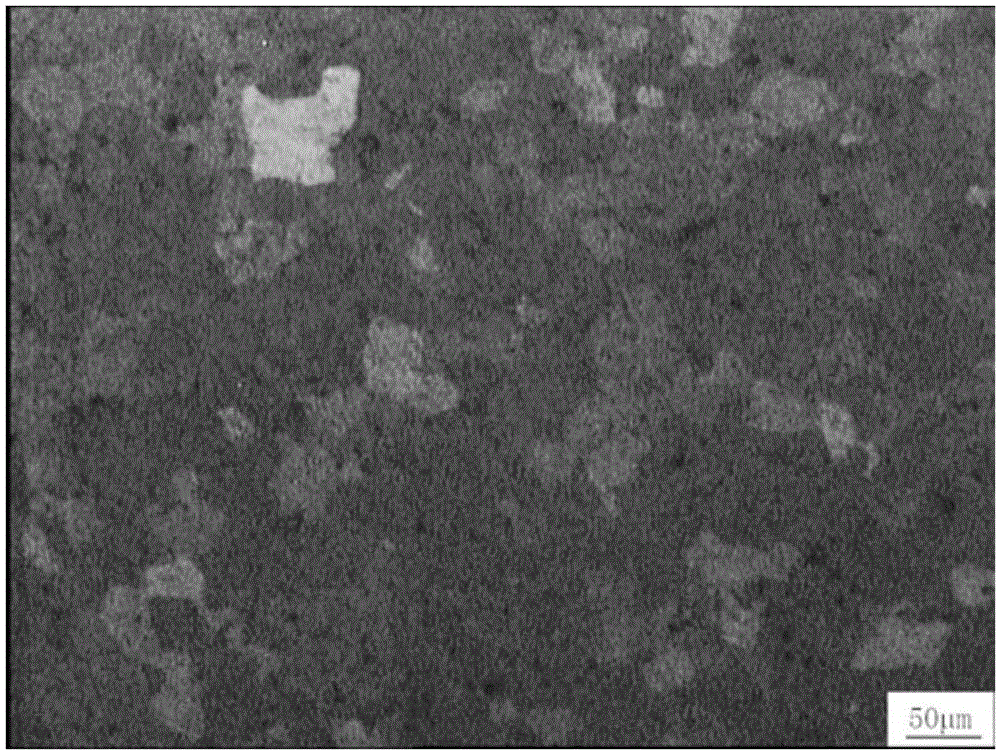

Silver-bearing Al-Cu-Mg alloy and heat treatment method for silver-bearing Al-Cu-Mg alloy to obtain high-strength P structure

The invention discloses silver-bearing Al-Cu-Mg alloy and a heat treatment method for the silver-bearing Al-Cu-Mg alloy to obtain the high-strength P structure. The heat treatment method comprises thesteps that an Al-Cu-Mg-(Ag) hot rolled plate is subjected to recrystallization annealing at 300-450 DEG C / 60-240 min at first and then subjected to solid solution quenching treatment at 480-510 DEG C / 20-120 min, and natural aging is conducted for at least 96 h. Al-Cu-Mg-(Ag) alloy comprises the following components of Al, Cu, Mg, Ag, Mn and Ti. According to the silver-bearing Al-Cu-Mg alloy and the heat treatment method for the silver-bearing Al-Cu-Mg alloy to obtain the high-strength P structure, the technology is simple and reasonable, the high-strength P structure is obtained by adding theAg element and applying the appropriate annealing and solid solution technology, thus, many {111} faces in hot-rolled Al-Cu-Mg-(Ag) alloy crystalline grains are in the direction close to the maximumadditional shear stress, sliding of dislocation under alternating stress is facilitated, stress concentration is relieved, and accordingly, the fatigue resistance is improved; and in addition, large torsion angle interfaces between P crystalline grains and crystalline grains surrounding the P crystalline grains exist, crack deflection is prone to be induced, a large deflection angle and a rough broken plane are caused, and thus, energy consumed by crack growth is increased, the obvious fatigue crack closure effect is generated, the fatigue crack growth rate is decreased; and accordingly, the alloy has good fatigue resistance and is suitable of industrial application.

Owner:CENT SOUTH UNIV

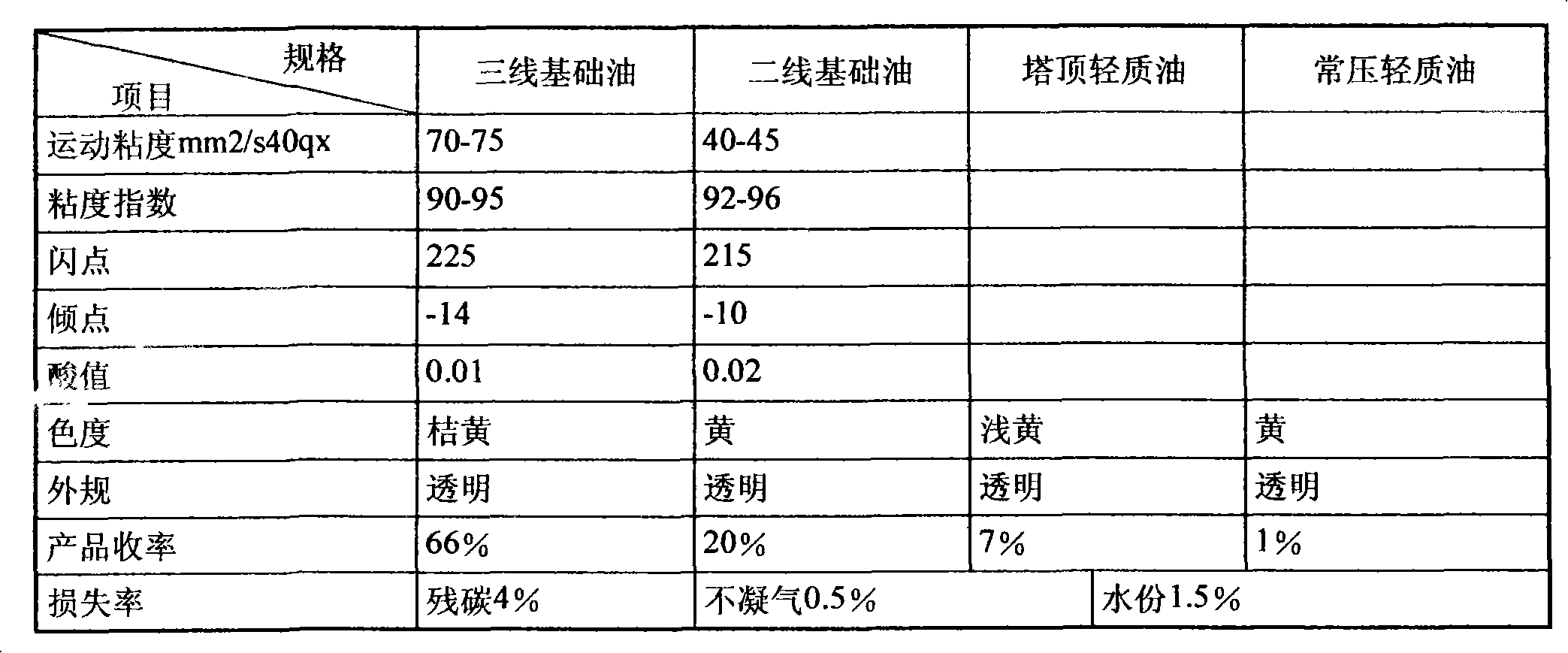

Process for refining base oil by using regenerated waste oil from inclined wall wiped film vacuum distillation

InactiveCN101633862AThe process is simple and reasonableEasy and safe manual operationDistillationLubricant compositionEvaporatorResidual oil

The invention relates to a process for refining base oil by using regenerated waste oil from inclined wall wiped film vacuum distillation, which belongs to the field of waste oil regeneration. The key technical point of the process is to emphasize the solution of the problem that the vacuum wiped film distillation technology in the prior art has drawbacks of large residual oil discharge amount and low product yield due to the fact that the distilled liquid film of a wiped film evaporator is easy to be scraped by a wiped film scraper blade to fall onto the bottom of the evaporator to be discharged. For solving the problem, the process adopts a technical scheme of high-temperature flocculation neutralization topping, inclined wall vacuum wiped film distillation, vacuum distillation tower rectification separation and vacuum high-temperature clay absorption refining. The technical key points of the process also include: the vacuum inclined wall wiped film vacuum distillation technology and a complete cone inclined wall wiped film evaporator are adopted; and technical processes that the cone barrel and heating evaporation liquid surface incline 2 to 30 degrees outwards, that two processes of distillation and gasification at different temperatures and the like are adopted; the discharge amount of residual oil is reduced; the product yield is increased; and the product quality is improved.

