Front car body connecting bush machining process

A processing technology and front body technology, which is applied to vehicle parts, transportation and packaging, etc., can solve problems such as unsuitable front body connection bushing processing technology, and achieve high production efficiency, good mechanical properties, and simple and reasonable overall process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0020] Example.

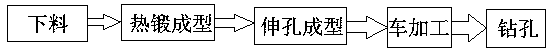

[0021] see figure 1 , the processing technology of the front body connection bushing in this embodiment, which makes full use of cold extrusion and lathe processing, the steps are as follows: (1) blanking: the raw material is wire rod, and the φ36 material is drawn to φ35 and blanked by a cold heading machine; (2) Hot forging: the material is hot forged, and the φ35 is hot forged into a special-shaped blank to prepare for the punching and punching forming sequence; (3) punching and forming: specific punches, dies, die cores, etc., composite cold Extrusion hot forging billet, because the pre-order adopts hot forging forming, the inner and outer coaxiality can reach within φ0.2; the extruded shape o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com