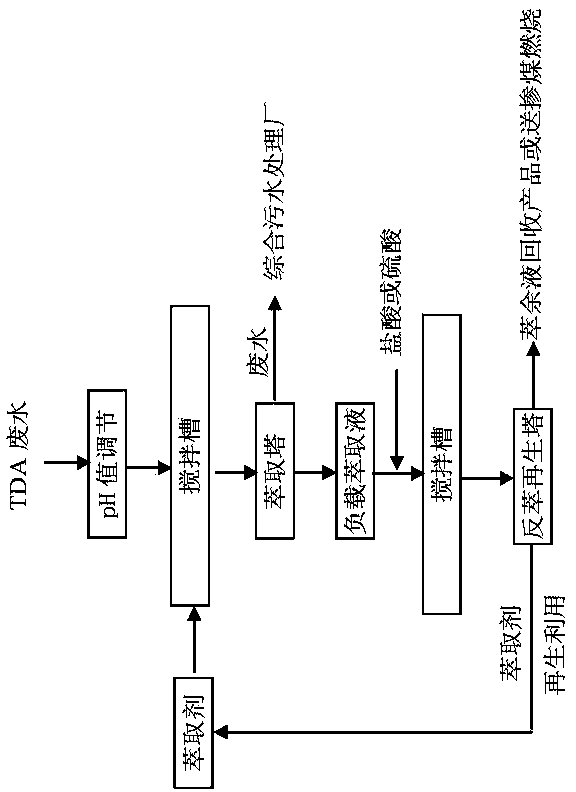

Method for treating TDA wastewater through complexing extraction

A technology for extraction and wastewater, applied in the direction of extraction water/sewage treatment, natural water treatment, chemical instruments and methods, etc., can solve the problem of high cost of oxidation treatment, achieve the effect of low treatment cost, simple and reasonable process, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1, a kind of method adopting complex extraction to process TDA waste water, its steps are as follows:

[0020] (1) pH value adjustment: adjust the pH value of TDA wastewater to 7 with inorganic acid;

[0021] (2) Extraction: The volume ratio of the extraction agent and the waste water is 4:1, stirring and mixing at a temperature of 0-10°C for 5-60 minutes, standing for 20-120 minutes to separate layers, the upper layer is the loaded extraction agent, and the lower layer is the extraction treatment waste water;

[0022] The extractant used in the extraction includes a complexing agent selected from 2-ethylhexylphosphonic acid-2-ethylhexyl ester, di(2,4,4-trimethylpentyl)phosphonic acid one or both of them.

Embodiment 2

[0023] Embodiment 2, a kind of method adopting complex extraction to process TDA waste water, its steps are as follows:

[0024] (1) pH value adjustment: adjust the pH value of TDA wastewater to 10 with inorganic acid;

[0025] (2) Extraction: The volume ratio of extractant and waste water is 1:8, stirring and mixing at a temperature of 10-20°C for 5-60 minutes, and standing for 20-120 minutes to separate layers. The upper layer is the loaded extractant, and the lower layer is the extracted waste. waste water;

[0026] The extraction agent used in the extraction includes a complexing agent, and then add one of the cosolvent and the diluent, and mix according to the required ratio; the complexing agent is selected from 2-ethylhexylphosphonic acid-2-ethyl one or both of hexyl ester and di(2,4,4-trimethylpentyl)phosphonic acid; Kind; Described diluent is selected from kerosene or cyclohexane.

Embodiment 3

[0027] Embodiment 3, a kind of method adopting complex extraction to process TDA waste water, its steps are as follows:

[0028] (1) pH value adjustment: Use mineral acid to adjust the pH value of TDA wastewater to 8-9;

[0029] (2) Extraction: The volume ratio of the extraction agent and the waste water is 4:1~1:8, stirring and mixing at a temperature of 20~30°C for 5~60 minutes, and standing for 20~120 minutes to separate layers. The upper layer is the loaded extraction agent, and the lower layer is Wastewater after extraction treatment;

[0030] The extraction agent used in the extraction includes a complexing agent, then add a cosolvent, a diluent, and mix according to the required ratio; the complexing agent is selected from 2-ethylhexylphosphonic acid-2-ethylhexyl ester, di One or two of (2,4,4-trimethylpentyl)phosphonic acid; the co-solvent is selected from one or more of n-octanol, isooctyl alcohol, and sec-octanol; the The diluent is selected from kerosene or cycloh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com