Owner:王延海

Walnut oil extraction

InactiveCN1712505AEfficient use ofThe process is simple and reasonableFatty-oils/fats productionHeating oilCarya illinoinensis

A squeezing process of walnut oil is carried out by choosing pecan, breaking kernels, putting kernels into pan, frying for 10-20mins at 120-140íÒC, breaking the fried products in breaker, heating oil press at 150-180íÒC for 25-35mins, putting the broken kernels into oil press, squeezing, preparing raw oil, filtering, putting raw oil into vacuum jar, filtering to remove impurities, obtaining refined oil, depositing refined oil for 20-30hrs, and packing into final oil. It achieves high efficiency, less consumption and no harmful by products.

Owner:张福贵

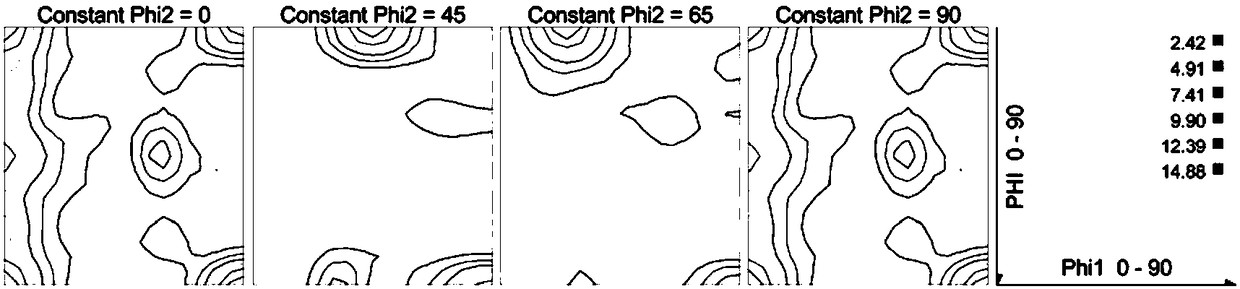

Method for improving the fatigue resistance performance of Al-Cu-Mg alloy

A method for improving the fatigue resistance performance of Al-Cu-Mg alloy is to perform high-temperature hot rolling, primary solution treatment, large deformation cold rolling, secondary solution treatment and natural aging treatment to homogenized aluminium alloy in sequence. According to the invention, relatively high temperature is kept before hot rolling, and then a material recrystallizes dynamically during the hot rolling process, so that a plurality of recrystallization textures such as Goss and Cube are formed, and the fatigue resistance performance of the aluminium alloy can be improved advantageously; solution treatment before cold rolling can greatly eliminate large second-phase particles except for impurities such as Fe and Si to prevent a high energy region from forming, so that uneven recrystallization can be avoided; after large deformation cold rolling deformation is performed, the dislocation density of the alloy is greatly improved, the alloy can obtain more stored energy, the recrystallization nucleation rate is increased during solution treatment, fine crystal grains can be formed, and the fatigue resistance performance of the aluminium alloy can be improved further. The process method provided by the invention is simple, convenient in operation, economical in cost and suitable for industrialized application.

Owner:CENT SOUTH UNIV

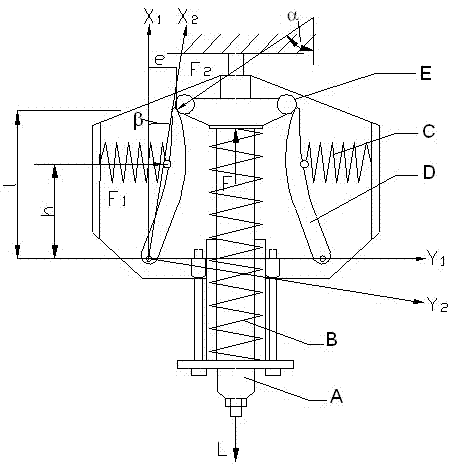

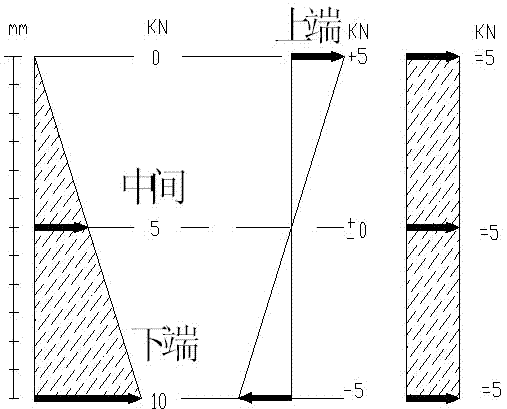

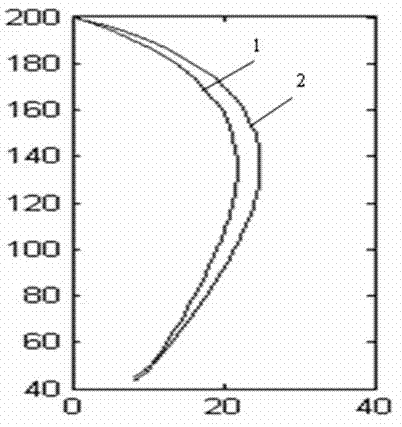

Constant force support lifting frame for support lifting of thermal power pipelines

InactiveCN102788197AMeet the requirements of high-precision hangingHigh precisionPipe supportsConstant forceSpring force

The invention provides a constant force support lifting frame for support lifting of thermal power pipelines. A main spring is mounted on a load pipe and fixed through a main spring pressure plate, auxiliary springs are mounted on two inner sides of an outer framework, two knife-shaped guide rails are mounted on the outer framework through a rotating shaft, the auxiliary springs on the two sides are connected with the knife-shaped guide rails through auxiliary spring pressure plates, and two groups of rollers are connected with the knife-shaped guide rails; the rollers move up and down and press the main spring when the load pipe is stressed by external force; and in different movement positions, swinging of the knife-shaped guide rails enable the auxiliary springs on the two sides to be compressed or stretched, the resultant force in the vertical direction is changed linearly and expresses the characteristic of being same with or opposite to the direction of the main spring force, and the force L output by the load pipe keeps constant during the whole movement process. The constant force support lifting frame has the advantages that the force balance principle design is adopted, the structural technology is simple and reasonable, friction pairs are less, the constant force support lifting frame is convenient to use, mount and maintain, the constancy is smaller than 4%, the load can exceed 200 KN greatly, the combination can be realized, and the precision can completely meet requirements of large-capability and high-performance equipment.

Owner:高勇

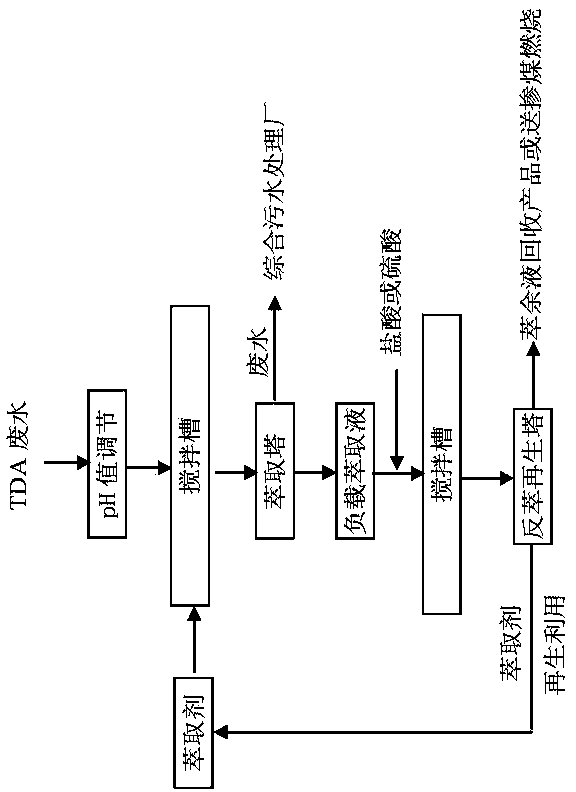

Method for treating TDA wastewater through complexing extraction

ActiveCN103922507AReduce concentrationThe process is simple and reasonableMultistage water/sewage treatmentNature of treatment waterKeroseneWastewater

