Blast drill bit heat treatment process

A drill and process technology, applied in heat treatment furnaces, heat treatment equipment, metal material coating processes, etc., can solve problems such as failure to meet customer requirements, and achieve the effects of increased strength, increased toughness, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

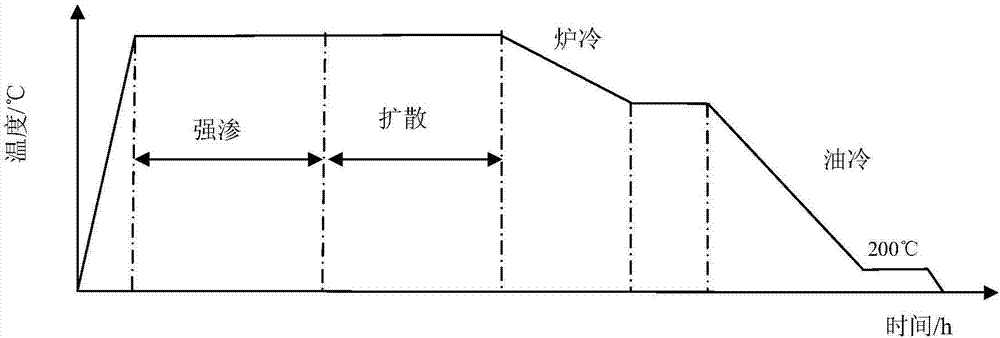

[0037] A heat treatment process for a drill bit for blasting, comprising the steps of:

[0038] Prepare the material components of the drill blank, which is composed as follows by mass percentage:

[0039] C 0.25, Si 1.45, Mn 1.3, Cr 0.5, Ni 1.8, Mo 0.6, V 0.2, S ≤0.01, P ≤0.015, Cu ≤0.2, the balance is Fe;

[0040] Carburize the surface of 10 drill bits after finish turning at 910°C for 8 hours, and the dripping speed of carburizing medium is 135 grains / min; then, diffuse for 5 hours, and the dripping speed of carburizing medium is 45 grains / min ; Cool to 850°C with the furnace, keep warm for 90 minutes, and quench the oil out of the furnace to 180°C and air cool;

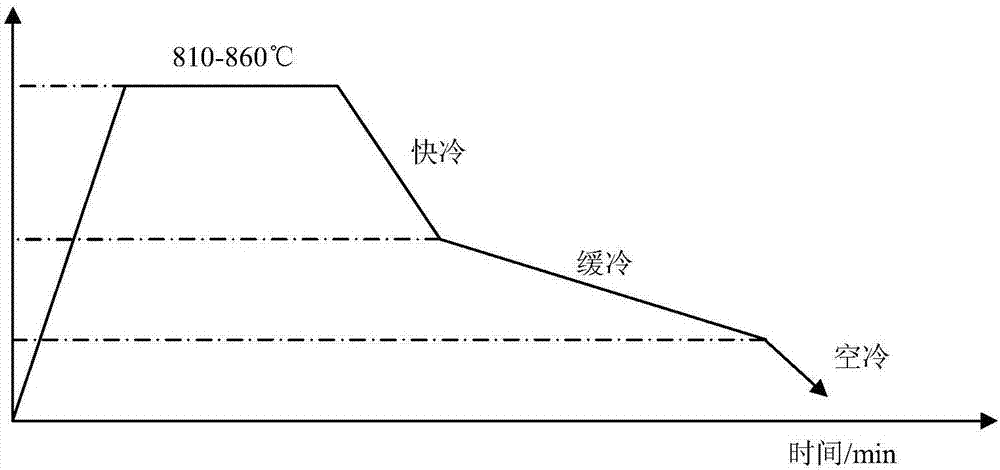

[0041] The second step: secondary quenching

[0042] Put the workpiece obtained in the first step at 810°C for 80 minutes, take it out of the furnace and quench it with oil to 360°C, then place it in a salt bath and cool it down to 180°C at a cooling rate of 1-2°C / min, then cool it naturally in the air to room ...

Embodiment 2

[0044] A heat treatment process for a drill bit for blasting, comprising the steps of:

[0045] Prepare the material components of the drill blank, which is composed as follows by mass percentage:

[0046] C 0.25, Si 1.45, Mn 1.3, Cr 0.5, Ni 1.8, Mo 0.6, V 0.2, S ≤0.01, P ≤0.015, Cu ≤0.2, the balance is Fe;

[0047] Carburize the surface of 10 drill bits after finish turning at 920°C for 7 hours, and the dripping speed of carburizing medium is 140 grains / minute; then, diffuse for 3 hours, and the dripping speed of carburizing medium is 30 grains / min ; Cool to 840°C with the furnace, keep warm for 60 minutes, and quench the oil out of the furnace to 200°C and air cool;

[0048] The second step: secondary quenching

[0049] Put the workpiece obtained in the first step at 840°C for 60 minutes, take it out of the furnace and quench it with oil to 400°C, then place it in a salt bath and cool it down to 200°C at a cooling rate of 2-3°C / min, then cool it naturally in the air to room...

Embodiment 3

[0051] A heat treatment process for a drill bit for blasting, comprising the steps of:

[0052] Prepare the material components of the drill blank, which is composed as follows by mass percentage:

[0053] C 0.25, Si 1.45, Mn 1.3, Cr 0.5, Ni 1.8, Mo 0.6, V 0.2, S ≤0.01, P ≤0.015, Cu ≤0.2, the balance is Fe;

[0054] Carburize the surface of 10 drill bits after finish turning at 930°C for 6 hours, and the carburizing medium dripping speed is 100 grains / min; then, diffuse for 2 hours, and the carburizing medium dripping speed is 18 grains / min ; Cool to 820°C with the furnace, keep warm for 20 minutes, and quench the oil out of the furnace to 220°C and air cool;

[0055] The second step: secondary quenching

[0056] The workpiece obtained in the first step is kept at 860°C for 120 minutes, and oil-quenched to 450°C, then placed in a salt bath and cooled to 220°C at a cooling rate of 4-5°C / min, and then naturally cooled in the air to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com