Flame-retardant impregnated film adhesive facing blockboard

A technology of impregnating film paper and blockboard, which is applied in the field of board processing, can solve the problems of poor flame retardant effect, and achieve the effects of improving flame retardant performance, reducing formaldehyde content of finished products, and good flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

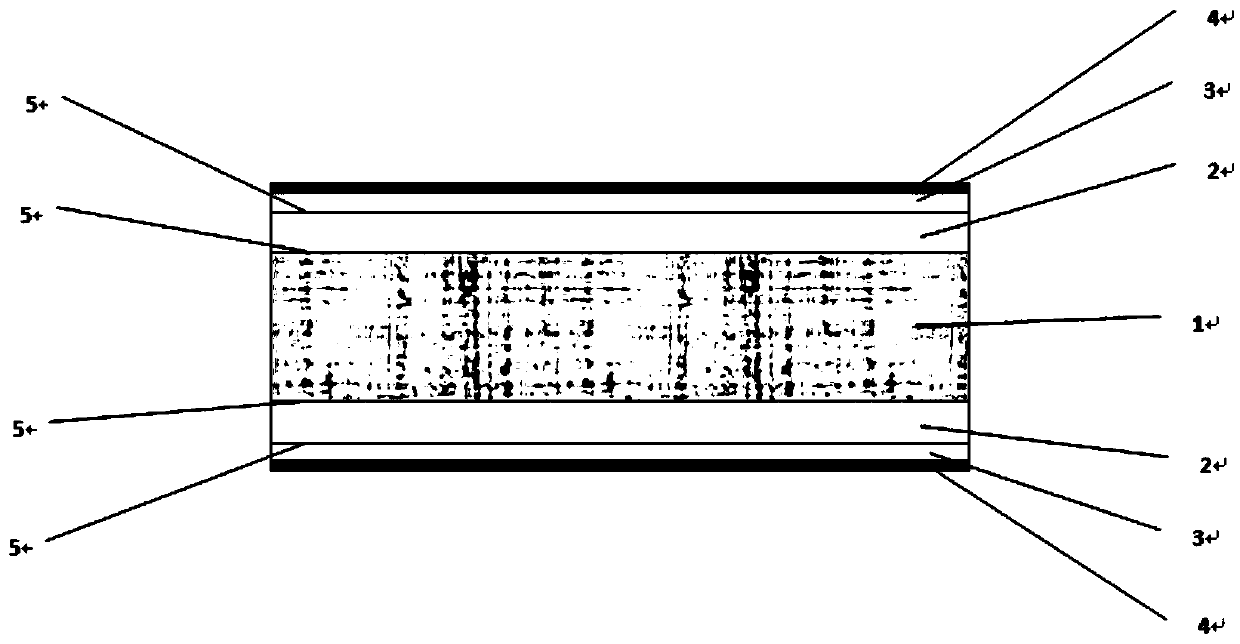

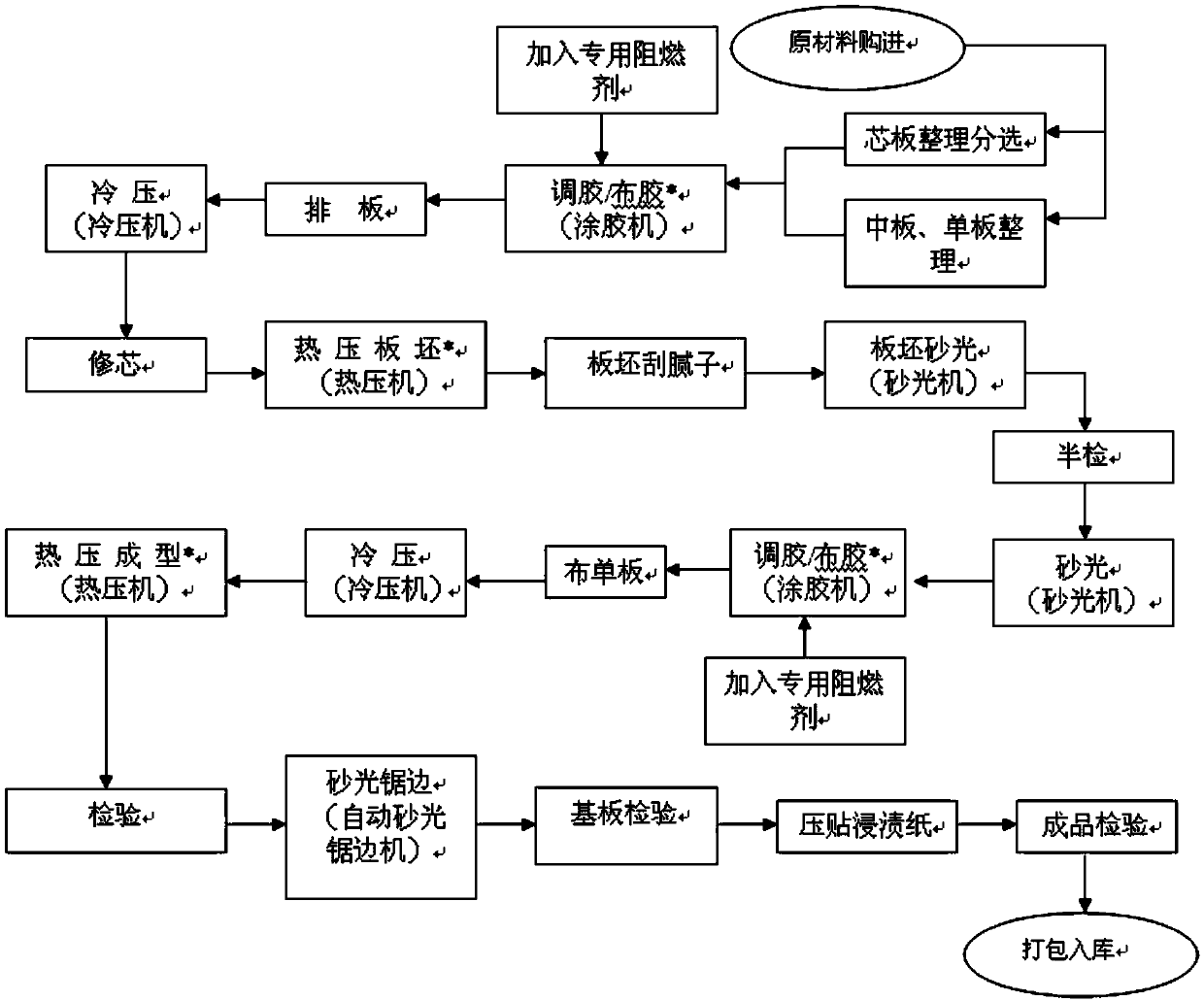

[0046] like Figure 1~2 As shown, the present invention provides a specific embodiment of a flame-retardant type impregnated film paper-decorated blockboard. Board 3, decorative film paper 4 and flame-retardant adhesive layer 5, the upper surface and lower surface of the board core 1 are respectively covered with the middle board 2 and pressed together to form a slab; between the upper surface of the board core 1 and the middle board 1. The lower surface of the core 1 and the middle plate 2 are respectively glued and connected through the flame-retardant adhesive layer 5. The flame-retardant adhesive layer 5 is made by coating the glue with a 25% ratio of urea flame retardant, and the amount of glue applied is 250g / ㎡; the upper surface and the lower surface of the slab are covered with poplar veneer 3 respectively, and the base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com