The invention discloses a method for treating 2,4-diaminotoluene (TDA) wastewater through complexing extraction. The method is characterized by mainly comprising the steps of pH value adjustment, extraction and an extraction agent recycling treatment process. The method adopts one or two of 2-ethylhexyl 2-ethylhexyl phosphonate, di(2,4,4-trimethyl amyl) phosphonic acid as a complexing agent, one or more of n-octyl alcohol, isooctanol and sec-octyl alcohol as a cosolvent, and kerosene or cyclohexane as a diluent for preparing a complexing exaction agent for separating TDA compounds which are hard to be biochemically treated in the wastewater, and the extraction agent is regenerated by using inorganic acid and is subsequently repeatedly used. The method is simple and reasonable in process, high in operability, convenient to operate and low in treatment cost. The TDA concentration of the wastewater treated by using the process is greatly reduced, the primary extraction removal rate of TDA is 95-99%, and a wide application prospect is achieved.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Preparation method of fiberboard adhesive

InactiveCN107033309AEnsure environmental stabilityThe process is simple and reasonableAldehyde/ketone condensation polymer adhesivesChemistryUrea

The invention discloses a preparation method of a fiberboard adhesive. The preparation method comprises the following steps that formaldehyde and water are mixed, and after the temperature is raised to 38-42 DEG C, an alkaline reagent is added to adjust the PH value to be 7.8-8.2; melamine and urea are added; heating is conducted, and when the temperature is raised to 83-87 DEG C, the temperature is naturally raised to 86-90 DEG C; an acid reagent is added to adjust the PH value to be 5.0-5.3, and the viscosity of a condensation point is tested every five minutes; after the viscosity reaches a set threshold, triethylamine and the alkaline reagent are added to adjust the PH value to be 5.5-5.8; after the temperature is reduced to 80-84 DEG C, urea is added again; after 15-25 minutes, the alkaline reagent is added to adjusted the PH value to be 7.1-7.6 after the viscosity is tested; melamine and urea are added again, and after the temperature is reduced to 55-65 DEG C, urea is added again; the temperature is reduced to 55-65 DEG C, the alkaline reagent is added to adjust the PH value to be 7.5-8.3, and the addition of the alkaline reagent is stopped after the viscosity reaches the set threshold; the temperature is reduced to 40 DEG C to discharge glue. The preparation method of the fiberboard adhesive is low in production cost and safe and stable in production process, and the formaldehyde discharge amount of the prepared adhesive meets high-standard environmental requirements.

Owner:曾华

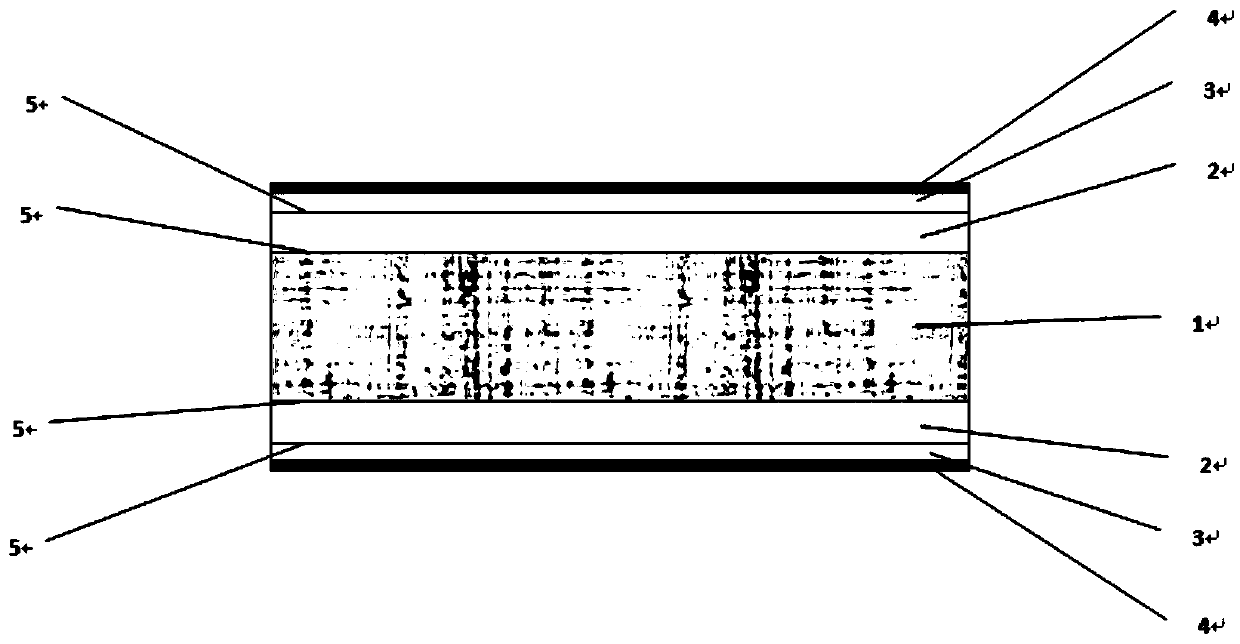

Flame-retardant impregnated film adhesive facing blockboard

PendingCN109514657AThe process is simple and reasonableGood flatnessOther plywood/veneer working apparatusWood veneer joiningAdhesiveEngineering

The invention provides a flame-retardant impregnated film adhesive facing blockboard. The flame-retardant impregnated film adhesive facing blockboard comprises a board core, middle boards, poplar veneers, decorative film adhesive and flame-retardant adhesive layers, wherein the upper surface and the lower surface of the board core are correspondingly covered with the middle boards and are integrally pressed to form a board blank; adhesive connection is correspondingly carried out between the upper surface of the board core and the middle board as well as between the lower surface of the boardcore and the middle board through flame retardant adhesive layers, wherein the flame retardant glue layers are prepared by coating glue added with 25% of a urea glue flame retardant; the upper surfaceand the lower surface of the board blank are correspondingly covered with the poplar veneers and are integrally made into a base board through cold and hot pressing, and the upper surface of the board blank and the poplar veneer and the lower surface of the board blank and the poplar veneer are correspondingly subjected to adhesive connection through the flame retardant adhesive layers, wherein the flame retardant adhesive layers are prepared by coating glue added with the urea glue flame retardant in a proportion of 30%; and the decorative film adhesive is correspondingly pasted on the uppersurface and the lower surface of the base board, and finished products of the flame-retardant impregnated film adhesive facing blockboard are obtained through hot pressing and integral forming, so that the flame retardant performance of the impregnated film adhesive facing blockboard is improved, and meanwhile, environment protection is achieved, and various home decoration requirements of peoplecan be met.

Owner:ZHEJIANG SHENGHUA YUNFENG GREENEO

Natural type coconut beverage and method for processing the same

InactiveCN101467765AThe process is simple and reasonableClarify transparent qualityFood preparationSucroseNutrient content

The invention provides natural coconut drink and preparing method thereof. The main ingredients are the coconut original juice, adding with sucrose, fructose syrup, citric acid, vitamin C, and water. The weight percentages are following: coconut original juice 5%-45%; sucrose 6%-14%; fructose syrup 0.2%-3%; citric acid 0.1%-0.6%, vitamin C 0.01%-0.55%; The rest is water. After raw materials processing, peeled, Java Juice, deployment, homogeneous, vacuum degassing, the completion of sterilization processes; process reasonably simple, transparent and quality beverages to clarify the stability and uniqueness of the original coconut flavor and nutritional ingredients, pure fresh taste, cool, sweet and sour entrance, family, and the crowd wide adaptability, palatability, and is particularly suited to long-term consumption.

Owner:TIANJIN ZHONGYING HEALTH FOOD

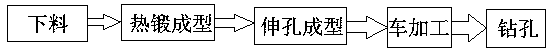

Front car body connecting bush machining process

InactiveCN109366109AImprove mechanical propertiesVersatilityVehicle componentsEngineeringMachining process

The invention relates to a front car body connecting bush machining process, and belongs to the field of automobile accessory production and manufacturing. The process comprises the steps of blanking,hot forging forming, stretching hole forming, turning machining and drilling. The process is simple and reasonable, the product size is stable, the material mechanical property is good, the production efficiency is high, and universal performance is realized; and a series of bushes with different specifications can be machined by adjusting the mold and the program, and the use requirements can bemet.

