Method for improving the fatigue resistance performance of Al-Cu-Mg alloy

An al-cu-mg, anti-fatigue technology, which is applied in the processing of Al-Cu-Mg alloys to improve the anti-fatigue performance of Al-Cu-Mg alloys, and can solve the problems of cost, inconvenience in industrial production, and low density of Gauss texture. problem, to achieve the effect of simple and reasonable process and high fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

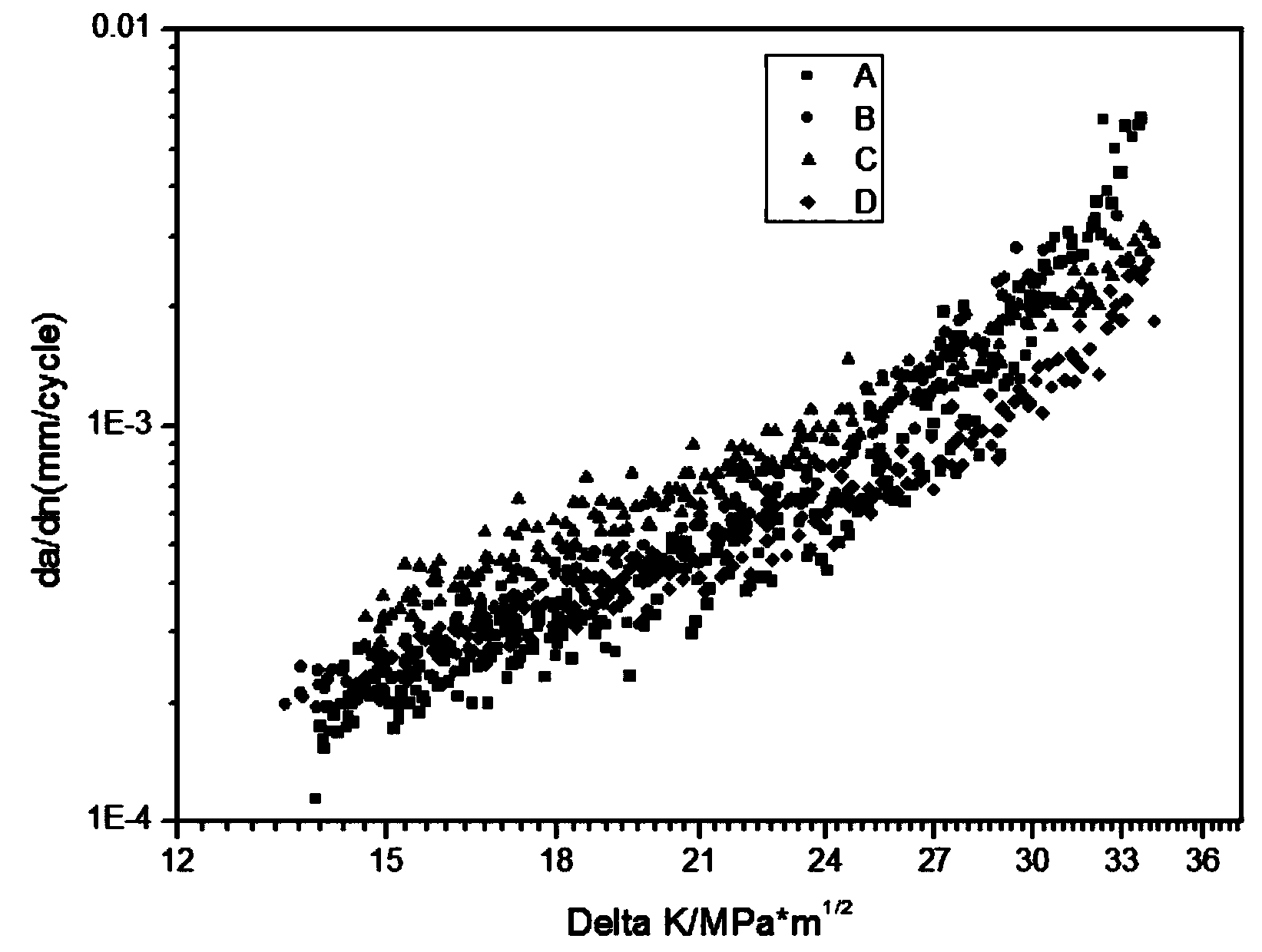

[0041] The alloy composition is: 3.8%Cu, 1.0%Mg, 0.3%Mn, and the balance of Al Al-Cu-Mg alloy is homogenized. After the ingot is kept at 430℃ for 1 hour, it is directly hot rolled with 70% deformation. Then, it was subjected to air solution treatment at 470°C for 1 hour and then subjected to 80% deformation cold rolling, and then subjected to 470°C salt bath solution treatment for 20 minutes and natural aging treatment after water quenching. The tensile strength is 456MPa, the yield strength is 327MPa, and the elongation is 23%. When the stress expansion factor ΔK=33MPa*m 1 / 2 When, the expansion rate of the alloy is 0.00595mm / cycle respectively.

Embodiment 2

[0043] The alloy composition is: 4.4% Cu, 1.3% Mg, 0.45% Mn, and the balance of Al Al-Cu-Mg alloy is homogenized. After the ingot is kept at 440°C for 1 hour, it is directly hot rolled with 70% deformation. After that, it is cold rolled with 80% deformation, and then annealed at 400°C for 1h, and then treated again with 490°C salt bath solution for 20 minutes and natural aging treatment after water quenching. The tensile strength is 476MPa, the yield strength is 334MPa, and the elongation is 23.2%. When the stress expansion factor ΔK=33MPa*m 1 / 2 When, the expansion rate of the alloy is 0.00335mm / cycle respectively.

Embodiment 3

[0045] The alloy composition is: 4.9% Cu, 1.5% Mg, 0.8% Mn, the balance of Al Al-Cu-Mg alloy is homogenized, the ingot is directly hot rolled with 70% deformation after 1 hour at 440°C, Then, air solution treatment was carried out at 490°C for 1 hour and then subjected to 80% deformation cold rolling, and then again subjected to 490°C salt bath solution treatment for 20 minutes after natural aging treatment. The tensile strength is 475MPa, the yield strength is 331MPa, and the elongation is 22.3%. When the stress expansion factor ΔK=33MPa*m 1 / 2 When, the expansion rate of the alloy is 0.0043mm / cycle respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com