Process for refining base oil by using regenerated waste oil from inclined wall wiped film vacuum distillation

A technology of waste engine oil and membrane distillation, applied in the direction of pervaporation, lubricating composition, etc., can solve the problems of increasing residual oil recovery and oil content, increase product yield, easy and safe manual operation, and simple process flow reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

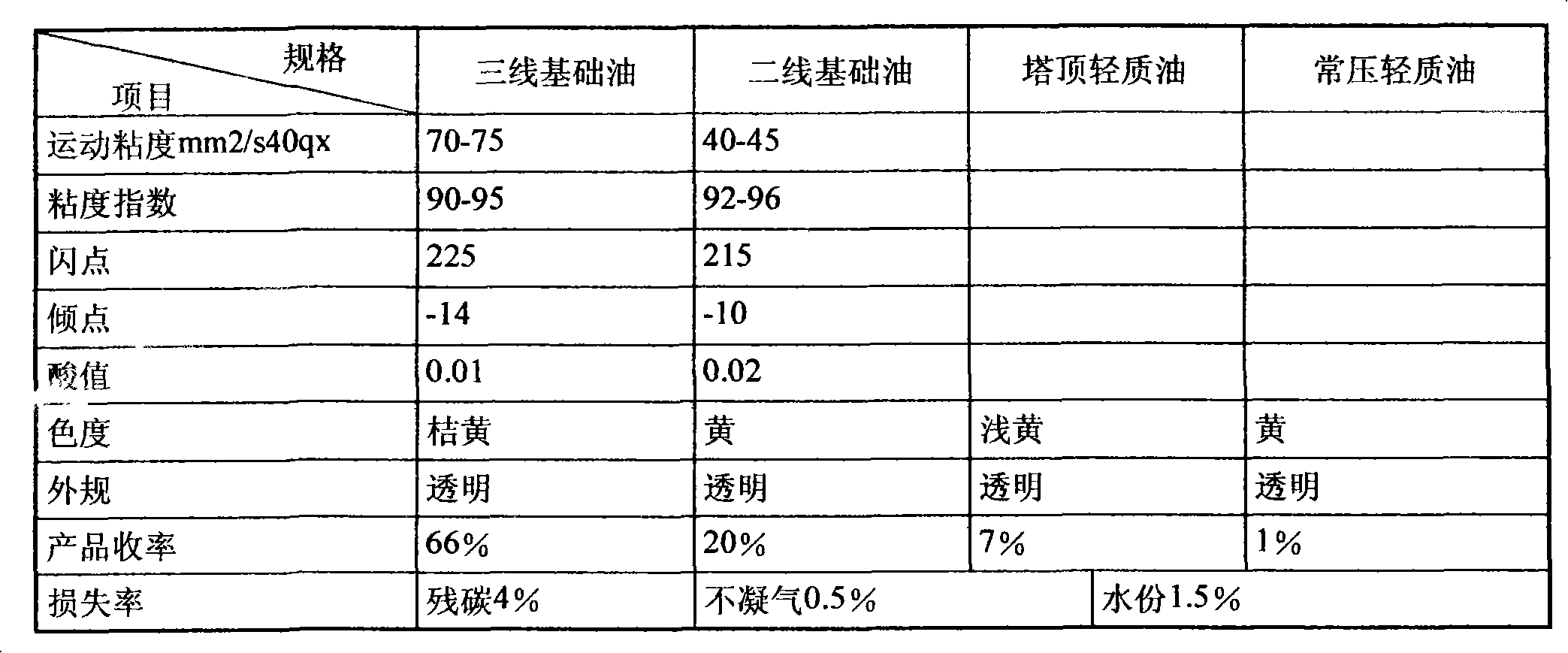

Examples

Embodiment Construction

[0013] 1. The high-temperature flocculation neutralization head in the A section, the raw material oil (waste engine oil) is pumped into the high-level oil tank, and the flow rate (500kg / h) from the high-level oil tank is controlled by the flow meter into the A1 heat exchanger. The reflux oil (200-204°C) and the reflux flow (220kg / h) are convectively heat-exchanged, and the second-line reflux oil is controlled at (50-60°C) by heat exchange and cooling. At this time, the temperature of the raw material oil (waste engine oil) can be heated up to (35-55°C) by heat exchange, enter the A2 heat exchanger and exchange heat with the return flow (450kg / h) of the third-line return hot oil (260-286°C), and the third-line reduction The reflux oil is cooled by heat exchange, and the oil temperature is controlled at (200-206°C), and pumped into the rectification tower of the C section minus the third-line reflux section. At this time, the raw oil (waste engine oil) can heat up (70-95°C) and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com