Owner:海盐猛凌汽车配件有限公司

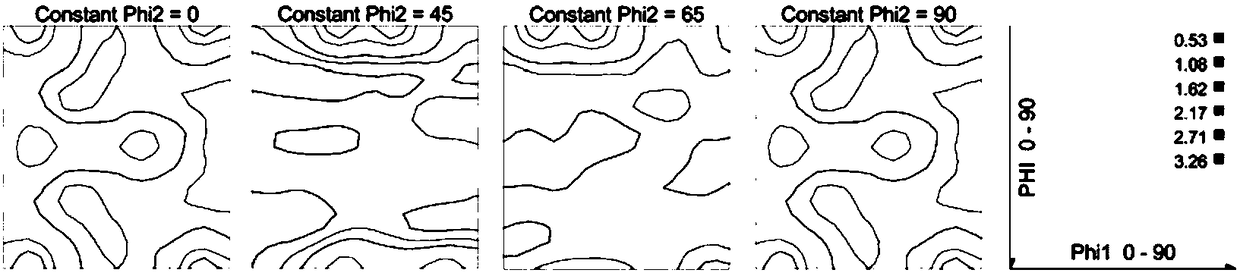

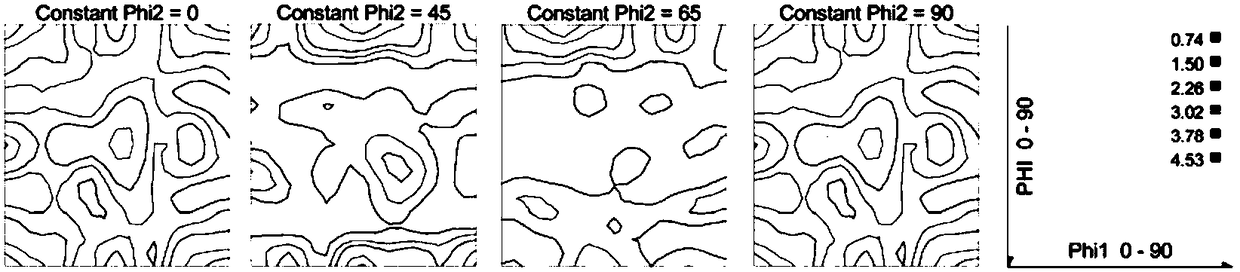

Al-Cu-Mg alloy with high-strength GoSS+P texture and excellent fatigue resistance and technology

The invention relates to an Al-Cu-Mg alloy with a high-strength Goss+P texture and excellent fatigue resistance and a technology. The alloy comprises 4.2-4.5% of Cu, 1.2-1.5% of Mg, 0.3-0.8% of Mn, 0.03-0.1% of Ti, less than 0.06% of Fe, and less than 0.06% of Si, wherein a mass ratio of Cu and Mg is 2.9-3.7. A hot processing method comprises the steps of homogenizing, quick high-temperature hot rolling, recrystallization annealing, solution hardening and natural ageing of an Al-Cu-Mg cast ingot. The technology is simple and reasonable, and a formation temperature of a P texture is reduced tobe the same as or close to a formation temperature of a Goss texture by controlling a Cu / Mg ratio of the alloy. Structural component segregation and nonuniform second-phase particle distribution are eliminated by homogenizing treatment; then, the high-temperature large deformation quick hot rolling is performed to form high-strength Brass texture; the high-strength Goss texture and the P texture are obtained by annealing and solution hardening treatment; deformation textures such as the Brass texture and a Copper texture are consumed to the greatest extent to form the high-strength Goss and Ptexture; fatigue crack propagation is impeded; and the alloy has the excellent fatigue resistance and is suitable for industrial application.

Owner:CENT SOUTH UNIV

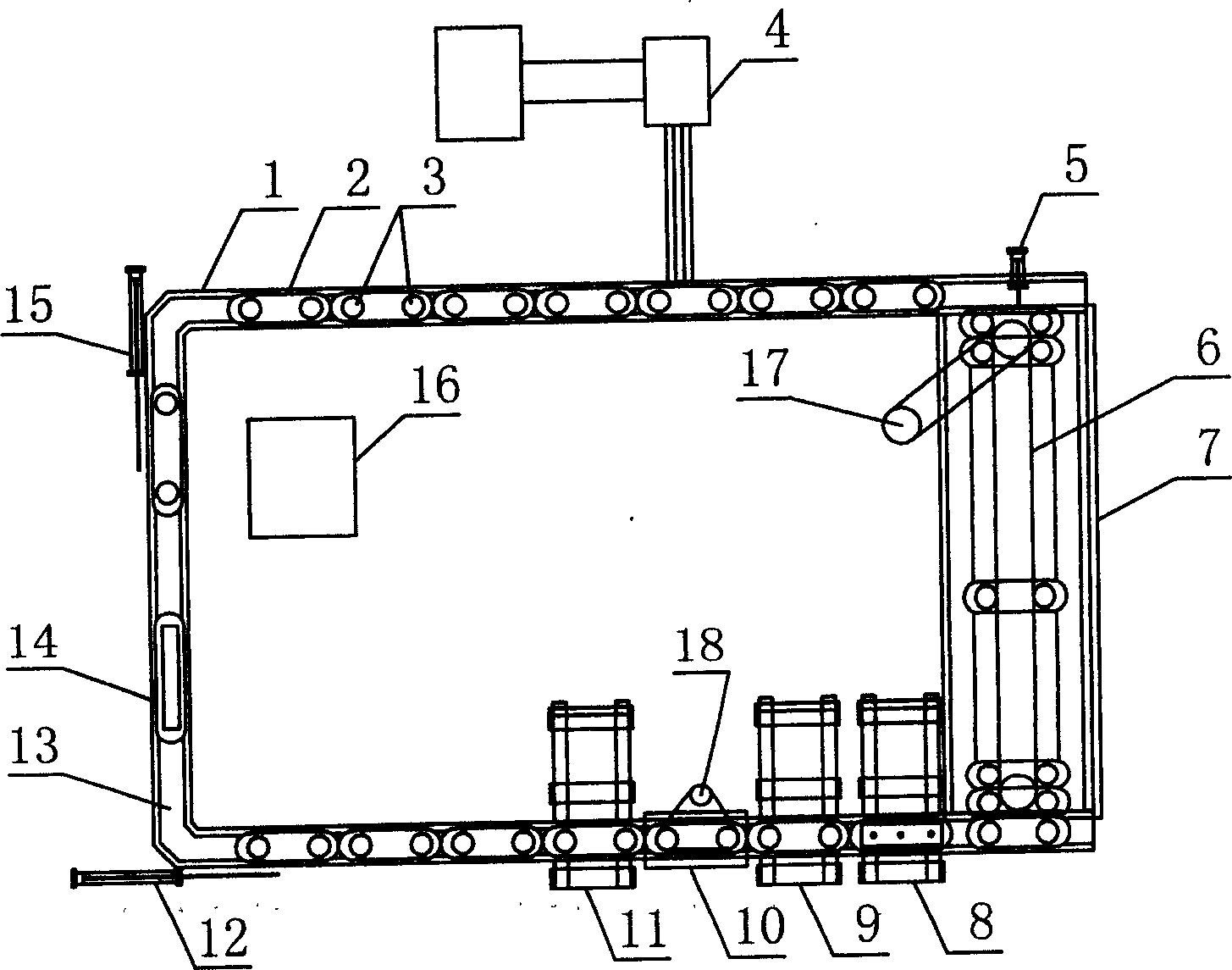

Full automatic bottle blowing technology for heat resistant bottle and bottle blowing machine for implementing said technology

A full-automatic blow mouding technology for making the refractory plastic bottles includes such steps as feeding bottle blank, heating, medium-temp blowing, high-temp blowing and meduim-temp blowing. Its blowing machine is composed of machine frame, feeder, endless conveying track, heater, medium-temp mould, high-temp mould, medium-temp shaping mould, and bottle releasing mechanism.

Owner:台州迈格机械模具有限公司

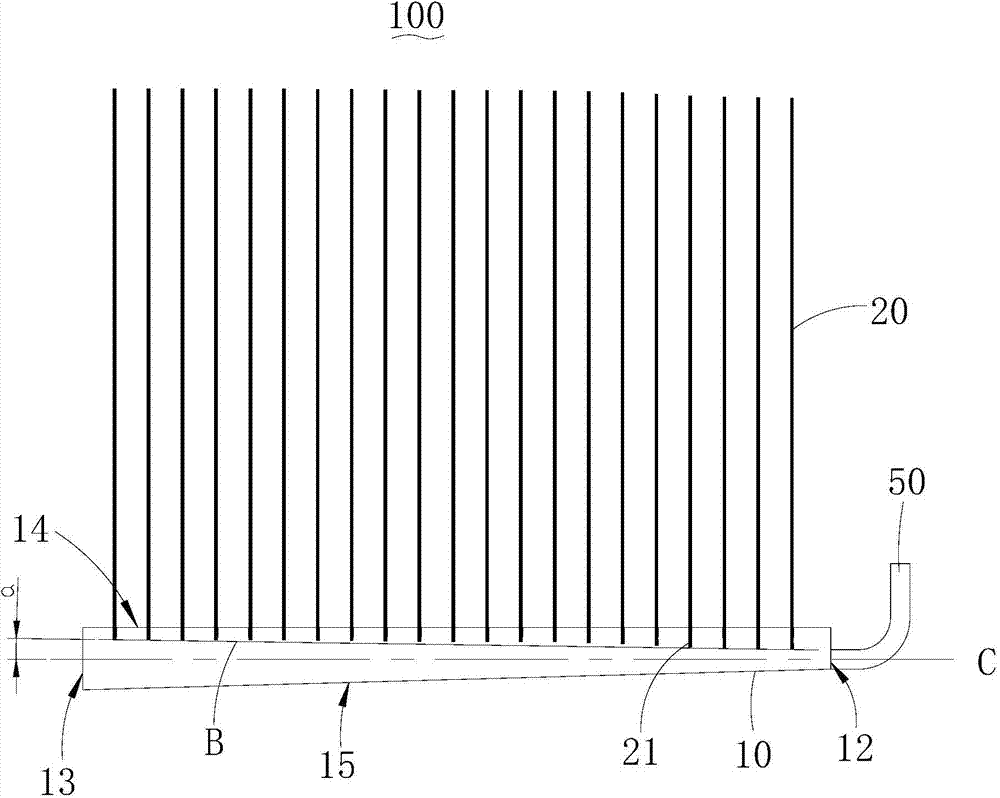

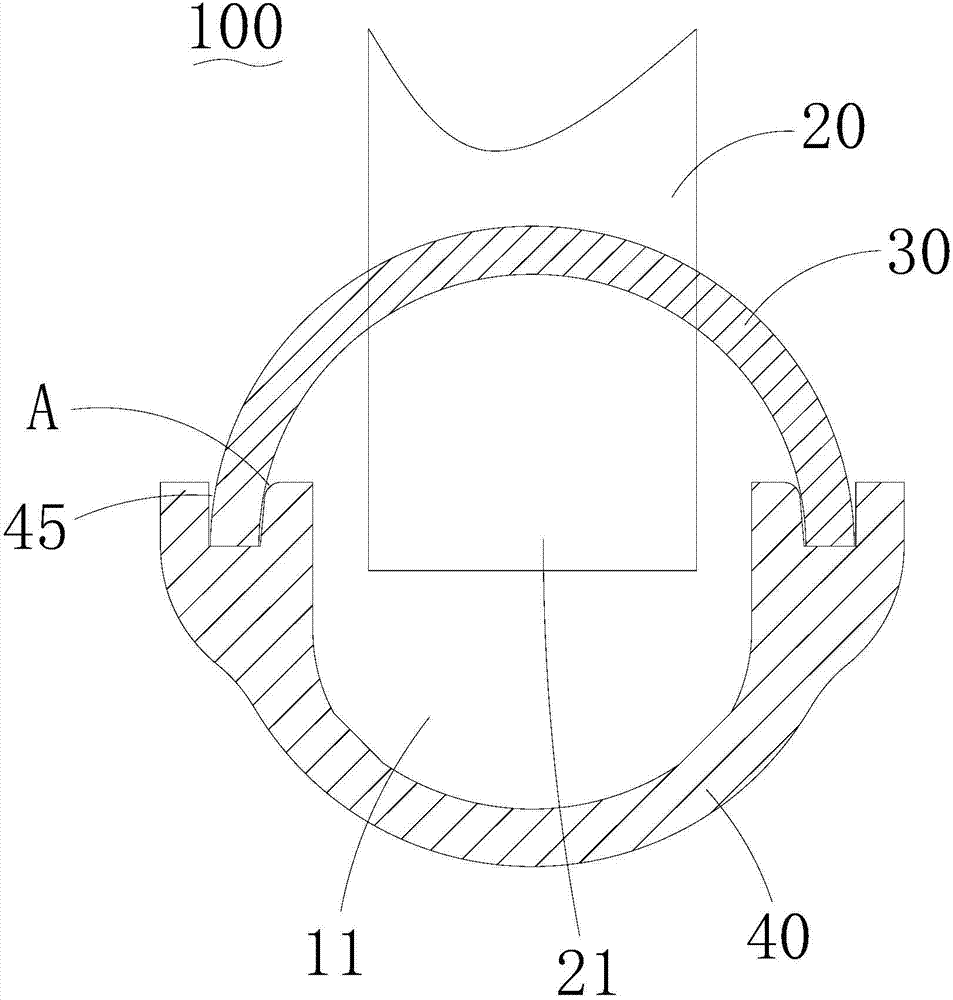

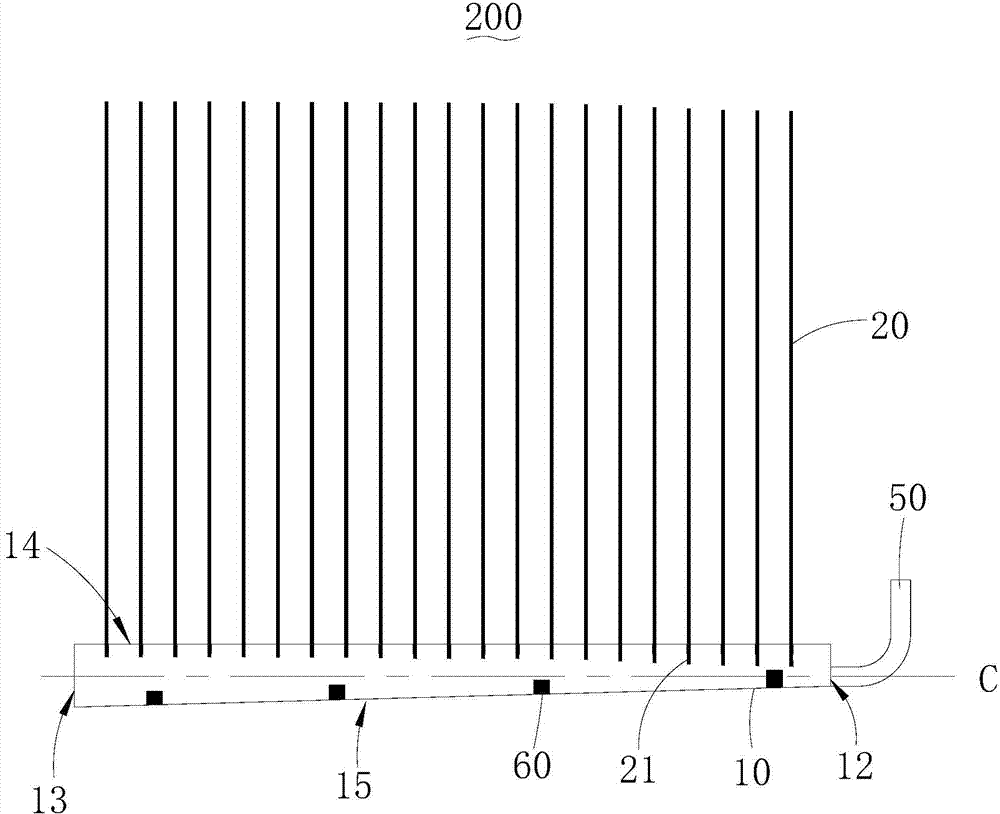

Parallel flow heat exchanger

InactiveCN104764255AEasy to installThe process is simple and reasonableEvaporators/condensersEngineeringPlate heat exchanger

The invention discloses a parallel flow heat exchanger. The parallel flow heat exchanger comprises a flow collecting pipe, a plurality of flat pipes inserted in the flow collecting pipe, fins connected between adjacent flat pipes, and a refrigerant pipe communicated with the flow collecting pipe, the flow collecting pipe comprises a first head face and a second head face opposite to the first head face, the flow collecting pipe has a first side and a second side opposite to the first side, the refrigerant pipe is communicated with the inside of the flow collecting pipe through the first head face, each flat pipe enters the flow collecting pipe from the first side of the flow collecting pipe, and the distance between the enter end of each flat pipe and the second side of the flow collecting pipe is increased gradually in the direction from the first head face to the second head face. By means of the scheme, the flow rate of the medium in the flat pipe at the far end is roughly the same with the flow rate of the medium in the flat pipe at the near end, the medium in each flat pipe is sufficient, the temperature distribution of the parallel flow heat exchanger at different positions is uniform, and the heat exchange efficiency of the parallel flow heat exchanger device is greatly improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Aluminum washed hand bag production method

InactiveCN103479011AIncrease productivityThe process is simple and reasonableLaminationHandbagsWashing handsWoven fabric

The invention provides an aluminum washed hand bag production method. According to the method, an aluminum plated film and non-woven fabric are manufactured; according the preset aluminum washing position and patterns, a plate roller is manufactured; the aluminum plated film is printed through the aluminum plated film transparent ink by the plate roller; the printed aluminum plated film undergoes aluminum washing operation; after the aluminum washed aluminum plated film is sized and dried, the aluminum plated film and the non-woven fabric are combined together in a hot-pressing mode; the aluminum plated film and the non-woven fabric which are combined undergo glue drying and curing processing to be manufactured into composite fabric; the composite fabric is manufactured into a hand bag. In this way, the traditional bag making technology is broken through, the aluminum layer with the aluminum plated film transparent ink is protected by reasonably utilizing the characteristic of aluminum washing solution corrosion resistance of the aluminum plated film transparent ink, and the aluminum washed hand bag with corresponding patterns is produced through reasonable combination of technological steps. Compared with the prior art, the aluminum washed hand bag production method is high in production efficiency, and simple and reasonable in technology, and the produced aluminum washed hand bag is good in waterproofness, solid, durable, beautiful in appearance and the like.

Owner:SHISHI XINGGANG PLASTIC PACKAGING

Method for preparing mutton spice by virtue of Maillard reaction

InactiveCN104431938AThe process is simple and reasonableHigh nutritional valueFood preparationXyloseEnzyme

The invention relates to the field of preparation of spices and particularly relates to a method for preparing a mutton spice by virtue of a Maillard reaction. The method comprises the following steps: (S1) mincing fresh mutton by virtue of a mincing machine, adding water and alkaline protease to carry out enzymolysis, and carrying out enzyme deactivation to obtain liquid supernatant, namely hydrolytic liquid; (S2) adding xylose and amino acid into the hydrolytic liquid, and reacting to obtain a Maillard reaction product; (S3) adding table salt, white granulated sugar, monosodium glutamate, bruised ginger, pepper powder, fennel powder and cassia bark powder into the Maillard reaction product, seasoning, uniformly stirring, and cooling to the room temperature to obtain a seasoned mixture; and (S4) carrying out spray drying and sterilization on the seasoned mixture, and finally packaging to obtain the finished mutton spice. The mutton spice is a natural perfume, simple and reasonable in process and high in nutrition value; by virtue of the Maillard reaction, the bacteria resistance and the oxidation resistance of the mutton spice are improved, the mutton smell is substantially reduced but not completely eliminated, and the little mutton flavor is preserved and is greatly improved; the mutton spice is delicious in taste and is suitable for being eaten by the majority of people.

Owner:广东华馨香料有限公司

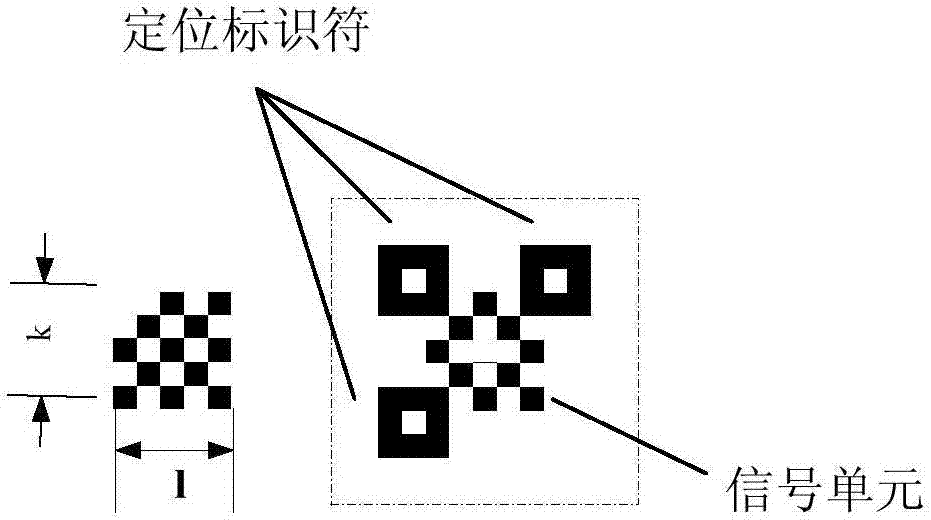

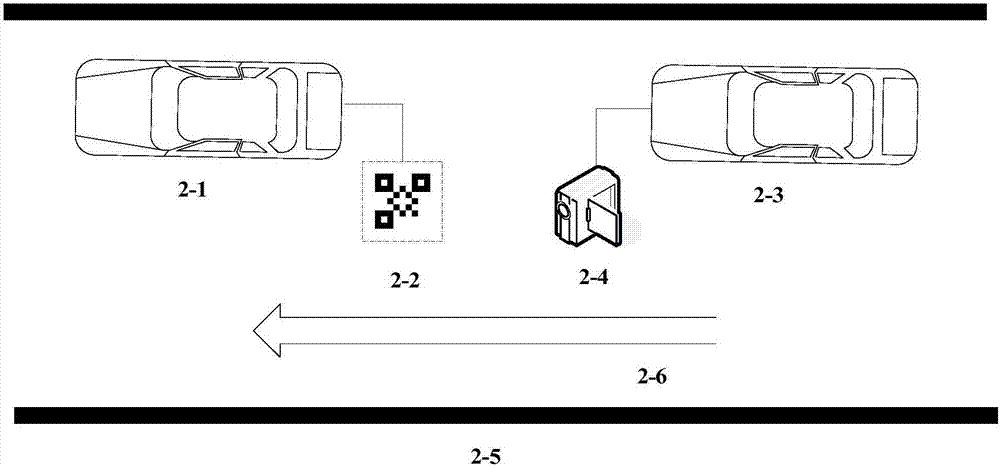

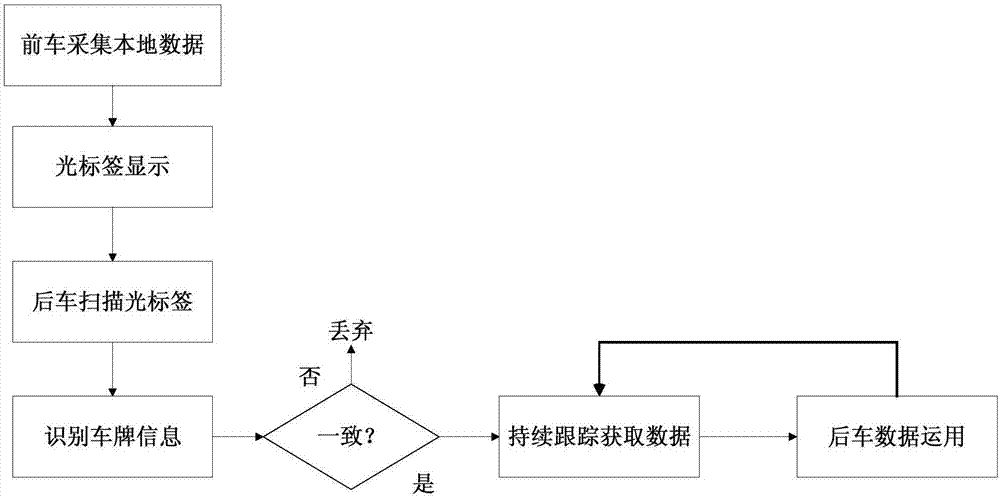

Vehicle-mounted auxiliary data transmission method based on optical label

InactiveCN106874821AThe process is simple and reasonableStrong channel directivitySensing by electromagnetic radiationData transmissionDirectivity

The invention provides a vehicle-mounted auxiliary data transmission method based on an optical label. The optical label and an optical label collecting device are arranged on two driving vehicles which need to transmit data on a road respectively or at the same time. The optical label displays the data information in the form of the optical label. The optical label collecting device on the other vehicle collects the displayed data and inputs the data into a vehicle-mounted computer of the vehicle where the optical label collecting device is located, so as to assist the vehicles to carry out related operations. According to the invention, the information interaction advantage of the optical label is used; the method has the advantages of simple and reasonable process, high passageway directivity of data interaction between vehicles, short action distance, large information transmission capacity and low equipment cost; and an upper layer application based on the technology is rich.

Owner:SHAANXI WHYHOW INFORMATION TECH CO LTD

Plywood glue and preparation method thereof

InactiveCN103756609AThe process is simple and reasonableLow production costAldehyde/ketone condensation polymer adhesivesUreaChemistry

The invention relates to plywood glue and a preparation method thereof. According to the plywood glue, urea is added into formaldehyde containing polyvinyl alcohol by specific ratio and program so as to guarantee the environmental protection property of the glue; the process is simple and reasonable and the production cost is low; gelling is not caused in a production process and the glue is not sprayed; the production is safe and stable and the storage period is long.

Owner:广西宾阳县荣良农业科技有限公司

Ficus carica juice

This invention provides a fig juice, whose weigh percentages are: 10% to 40% of fig war juice, no more than 40% of syrup, 2% to 4% of bee honey, 0.02% to 0.08% of Vitamin C, 0.02% to 0.06% of preservative, 0.2% to 0.3% of macassar gum, and the other being water. This fig juice is finished by traditional processes, such as raw material processing, extracting liquor, preparing, homogenizing, vacuum degassing, sterilizing and so on. This fig juice with precise and appropriate preparation brings out the best in each other and is suitable for all ages, with wide crowd suitability and good palatability, and is especially suitable for drinking in long time.

Owner:TIANJIN ZHONGYING HEALTH FOOD

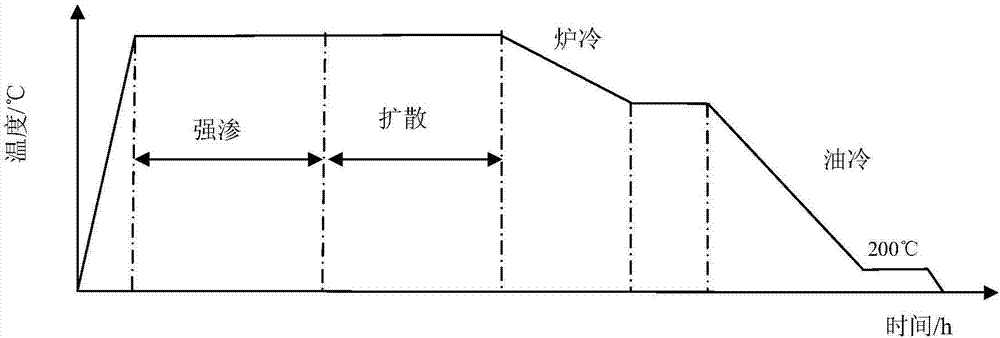

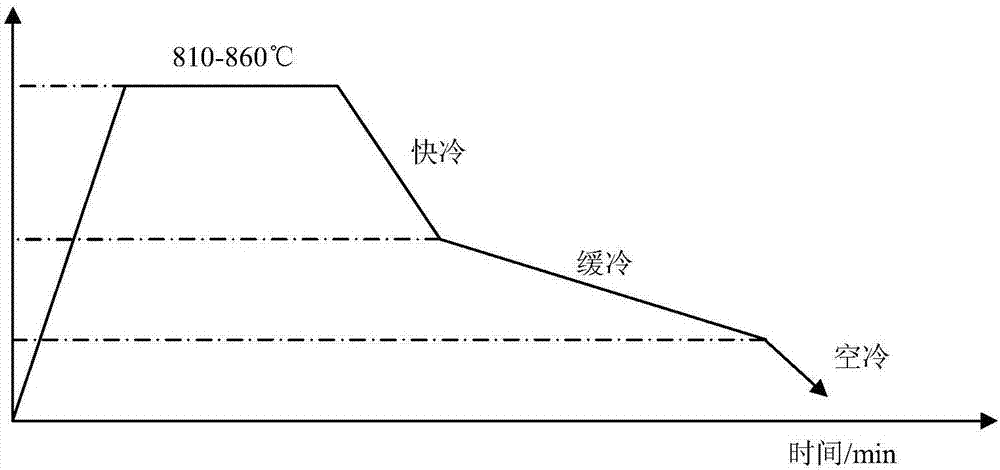

Blast drill bit heat treatment process

ActiveCN107099767AImprove surface strengthHigh strengthSolid state diffusion coatingFurnace typesEqualizationService condition

Disclosed is a blast drill bit heat treatment process. Surface carburizing is performed at the temperature between 910 DEG C and 930 DEG C, then cooling with furnace is performed till the temperature reaches 820 DEG C to 860 DEG C, heat preservation is performed, furnace discharging and oil quenching are performed till the temperature reaches 180 DEG C to 220 DEG C, and oil discharging and air cooling are performed; and then temperature equalization is performed at the temperature between 810 DEG C and 860 DEG C, the temperature is decreased to 350 DEG C to 450 DEG C at the cooling speed being 100 DEG C-150 DEG C per minute, then the temperature is decreased to 180 DEG C to 220 DEG C at the cooling speed being 1 DEG C-5 DEG C per minute, and natural cooling is performed in air. The blast drill bit heat treatment process is simple and reasonable, the material subjected to heat treatment has the structure with the surface possessing lower bainite and a little cryptocrystalline martensite and the core possessing upper bainite and a little lath martensite, the surface strength and hardness are high, the abrasion resistance is achieved, the impact toughness is high, the core toughness is good, and the structural stress is small; and as for the material subjected to heat treatment, the strength is slightly improved, the toughness is substantially improved, the requirement of the service conditions of drill tools for blasting is met, the material is resistant to abrasion and can bear repeated and circulating heavy impact load, and the service life of the drill tools is substantially prolonged.

Owner:长沙天和钻具机械有限公司

A Method of Improving the Fatigue Resistance of Al-cu-mg Alloy

A method for improving the fatigue resistance performance of Al-Cu-Mg alloy is to perform high-temperature hot rolling, primary solution treatment, large deformation cold rolling, secondary solution treatment and natural aging treatment to homogenized aluminium alloy in sequence. According to the invention, relatively high temperature is kept before hot rolling, and then a material recrystallizes dynamically during the hot rolling process, so that a plurality of recrystallization textures such as Goss and Cube are formed, and the fatigue resistance performance of the aluminium alloy can be improved advantageously; solution treatment before cold rolling can greatly eliminate large second-phase particles except for impurities such as Fe and Si to prevent a high energy region from forming, so that uneven recrystallization can be avoided; after large deformation cold rolling deformation is performed, the dislocation density of the alloy is greatly improved, the alloy can obtain more stored energy, the recrystallization nucleation rate is increased during solution treatment, fine crystal grains can be formed, and the fatigue resistance performance of the aluminium alloy can be improved further. The process method provided by the invention is simple, convenient in operation, economical in cost and suitable for industrialized application.

Owner:CENT SOUTH UNIV

Almond and pearl paste and preparation method thereof

The invention discloses an almond and pearl paste and a preparation method thereof. The almond and pearl paste comprises the following required raw materials by weight percent: 38% of almond powder, 25% of puffing rice flour, 15% of pearl powder, 12% of powdered milk and 10% of white granulated sugar. The production process comprises the following steps: selecting almonds, soaking, peeling, detoxifying, milling, separating, homogenizing, spraying, drying, sieving, preparing and packaging. The invention has the beneficial effects that the process is simple and reasonable, the nutrition is abundant, the drinking is convenient, the senility of the skin can be effectively delayed, and the skin is clean, bright and beautiful and is rich in luster and elasticity. After being eaten frequently, the almond and pearl paste can have the functions of beautifying the face, nourishing the skin, prolonging the life and enhancing the immunological competence of a human body.

Owner:鲍整强

Face-beautifying yogurt and preparation method thereof

InactiveCN104472691AThe process is simple and reasonableGuaranteed stabilityMilk preparationWaxNutrient

The invention discloses face-beautifying yogurt and a preparation method thereof. The face-beautifying yogurt comprises raw materials including the following components in parts by weight: 4-8 parts of wax gourds, 4-8 parts of carrots, 8-12 parts of peaches, 6-10 parts of water chestnuts, 1-2 parts of kudzuvine root powder, 1-2 parts of camellia pollen, 2-4 parts of white sesame powder, 1-2 parts of royal jelly, 6-8 parts of a face-beautifying extracting liquid, 12-16 parts of saccharose, a proper amount of yogurt fermentation bacteria and 180-220 parts of fresh milk. The preparation method comprises the following steps: uniformly mixing, then homogenizing to obtain original pulp, then sterilizing, inoculating the yogurt fermentation bacteria according to an ordinary yogurt preparation process, and then refrigerating to obtain a product. The face-beautifying yogurt disclosed by the invention is fragrant and sweet in taste and rich in nutrient, and has health-care and food therapy effects such as functions of maintaining beauty and keeping young, and the like; and compared with existing yogurt, the face-beautifying yogurt is simple and reasonable in preparation process; and moreover, the stability, high activity and functional nutrition performance of the product can be ensured.

Owner:QINGDAO DERUN BATTERY MATERIALS

Method for removing cadmium and thallium from crude indium by vacuum distillation furnace

InactiveCN103572076AThe process is simple and reasonableLow costProcess efficiency improvementIndiumElectric heating

The invention relates to a method for removing cadmium and thallium from crude indium by a vacuum distillation furnace. The method comprises the technological steps of: playing a tray loaded with an ordinary crude indium raw material into an electric heating type vacuum distillation furnace, starting a vacuum pump to control the vacuum degree in the distillation furnace at 25Pa-50Pa, starting a heating device to make the bottom temperature of the tray reach 700DEG C-750DEG C, and maintaining a constant temperature within the temperature range for 120min so as to volatilize and remove cadmium impurities from the crude indium; and warming the heating device to make the bottom temperature of the tray reach 1000DEG C-1100DEG C, and maintaining a constant temperature within the temperature range for 120min so as to volatilize and remove thallium impurities from the crude indium, thus obtaining refined indium. The method provided by the invention makes full use of the physical property differences between substances, uses a physical method to perform separation, and has the advantages of simple and reasonable process, no pollution, low cost, safety, easy operation, and excellent cadmium and thallium removal effects.

Owner:SHAANXI ZINC IND

Mango honey dew beverage

InactiveCN101467773AThe process is simple and reasonablePrecise recipeFood preparationSodium carboxymethylcelluloseLower blood pressure

The invention provides a mango juice drink which is prepared by mixing the fresh mangoes, filtered water, white sugar, citric acid, sodium citrate, sodium carboxymethyl cellulose, monosodium glutamate, sodium chloride, ethyl maltol and vitamin. The weight percentages are following: fresh mangoes 40-60%, white sugar 5-10%; citric acid 1-5%, sodium citrate 0.5-1.0%; sodium carboxymethyl cellulose 0.5-1.0%; essence 0.1-0.3%; sodium chloride 0.1-0.3%; ethyl maltol 0.1-0.3% and vitamin 0.1-0.5%. The rest is water. After handling raw materials, blending, homogeneous, vacuum degassing, sterilization and other traditional processes completed; process is simple and reasonable formula concentrating, complement each other, with stopping thirst, lower blood pressure, anti-aging and enhance immunity, the role of family, groups wide adaptability, palatability, and is suitable for long-term consumption.

Owner:TIANJIN ZHONGYING HEALTH FOOD

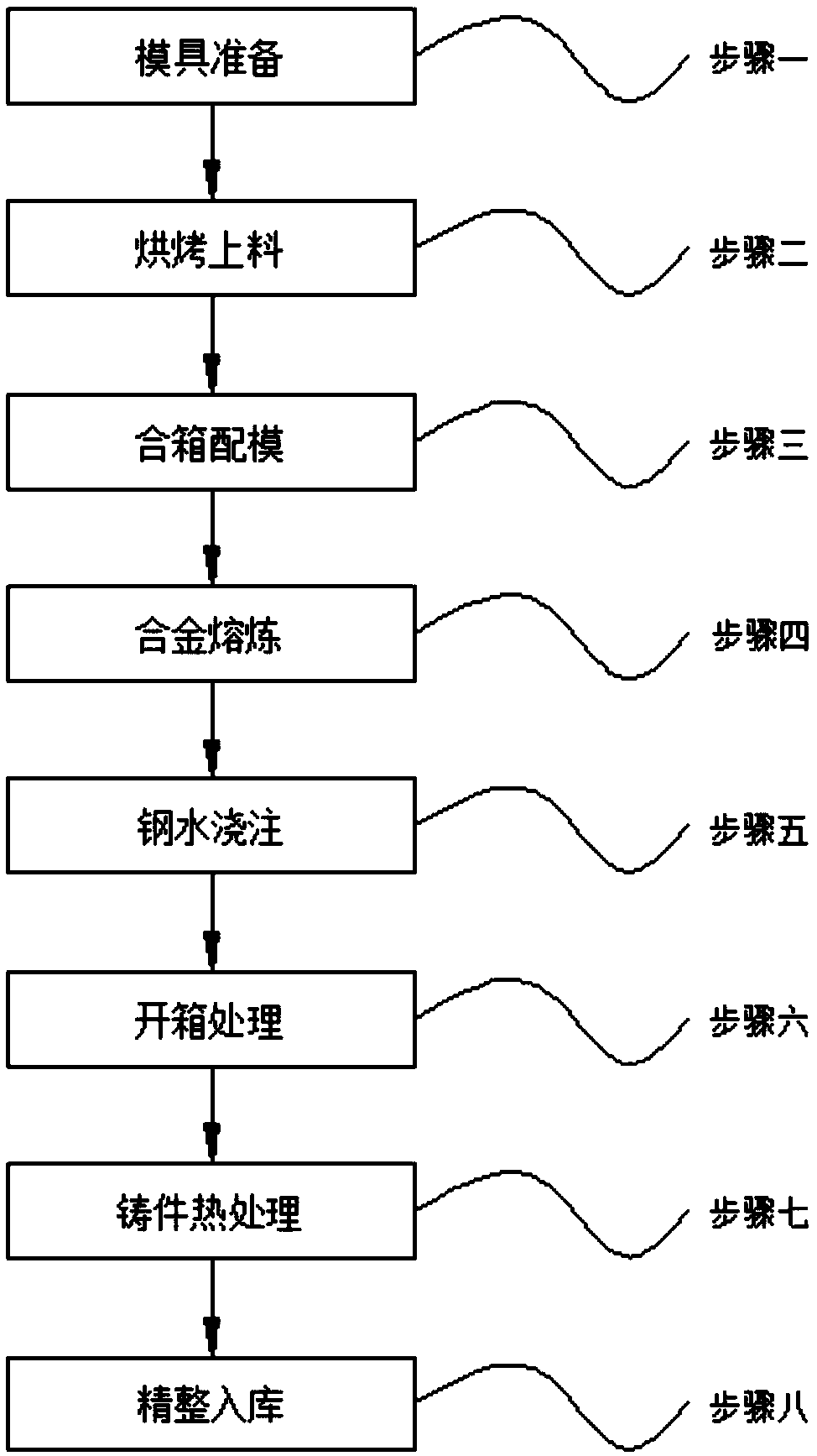

Production process of casting of rapid start-and-stop power station extraction check valve

InactiveCN109108221AThe process is simple and reasonableAvoid trachomaFoundry mouldsAbrasion apparatusWrinkleAdhesive

The invention discloses a production process of a casting of a rapid start-and-stop power station extraction check valve. The production process comprises the following steps: 1, preparing a mold; 2,baking and feeding; 3, closing a box and matching a mold; 4, smelting alloy; 5, performing molten steel casting; 6, opening the box and performing treatment; 7, performing heat treatment on the casting; and 8, finishing and putting into storage, wherein in the step 1, according to the structural characteristics, the technical requirements, the product batches and the production conditions of checkvalve parts, a sand core is manufactured by using casting sand and a molding sand adhesive and a model of the casting is prepared. The production process is simple and reasonable in process; the sandmold and sand core can be strictly adjusted in the production process, so that the defects of sand holes, gas holes and dispersed shrinkage can be effectively avoided; and the casting is finely trimmed and polished for many times, so that wrinkles on the surface of the casting can be flattened effectively, the surface of the casting is smooth and flat, the size precision of the casting is improved and the rejection rate is reduced.

Owner:欧通集团青田万鑫阀门科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com